NEXTTEQ NX-300 User manual

Nextteq Instruction Manual

NX-300 Constant Flow

Air Sampling Pump

Air Sampling Pump

2Designed, built and supported by industry professionals for industry professionals.

Safety Warning

Before using this product, be sure to read “Operation Settings When an Error

Occurs,” and then configure the settings accordingly. (See Section 4.14.8, Page 53)

This operation manual describes precautions that are important for preventing

accidents as well as instructions for using the product.

To ensure safety, read this operation manual thoroughly before use, and use the

product correctly.

After reading this operation manual, keep it in a safe place where it can be referred

to at any time. This manual is also available at www.nextteq.com

Designed, built and supported by industry professionals for industry professionals

3

TABLE OF CONTENTS

1 Introduction...................................................................................................5

1.1 Indications Used in This Manual..............................................................5

1.1.1 “Danger,” “Warning,” and “Caution”..........................................5

1.1.2 “Important” and “Note” .............................................................5

1.1.3 Symbols.....................................................................................5

1.2 Checking the Packed Items........................................................6

2 Safety Instructions........................................................................................7

3 About This Product .......................................................................................10

3.1 Overview............... ................................................................................10

3.2 Features........ ........................................................................................10

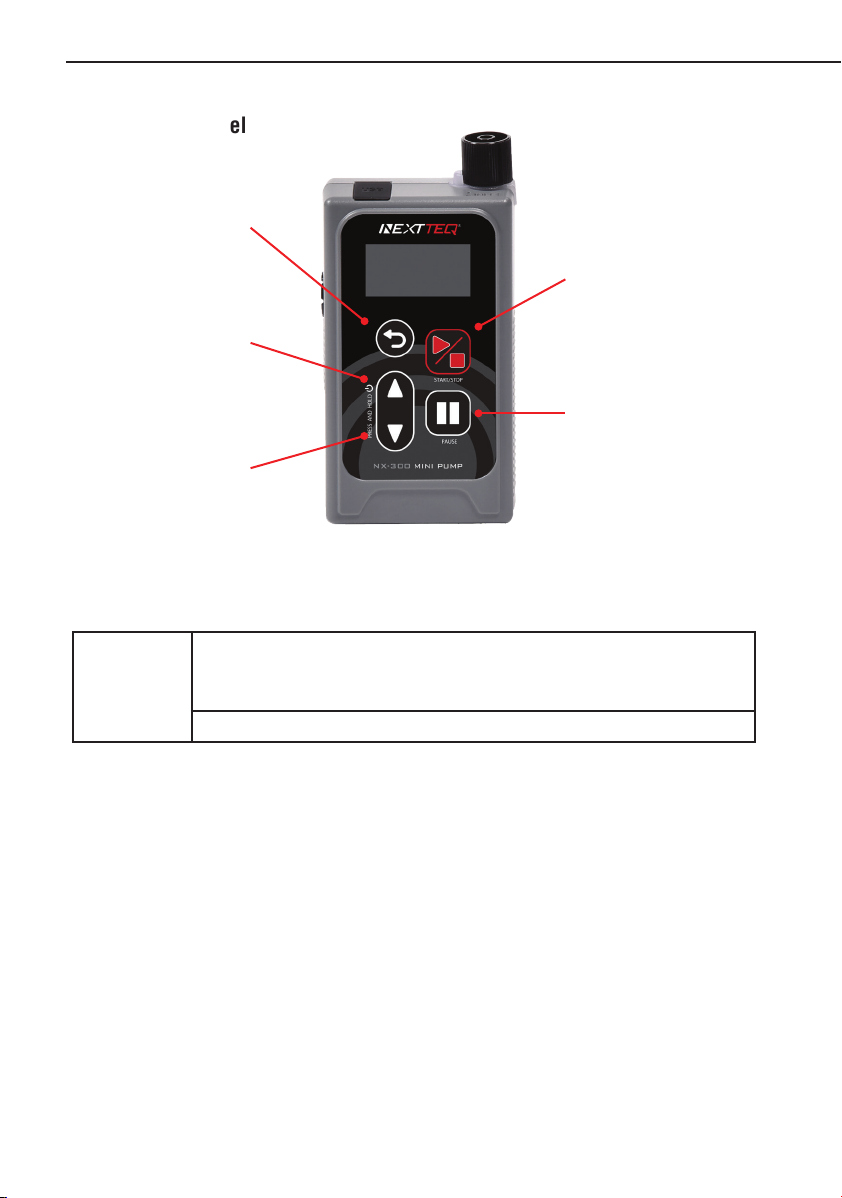

3.3 Names of the Parts................................................................................11

3.3.1 Main Unit ...................................................................................11

3.3.2 Control Panel .............................................................................12

4 Operation Procedures...................................................................................13

4.1 Preparing the Power Supply and Turning the Pump ON and OFF............13

4.1.1 Installing and Removing Batteries................................................13

4.1.2 External Power Supply .................................................................14

4.1.3 Turning the Pump ON and OFF.....................................................15

4.1.4 Remaining Battery Level Display..................................................15

4.2 Pressure Loss .........................................................................................16

4.3 Using a Micro Impinger ..........................................................................16

4.4 Attaching and Removing the Intake Port.................................................17

4.5 Using the Low Flow Rate Orifice and Adapter .........................................18

4.6 Installing the Pump and Connecting the Tube.........................................19

4.7 [HOME] Screen and [MENU] Screen.......................................................20

4.8 Sampling Procedures (Setup).................................................................21

4.8.1 Setting the Sampling Conditions................................................21

4.8.2 Setting the Flow Rate.................................................................22

4.8.3 Setting the Flow Rate Conversion Temperature .........................22

4.8.4 Setting the Sampling Start Operation.........................................23

4.8.5 Setting the Sampling Stop Operation.........................................24

4.8.6 Screens Displayed from the Start to the Stop of Operations......27

4.8.7 During Operation Standby .........................................................28

4.8.8 During Operation .......................................................................29

4.8.9 When the Pump Finishes Operating...........................................31

4Designed, built and supported by industry professionals for industry professionals.

4

TABLE OF CONTENTS CONTINUED...

