NHP TemBreak PRO P User manual

Version

1.3.0

NHP Electrical Engineering Products

AU 1300 NHP NHP

NZ 0800 NHP NHP

nhp.com.au

nhp-nz.com

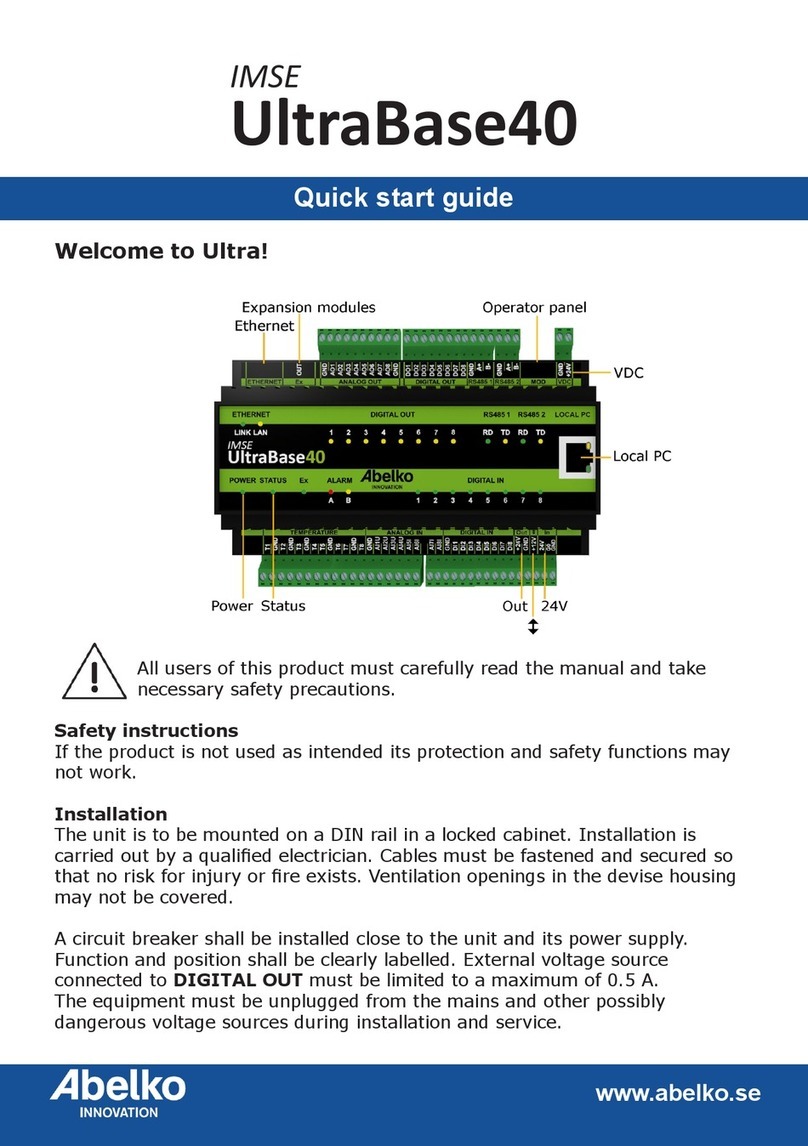

P Model Moulded Case CircuitBreaker

Basic Electronic Trip Unit from 160A up to630A

USER MANUAL

2

TemBreak PRO P_BE-UM-001-EN V1.3.0

Using this manual

Safety Precautions

Authorised Personnel Only

The product or system described in this documentation must be installed, operated and maintained by qualified personnel only. NHP or Terasaki accept no

responsibility for the consequences of the use of this equipment by unqualified personnel.

A qualified person is one with the necessary skills and knowledge of the construction and operation of the installation of electrical equipment and has been

trained to identify and avoid risks.

Appropriate use of NHP / Terasaki products

NHP / Terasaki products are intended to be used only for the applications described in the catalogue and technical documentation, which is dedicated to

them. If products and components from other manufacturers are used, they must be recommended or approved by NHP or Terasaki.

Appropriate use of NHP / Terasaki products during transport, storage, installation, assembly, commissioning, operation and maintenance is necessary to

ensure safe operation and without any problems.

The permissible ambient conditions must be met. The information contained in the technical documentation must be observed.

Publication of responsibility

The contents of this document have been reviewed to ensure that the reliability of the information is correct at time of publication.

NHP or Terasaki are not responsible for printing or damage resulting from errors. NHP or Terasaki reserve the right to make corrections and changes

needed in subsequent edition.

