Cables

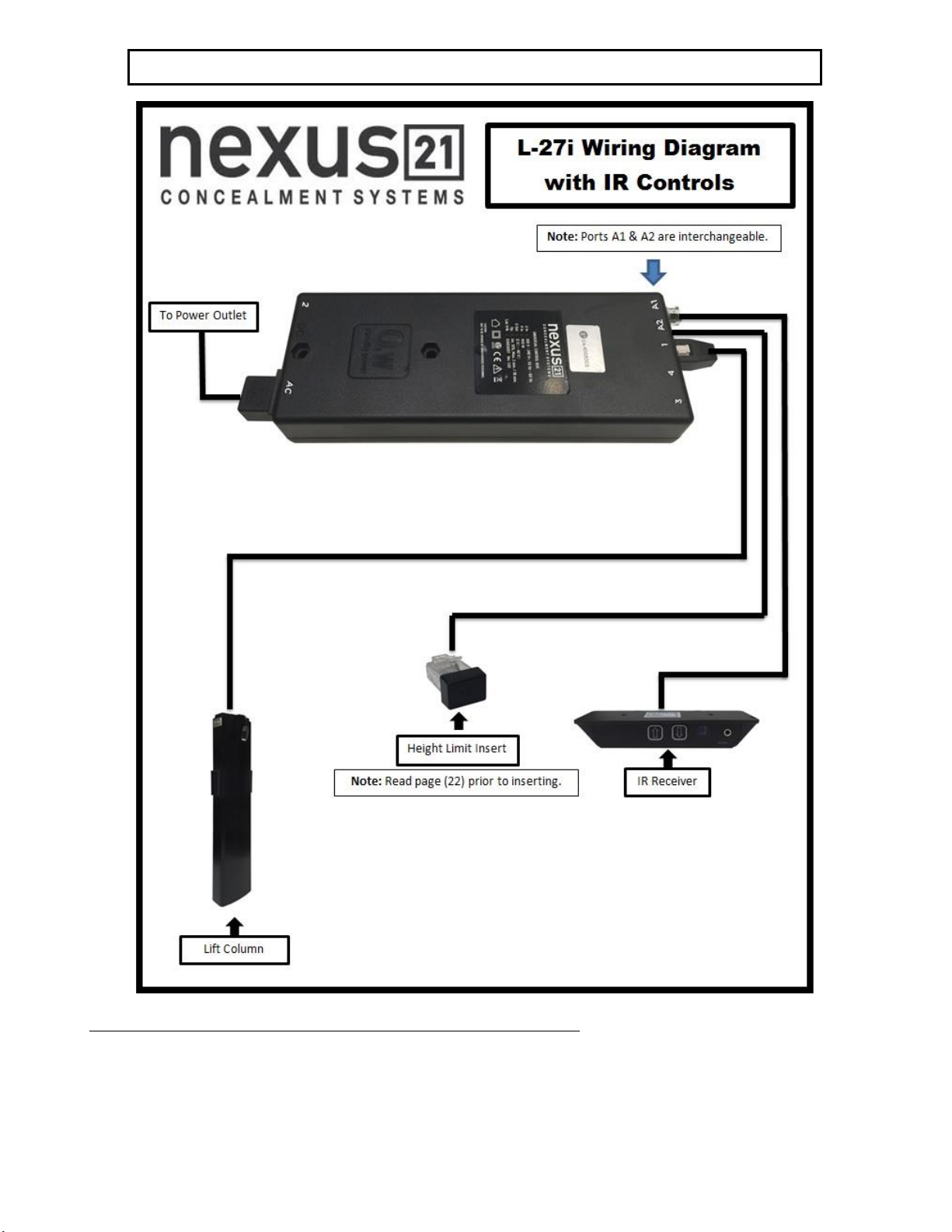

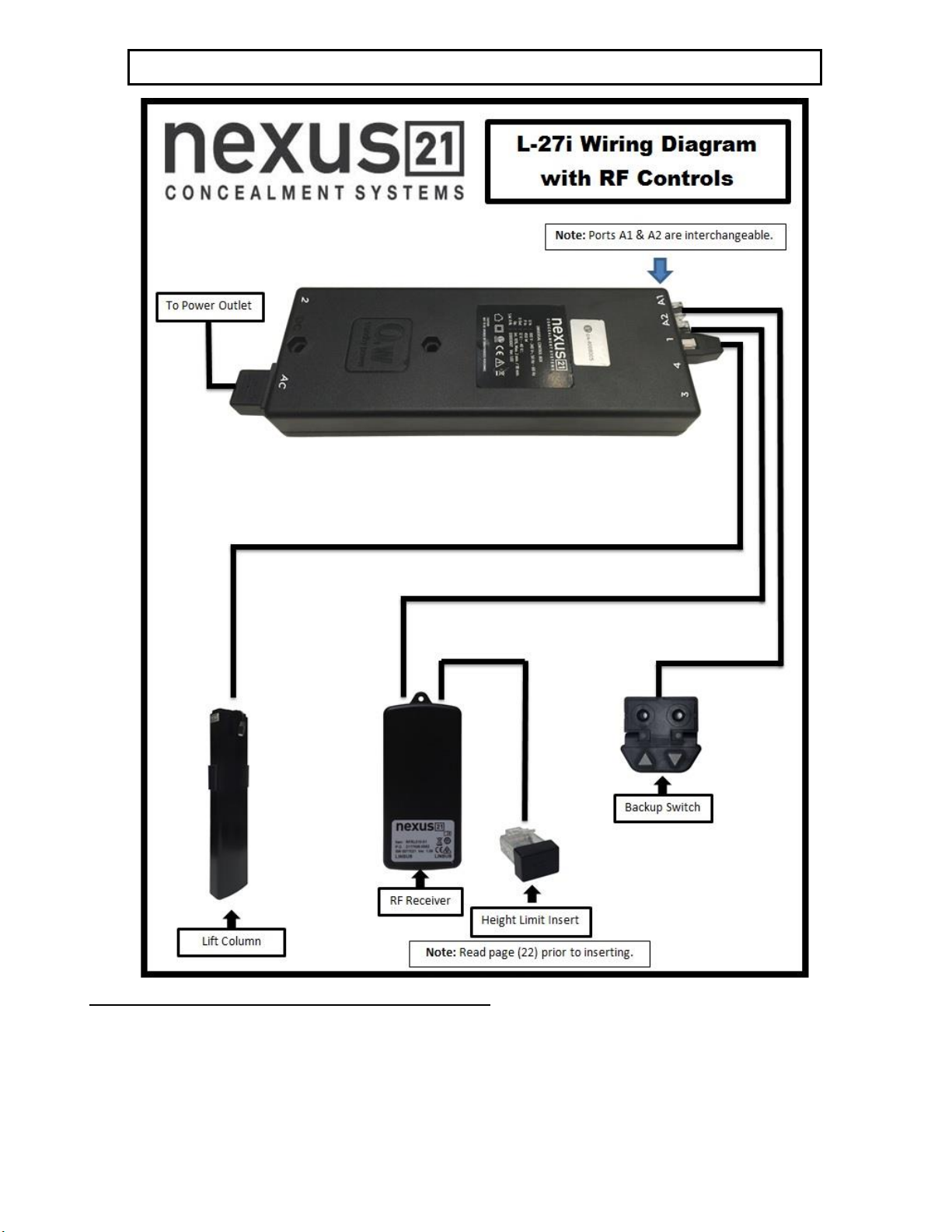

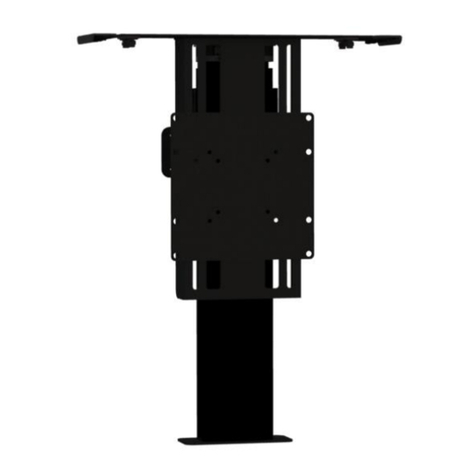

Motor Cable –Black cable with white, six-pin plugs. Use this cable to connect the Lift Column to the Control Box

(using port #1 on the Control Box). Six feet long.

Power Cable –Connects Control Box to power outlet. Three feet long.

RF Cable (only present if you ordered the RF version of the Lift System) –Use to connect the RF Receiver to the

Control Box. Ends have telephone-style connectors. One foot long.

TIP: It is recommended to install a surge protector (not included) inside your cabinet to plug in the Lift System,

Control Box, TV and any other components in the cabinet.