4.9 Pause Function......................................................................................32

4.10 Key Lock Function.................................................................................33

4.11 Errors Displayed....................................................................................34

4.12 Measurement Value Overflow ...............................................................35

4.12.1 Instantaneous Flow Rate............................................................35

4.12.2 Accumulated Flow Rate and Sampling Time..............................35

4.13 Checking Previous Sampling Data (Previous Data)...............................36

4.14 Extra Menu............................................................................................40

4.14.1 User Calibration .........................................................................41

4.14.2 Checking the User Calibration Logs...........................................46

4.14.3 ON/OFF Setting for Sleep Mode .................................................47

4.14.4 ON/OFF Setting for the Operation Indicator LED........................47

4.14.5 Testing.......................................................................................48

4.14.6 Interval Timer ............................................................................50

4.14.7 Checking the Operating Time.....................................................53

4.14.8 Operation Settings When an Error Occurs.................................53

4.14.9 Returning to the Factory Default Setting (Initialization) .............55

5 Troubleshooting............................................................................................56

6 Specifications...............................................................................................57

6.1 Specifications ..........................................................................................57

6.2 List of Materials Used..............................................................................58

6.3 Spare Parts, Consumables, and Optional Parts .......................................58

7 Maintenance.................................................................................................59

7.1 Replacing the Filter Element....................................................................59

7.2 Periodic Inspections................................................................................59

8 Warranty and Repairs...................................................................................60

9 Product Disposal ..........................................................................................61

10 Inquiries........................................................................................................61

11 Nextteq NX-1000 Gas Sampling Pump Deluxe Kit.......................................62

12 NXM Series Portable Multi Gas Detector.....................................................63

5

1 INTRODUCTION

1.1 Indications Used in This Manual

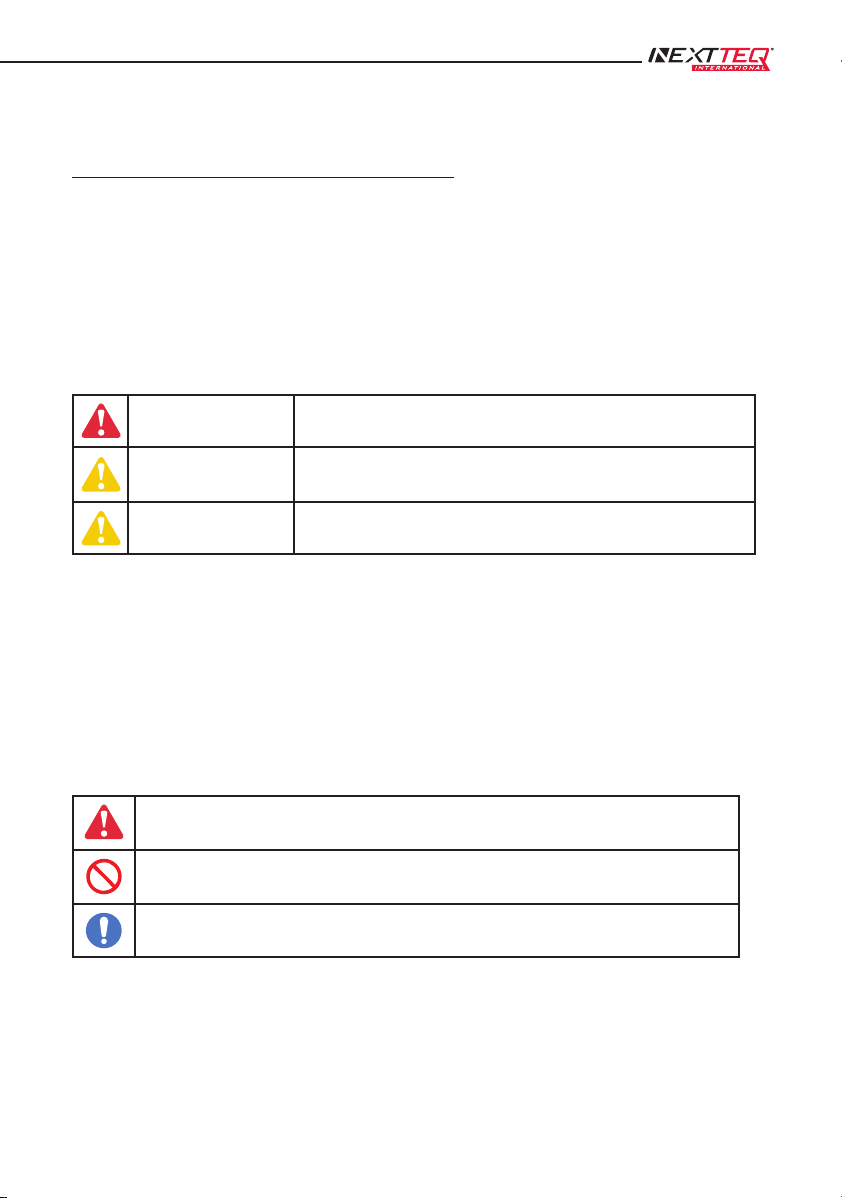

1.1.1 “Danger,” “Warning,” and “Caution”

This product is designed with the safety of the user as the top priority. However, some unavoidable risks

remain due to the characteristics of the product. In this manual, the severity and level of danger of these

risks are divided into three categories, indicated as “Danger,” “Warning,” and “Caution.” Carefully read

and make sure that you understand the indicated items before operating or performing maintenance on

this product. The indications “Danger,” “Warning,” and “Caution” are in order of the severity of risk (with

“Danger” greater than “Warning,” which is greater than “Caution”). The details are explained below.

DANGER Indicates a dangerous situation that if not avoided will result in serious

injury or death.

WARNING Indicates a situation that if not avoided could result in serious injury

or death.

CAUTION Indicates a situation that if not avoided could result in minor to

moderate injuries, or could result in property damage or breakage.

1.1.2 “Important” and “Note”

In addition to “Danger,” “Warning,” and “Caution,” items that are important or essential to the user are

indicated using the words “Important” and “Note.”

1.1.3 Symbols

In this manual, in addition to the indications “Danger,” “Warning,” and “Caution,” the following symbols

are used to make it easier to understand the content of these warnings.

This symbol indicates a danger that could pose a hazard to someone.

This symbol indicates something that is prohibited and must not occur.

This symbol indicates something that is a necessity and must occur.

