NEXTTEQ NXM User manual

INSTRUCTION MANUAL

Multi Gas Detector

®

Exclusive Nextteq®International Product

Multi Gas Detector

3

TABLE OF CONTENTS

1 PRODUCT INTRODUCTION.............................................. 4

1.1 KEY FEATURES ..................................................... 4

1.2 PROGRAMMABLE OPTIONS ...................................... 4

2 WARNINGS ................................................................ 5

2.1 CAUTION............................................................. 6

3 PRODUCT OVERVIEW.................................................... 6

3.1 DISPLAY SYMBOLS ................................................ 7

4 CHARGING AND ACTIVATING ........................................... 7

4.1 CHARGING........................................................... 7

4.2 POWER ON .......................................................... 7

4.3 POWER OFF ......................................................... 8

5 DEVICE OPERATIONS .................................................... 8

5.1 OPERATIONAL MODES ............................................ 8

5.2 DISPLAY MODES ................................................... 9

5.2.1 MEASURING MODE ........................................ 9

5.2.2 SAFE ZONE MODE.......................................... 9

5.3 DISPLAY SCREENS................................................10

5.4 DISPLAY DETAILS .................................................10

5.5 ALARMS AND NOTIFICATIONS ..................................13

5.6 DETECTED CONCENTRATION VALUES..........................15

5.7 ALARM VALUES ...................................................15

5.7.1 DEFAULT ALARM SETTINGS.............................16

6 SELF-TEST................................................................17

7 BUMP TEST...............................................................18

7.1 BUMP TEST REMINDER ..........................................18

7.1.1 CHECK BUMP TEST INTERVAL DATE AND LATEST

BUMP TEST DATE .........................................18

7.2 PERFORM A BUMP TEST.........................................19

8 CALIBRATION ............................................................21

8.1 CHECK SPAN CALIBRATION INTERVAL DATE AND LATEST ....

SPAN CALIBRATON DATE ........................................21

8.2 DEFAULT GAS CONCENTRATIONS FOR CALIBRATION.......21

8.3 ZERO (FRESH AIR) CALIBRATION...............................22

8.4 SPAN (STANDARD) CALIBRATION ..............................24

8.5 EXITING THE CALIBRATION MENU..............................26

9 LOGGING..................................................................26

10 MAINTENANCE AND DISPOSAL .......................................27

10.1 MAINTENANCE.....................................................27

10.2 DISPOSAL ..........................................................27

11 SPECIFICATIONS ........................................................28

12 WARRANTY...............................................................30

12.1 LIMITED WARRANTY .............................................30

12.2 WARRANTY DISCLAIMER ........................................31

4 5

Nextteq International LLC Toll Free: 877-312-2333 www.nextteq.com [email protected]Designed, built and supported by industry professionals for industry professionals.

