5FORM NO. L-20143-M-1216

INSTALLATION

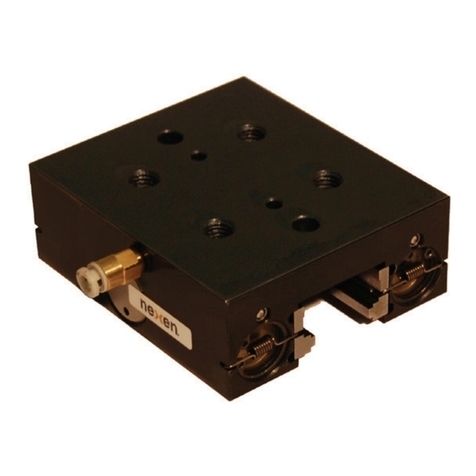

Air Champ II

Shaft

19 18

17

16

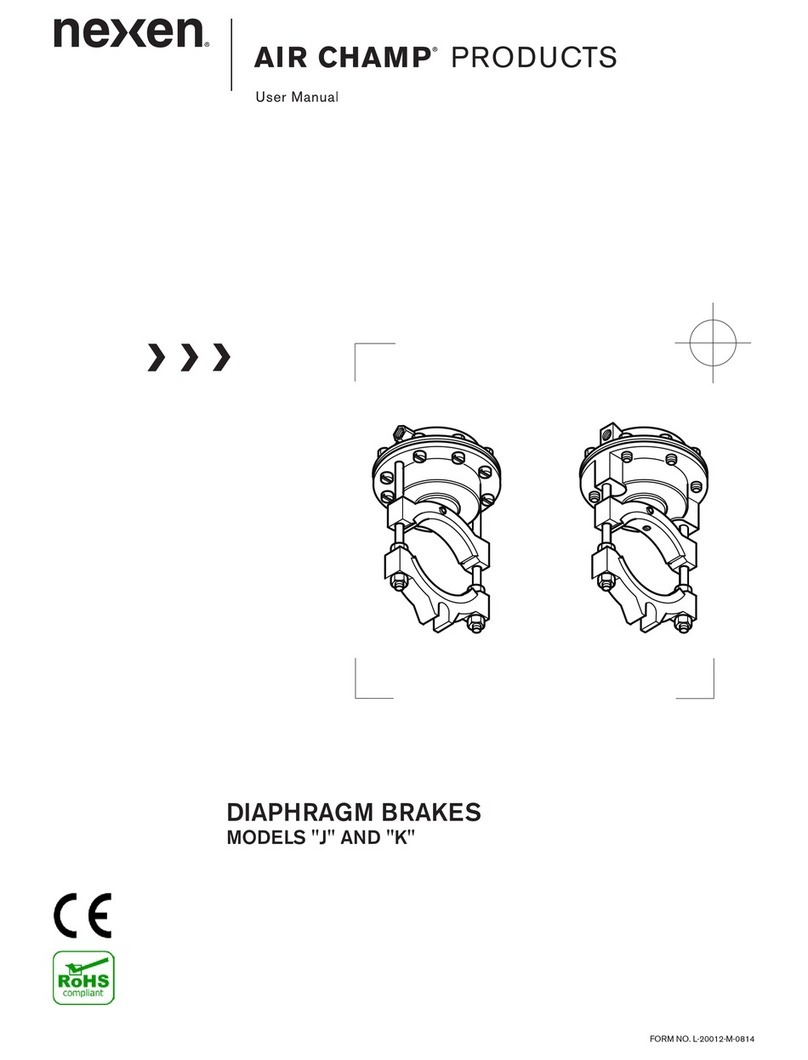

FIGURE 1

SHEAVE MOUNT AND PILOT MOUNT

Refer to Figure 1.

NOTE: If Air Champ II unit slides with minimal resistance

onto customer supplied shaft use standard

mounting procedure. If Air Champ II clutch binds on

the through shaft when sliding past the adjustment

nut (Item 16) then follow the optional mounting

procedure.