6Designed, built and supported by industry professionals for industry professionals.

6

1.2 Checking the Packed Items

After opening the packaging, confirm that all the items have been included. If one of the packed items is

damaged or missing, contact your Nextteq representative. In addition, after opening the packaging, it is

recommended that you store the packing material and box so that you can reuse it in the event that you

request repairs. If you decide to dispose of them however, do so in accordance with your local laws and

regulations, and as indicated by your municipality.

(1) Main unit: 1

(2) AA batteries for checking

operations: 2

(3) Low flow rate orifice: 1

(4) Adapter: 1

(5) Operation manual (this document):1

This product should only be operated by trained and experienced operators that understand the specialized

technology and dangers involved. Untrained or currently-being-trained operators should only

operate the product under close supervision by a person that is already trained or has sufficient specialized

experience.

This operation manual is written assuming the product will be operated by a person that understands the

risks of operating the product.

7

2 SAFETY INSTRUCTIONS

The precautionary information in this operation manual is for ensuring that the product is used safely and

for preventing injury to you and other people and damage to equipment. It is all important for ensuring

safety, so be sure to read it thoroughly before using the product and observe it during use.

DANGER

This product is not explosion proof, so do not use it near combustible or flammable

materials. Doing so could cause explosion or fire.

Do not operate the product near highly flammable or combustible items. Also, do not take in

any gas other than the air. Doing so could cause explosion or fire.

Keep the product away from open flames. Do not burn the product in a fire. Doing so could

cause explosion or fire.

Do not connect to the connector electrode using wire or other metal objects. Doing so could

cause burns, a battery leak, heat generation, or an explosion.

WARNING

Do not expose the product directly to water. Doing so could cause an electric shock or fire.

Do not subject the product to strong impacts or drops. Doing so could cause a malfunction

or accident.

Do not leave the product inside a car in the hot sun, or store it in strong direct sunlight, in

front of heating equipment, or near a fire. Doing so could cause operational problems or a

malfunction.

Do not connect to the connector using wire or other metal objects, or any other method not

specified in this manual. Doing so could cause fire or equipment damage.

Never attempt to disassemble or modify the product. Doing so could cause a malfunction or

accident.

If a problem occurs during operation, immediately stop operating the product, and identify

and eliminate the cause. If it is determined that the product caused the problem, contact your

Nextteq representative or the vendor where you purchased the product.

8Designed, built and supported by industry professionals for industry professionals.

8

Do not cover this product with a cloth or blanket or enclose it inside a box when it is

operating. Doing so could cause heat buildup, a fire or malfunction.

Do not block the exhaust port. Doing so could limit the required flow rate, causing the

internal temperature to rise, leading to a malfunction or fire.

This product is designed for indoor use. Do not use it in an environment in which it will be

exposed to the wind and rain. Doing so could cause a malfunction.

Do not operate this product if it malfunctions, requires repair, or has a cracked or broken

case or other visible or known damage.

CAUTION

If not using the product for an extended period, remove the batteries and store it at a dry, low

temperature location, away from direct sunlight.

Install the product at a level, stable location. Not doing so could cause operational problems

or a malfunction.

Do not place anything on top of the product. Doing so could cause damage to the product

resulting in a malfunction or accident.

When assembling this product, such as when inserting the batteries, be careful that your

fingers do not get pinched.

This product is an air sampling pump. Do not use it for any purpose not indicated in this

manual. Doing so could cause a malfunction.

Do not permit water, other liquids, or non-atmospheric gases to enter the product. Doing so

could cause a malfunction.

Be sure to operate the product with a filter element and sampling unit installed at the intake

port. Sampling air directly for long periods could cause a malfunction.

Do not permit flammable gases, corrosive gases, or chemicals to enter the product. Doing so

could cause a malfunction or fire.

9

Do not insert screws or other foreign objects into the intake port or exhaust port. If a foreign

object accidentally enters the product, immediately switch the power OFF. Then contact your

Nextteq representative or the vendor where you purchased the product.

The normal operating temperature range of this product is 0 to 40˚C, with humidity between

10 and 90 % RH (and no condensation). Operating the product outside these temperature

and humidity ranges could reduce performance, shorten the service life, or cause a

malfunction.

Remove the batteries and disconnect any external batteries before cleaning or inspecting the

product. Not doing so could cause an electric shock, battery leakage, or other problems.

Keep the product away from sources of noise. Also, do not place it in areas with strong

magnetic fields, high dust levels, or high humidity. Doing so could cause product damage or

other problems.

IMPORTANT

Please be aware that in the unlikely event of a product failure, Nextteq International LLC bears no respon-

sibility to compensate for sampling data not acquired or recorded, and is not responsible for loss of data,

or for other direct or indirect damages incurred from such loss. Be sure to back up* data on a regular

basis in case of an accident or failure.

* This product does not have a data output function. To back up the results, you may write them down or

take a photograph.

10 Designed, built and supported by industry professionals for industry professionals.

10

3 ABOUT THIS PRODUCT

3.1 Overview

The personal mini pump NX-300 is a lightweight, portable air sampling pump equipped with functionality

for measuring accumulated flow rates. The flow rate for this pump is 10 mL/min to 300 mL/min, which in

the air sampling pump lineup from Nextteq is a particularly low flow rate range.

It is equipped with a pressure loss correction function and a constant flow rate function. The pump is

controlled so as to maintain the set flow rate even if you are using sampling tubes with different pressure

loss values, or the pressure loss changes during sampling. As a result, this can be used as an air sampling

pump for toxic substances in work environments, indoor environments, and ambient environments.

3.2 Features

A pressure loss correction function is built in, which suppresses intake flow rate fluctuations if

sampling tubes with different pressure loss values are used with the same set flow rate.

A constant flow rate function is built in, which suppresses intake flow rate

fluctuations if a sampling material is used with a pressure loss that changes due to sampling.

An organic EL graphics display has been adopted as the indicator, so you can

check the flow rate information even in a dark location.

The product can run for approx. 10 hours on two alkaline batteries (100 mL/min, unloaded

conditions).

The USB terminal can be connected to a mobile battery* with an output of at least 5 V DC and

500 mA or to an AC adapter for use as an external power supply.

* The product might not operate properly depending on the mobile battery specifications.