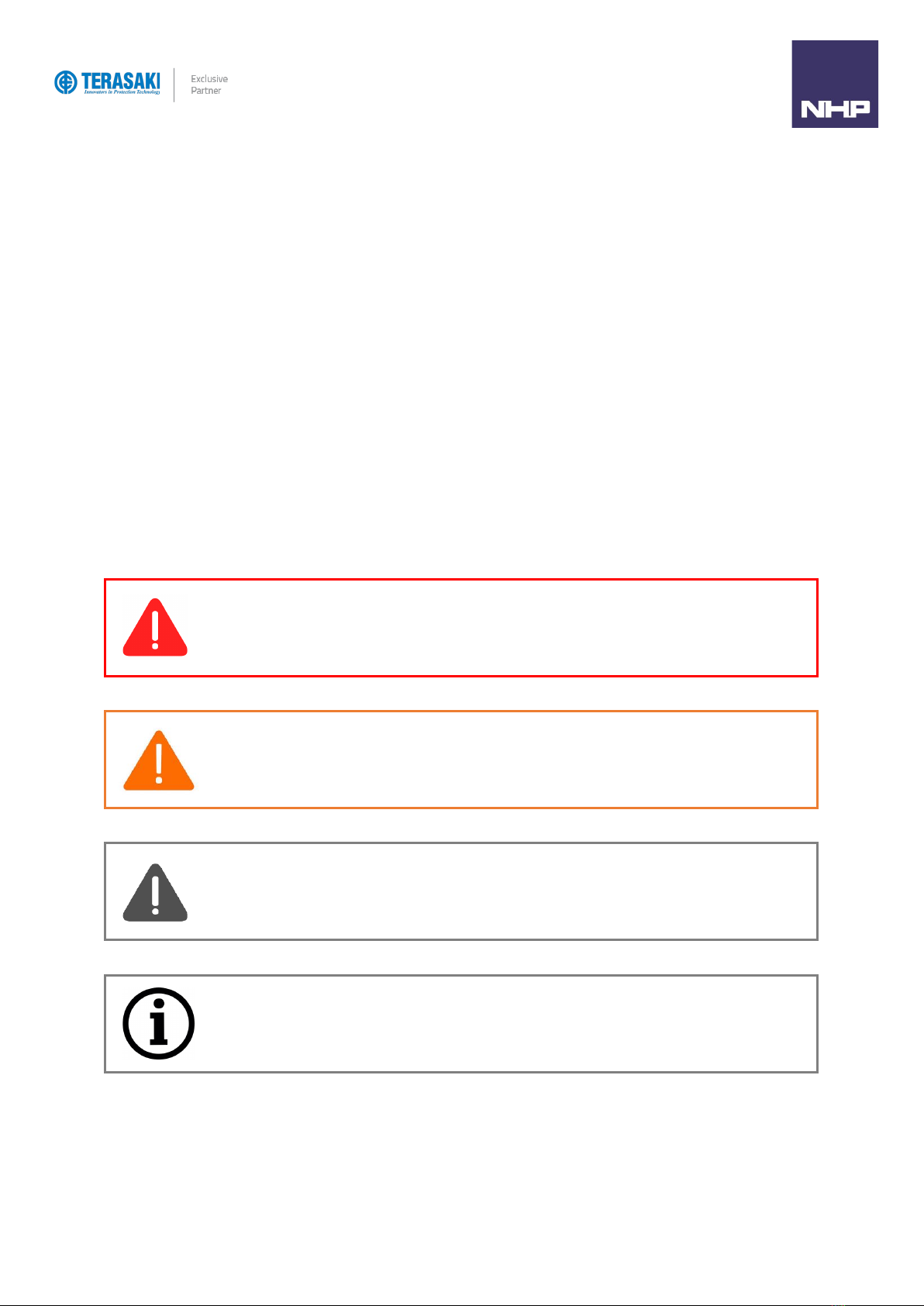

Warnings and notes

This documentation contains safety instructions that you must follow for your personal safety and to prevent damage to property.

Safety instructions, referring to your personal safety are reported in the literature by a safety alert symbol.

Safety warning symbols and the words below are classified according to the degree of risk.

WARNING: Indicates an imminently hazardous situation which, if it cannot be avoided, will result in death or

serious injury.

WARNING: Indicates a potentially hazardous situation which, if it cannot be avoided, can result serious injury or

death.

WARNING: Indicates a potentially hazardous situation which, if it cannot be avoided, may cause minor or

moderate injury.

Notice: Indicates a warning of property damage and can also indicate important operating and especially useful

information on the product, that it should pay particular attention to efficient and safe operation.

3

TemBreak PRO P_BE-UM-001-EN V1.3.0

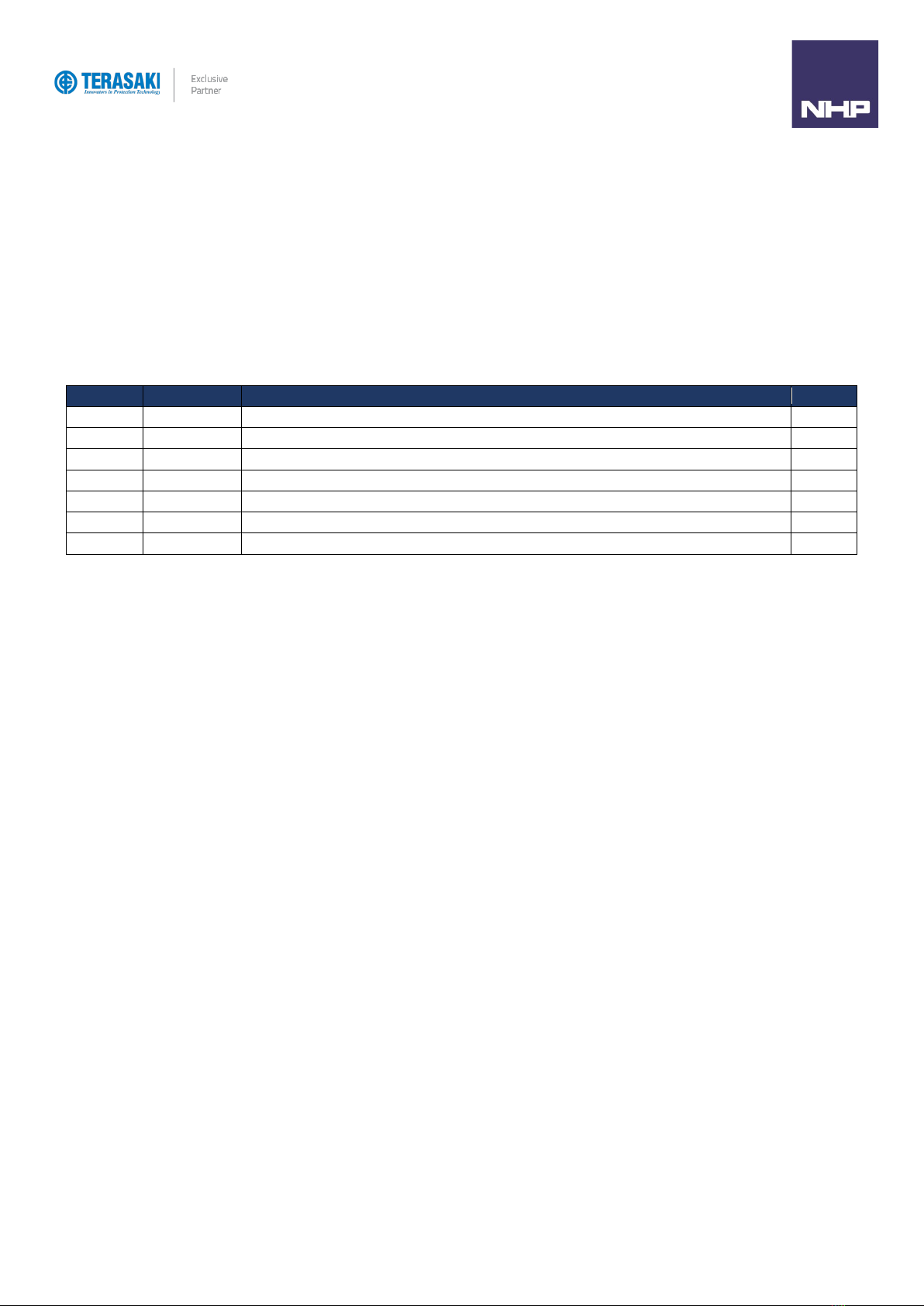

Summary of Changes

This section highlights the details of changes made since the previous issue of this document.

The versioning convention used to track changes in this document follows the structure Vx.y.z where:

x: Major revision, where extensive changes are made which is generally incompatible with the previous version. Such changes may include new

products and/or features, or removal of information which is no longer relevant or applicable to the previous version

y: Minor revision, where changes made do not change the overall scope of the previous version, but may include additional information which

complements or corrects the previous version, or provides additional clarity on an existing topic.

z: Patch version, where small changes are made to correct minor errors or adjust existing text, charts, figures and/or images, and which do not

add or remove information from the previous version. Example changes may include spelling corrections, image re-sizing and adjustments,

updated images, etc.