Hardware

10. One (1) –Assorted Bag of TV Mounting Screws

11. Six (6) -- 6mm x 12mm Button Head Machine Screws

12. Two (2) -- Screen Locks (Located in box with Part #6 & 7)

13. Four (4) -- 3/8”-16 x ¾” Button Head Machine Screws

14. Two (2) -- #10 x 1 ¾” Flat Head Wood Screws

15. Four (4) -- #8 x ¾” Flat Head Wood Screws

16. Two (2) -- #4 x 1” Pan Head Wood Screws

17. Four (4) -- 6mm x 40mm Flat Head Machine Screws

18. Four (4) -- 6mm x 12mm Flat Head Machine Screws

19. Eight (8) -- #10 x ¾” Truss Head Wood Screws

20. Four (4) -- 6mm x 16mm Button Head Machine Screws

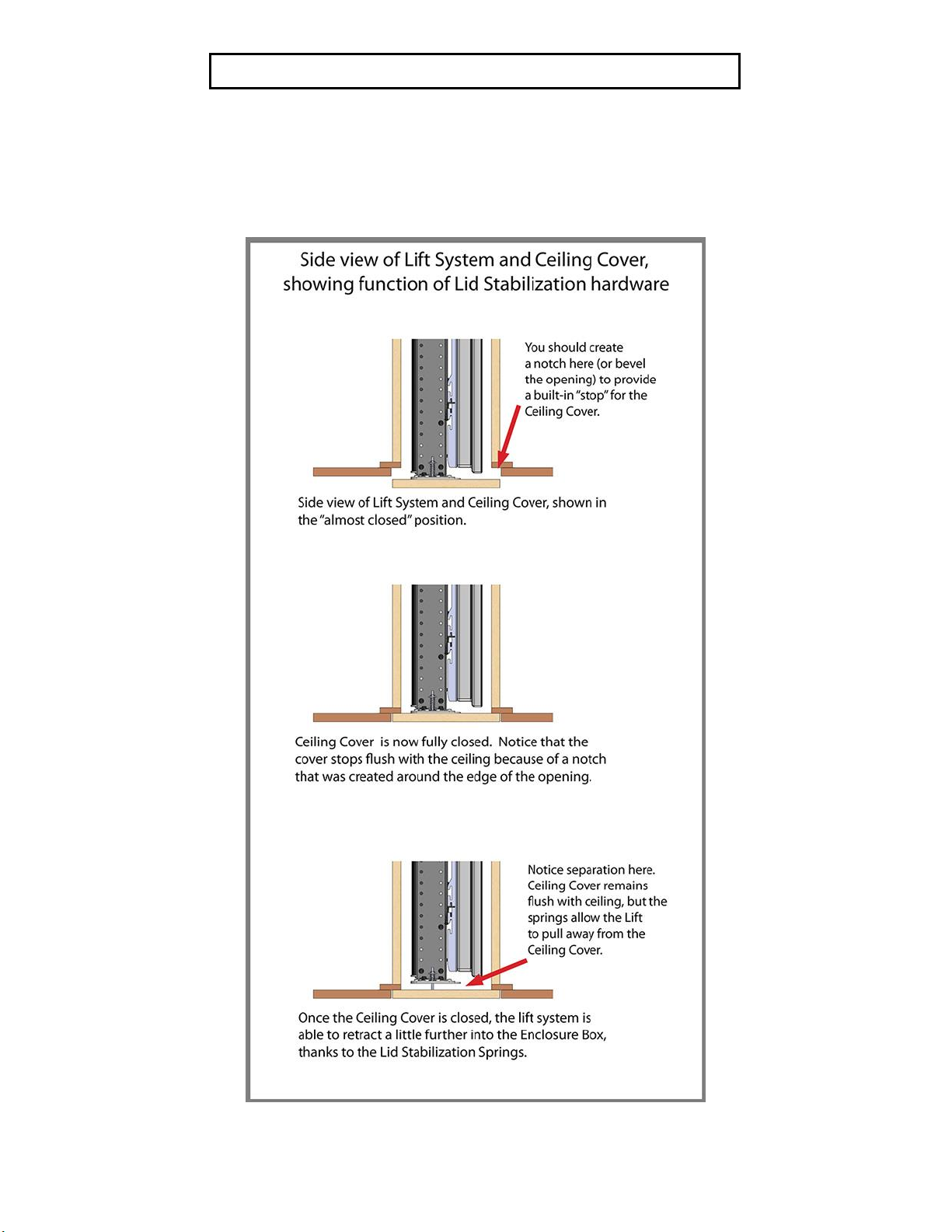

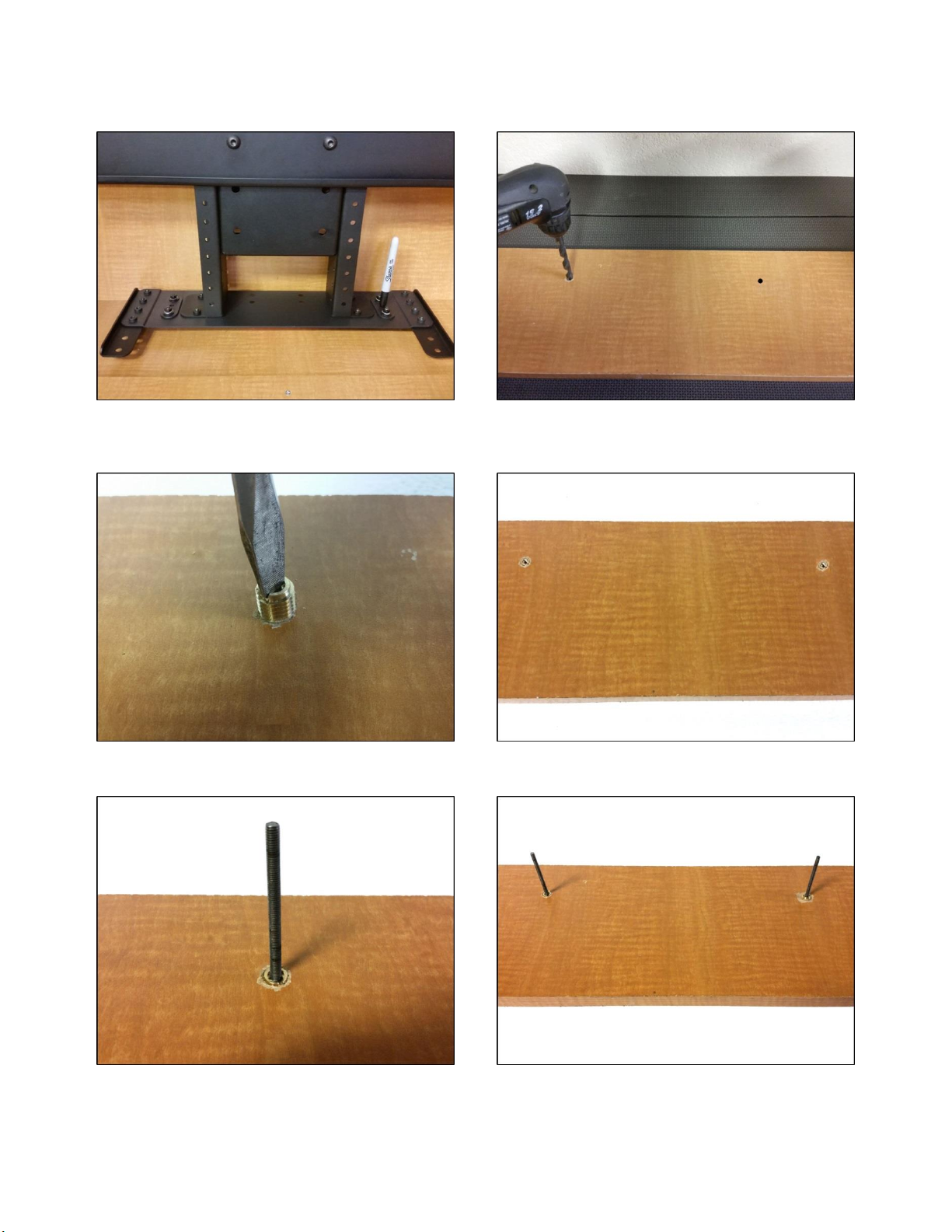

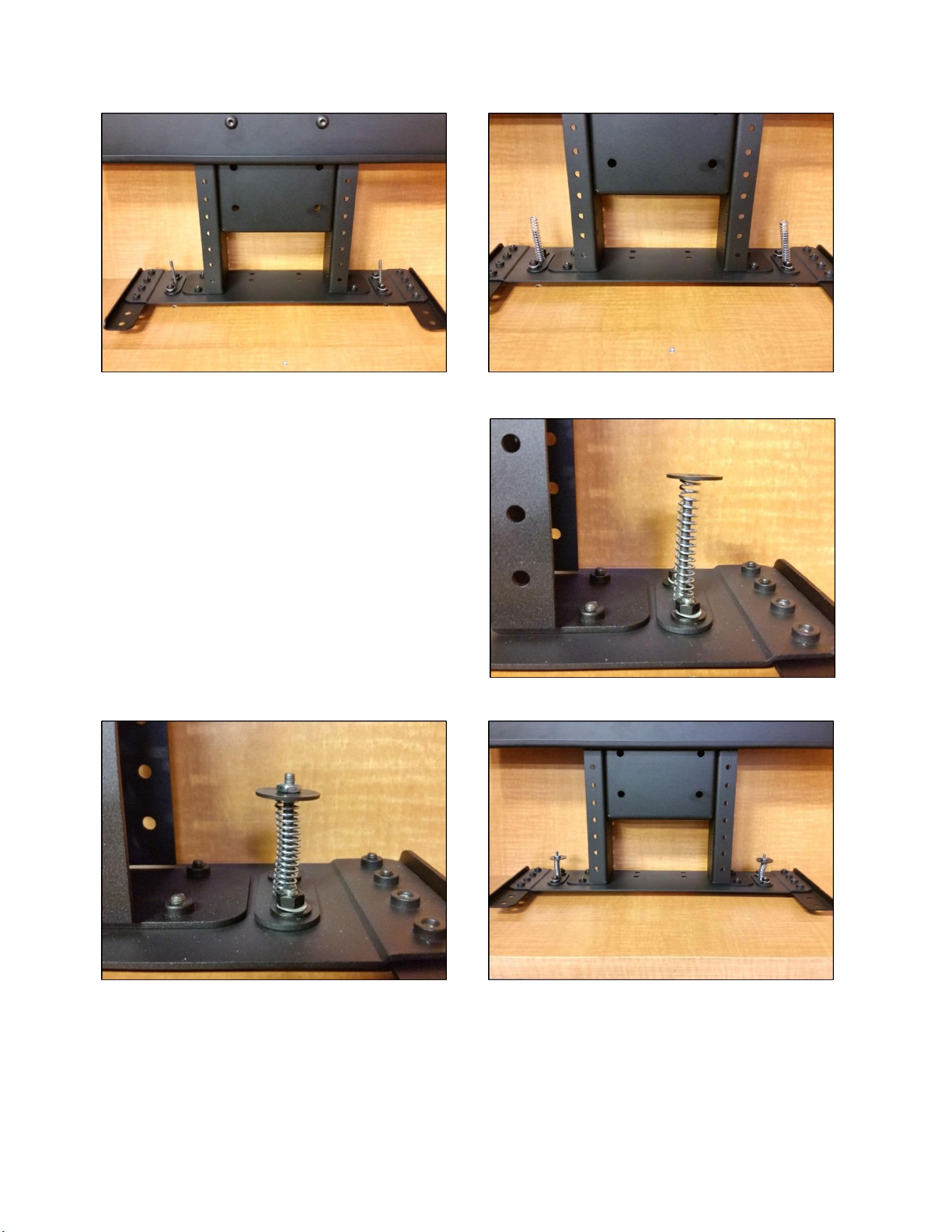