NX-300 Constant Flow Range of

10-30 mL/min is a perfect pump for

TWA Nextteq tubes and other low

flow applications.

NX-300 withstands high back pressure –

perfect for use with sorbent tubes.

At 190g (with batteries), 6.70 oz,

the NX-300 is the lightest low flow,

constant flow sampling pump in the

market!

With 10 hours of operation on two

alkaline batteries (100mL/min,

unloaded conditions), provides a full

days’ use with no downtime.

The small size allows one to fit the

NX-300 in a pocket!

W 63 mm – 2.5 in

D 29 mm – 1.1 in

H 115 mm – 4.5 in

Organic Electroluminescent (organic

EL) graphics display allows use in

dark locations.

An operating temperature and hu-

midity range of 0-40˚C (32-104˚F)

and 10-90% RH, makes the NX-300

ideal for almost any application.

11

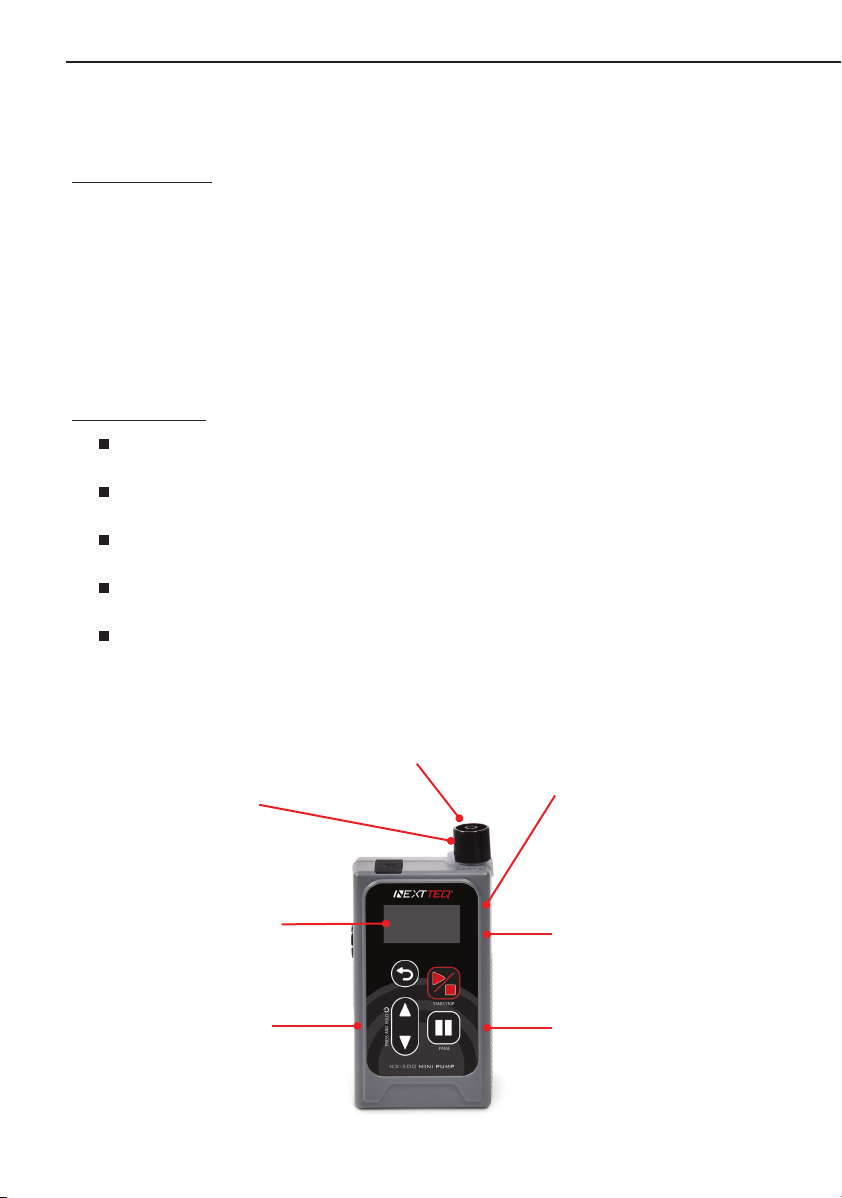

3.3 Names of the Parts

3.3.1 Main Unit

Pump Status and the Color of the Operation Indicator LED (Operating Mode)

Color of the Operation Indicator LED Pump Status (Operating Mode)

Orange During Delay and Manual operation

Green During Run Timer (Run.T) and Interval Timer

operation

Blue During Volume operation

Red During an error

USB Terminal (for external power

supply, Micro B) – allows for extra

sampling time.

Intake port – for use with various

sampling media that requires

constant flow and constant pressure.

Operation indicator LED –

for immediate visual status.

Exhaust port – indented

to protect port to allow for

continuous exhaust.

Battery cover – protects batteries

from harsh environments and allows

rapid change of batteries.

Control panel –

simple design provides

ease of use.

Organic EL

display – for easy

readings in dark

locations.

12 Designed, built and supported by industry professionals for industry professionals.

12

3.3.2 Control Panel

Note

If you press and hold the [BACK] key for 1 second or longer, the system will return

to the [HOME] screen. (If this operation is performed in the setting screen, the

setting details will be lost.)

When changing the setting values, press and hold the [UP] key or [DOWN] key

[START/STOP] Key –

This starts the measurement.

This is for applying the selected

and set items.

[PAUSE] Key –

This pauses the pump operation

[UP] Key and [DOWN] key

simultaneously –

This turns the power ON and

OFF.

[BACK] Key –

This returns to the previous

screen.

[UP] Key –

This is for changing setting

values and for moving to

selected and set items.

[DOWN] Key –

This is for changing setting

values and for moving to

selected and set items.