Version

Publication date

Changes

By

V 1.0.0

19-Apr-2021

Initial release

D.NAT

V 1.1.0

26-Apr-2021

Product information corrections

D.NAT

V 1.2.0

29-Apr-2021

Neutral Protection information correction

D.NAT

V 1.3.0

13-May-2021

Clearance distance corrections

N.ALEX

4

TemBreak PRO P_BE-UM-001-EN V1.3.0

Table of Contents

Using this manual 2

Safety Precautions 2

Summary of Changes 3

Table of Contents 4

Introduction 5

Who Should Use This Manual? 5

Additional resources 5

Terminology and Abbreviations 6

Product Information 7

Part Number Break Down 8

Available MCCBs in the TemBreak PRO range: 9

P160_BE and P250_BE Information 10

P400_BE Information 11

P630_BE Information 12

Internal Accessories 13

Auxiliary & Alarm Switches 13

Auxiliary Contact 13

Alarm Contact 13

Shunt Trip 14

Under Voltage Trips 14

Plugs & Ports 15

Installation 16

Precautions 16

Mounting Angles 16

Direction of Power Supply 16

Clearances 17

Internal Accessory Mounting Locations 19

P160 internal accessories combination 19

P250 internal accessories combination 20

P400/630 internal accessories combination 21

Alarm, Shunt & UVT Installation 22

Standard Alarm & Auxiliary installation 22

Shunt & UVT installation 23

Protection Settings 24

Trip Curve 24

Long Time Delay (LTD) protection 25

Adjusting Ir(Current) 26

Adjusting tr(Time Delay) 27

Thermal memory / Hot–Cold start mode 28

Short Time Delay Protection (STD) 29

Adjusting Isd (Current) 30

Adjusting tsd (Time Delay) 31

Isd Time Delay Adjustment Settings (ms) 31

I2t function for STD 32

Thermal Self Protection 34

Instantaneous Protection (INST) 35

Adjusting Ii(Current) 35

Ground/Earth Fault Protection (GF) 36

Neutral Protection (NP) 37

Alarms & Indication 38

System Alarms 38

Trip Alarm 39

PTA (Pre-Trip Alarm) 40

OAC and PTA cable 40

OCR Power Supply 41

Commissioning 42

LTD Adjustments (Ir, tr) 42

STD Adjustments (Isd, tsd) 43

INST Protection Adjustments (Ii) 44

INST Protection Only Setting 45

LSIG 3P –GF Protection Adjustments (Ig) 46

LSIG 4P –NP and GF Protection Adjustments (IN, Ig) 47

Troubleshooting 48

Annex A –Dimensions 50

P160 Dimensions 50

P250 Dimensions 51

P400 Dimensions 52

P630 Dimensions 53

Annex B –Trip Curves 54

Annex C –I2t Let-Through Curves 55

P160_BE 55

P250_BE 56

P400_BE 57

P630_BE 58

Annex D –Peak Let Through Curves 59

P160_BE 59

P250_BE 60

P400_BE 61

P630_BE 62

Annex E –Watts Loss 63

Annex F –Rated Temperature Tables 64

5

TemBreak PRO P_BE-UM-001-EN V1.3.0

Introduction

This user manual describes the TemBreak PRO Basic Electronic (P_BE) MCCB features and instructions for use, and provides information for

commissioning and configuring.

Some additional features may require the use of additional products and accessories to achieve full utilization of that feature. Refer the respective User

Manual in the TemBreak PRO series for additional information on the respective product.

Who Should Use This Manual?

This manual aims to provide users, electricians, panel builders and maintenance personnel, with the technical information required for commissioning and

operation of the NHP / Terasaki TemBreak PROP_BE MCCB.

Users of this document must have at minimum a basic understanding of electrical circuit protection topics including (but not limited to):

-

Power distribution and reticulation

-

Circuit protection devices

-

Fault currents

-

Arc faults

-

Temperature rise and thermal derating of switchgear

Additional resources

The following resources contain additional information which should be read in conjunction with this document.

Resource

Description

NHP/Terasaki TemBreak PRO P_BE Installation

Instructions

P160_3_BE-IN-001-EN

P160_4_BE-IN-001-EN

P250_3_BE-IN-001-EN

P250_4_BE-IN-001-EN

P400_3_BE-IN-001-EN

P400_4_BE-IN-001-EN

P630_3_BE-IN-001-EN

P630_4_BE-IN-001-EN

Information on installing, mounting, and wiring the TemBreak PRO Basic Electronic

MCCB.

Notice: Not all OCRs in the TemBreak PRO series are identical. This document specifically covers the P_BE

OCRs only. Refer to the respective OCR User Manual (e.g. B_SE, P_SE, etc.) for information and instructions

on other OCRs in the TemBreak PRO series.

Introduction

6

TemBreak PRO P_BE-UM-001-EN V1.3.0

Terminology and Abbreviations

Abbreviation

Description

Abbreviation

Description

ACP

Auxiliary Communications port: Plug for Smart auxiliary /

alarm contact block

MIP

Maintenance Interface Port: Plug for temporary

connection to OCR testing, servicing, and maintenance

tools

AL

Alarm: An auxiliary contact indicating trip status

N

Neutral

ASCII

American Standard Code for Information Interchange

NP

Neutral Protection

AX or AUX

Auxiliary: Auxiliary contact indicating open / closed

OAC

Optional Alarm Contact: Connection connector optional

alarm output contact

BE

Basic Electronic Trip Unit (dial type, LSI and LSIG)

OCR

Over Current Relay

CCW

Connected Components Workbench software

P or PTA

Pre-trip Alarm

CIP 1 2

1Communication Interface Port: Plug for control power

and data for use with the TPED remote display and

TPCM communication module

2Common Industrial Protocol

PDU

Protocol Data Unit

CRC

Cyclic Redundancy Check –error-detecting code used at

the end of each Modbus message

PELV

Protected Extra Low Voltage (earthed system)

dec

Decimal (base-10) numbering system

PTA

Pre-Trip Alarm: is a programmable output contact to

advise when a trip may be imminent.

DINT

Signed Double Integer datatype (4 bytes or 32 bits in

length)

RTU

Remote Terminal Unit

EIPM

TemBreak PRO Ethernet/IP Module

S or STD

Short Time Delay Protection

FF

Fixed Thermal and Fixed Magnetic

SE

Smart Energy Trip Unit

FM

Fixed Thermal and Adjustable Magnetic

SELV

Separated Extra Low Voltage

G or GF

Ground Fault Protection

SN

Solid Neutral

hex

Hexadecimal (base-16) numbering system

SSID

Service Set Identifier (name of the Wi-Fi wireless

network)

I or INST

Instantaneous Protection

STR

String datatype

IEC

International Electrotechnical Commission

TCP

Transmission Control Protocol

IEEE

Institute of Electrical and Electronics Engineers

TF

Adjustable Thermal and Fixed Magnetic

Ig

Ground Fault Protection Current

THD

Total Harmonic Distortion

Ii

Instantaneous Protection Current

TM

Adjustable Thermal Magnetic

In

Rated Current

TPCM

TemCom PRO Communication Module

IN

Neutral Protection Current

TPED

TemView PRO External Display

INT

Signed Integer datatype (2 bytes or 16 bits in length)

tr

LTD Time delay

IP

International Protection (Ingress Protection)

tsd

STD Time delay

Ir

LTD Protection Current

ttsp

Thermal Self-Protection Time delay

Isd

STD Protection Current

UDINT

Unsigned Integer (2 bytes or 16-bits in length)

Itsp

Thermal Self-Protection Current

UINT

Unsigned Integer (2 bytes or 16 bits in length)

L or LTD

Long Time Delay Protection

ULINT

Unsigned Long Integer datatype (8 bytes or 64 bits in

length)

LCD

Liquid Crystal Display (LCD)

URLs

Uniform Resource Locator (address of an Internet

website)

LED

Light Emitting Diode

WORD

2 bytes or 16-bits of data

LINT

Signed Long Integer datatype (8 bytes or 64 bits in

length)

ZSI

Zone Selective Interlocking (zone selectivity)

LSI

Long Time, Short Time and Instantaneous Protection

θ

Thermal imaging value

LSIG

Long Time, Short Time, Instantaneous and Ground Fault

Protection

θC

Cold start mode thermal imaging value

MCCB

Moulded Case Circuit Breaker

θH

Hot start mode thermal imaging value

microSD

Micro Secure Digital

θtrip

Thermal imaging value tripping threshold

7

TemBreak PRO P_BE-UM-001-EN V1.3.0

Product Information

The TemBreak PRO P model Basic Electronic MCCB with trip unit type P_BE, in addition to protecting against overloads and short circuits, offers flexibility

via provide fully adjustable LSI(G) (long time, short time, instantaneous, ground fault) protection settings via preset rotary switches as well as a host of other

standard or optional features. This allows for improved selectivity combinations between MCCBs or other circuit breaker types.

