33

33

3FORMNO.L-20264-C-1201

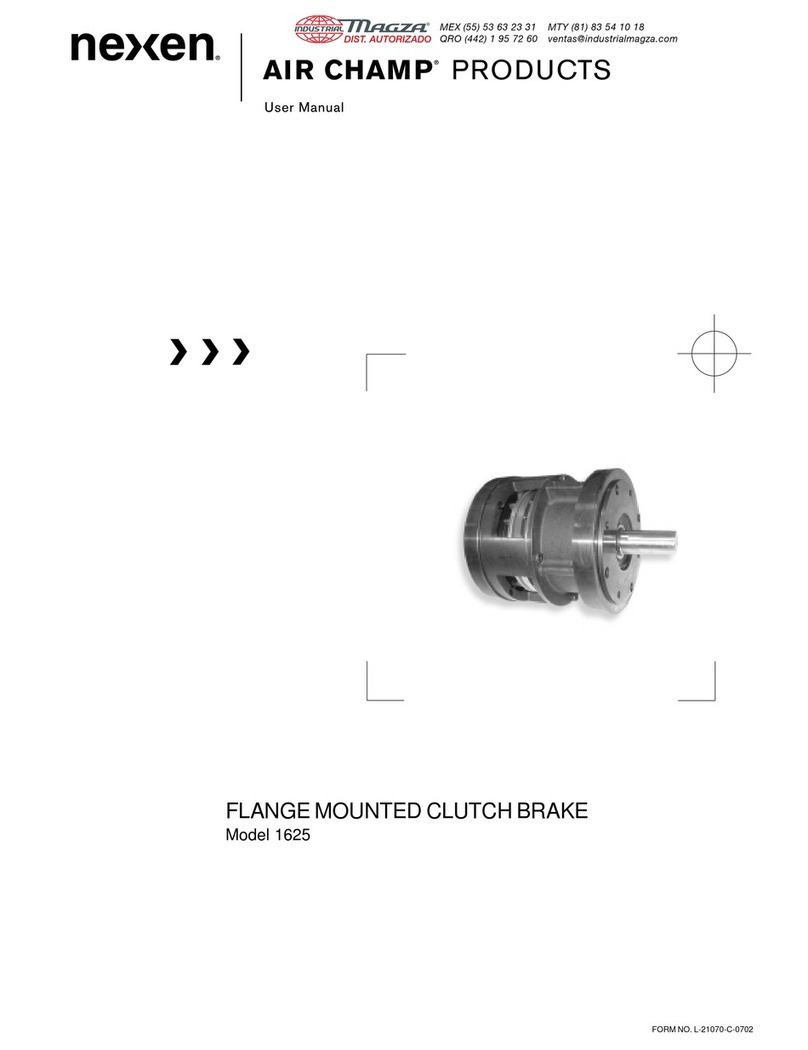

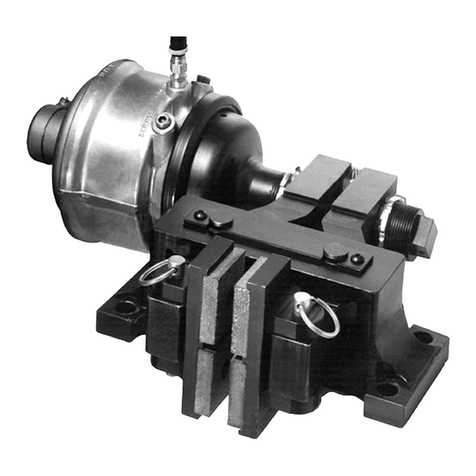

DOUBLE FLEX COUPLING

Torque Limiter,

H Series Clutch, or

H Series Tooth Clutch

FIGURE 2

7813

25534

6

6

YLBMESSARETPADAGNILPUOCXELFELBUOD

LEDOM

gnilpuoC retpadA ylbmessA rotpadA ylbmessA

yticapaCtnemngilasiM tnemngilasiM yticapaC

gnipmalC.S.C.H.S )2metI(euqroT )4ytQ( ylnOstinUnepO

gnipmalC.S.C.H.S ytQ()2metI(euqroT )6 ylnOstinUdesolcnE

tuN.xeH gnipmalC euqroT )6metI( gnipmalC euqroT

.GNALAIXAARAP

02LT,03H5,03H4589909 .geD331.0360.0.sbL.nI441.sbL.nI401.sbL.nI021

03LT,53H5,53H4580019 .geD341.0870.0.sbL.nI441.sbL.nI401.sbL.nI612

04H5,04H4581019 .geD361.0580.0.sbL.nI441.sbL.nI401.sbL.nI612

04LT,54H5,54H4582019 .geD381.0190.0.sbL.nI441.sbL.nI581.sbL.nI633

05LT,05H5,05H4583019 .geD312.0401.0.sbL.nI003.sbL.nI704.sbL.nI633

06LT,06H5,06H4584019 .geD342.0711.0.sbL.nI003.sbL.nI704.sbL.nI294

07LT,07H5,07H4585019 .geD372.0731.0.sbL.nI0231.sbL.nI078.sbL.nI069

08LT,08H5587119 .geD313.0071.0.sbL.nI0231.sbL.nI078.sbL.nI4461

deecxetonseodhcaefoegatnecrepdenibmocehterusekam,deriuqerllaeratnemngilasimlaixadna,ralugna,lellarapfI .%001

ehtfo%05fI.dewollasitnemngilasimlaixaroralugnaon,deriuqersitnemngilasimlellarapehtfo%001fI:ELPMAXE .elbaliavaeblliwgnitarlaixaehtro%05rotnemngilasimralugnaseerged5.1ylno,deriuqersitnemngilasimlellarap