13

4 OPERATION PROCEDURES

4.1 Preparing the Power Supply and Turning the Pump ON and OFF

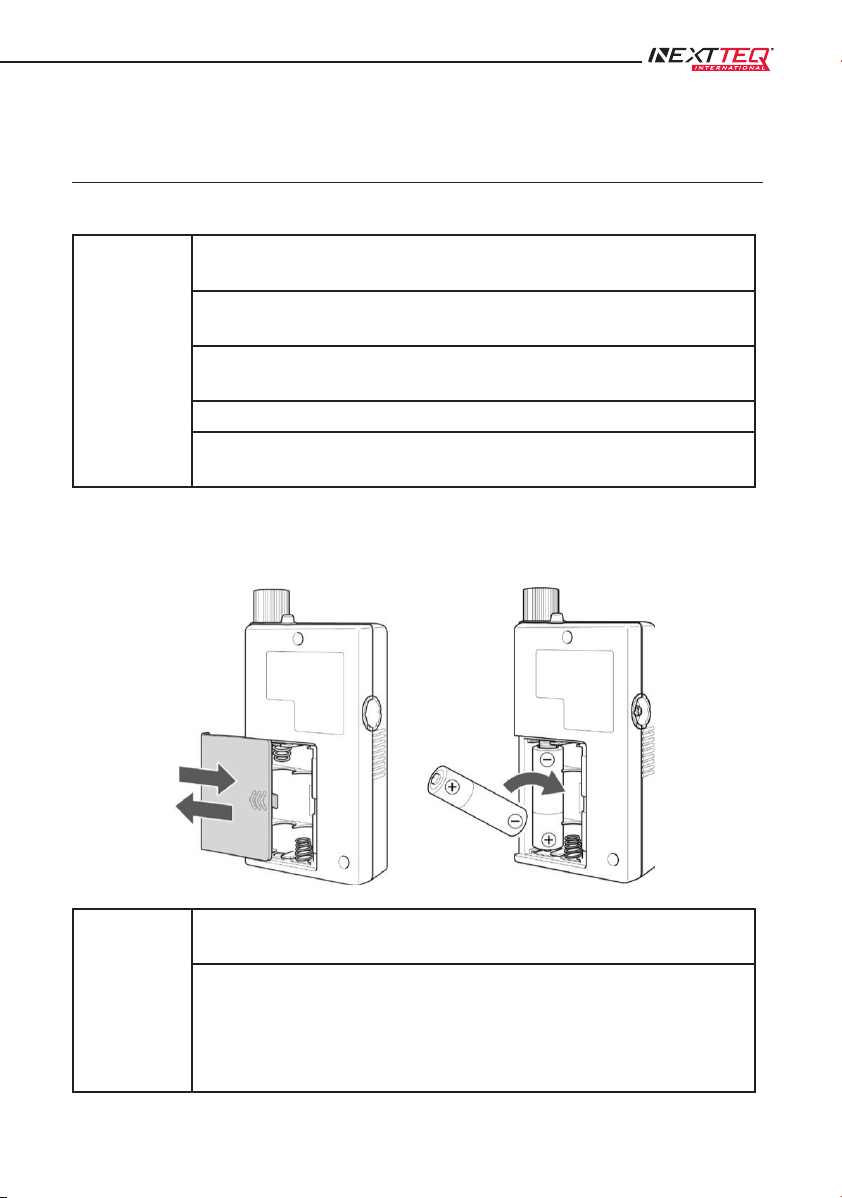

4.1.1 Installing and Removing Batteries

Important

When replacing the batteries, ensure that both of the two batteries are replaced

simultaneously with new ones.

Check the recommended usage time for the batteries and use them before this

time expires.

Be careful not to put the batteries in backwards.

(Do not accidentally reverse the + and - ends.)

Remove the batteries when the product is not in use.

If the batteries leak, the fluid could damage the circuit boards inside the product.

In this case, request repairs or an inspection.

(1) Slide the battery cover and remove it.

(2) Insert two AA batteries (alkaline batteries recommended).

(3) Restore the battery cover.

Note

You can also use rechargeable AA batteries, but limitations will result regarding the

battery level indicator. (Page 15)

If the batteries run out and the power is inadvertently turned OFF, sampling will be

discontinued, and it will not be possible to continue. The discontinued data can be

viewed by selecting “Previous Data” in the main menu. (2 Previous Data). (Page 36)

Note that if you use the pause function, you can replace the batteries and then

continue sampling. (Page 32)

14 Designed, built and supported by industry professionals for industry professionals.

14

NX-300 MINI PUMP

4.1.2 External Power Supply

With this product, you can use an external power supply other than the regular batteries by using the USB

terminal. Note that if a mobile battery is used, ensure that the output is at least 5 V and 500 mA.

Important

Mobile batteries sold for use with smartphones are equipped with a function that

stops the current supply if it drops below a certain value. Accordingly, If the current

value for this product is below the above-mentioned threshold value, the pump may

not operate properly with the mobile battery. It may stop operating for example, or

the power may turn OFF after 10 or 20 seconds.

Note

You can also use an AC adapter with an output of at least 5 V and 500 mA.

If there are batteries in the product when an external power supply is connected, the

external power supply connection will take priority when running it.

In this case, if the power supplied from the external power supply stops, the product

will switch to the power supplied by the internal batteries and it will continue to

operate, thus avoiding problems.

15

4.1.3 Turning the Pump ON and OFF

To turn the power ON or OFF, simultaneously press and hold the [UP] key and [DOWN] key for

approximately 2 seconds. Note that if the power is ON and you are turning it OFF, operation of either the

[UP] key or [DOWN] key will be applied. Continue to press and hold however.

Note

After the power is ON, if you continue to press and hold the [UP] key and [DOWN]

key, the power will turn OFF, after which it will not turn ON.

The product may not operate as per the specifications immediately after the power is

turned ON. Let it warm up (with the pump running) for several minutes before use.