Features

-LSI or LSIG

-Setting by rotary dial

-Over temperature alarm LED

-Signalling the OCR LED status (Ready)

-Signalling PTA overload pre-warning LED

-LED signalling overload alarm (>Ir)

-Possible adjustment of thresholds and time delays for LSIG 6)

-Possible adjustment of the protection of neutral pole on 4-pole versions (neutral pole positioned to the right)

Frame Sizes

-P160

-P250

-P400

-P630

Protection Functions

-Long Time Delay

-Short Time Delay

-Instantaneous

-Ground Fault (LSIG model)

-Neutral Protection (LSIG 4P model)

Additional Certificates

Product Information

8

TemBreak PRO P_BE-UM-001-EN V1.3.0

Part Number Break Down

P

160

F

2

4

160

BE

G

a)

b)

c)

d)

e)

f)

g)

h)

a) Model Type

A

Basic applications

(160…250 A)

P

Mid to advanced applications

(160…630 A)

B

High current, high kA applications

(160…1600 A)

ZS

Earth Leakage applications

(125…800 A)

XS

Highest current applications

(2000…3200 A)

b) Ampere Frame

125

A

160

A

250

A

400

A

630

A

800

A

1000

A

1250

A

1600

A

2000

A

2500

A

3200

A

c) Short Circuit Break Capacity Icu (kA)

R

200 kA

L

150 kA

P

125 kA

S

110 kA

G

100 kA

HL

85 kA

H

70 kA

M

65 kA

N

50 kA

F

36 kA

E

25 kA

D

Switch

d) Pole Pitch Size (mm) 1)

1

25

2

30

3

35

e) No. of Poles

1

6)

2

7)

3

4

f) Trip Unit Rating (In)

In

x A

g) Trip Unit Type

TF

Adj Thermal Fix Magnetic 3)

FF

Fix Thermal Fix Magnetic 3)

FM

Fix Thermal Adj Magnetic 8)

TM

Adj Thermal Adj Magnetic

SX

Smart Ammeter 4) 5)

BE

Basic Electronic 5)

SE

Smart Energy 5)

NN

Non-Auto Switch

h) Trip Unit Option

G

Ground Fault 2)

N

Neutral 2)

P

Pre-Trip Alarm 2)

SN

Solid Neutral 8)

1. 160AF only

2. For P_SE versions these features are standard and therefore are not added to the end of the part number.

3. Only available in A & ZS models

4. Only available in B models

5. Not available in A models

6. Only available in A and B models (FF Only Trip Unit)

7. Not available in A and B models (FF Only Trip Unit)

8. ZS Models

Notice: Not all combinations are possible. Confirm part number combination with NHP for availability.

Product Information

9

TemBreak PRO P_BE-UM-001-EN V1.3.0

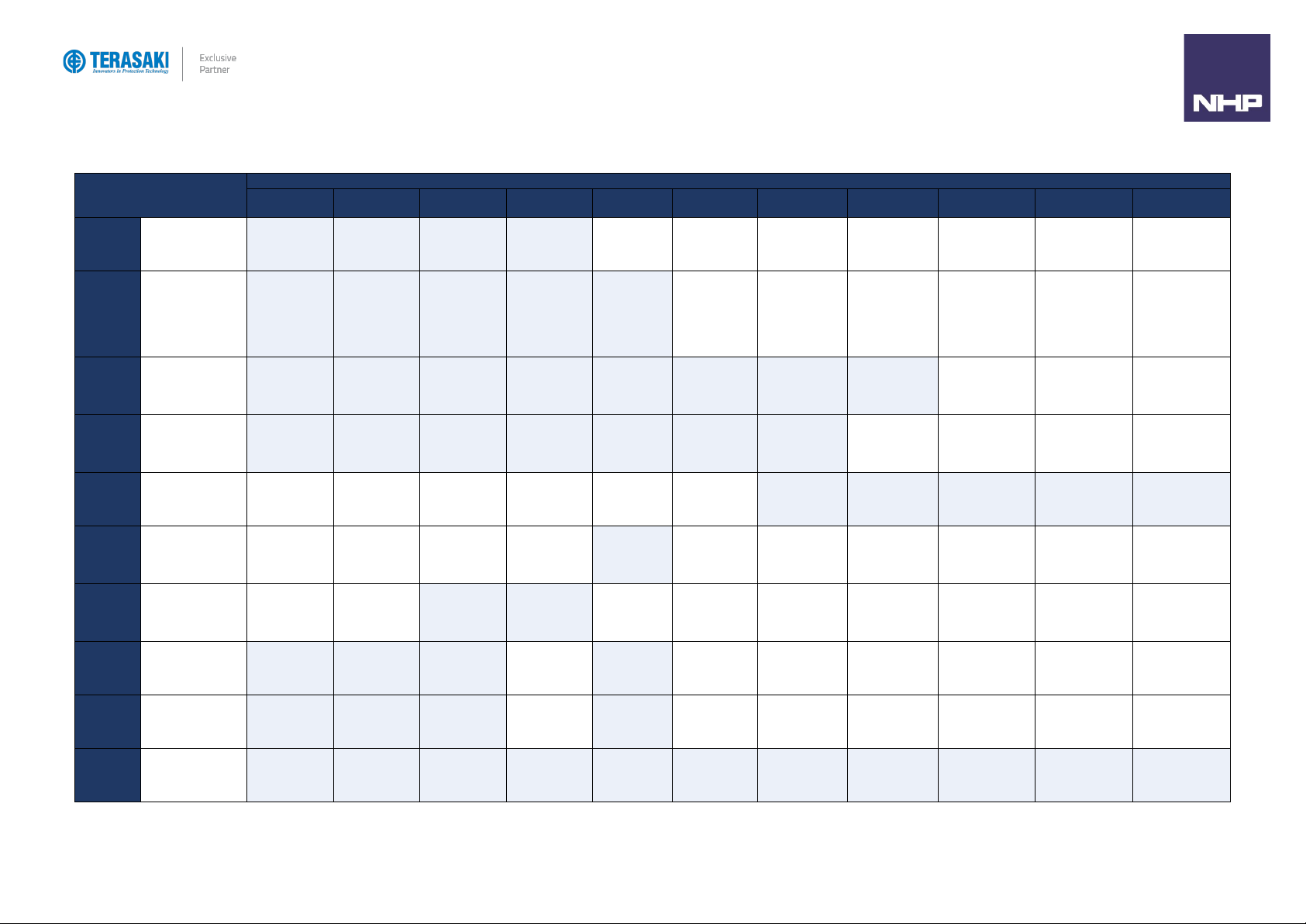

Available MCCBs in the TemBreak PRO range:

Rating

Short Circuit Break Capacity

(kA)

Frame Size

160

250

400

630

800

1000

1250

1600

2000

2500

3200

E

25

A160E –TF

A160E –FF

B160E –FF

A250E –TM

P400E-TM

P630E –TM

F

36

A160F –TF

P160F –FF

P160F –TM

P160F –BE

P160F –BEG

P160F –SE

A250F –TM

P250F –TM

P250F –BE

P250F –BEG

P250F –SE

P400F –TM

P400F –BE

P400F –BEG

P400F –SE

P630F –TM

P630F –BE

P630F –BEG

P630F –SE

B800F –TM

N

50

P160N –TM

P160N –BE

P160N –BEG

P160N –SE

P250N –TM

P250N –BE

P250N –BEG

P250N –SE

P400N –TM

P400N –BE

P400N –BEG

P400N –SE

P630N –TM

P630N –BE

P630N –BEG

P630N –SE

B800N –TM

B800N –BE

B800N –SX

B800N –SE

B1000N –BE

B1000N –SX

B1000N –SE

B1250N –BE

B1600N –BE

H

70

P160H –TM

P160H –BE

P160H –BEG

P160H –SE

P250H –TM

P250H –BE

P250H –BEG

P250H –SE

P400H –TM

P400H –BE

P400H –BEG

P400H –SE

P630H –TM

P630H –BE

P630H –BEG

P630H –SE

B800H –TM

B800H –BE

B800H –SX

B800H –SE

B1000H –BE

B1000H –SX

B1000H –SE

B1250H –BE

HL

85

B1250HL –BE

B1600HL –BE

XS2000HL –BE

XS2500HL –BE

XS3200HL –BE

G

100

B800G –TM

B800G –BE

B800G –SX

B800G –SE

S

110

P400S –TM

P400S –BE

P400S –BEG

P400S –SE

P630S –TM

P630S –BE

P630S –BEG

P630S –SE

P

125

B160P –TM

B250P –TM

B250P –BE

B250P –SE

B400P –BE

B800P –BE

B800P –SX

B800P –SE

R

200

B160R –TM

B250R –TM

B400R –BE

B800R –BE

B800R –SX

B800R –SE

D

Switch

A160D –NN

P160D –NN

A250D –NN

P250D –NN

P400D –NN

P630D –NN

B800D –NN

B1000D –NN

B1250D –NN

B1600D –NN

XS2000D –NN

XS2500D –NN

XS3200D –NN

Product Information

10

TemBreak PRO P_BE-UM-001-EN V1.3.0

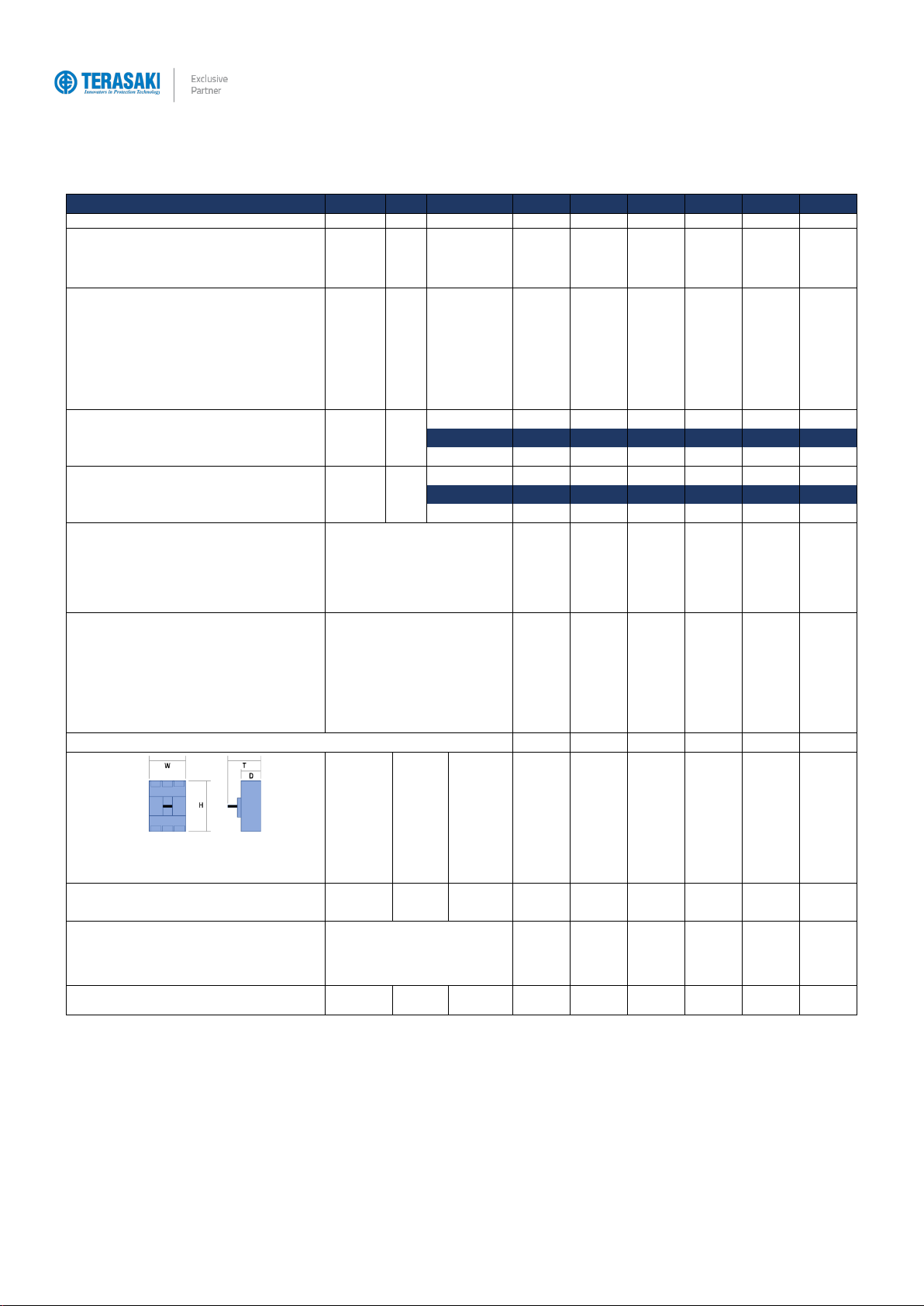

P160_BE and P250_BE Information

Frame / Model

Attribute

Unit

Condition

P160F

P160N

P160H

P250F

P250N

P250H

Number of Poles

3, 4

3, 4

3, 4

3, 4

3, 4

3, 4

Nominal current ratings

ICT

(A)

50°C

40 A

40 A

40 A

40 A

40 A

40 A

Trip unit ratings

100 A

100 A

100 A

100 A

100 A

100 A

160 A

160 A

160 A

160 A

160 A

160 A

─

─

─

250 A

250 A

250 A

Electrical characteristics

Rated maximum operational voltage

Ue

(V)