1 PRODUCT INTRODUCTION

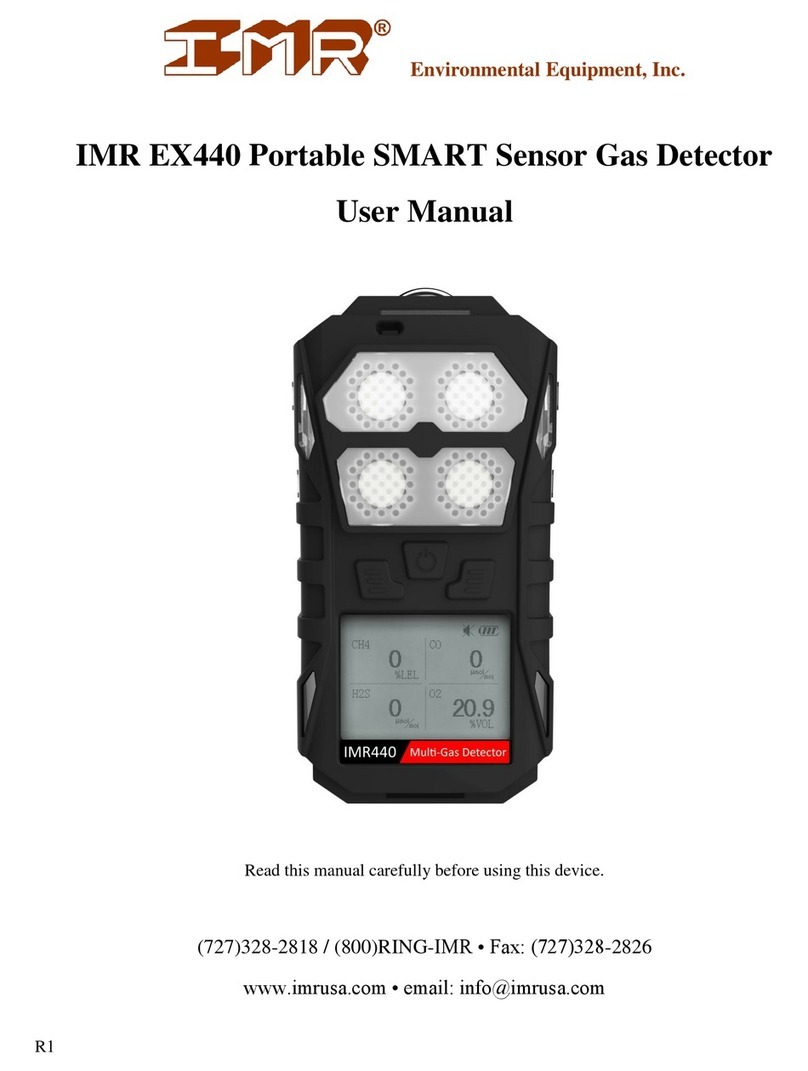

The NXM Multi Gas series is a diffusion gas monitor that

simultaneously detects up to four gases, including hydrogen sulfide

(H2S), carbon monoxide (CO), oxygen (O2) and combustibles (LEL).

The unit alarms in three ways: visual, vibration, and audible when the

risk occurs. A dual sensor detects both CO and H2S.

The NXM displays real-time gas concentrations with configurable

settings for high and low alarm points for each sensor plus STEL and

TWA alarm points for toxic gases. The unit will operate continuously

for up to 60 days on a battery charge. Sensors for combustible gases

are offered in either Catalytic Bead or Infrared.

1.1 Key Features

• Small and lightweight

• Stores up to 30 Events (Alarms/Bump Tests/Calibration/Data)

• Simultaneously monitors and detects 4 different gases

• Easy-to-read LCD display

• Single button operation

• Rugged housing

• IP67 dust tight and water resistant

• IR sensor is immune to poisoning

• IR sensor detects LEL gases in inert (O2 deficient)

environments

• 60-day use with one 4–6-hour charge

• Configuration via NXI exclusive IR link

• Easy check and calibration via NXI Docking Station

• Combustible (LEL) available with either IR Sensor (P/N

NX90221) or Catalytic Bead Sensor (P/N NX90222)

1.2 Programmable options

The options below are configured with the IR Link software.

• Stealth Mode

• Go/No Go display

• Bump Test due

• Calibration due

• Calibration gas concentrations

• Alarm levels

• STEL and TWA levels

• Firmware updates

2 Warnings

• Any unauthorized attempt to repair or modify the product,

or any other cause of damage beyond the range of the intended use

including damage by fire, lightning, or other hazard, voids liability of

the manufacturer.

• Do not use the device if it appears to be damaged.

• Remove any debris from the surface of the sensor, LED, or buzzer

hole before use.

• Test the performance of the gas sensor beyond the alarm level

regularly.

• Test the device on a regular basis to ensure the LED, alarms, and

vibration actions function properly.

• Use the device under the conditions instructed, including the

temperature, humidity, and pressure range. An environment

outside the user instructions may cause malfunction or failure.

• The sensors inside the device may indicate the gas concentration

differently according to the environment such as temperature,

pressure, and humidity. Calibrate the detector under the same or a

similar environment to the specification.

• Extreme changes in temperature may cause drastic changes of

the gas concentration (e.g. using the detector where there is a huge

gap between the inside and outside temperature). Use the device

when the concentration becomes stable.

• Severe pressure or impact may cause drastic changes of the gas

concentration. Therefore, please use the device when the

concentration is stable. Severe pressure or impact may also cause

malfunction in the sensor or the device.

• The alarms are set according to international standards and must be

changed by an authorized expert.

• Charging or replacing the battery should be done in a safe area

where there is no risk of explosion or fire. Changing the sensor

or battery with improper replacements, which are not authorized

by the manufacturer, may invalidate the warranty.

• IR communication should be done in a safe area where there is no

risk of explosion or fire.

• Do not use expired gas cylinders.

• Use certified gas cylinders only.

• Do not use a gas detector which has failed or cannot pass a bump

or calibration test.

6 7

Nextteq International LLC Toll Free: 877-312-2333 www.nextteq.com [email protected]Designed, built and supported by industry professionals for industry professionals.