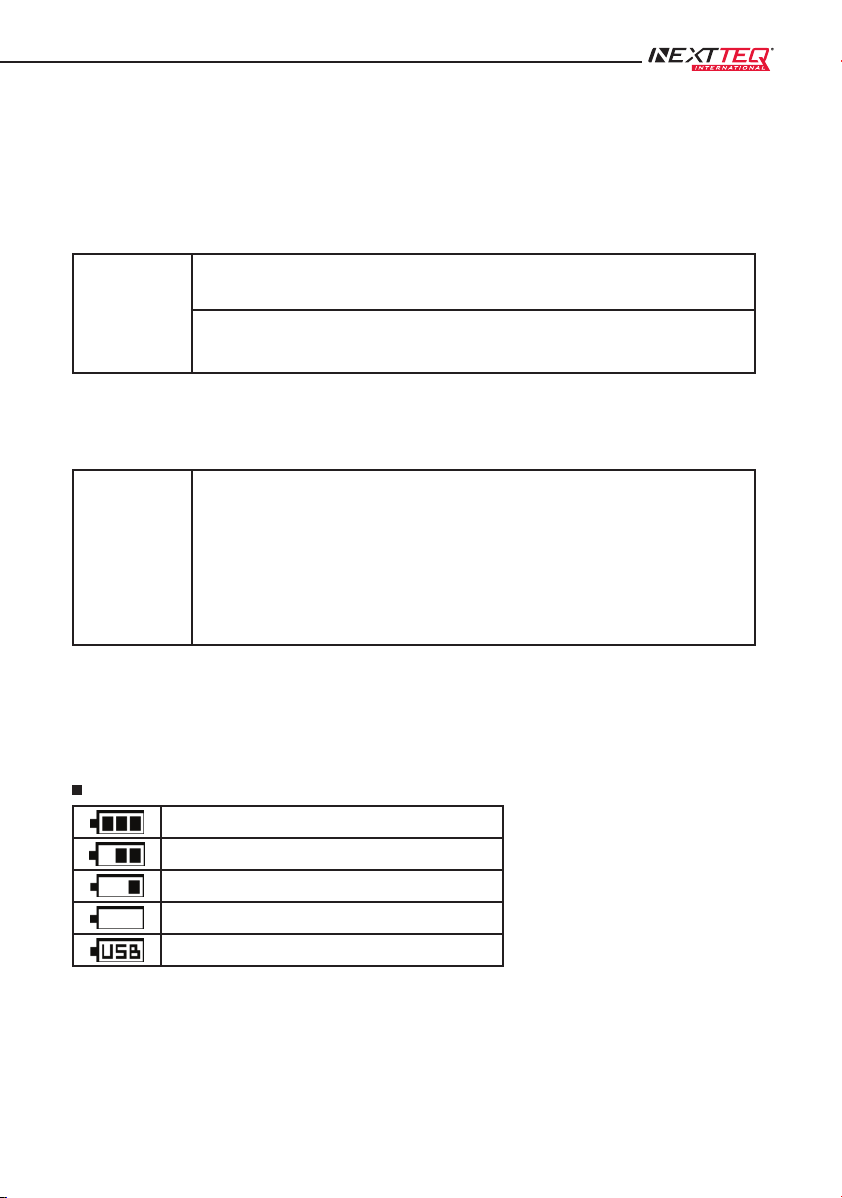

4.1.4 Remaining Battery Level Display

Important

The remaining battery level is displayed at the top right of the screen, but only

during intake. The remaining battery level will not be displayed during setting

changes or other operations, or during standby via timer operation. Also, the

remaining battery level display is designed on the assumption that alkaline batteries

are being used in this product. Rechargeable AA batteries can also be used.

However, because of differences in discharge characteristics, the relationship

between the remaining battery level displayed and the operating time will also differ.

The remaining battery level is displayed as four stages. Note that when power is supplied from the USB

terminal, USB will be displayed in the remaining battery level area and the bar graph will not be displayed.

In this case, check the remaining battery level display on the mobile battery.

Battery Level Display

Over 2.8 V

Between 2.5 V and 2.8 V

Between 2.3 V and 2.5 V

Less than 2.3 V

When power is supplied from the USB terminal

16 Designed, built and supported by industry professionals for industry professionals.

16

Remaining Battery Level Display and Reference Operating Times Until the Pump Stops

(When alkaline batteries are used, and Sleep Mode is set to OFF)

Flow Rate Load

10 mL/min Heat desorption

tube

9 to 10 hours 6 to 9 hours 2.5 to 6 hours

50 mL/min Charcoal tube 5 to 5.5 hours 3.5 to 5 hours 1.5 to 3.5 hours

100 mL/min Charcoal tube 10 to 11 hours 6.5 to 10 hours 2.5 to 6.5 hours

100 mL/min Load equivalent to

20 kPa

5.5 to 6.5 hours 3.5 to 5.5 hours 1.5 to 3.5 hours

200 mL/min Load equivalent to

20 kPa

5 to 5.5 hours 3 to 5 hours 1.5 to 3 hours

300 mL/min Charcoal tube 6 to 7 hours 4 to 6 hours 2 to 4 hours

These values are based on actual measured values under a 25˚C environment. Note that these values

are not guaranteed.

4.2 Pressure Loss

Pressure loss occurs due to sampling tubes or other sampling materials attached

to the intake port. A constant flow rate usage range has been established for this

product (Page 57). If the specified range is exceeded, a malfunction could occur.

However, this product is not equipped with a function to measure pressure loss.

It is recommended that you measure the pressure loss of the sampling material in

advance, as per the figure.