AC 50/60 Hz

690

690

690

690

690

690

(V)

DC

─

─

─

─

─

─

Rated insulation voltage

Ui

(V)

800

800

800

800

800

800

Rated impulse withstand voltage

Uimp

(kV)

8

8

8

8

8

8

Selectivity category

A

A

A

A

A

A

Rated short time withstand current

Icw

(kA)

0.4 sec

─

─

─

─

─

─

Ultimate breaking capacity

Icu

(kA)

690 Vac

6

6

6

6

6

6

(IEC, JIS, AS/NZS)

400 /415 Vac

36

50

70

36

50

70

240 Vac

50

85

85

50

85

85

Service breaking capacity

Ics

(kA)

690 Vac

6

6

6

6

6

6

(IEC, JIS, AS/NZS)

400 /415 Vac

36

50

50

36

50

50

220 /240 Vac

50

85

85

50

85

85

Protection - Over Current Release types

Std Standard

Opt Optional

─Not Available

M Req Module Required

BE 6 dial Adjustable LSI

Std

Std

Std

Std

Std

Std

BE-G 7 dial Adjustable LSIG (Ground Fault)

Std

Std

Std

Std

Std

Std

BE Instantaneous only setting (ICB) 1)

Std

Std

Std

Std

Std

Std

LT Adjustable 40% to 100% in 1% increments

Std

Std

Std

Std

Std

Std

Instantaneous setting independently adjustable

Std

Std

Std

Std

Std

Std

Installation (Std / Opt / ─ )

Std Standard

Opt Optional

─Not Available

Front connection (FC)

Std

Std

Std

Std

Std

Std

Extension bar (FB)

Opt

Opt

Opt

Opt

Opt

Opt

Cable tunnel clamp (FW)

Opt

Opt

Opt

Opt

Opt

Opt

Rear Connection (RC)

Opt

Opt

Opt

Opt

Opt

Opt

DIN rail adaptor

Opt

Opt

Opt

Opt

Opt

Opt

Withdrawable mechanism

Opt

Opt

Opt

Opt

Opt

Opt

Plug-in

Opt

Opt

Opt

Opt

Opt

Opt

Reverse supply connection possible to 440V

Yes

Yes

Yes

Yes

Yes

Yes

Dimensions

H

(mm)

165

165

165

165

165

165

W

(mm)

1 pole

─

─

─

─

─

─

2 pole

─

─

─

─

─

─

3 pole

90

90

90

105

105

105

4 pole

120

120

120

140

140

140

D

(mm)

68

68

68

68

68

68

T

(mm)

95.5

95.5

95.5

95.5

95.5

95.5

Weight

W

(kg)

3 pole

1.0

1.0

1.0

1.5

1.5

1.5

4 pole

1.3

1.3

1.3

2

2

2

Operation options (Std / Opt / ─ )

Std Standard

Opt Optional

─Not Available

Toggle operation

Std

Std

Std

Std

Std

Std

Extension handle TP-HS/HP or Direct mount T2HB

Opt

Opt

Opt

Opt

Opt

Opt

Motor operation TP-MC

Opt

Opt

Opt

Opt

Opt

Opt

Endurance

Electrical

Cycles

415 Vac

30000

30000

30000

10000

10000

10000

Mechanical

Cycles

50000

50000

50000

30000

30000

30000

Product Information

11

TemBreak PRO P_BE-UM-001-EN V1.3.0

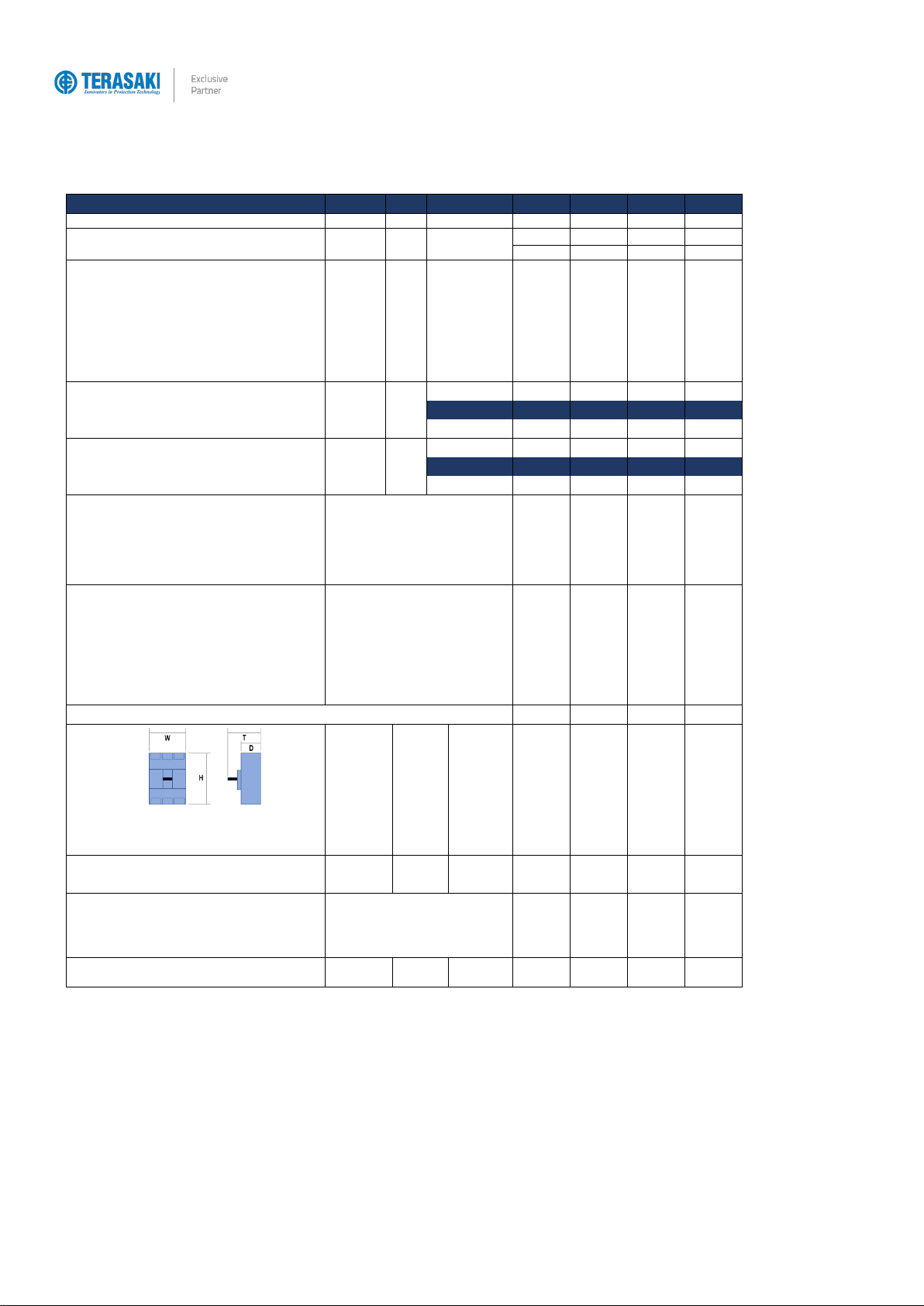

P400_BE Information

Frame / Model

Attribute

Unit

Condition

P400F

P400N

P400H

P400S

Number of Poles

3, 4

3, 4

3, 4

3, 4

Nominal current ratings

ICT

(A)