2.1 Caution

• Read the manual before first use and follow all instructions.

• The device is not a measurement device, but a gas detector.

• Please stop using and consult the manufacturer if the

calibration fails continuously.

• Test the device every 30 days under the atmospheric

environment of clean air without gases.

• Clean the exterior of the device with a soft cloth. Do not use

chemical detergents.

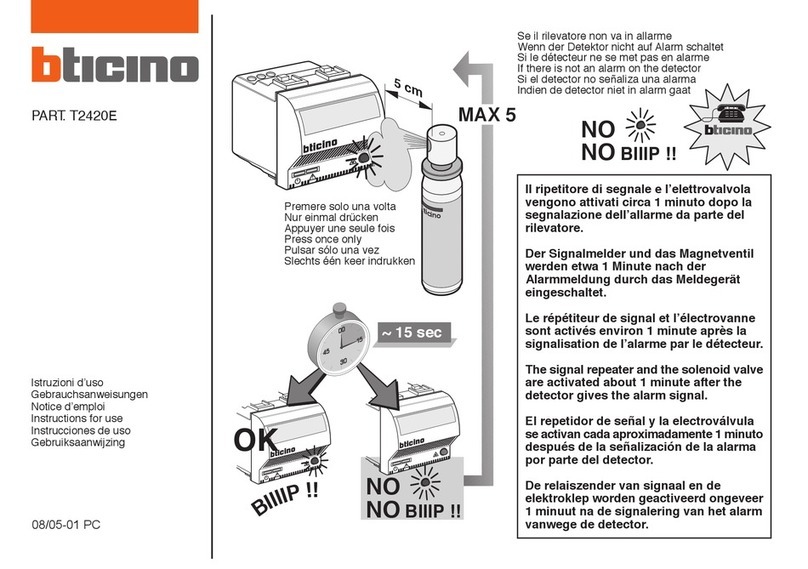

3. Product Overview IR Port

Display

Multifunction Key

LEL Sensor

O2Sensor

Alarm

LEDs

Alarm

LEDs

Alarm

Buzzer

Dual

CO & H2S

Sensor

HIGH

High Alarm Fresh Air Calibration

LOW

Low Alarm Device Stablilization

& Calibration Successful

Alarm Condition Standard Gas

Calibration

STEL

Short Term

Exposure Limit

Alarm

Remaining Battery

TWA

Time Weighted

Average Alarm

3.1 Display symbols

4 CHARGING AND ACTIVATING

4.1 Charging

The NXM Multi-Gas Monitor ships with a charging cable and a

selection of the more common wall plugs.

1) Choose the correct plug for the type of wall outlet available and

attach it to the power supply.

2) Insert the adapter to the charging slot on the bottom of the

unit.

3) Plug the other end into a standard outlet.

4.2 Power On

Press and hold down the MULTIFUNCTION KEY for 3 seconds until

the device switches on..

(The device will power on only when pressing the key for longer

than 3 seconds.)

8 9

Nextteq International LLC Toll Free: 877-312-2333 www.nextteq.com [email protected]Designed, built and supported by industry professionals for industry professionals.

5.2 Display Modes

5.2.1 Measuring Mode

Measuring Mode is the default display. Oxygen is displayed in

% by volume, combustible gases in %LEL, and H2S and

CO in PPM units. The values are displayed in

real time. If the levels exceed the threshold

for either LOW alarm or HIGH alarm or TWA/

STEL, the display icons of LOW, HIGH, TWA

or STEL blink regularly and the audible, LED,

and vibration alarms activate. Exit the area

immediately.

When the device enters a safe area and the concentrations

detected by the device decline, the alarm stops. A device in

a safe area after an alarm will continue to display the icon of

the alarm until the MULTIFUNCTION KEY is pressed.

5.2.2 Safe Zone Mode

Safe Zone Mode is used as a go/no-go monitor. If

concentrations exceed an alarm threshold, alarms will

activate as described in Measuring Mode and

Oxygen is displayed in % by volume,

combustible gases in %LEL, and

H2S and CO in PPM. If the alarms

activate, exit the area immediately.

When the device enters a safe area and the

concentrations detected by the device decline, the alarm

stops. A device in a safe area after an alarm will continue to

display the icon of the alarm until the MULTIFUNCTION

KEY is pressed.

During the power up sequence, the display will cycle through the

gas types, firmware version, display test and alarm test, followed

by a 10-second warm up. Once powered, the device will enter an

additional warmup stage to stabilize the sensors. When the warmup

process is complete, the device will enter measuring mode and is

ready to detect gases.