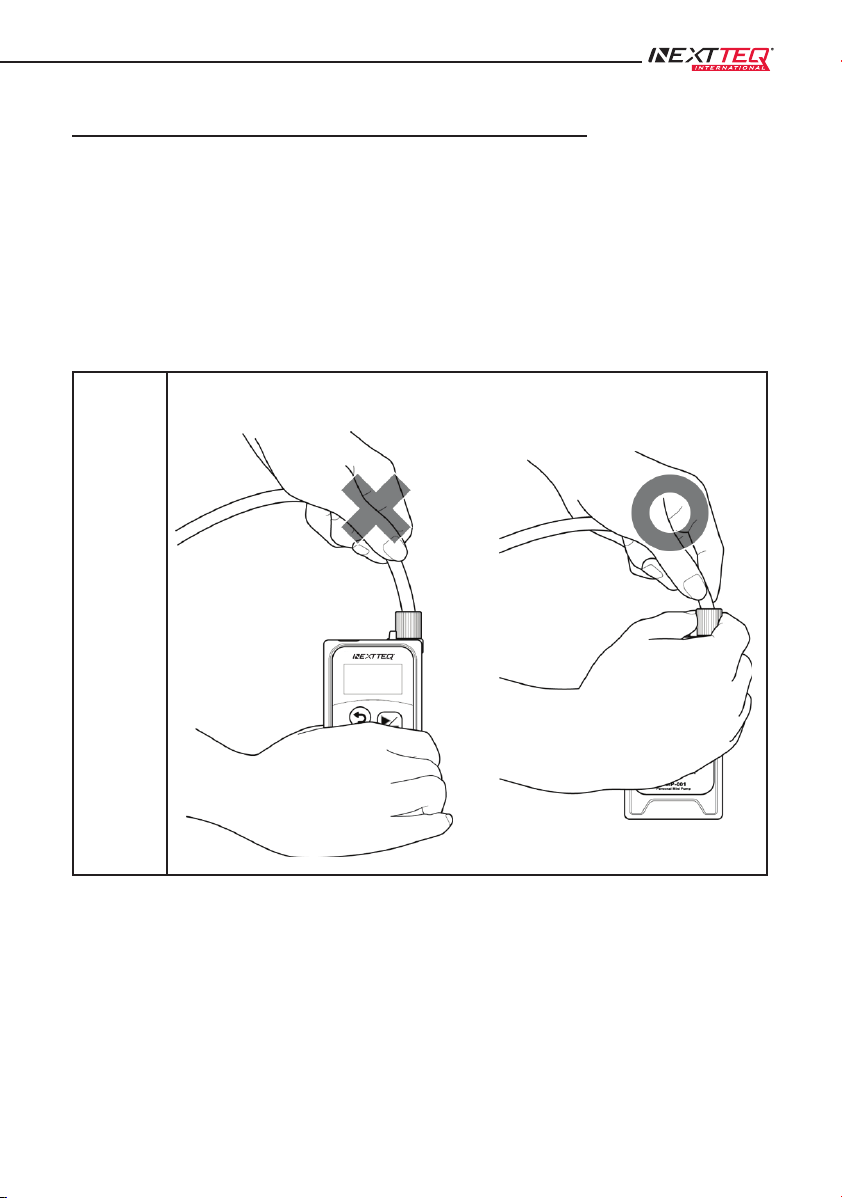

4.3 Using a Micro Impinger

When a micro impinger is used, if the tubing is

connected incorrectly, liquid will inadvertently

be taken into the main unit, resulting in a

malfunction. Accordingly, connect the tubing as

per the figure to the right.

Important As per the figure on the above right, never connect tubing in which liquid is taken in directly.

17

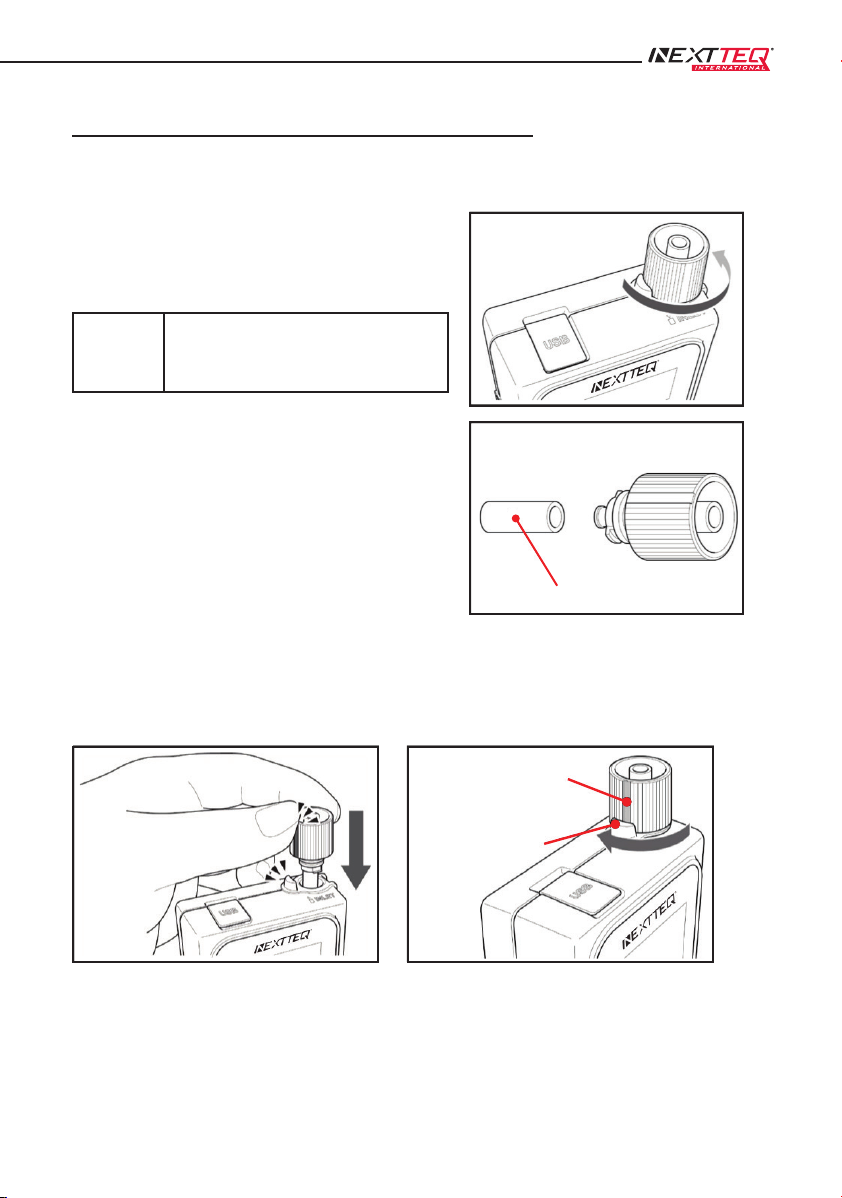

Point with the widest

raised element

Operation indicator

LED

Filter Element

4.4 Attaching and Removing the Intake Port

To remove the intake port, turn it in the counterclockwise direction.

Pull gently on the filter element attached to the

intake port to remove the filter element and then

replace it.

Important

To prevent malfunctions due to the intake

of foreign objects and fine particles, be

sure to attach a filter element.

Match the point on the intake port with the widest raised element* to the operation indicator LED.

Then push the intake port in and turn it 90 degrees in the clockwise direction.

* There are two points on the intake port to serve as positioning guides.