Contents of hardware pack that is labeled “Lid Stabilization Pack”

21. Two (2) -- 10-32 Nut

22.Two (2) -- 10-32 x 3” Threaded Studs

23 Two (2) -- Lid Stabilization Springs

24. Two (2) -- Brass Threaded Inserts

25. Two (2) –Flat Washers

Other items that are included, but not shown in Parts View diagram on “Supplemental Page A” (at the end of this

document):

RF Controls or IR Controls (see explanation on page 6)

Two (2) -- Allen Wrench –4mm and 7/32”

One (1) -- “Snakeskin” Wire Management Sleeve – 3 feet long

Two (4) -- Velcro end Ties, for use with Wire Management Snakeskin

Two (4) -- Plastic Ties, also for use with Wire Management Snakeskin

Four (4) -- Wire Clips

One (1) -- Small Cable Re-coiler

Four (4) -- Square Multi-Mount Washers

Wire Management

The Lift System has no exposed gears or moving parts that can damage your

wires, so wire management is simple. We have included a three-foot long

“SNAKESKIN” sleeve, which is a state-of-the-art wire bundling and

protection system (the sleeve can be cut shorter if you wish). The System

also includes 4 Velcro end ties, 4 plastic ties and a small cable re-coiler. Use

the Velcro ties at the ends of the SNAKESKIN, to close the ends of the sleeve

and to keep the wires together inside it. Use the plastic ties to fasten the

cable bundle in a fixed position, so it moves up and down with the lift. Use

the small cable re-coiler to assist pulling the cables back into your enclosure.