Caution A proper calibration is always required before using the

device at the work site. The user shall check whether the device

is properly sensing the levels of dangerous gases and ensure the

detecting section of the device is not blocked.

4.3 Power Off

Press and hold down the MULTIFUNCTION KEY until the device

switches off after a 3-second countdown.

(The device will power off only when pressing the key for longer

than 3 seconds.)

5 DEVICE OPERATIONS

5.1 Operational Modes

• Measuring Mode

The device displays real-time gas concentrations and the battery

power level.

• Safe Zone Mode

The device displays SAFE ZONE unless concentrations exceed an

alarm threshold.

10 11

Nextteq International LLC Toll Free: 877-312-2333 www.nextteq.com [email protected]Designed, built and supported by industry professionals for industry professionals.

5.3 Display Screens

Display screens are visible in the following order by pressing the

MULTIFUNCTION KEY

Measuring Mode

Default display.

Minimum Concentration

The lowest gas concentration that the O2 sensor has

detected since the measurements were last cleared.

Time Weighted Average

The acceptable average concentration level of each gas

over the last eight hours.

Short Term Exposure Limit

The acceptable average concentration level of each gas

over the last 15 minutes.

Clear Stored Values

Clear Low, High, TWA, STEL values. To clear, press and

hold the MULTIFUNCTION KEY for 3 seconds. The unit

beeps once then displays OK. Press the MULTIFUNCTION

KEY to continue through the display screens or wait 10

seconds to return to Measuring Mode.

Alarm Values

Displays the alarm values for each gas. Press and hold

the MULTIFUNCTION KEY for 3 seconds to enter the Alarm

Values menu, then step through LOW, HIGH, TWA, STEL

values by pressing the MULTIFUNCTION KEY.

Note: The screen will revert to measuring mode if the

MULTIFUNCTION key is not pressed within 10 seconds.

5.4 Display Details

12 13

Nextteq International LLC Toll Free: 877-312-2333 www.nextteq.com [email protected]Designed, built and supported by industry professionals for industry professionals.

5.5 Alarms and Notifications

Type Alarm

Condition

LCD Display Audio/Visual/

Physical Display

Action

Low

Alarm

LOW alarm

value

exceeded Icon & gas

concentration

levels

displayed

Press the

MULTIFUNCTION

KEY to silience

audio. LED and

vibration continue.

High

Alarm

HIGH

alarm value

exceeded Icon & gas

concentration

levels

displayed

Leave the area

immediately!

Alarms stop when

the device is in

a safe area and

concentrations are

normal

TWA

Alarm

TWA alarm

value

exceeded Icon & gas

concentration

levels

displayed

Alarms stop when

gas concentration

levels reach the

configured alarm off

value and device is

in a safe area.

STEL

Alarm

STEL

alarm value

exceeded Icon & gas

concentration

levels

displayed

Alarms stop when

gas concentration

levels reach the

configured alarm off

value and device is

in a safe area.

LEL Sensor Type and Firmware Version

Displays the LEL sensor type. N (Non-Dispersive Infrared)

or P (Pellistor/Catalytic Bead)

Displays the current firmware version.

Press and hold the MULTIFUNCTION KEY for 3 seconds to

initiate a self-test.

Short Term Exposure Limit

The acceptable average concentration level of each gas

over the last 15 minutes.

Date/Time

Displays date by default. Hold the MULTIFUNCTION KEY

for 3 seconds to toggle back and forth between Date and

Time.

Note: The date and time automatically sync with that of

the PC when linked with the NXI IR-LINK.

Short Term Exposure Limit

The acceptable average concentration level of each gas

over the last 15 minutes.

14 15

Nextteq International LLC Toll Free: 877-312-2333 www.nextteq.com [email protected]Designed, built and supported by industry professionals for industry professionals.

5.6 Detected Concentration Values

View as described under Display Details. To clear the values,

do the following. Press MULTIFUNCTION KEY for 3 seconds on

the CLR (Clear) mode on the LCD monitor. OK will appear on the

LCD monitor to notify the completion of the initialization.

5.7 Alarm Values

To view configured alarm values, do the following. Press the

MULTIFUNCTION KEY for 3 seconds in ALARM VAL mode. The

configured value for the LOW alarm is displayed. Press the

MULTIFUNCTION KEY once to cycle through and view each

alarm value.