18 Designed, built and supported by industry professionals for industry professionals.

18

Adapter

Sampling tube

Adapter

Low flow rate orifice

Low flow rate orifice adapter

Adapter

Sampling tube

4.5 Using the Low Flow Rate Orifice and Adapter

A low flow rate orifice and adapter are provided with this pump. If you are using the pump with a flow of 50

mL/min or less, attach the low flow rate orifice adapter with the low flow rate orifice connected to the intake

port, and then connect the sampling tube, etc.

Important

When the settings are configured to 50 mL/min or less, if a low flow rate orifice adapter

is not used, the indicated value will not reach the set value or will fluctuate significantly

during operation, so be sure to use it. Note that even if the low flow rate orifice adapter

is used, the pump may operate intermittently depending on the set flow rate and the

load conditions.

When connecting the low flow rate orifice to the adapter, be sure that the arrow on the

low flow rate orifice faces downwards with respect to the adapter.

Note

If the flow rate is set to a value at which the low flow rate

orifice adapter is not used, sampling can be performed with

the sampling tube connected directly to the adapter.

Note that in this case, be very careful not to lose the low flow

rate orifice.

19

4.6 Installing the Pump and Connecting the Tube

Install this pump on a flat surface. Avoid sites with high humidity, moist sites, sites close to open flames or

heat sources, and sites with extremely high dust levels.

Confirm that the filter element is attached to the intake port. Also, replace the filter element if it becomes

very dirty. (Page 17)

Tubes with an inner diameter of 5 mm or 7 mm can be attached to the intake port.

Important

When removing tubing from the intake port, grip the intake port, not the main unit. There

is a risk that the tube will be damaged if you pull on it with too much force.

20 Designed, built and supported by industry professionals for industry professionals.

20

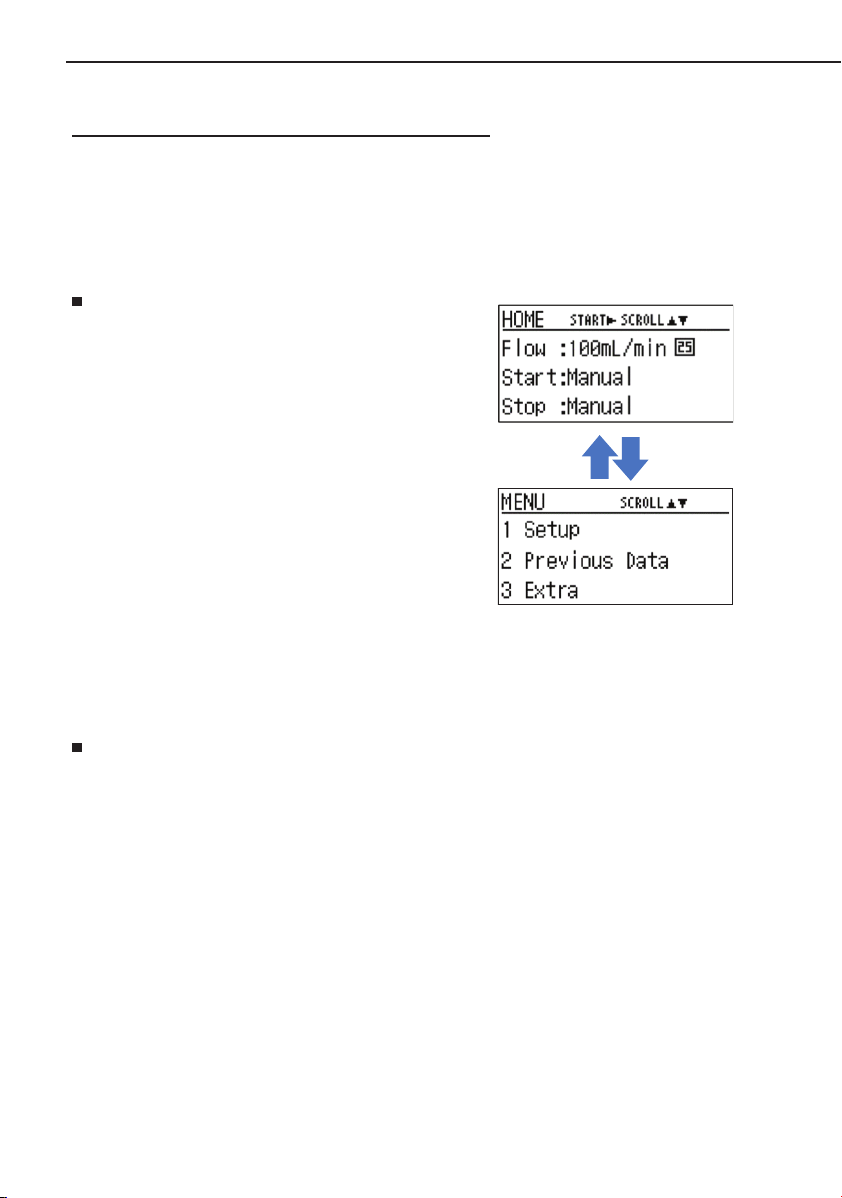

4.7 [HOME] Screen and [MENU] Screen

When the power is turned ON (by pressing and holding the [UP] key and [DOWN] key simultaneously),

the version information will be displayed, and then the system will proceed to the [HOME] screen.

[HOME] Screen

The sampling conditions are displayed.

The key based operations are as follows.

[START/STOP] key

This starts the sampling.

[UP] key or [DOWN] key

This switches to the [MENU] screen.

[MENU] Screen

This screen consists of the following three items.

The selected item will blink.

1 Setup

This is for setting the sampling conditions. (Page 21)

2 Previous Data

This is for checking previous sampling data. (Page 36)

3 Extra

This is for setting various settings other than the sampling conditions. (Page 40)

The key based operations are as follows.

[BACK] key: This switches to the [HOME] screen.

[UP] key or [DOWN] key: This switches the item selected.

[START/STOP] key: This switches to the screen for the item selected.

Table of contents

Other NEXTTEQ Water Pump manuals

Popular Water Pump manuals by other brands

Tuthill

Tuthill AC Installation and service instructions

FLOJET

FLOJET G-57 Series Installation & operation instructions

Miller

Miller JUMBO Operation and maintenance manual

Corken

Corken PT Series Installation, operation & maintenance manual

Ingersoll-Rand

Ingersoll-Rand ARO EVO Series Operator's manual

airbox

airbox VARIFLOW user manual