Standard Mounting Procedure.

NOTE: If mounting a customer supplied sheave to the Air

Champ II, the sheave must be mounted to the Air

Champ II first, using bolts that will not bottom out

against the friction material.

1. Insert the Key (Item 19) in the shaft keyway

2. Slide the Air Champ II onto the shaft as far as possible

with the Key fully seated into the Hub

NOTE: Refer to Table 1 for minimum shaft insertion.

3. Tighten the Set Screws (Item 18) to the torque specified

in Table 2.

Optional Mounting Procedure.

NOTE: Some Air Champ II’s may require the (Item 17) Set

Screw to be loosening for through shaft mounting.

If Air Champ II clutch binds on the through shaft

when sliding past the adjustment nut (Item 16)

then follow the procedure below.

1. Insert the Key (Item 19) in the shaft keyway.

2. Loosen Set Screw (Item 17) until Air Champ II

product slides over through shaft.

3. Slide Air Champ II product to desired position on

through shaft. Make sure the key is fully seated in

the hub.

4. Turn the adjustment nut (Item 16) unit the friction facing

gap is between 0.020 inch [0.51 mm] to 0.060 inch

[1.51 mm]. The adjustment nut comes with quantity 1

set screw (Item 17) and must be tightened onto the

hub flat.

NOTE: The Air Champ II comes with a machined flat on

the threaded portion of the hub. Set screw (Item

17) must always be tightened onto this flat (See

Figure 1). Two holes are provided in the adjustment

nut (Item 16) for set screw (Item 17). The set screw

can be installed in either threaded hole, but must

be tightened down over the hub flat. For set screw

(Item 17) Nexen recommends the use of a thread

locking compound in high vibration applications,

(Example: Loctite 242).

5. Once in the desired position over the hub flat, tighten

the set screw (Item 17). (See Table 5 Page 7 for set

screw (Item 17) tightening torque)

6. Tighten the Set Screw (Item 18) to torque specified

in Table 2.

TABLE 1

LEDOM NOITRESNITFAHSMUMINIM

054-F.nI000.2mm08.05

006-L.nI005.2mm05.36

008-M.nI057.3mm52.59

0001-H.nI573.4mm21.111

TABLE 2

LEDOM .ONMETI NOITPIRCSED EUQROT

054-F DTS81

RTM81

02-052.

0.1-6M

.sbL.nI80.43

]mN58.3[

006-L DTS81

RTM81

42-213.

0.1-6M

.sbL.nI80.43

]mN58.3[

008-M DTS81

RTM81

61-573.

5.1-01M

.sbL.nI13.631

]mN4.51[

0001-H DTS81

RTM81

61-573.

5.1-01M

.sbL.nI13.631

]mN4.51[

TABLE 3

LEDOM GNILPUOC

EZIS

NOITAIRAVDERUSAEM

081STNIOPTA

TRAPASEERGED

TAOLFLAIXA

EULAVMUMIXAM(

MORF

DEDNEMMOCER

)GNICAPSLAITINI

LELLARAP

MUMIXAM

RALUGNA

MUMIXAM

054-F .nI8/5-2

]mm57.66[

.nI510.0

]mm183.0[

.nI40.0

]mm610.1[

.nI8/1+

]mm573.1+[

006-L .nI4

]mm6.101[

.nI510.0

]mm183.0[

.nI460.0

]mm526.1[

.nI8/1+

]mm573.1+[

008-M .nI7

]mm8.771[

.nI510.0

]mm183.0[

.nI211.0

]mm548.2[

.nI8/1+

]mm573.1+[

0001-H .nI8

]mm2.302[

.nI510.0

]mm183.0[

.nI821.0

]mm152.3[

.nI8/1+

]mm573.1+[

Disc Screws Torque

10" #10 Flat Head 65 in-lbs

12", 14", 16" .250-20 Flat Head 105 in-lbs

18

Set Screw

Aligned with

Hub Flat