Type Alarm

Condition

LCD Display Audio/Visual/

Physical Display

Action

Over

Range

Alarm

Gas

concentrations

exceed

maximum

sensor range

Press the

MULTIFUNCTION

KEY or reset the

device to clear.

See LEL sensor

types for more

info.

Bump

Test

Bump Test due

for gas sensor

indicated on

display

Clears after

successful Bump Test

Notifies the

user to perform

a bump test

at intervals

specified using

the IR-LINK.

Execute

Calibration

Calibration

due for

gas sensor

indicated on

display

Clears after

successful Calibration

Notifies the

user to perform

a calibration

test at intervals

specified using

the IR-LINK.

Calibration

Failed

Displays

sensor failing

calibration

Clears after

successful Calibration

16 17

Nextteq International LLC Toll Free: 877-312-2333 www.nextteq.com [email protected]Designed, built and supported by industry professionals for industry professionals.

6 SELF-TEST

Press the MULTIFUNCTION KEY to cycle

through the menus until sensor type and

firmware version are displayed. Press and

hold the MULTIFUNCTION KEY for 3 seconds.

The device will start the self-test to check the

Buzzer, LED, LCD, Vibration Motor, Memory,

and Temperature functions.

5.7.1 Default Alarm Settings

Setting Combustible

(Lower

Explosive

Limit)

O2 CO H2S

LOW Alarm 10% LEL 19.5% 35 ppm 5 ppm

HIGH Alarm 20% LEL 23.5% 200 ppm 10 ppm

TWA 25 ppm 1 ppm

STEL 200 ppm 5 ppm

Caution The values of different gases in the device are set based

on international standards. The alarm values for each gas can be

modified upon the approval and monitoring of an authorized expert.

The modification may be done through NXI IR-LINK under the

Options Menu.

Dates and Times

Press the MULTIFUNCTION KEY for 3

seconds while viewing the date to cycle to

the day and time. Press the MULTIFUNC-

TION KEY for 3 seconds to return to the

date display.

Note: The current time is automatically

synchronized with the PC when linked to

the NXI IR-LINK.

18 19

Nextteq International LLC Toll Free: 877-312-2333 www.nextteq.com [email protected]Designed, built and supported by industry professionals for industry professionals.

7.2 Perform a Bump Test

1) Check the Measuring Mode

display to ensure that the 02

sensor reads 20.9 and the other

gases read zero.

2) Clip the calibration cap to the

front of the unit as shown.

You should hear a click when

the cap is installed correctly.

Note: Be sure the word

“Calibration” is at the top of

the cap.

3) Check the regulator

connection to the gas

bottle and the hose

connections to the calibration

cap and the regulator to ensure

there are no leaks. Note: Do not

turn on the gas at this point.

4) Press the MULTIFUNCTION KEY

under CAL SPAN to enter BUMP

TEST mode.

5) Press the MULTIFUNCTION

KEY to advance to the Bump

Test screen. BUMP TEST

displays.

7 BUMP TEST

A bump test verifies the device is working correctly. A known

concentration of gas is applied to the sensors to confirm the

unit detects the gas and the alarms trigger.

Do not use the monitor until a successful Bump Test or Calibration is

performed. A Bump Test should be performed daily before use.

Perform the Bump Test in a clean environment.

7.1 Bump Test Reminder

The bump test reminder option is enabled using the NXI IR

Link and software or the NXI docking station. The reminder

can be set from n/a (off) to 365 days. Off is the default.

7.1.1 Check bump test interval date and latest bump test date

Cycle through the menus until BUM CAL DATE appears.

Press the MULTIFUNCTION KEY button for 3 seconds to view

the BUM DATE. Press the MULTIFUNCTION KEY button for 3

seconds to continue cycling through the screens. The interval

date set via IR-Link is displayed. Bump test interval date and

the latest bump test date will appear in the order above.

20 21

Nextteq International LLC Toll Free: 877-312-2333 www.nextteq.com [email protected]Designed, built and supported by industry professionals for industry professionals.

8 CALIBRATION

The calibration process adjusts the sensors’ responses by using a

known concentration of calibration gas. Sensors will become less

accurate for several reasons so a full calibration should be performed

on a regular basis to ensure accuracy. A full calibration consists of a

2-step process consisting of a Zero (fresh air) calibration and a Span

Calibration.

Calibration should be performed before the first use, one year after the

purchase and regularly every six months.

Zero Calibration adjusts the zero offset of the toxic gas and LEL

sensors to zero and sets the oxygen sensor to 20.9% Vol.