50°C

Calibration

250 A

250 A

250 A

250 A

Trip unit ratings

400 A

400 A

400 A

400 A

Electrical characteristics

Rated maximum operational voltage

Ue

(V)

AC 50/60 Hz

690

690

690

690

(V)

DC

─

─

─

─

Rated insulation voltage

Ui

(V)

800

800

800

800

Rated impulse withstand voltage

Uimp

(kV)

8

8

8

8

Selectivity category

B

B

B

B

Rated short time withstand current

Icw

(kA)

0.4 sec

5

5

5

5

Ultimate breaking capacity

Icu

(kA)

690 Vac

7

12

12

12

(IEC, JIS, AS/NZS)

400 /415 Vac

36

50

70

110

240 Vac

50

85

100

125

Service breaking capacity

Ics

(kA)

690 Vac

7

12

12

12

(IEC, JIS, AS/NZS)

400 /415 Vac

36

50

70

110

220 /240 Vac

50

85

100

125

Protection - Over Current Release types

Std Standard

Opt Optional

─Not Available

M Req Module Required

BE 6 dial Adjustable LSI

Std

Std

Std

Std

BE-G 7 dial Adjustable LSIG (Ground Fault)

Std

Std

Std

Std

BE Instantaneous only setting (ICB) 1)

Std

Std

Std

Std

LT Adjustable 40% to 100% in 1% increments

Std

Std

Std

Std

Instantaneous setting independently adjustable

Std

Std

Std

Std

Installation (Std / Opt / ─ )

Std Standard

Opt Optional

─Not Available

Front connection (FC)

Std

Std

Std

Std

Extension bar (FB)

Std

Std

Std

Std

Cable tunnel clamp (FW)

Opt

Opt

Opt

Opt

Rear connection (RC)

Opt

Opt

Opt

Opt

DIN rail adaptor

─

─

─

─

Withdrawable mechanism

Opt

Opt

Opt

Opt

Plug-in

Opt

Opt

Opt

Opt

Reverse supply connection possible to 440V

Yes

Yes

Yes

Yes

Dimensions

H

(mm)

260

260

260

260

W

(mm)

1 pole

─

─

─

─

2 pole

─

─

─

─

3 pole

140

140

140

140

4 pole

185

185

185

185

D

(mm)

103

103

103

103

T

(mm)

145

145

145

145

Weight

W

(kg)

3 pole

4.3

4.3

4.3

4.3

4 pole

5.7

5.7

5.7

5.7

Operation options (Std / Opt / ─ )

Std Standard

Opt Optional

─Not Available

Toggle operation

Std

Std

Std

Std

Extension handle TP-HS/HP or Direct mount T2HB

Opt

Opt

Opt

Opt

Motor operation TP-MC

Opt

Opt

Opt

Opt

Endurance

Electrical

Cycles

415 Vac

6000

6000

6000

6000

Mechanical

Cycles

15000

15000

15000

15000

Product Information

12

TemBreak PRO P_BE-UM-001-EN V1.3.0

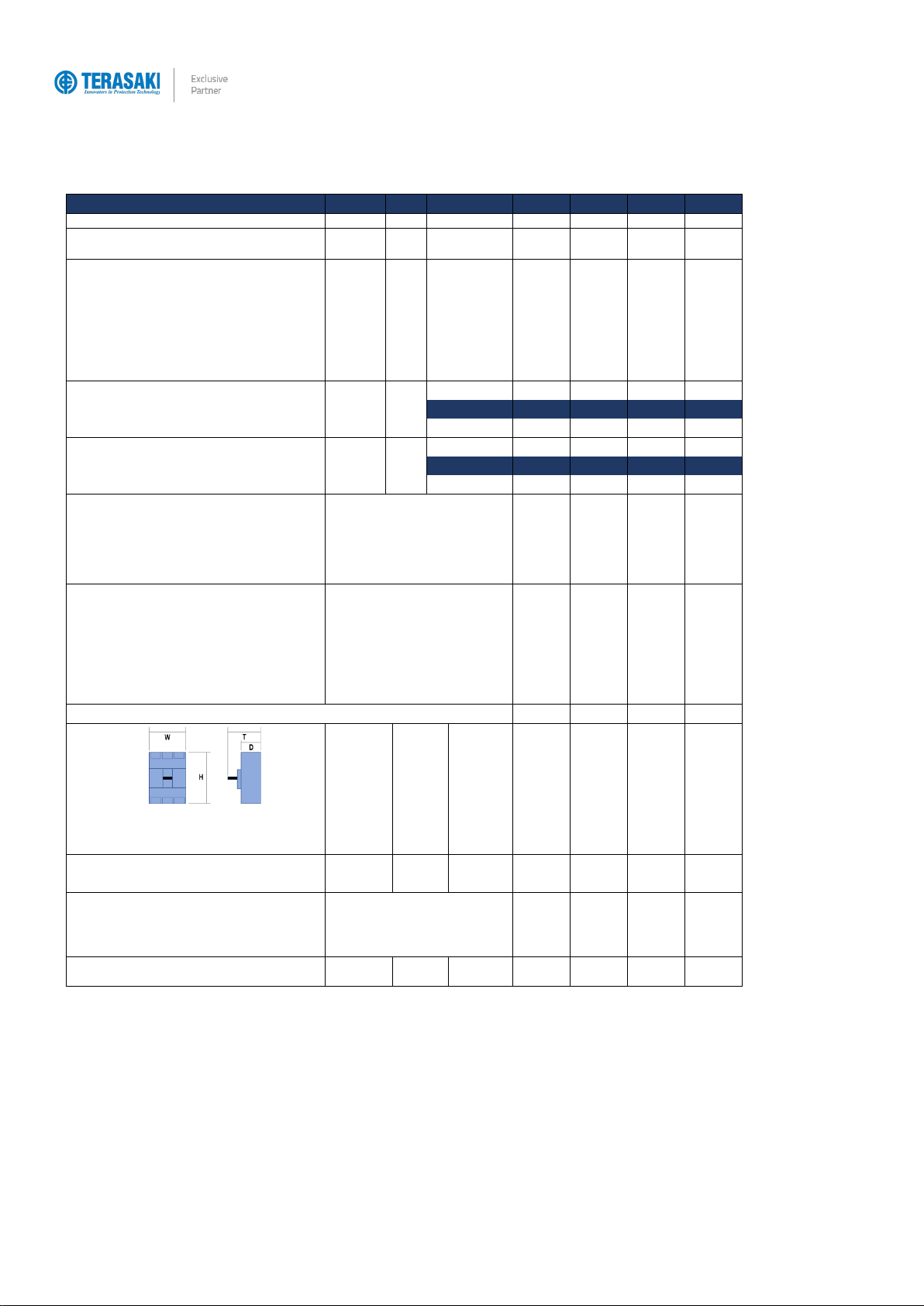

P630_BE Information

Frame / Model

Attribute

Unit

Condition

P630F

P630N

P630H

P630S

Number of Poles

3, 4

3, 4

3, 4

3, 4

Nominal current ratings

ICT

(A)