TABLE 2TABLE 2

TABLE 2TABLE 2

TABLE 2

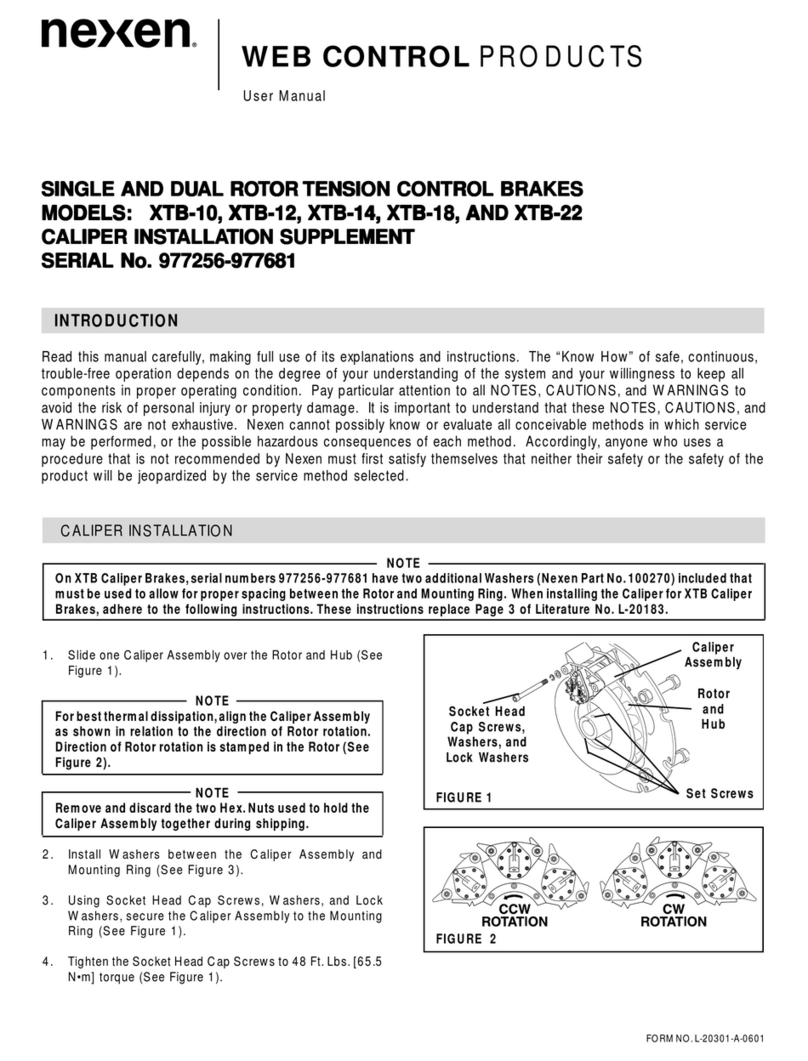

1. Insert thetaperlock bushinginto theCoupling Hub (Item4)

(See Figure 2).

2. Slidethe CouplingHub(Item4) withthe customersupplied

taperlockbushingandkeyontooneshaft;then,installtheset

screwsprovidedwiththetaperlock bushing (SeeFigure2).

NOTE

Make sure there are no burrs on the shafts or keys.

NOTE

Do not tighten the set screws provided with the taper

lock bushing at this time.

3. Using the Socket Head Cap Screws (Item 2), attach the

Coupling Adapter (Item 1) to the Clutch or Torque Limiter

(See Figure 2).

4. Tighten the Socket Head Cap Screws (Item 2) to the

recommended torque (See Table 2).

5. SlidetheCouplingAdapterwiththeClutchorTorqueLimiter

onto the other shaft (See Figure 2).

6. Tightenthetaperlockbushingsetscrewstotherecommended

torque.

7. Adjust thehubseparation towithinthe limitsforparallel and

angularmisalignment (SeeTable 2).

NOTE

Forbestresults,Nexenrecommendstheuseofadial

indicator when checking the limits for parallel and

angular misalignment. To ensure accurate readings,

always rotate the hub on which the dial indicator

probe is mounted.

CAUTION

Coupling and shaft alignment should be checked

periodically, due to equipment shifting, etc. Alignment

should be rechecked after the first forty hours of

operation.

6

Customer supplied

taper lock bushing

and key

®

DIST. AUTORIZADO

MEX (55) 53 63 23 31

QRO (442) 1 95 72 60

MTY (81) 83 54 10 18