Span Calibration adjusts the toxic gas sensor response to account for

sensor drift. Always perform a Zero Calibration prior to a Span

Calibration.

8.1 Check span calibration interval date and latest span

calibraton date

Press the KEY button ( ) for three seconds under the Cal

Date when you set the interval date via IR-Link. The set value for

interval is displayed, calibration interval date and latest

calibration date will appear in the mentioned order.

8.2 Default Gas Concentrations for Calibration

The concentration for calibration may be modified on a PC

through NXI IR-LINK (Options Menu).

3 sec

6) Press and hold the MULTI-

FUNCTION KEY to start the

Bump Test. GAS NO and

a 45-second timer are displayed.

7) Turn on the gas regulator. GAS

IN is displayed and alternates

with real-time gas measure-

ments. The 45-second timer

counts down. Results appear

in approximately 20 seconds.

8) If the Bump Test is successful,

OK appears in all 4 sections of

the display.

9) If the Bump Test fails, the

sensor(s) that are suspect is/are

displayed. The display continues

to flash with the failure results

until a successful Bump Test or

Calibration is performed.

a. Check calibration gas concen-

trations, cylinder expiration

date, and device gas settings

then retest the unit.

b. If the unit fails on re-test,

perform a Zero Calibration

followed by a Span

Calibration.

The unit must be calibrated if it

fails a Bump Test.

Do not use the Multi-gas

Monitor until the discrepancies

are identified and addressed.

10) Turn off the gas regulator,

disconnect the hose and

calibration cap, and wait for the

gas to dissipate.

22 23

Nextteq International LLC Toll Free: 877-312-2333 www.nextteq.com [email protected]Designed, built and supported by industry professionals for industry professionals.

3) A 10-second countdown begins

and the device cycles through

detected gas level displays.

4) If the Zero Calibration is

successful, OK appears

in all 4 sections of the

display for approximately 5

seconds then returns to the

CAL ZERO display. Press the

MULTIFUNCTION KEY to the

CAL ESC to exit or wait

approximately 10 seconds for

the unit to return to the

Measuring Mode menu.

5) If the Zero Calibration fails, the

sensor(s) that is/are suspect

is/are displayed. The display

continues to flash with the

failure results until a

successful Calibration is

performed.

If the calibration continues to

fail, discontinue use and

contact Nextteq Technical

Support.

1) From the Measuring Mode menu,

press the MULTIFUNCTION KEY

to cycle through the menus to

the Calibration Menu.

2) Press and hold the

MULTIFUNCTION KEY for 3

seconds to access the

Calibration menus. CAL ZERO

will display. Press and hold the

MULTIFUNCTION KEY for 5

seconds to begin the calibration

process.

Gas Type Combustible Oxygen Carbon

Monoxide

Hydrogen

Sulfide

Concentration 50%LEL(CH4) 17 %Vol 100 ppm 25 ppm

Caution: The initial calibration is executed at the manufacturer before

device release. The calibration values are saved in the device which

means inaccurate calibration may impair the accuracy of the device

performance. Normally, the calibration should be done once a year

after the purchase and regularly every six months thereafter.

8.3 Zero (Fresh Air) Calibration

Calibration assumes that the oxygen concentration

is 20.9% vol, the combustible gas level is 0%LEL, and

the toxic gas level is 0ppm in normal fresh atmospheric

conditions; therefore, fresh air calibration must be conducted in

clear air without impact from other gases. Fresh air calibration in

airtight spaces is not recommended. Be sure to avoid operation

in work environments where people may inhale gases.

24 25

Nextteq International LLC Toll Free: 877-312-2333 www.nextteq.com [email protected]Designed, built and supported by industry professionals for industry professionals.

8.4 Span (Standard) Calibration

If not already completed, perform a Zero Calibration. When

performing a Span Calibration, use certified calibration gas at the

required concentration level. Do not use expired calibration gas.

Note: All alarms are muted for approximately one minute after a successful

Span Calibration.

1) Check the Measuring Mode

display to ensure that the 02

sensor reads 20.9 and the other

gases read zero.

2) Clip the calibration cap to the

front of the unit as shown. You

should hear a click when the cap

is installed correctly. Note: Be

sure the word “Calibration” is at

the top of the cap.

3) Check the regulator connection

to the gas bottle and the hose

connections to the calibration cap

and the regulator to ensure there

are no leaks. Note: Do not turn on

the gas at this point.

4) Cycle through the display screens

by pressing the MULTIFUNCTION

KEY to reach the Calibration

screen.

5) Press and hold the

MULTIFUNCTION KEY for 3

seconds to enter the Calibration

menu. CAL ZERO displays.

6) Press the MULTIFUNCTION KEY

to advance to the Span Calibration

screen. CAL SPAN displays.

7) Press and hold the

MULTIFUNCTION KEY for 5 seconds

to start the Span Calibration. Ninety-

second timer appears in the lower

right corner while the display cycles

through detected concentrations of

each gas.

8) Turn on the gas regulator and

wait for the calibration timer to

reach zero.

9) If the Span Calibration is successful,

OK appears in all 4 sections of the

display.

10) If the Span Calibration fails, the

sensor(s) that is/are suspect is/are

displayed. The display continues to

flash with the failure results until a

successful Calibration is performed.

Clear the stored values, perform

a Zero Calibration and attempt

another Span Calibration.

If the unit continues to fail, contact

Nextteq Technical Support.

11) Turn off the gas regulator,

disconnect the hose and calibration

cap, and wait for the gas to

dissipate.

1

7

2

8

9

4

10

5

6

26 27

Nextteq International LLC Toll Free: 877-312-2333 www.nextteq.com [email protected]Designed, built and supported by industry professionals for industry professionals.

Log Categories Log Details Retention

EVENT Log (High, Low,

TWA, STEL) Alarm

Occurrence time,

Duration, Alarm Type,

Gas Concentration, Serial

Number

30

BUMP TEST Log Test date, Pass/non-

pass, Calibration Gas

Concentration, Detected

Concentration

30

CALIBRATION Log Date of the Calibration,

Type, Calibration Gas

Concentration, Detected

Concentration

2 months or more

DATA Log Time, Date of executing

IR-LINK, Concentration,

Alarm Types, Options

Records status every

second

2 months or more

10 MAINTENANCE AND DISPOSAL

10.1Maintenance

CAUTION: Do not clean the instrument in a hazardous environment.

Static charge build up may result in an explosion.

Clean the display and case as needed with a soft cloth. Do not use

detergents or chemicals. If necessary, dampen the cloth with water

only.

Install the Calibration Cap before cleaning the monitor case to keep

contaminants and moisture away from the sensors.

10.2 Disposal

Dispose of the device in accordance with local electronics

recycling or waste disposal regulations.

8.5 Exiting the Calibration Menu

To exit the Calibration Menu, do the following:

1) Press the MULTIFUNCTION KEY until CAL ESC is displayed.

2) Press and hold the MULTIFUNCTION KEY for approximately 5

seconds until the display returns to the Calibration screen.

3) Press the MULTIFUNCTION KEY again and the unit will return

to the Measuring Mode screen.

Note: If the MULTIFUNCTION KEY is not pressed within 20 seconds,

the display reverts to the Measuring Mode screen.

8.6 Docking Station

The NXI Docking Station can also be used to easily perform

calibration, bump test, and event management on multiple devices

at a time.

9 LOGGING

Event logs and data are stored in internal memory. Refer to the table

below for retention times. When the capacity is exceeded, the oldest

logs are overwritten.

Event logs can be downloaded using a PC through the NXI IR-LINK or

the NXI Docking Station.

Data log records the operation status every second. Normal data logs

do not last more than 2 months.

28 29

Nextteq International LLC Toll Free: 877-312-2333 www.nextteq.com [email protected]Designed, built and supported by industry professionals for industry professionals.

Battery Manufacturer: SAMSUNG SDI

Product Name: ICP103450S

Type: Lithium-Ion Charger

Nominal Voltage: 3.7V

Nominal Capacity: 2000mAh

Max Charging Voltage: 6.3V

Battery

Charge

Duration

NXM-P: 24 Hours

NXM-IR: 60 Days

Case Rubber-based over-molded case

Size (W x D x H) 2.36 x 1.57 x 4.64in

Weight 8.46 oz

Options and

Accessories

NX1000 (Sampling pump)

NXI IR-LINK

NXI Docking-Station

Certification NX1000 (Sampling pump)

NXI IR-LINK

NXI Docking-Station

Compatible options IR-LINK, Docking Station, Sampling Pump.

Compatible Nextteq®

options

Nextteq IR-Link

Docking Station

SP-pump 101

11 SPECIFICATIONS

Model NXM

Gas Combustible O2 CO H2S

Detecting Method Diffusion / Sampling (with optional Sampling Pump)

Measuring

Mechanism

Catalytic

(NXM-P)

NDIR (NXM-IR)

Electrochemical Electrochemical Electrochemical

Range 0~100 %LEL 0~30 %vol 0~500 ppm 0~100 ppm

Sensor life > 5 years < 3 years > 5 years > 5 years

Response

Time

< 15sec/90%scale

< 15sec/90%scale

< 30sec/90%scale

< 30sec/90%scale

Accuracy ± 3%/ Full Scale

Resolution 1%LEL 0.1 %vol 1 ppm 0.1 ppm

Operation MULTIFUNCTION KEY

Display Digital LCD display, LCD Backlight, Indicator LED

Alarm Visual: LCD alarm display, LCD Backlight, Indicator LED

Audible: Buzzer (90dB at 10cm)

Physical: Vibration

Data Saving Event Log: 30 EA

Calibration Log: 30 EA

Bump Log: 30 EA

Data log: Two months or longer

How to

Wear

Belt Clip

Temperature -20˚C ~ +50˚C

Humidity 10 to 95% RH (Non-condensing)

30 31

Nextteq International LLC Toll Free: 877-312-2333 www.nextteq.com [email protected]Designed, built and supported by industry professionals for industry professionals.

12.2 Warranty Disclaimer

Nextteq accepts no liability for consequential or indirect

loss or damage howsoever arising (including any loss or

damage arising out of the use of the instrument) and all

liability in respect of any third party is expressly excluded.

This warranty does not cover the accuracy of the calibration of

the unit or the cosmetic finish of the product. The unit must

be maintained in accordance with the instructions in this

manual. The warranty on replacement consumable items

supplied under warranty to replace faulty items will be limited

to the unexpired warranty of the original supplied item.

Nextteq reserves the right to determine a reduced warranty

period, or decline a warranty period for any sensor supplied

for use in an environment or for an application known to carry

risk of degradation or damage to the sensor. Our liability in

respect of defective equipment shall be limited to the

obligations set out in the guarantee and any extended

warranty, condition or statement, express or implied, statutory

or otherwise as to the merchantable quality of our equipment

or its fitness for any particular purpose is excluded except as

prohibited by statute. This guarantee shall not affect a

customer’s statutory rights.

Nextteq reserves the right to apply a handling and carriage

charge whereby units returned as faulty are found to require

only normal calibration or servicing, which the customer then

declines to proceed with.

For warranty and technical support inquiries, please contact:

Nextteq International Customer Support

Tel: 813-249-5888

Toll Free: 877-312-2333

Fax: 813-249-0188

Toll Free: 877-312-2444

Email: [email protected]

12 WARRANTY

12.1 Limited Warranty

Nextteq warrants this product to be free from defects in

material and workmanship under normal use and service

for a period of two years from the manufacturing date for

this NXM product. This warranty is valid only if the personal

monitor is activated by the ‘activate by’ date on the external

packaging. This warranty extends only to the sale of new and

unused products to the original buyer.

Warranty Procedure

To facilitate efficient processing of any claim, contact your local

Nextteq agent/distributor, a Nextteq regional office or our global

customer support team (English speaking) at 813-249-5888 or

Authorization) number for identification and traceability

purposes.

Be sure to include:

• Your company name, contact name, phone number and

email address.

• Description and quantity of goods being returned,

including any accessories.

• Instrument serial number(s).

• Reason for return.

Products will not be accepted for warranty without a

Nextteq RMA #. It is essential that the address label is

securely attached to the outer packaging of the returned

goods. The guarantee will be rendered invalid if the instrument

is found to have been altered, incorrectly stored, modified,

dismantled, tampered with, has not used Nextteq spares for

replacement parts (including sensors) or has been serviced or

repaired by any party not authorized and certified by Nextteq

to do so. The warranty does not cover misuse or abuse of the

unit including use outside of specified limits.

©2023 Nextteq®International LLC

All rights reserved.

This book is fully protected by copyright and no part of it

may be reproduced in any form, by photocopy, microfilm, or

any other means, without prior written permission of

Nextteq® International LLC.

P/N NX90524

Nextteq and NXI are registered trademarks of Nextteq

International LLC. All other brand names and trademarks

mentioned in this document are the properties of their

respective holders.

Nextteq®International LLC

website http://www.nextteq.com

Tampa, FL

Tel: 813-249-5888

Toll Free: 877-312-2333

Fax: 813-249-0188

Toll Free Fax: 877-312-2444

Email: [email protected]

Printed in the United States of America

Table of contents