50°C

630A

630A

630A

630A

Trip unit ratings

Calibration

Electrical characteristics

Rated maximum operational voltage

Ue

(V)

AC 50/60 Hz

690

690

690

690

(V)

DC

─

─

─

─

Rated insulation voltage

Ui

(V)

800

800

800

800

Rated impulse withstand voltage

Uimp

(kV)

8

8

8

8

Selectivity category

A

A

A

A

Rated short time withstand current

Icw

(kA)

0.4 sec

─

─

─

─

Ultimate breaking capacity

Icu

(kA)

690 Vac

7

12

12

12

(IEC, JIS, AS/NZS)

400 /415 Vac

36

50

70

110

240 Vac

50

85

100

125

Service breaking capacity

Ics

(kA)

690 Vac

7

12

12

12

(IEC, JIS, AS/NZS)

400 /415 Vac

36

50

70

110

220 /240 Vac

50

85

100

125

Protection - Over Current Release types

Std Standard

Opt Optional

─Not Available

M Req Module Required

BE 6 dial Adjustable LSI

Std

Std

Std

Std

BE-G 7 dial Adjustable LSIG (Ground Fault)

Std

Std

Std

Std

BE Instantaneous only setting (ICB) 1)

Std

Std

Std

Std

LT Adjustable 40% to 100% in 1% increments

Std

Std

Std

Std

Instantaneous setting independently adjustable

Std

Std

Std

Std

Installation (Std / Opt / ─ )

Std Standard

Opt Optional

─Not Available

Front connection (FC)

Std

Std

Std

Std

Extension bar (FB)

Std

Std

Std

Std

Cable tunnel clamp (FW)

Opt

Opt

Opt

Opt

Rear connection (RC)

Opt

Opt

Opt

Opt

DIN rail adaptor

─

─

─

─

Withdrawable mechanism

Opt

Opt

Opt

Opt

Plug-in

Opt

Opt

Opt

Opt

Reverse supply connection possible to 440V

Yes

Yes

Yes

Yes

Dimensions

H

(mm)

260

260

260

260

W

(mm)

1 pole

─

─

─

─

2 pole

─

─

─

─

3 pole

140

140

140

140

4 pole

185

185

185

185

D

(mm)

103

103

103

103

T

(mm)

145

145

145

145

Weight

W

(kg)

3 pole

5.0

5.0

5.0

5.0

4 pole

6.6

6.6

6.6

6.6

Operation options (Std / Opt / ─ )

Std Standard

Opt Optional

─Not Available

Toggle operation

Std

Std

Std

Std

Extension handle TP-HS/HP or Direct mount T2HB

Opt

Opt

Opt

Opt

Motor operation TP-MC

Opt

Opt

Opt

Opt

Endurance

Electrical

Cycles

415 Vac

4000

4000

4000

4000

Mechanical

Cycles

15000

15000

15000

15000

13

TemBreak PRO P_BE-UM-001-EN V1.3.0

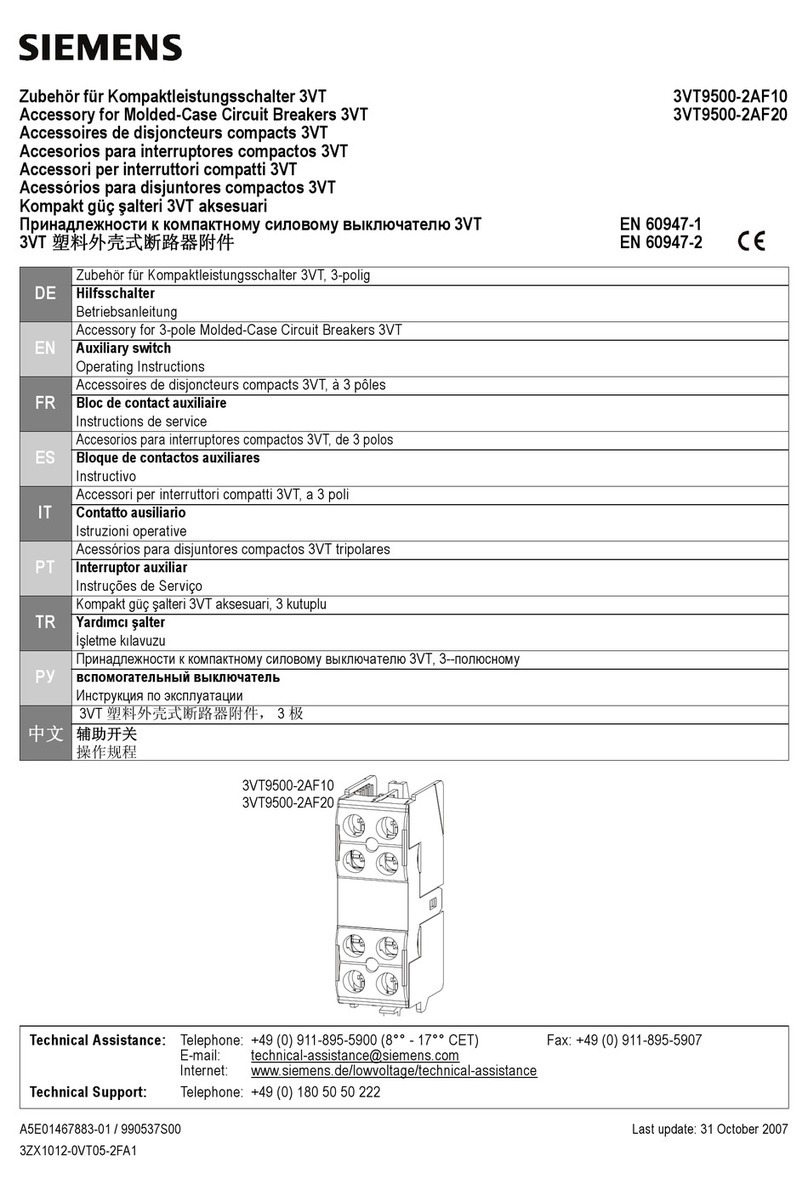

Internal Accessories

Internal accessories include Auxiliary and Alarm contacts, Shunt Trip and Undervoltage Trip (UVT) modules, which may be installed under the front cover of

the MCCB in various combinations to provide additional functionality and connection with external control circuits.

Auxiliary & Alarm Switches

Auxiliary Contact

An auxiliary contact can be installed to indicate whether an MCCB is Open (both OFF and Tripped positions) or

Closed (ON). Auxiliary contacts come in either general purpose or micro-switch type, with some combinations pre-

wired or with terminals. Each contact type is provided as a single change-over switching arrangement (1x C/O).

Alarm Contact

An alarm contact can be installed to indicate whether an MCCB is in the Tripped or Not Tripped position (ON, OFF).

Alarm contacts come in either general purpose or micro-switch type, with some combinations pre-wired or with

terminals. Each contact type is provided as a single change-over switching arrangement (1x C/O).

Part Number

Description

Contact Type

Connection Type

T2AX00LML3SWA

Auxiliary

General purpose

Pre-wired

T2AX00LML3STA

Auxiliary

General purpose

Terminal

T2AX00LML3RWA

Auxiliary

Micro-switch

Pre-wired

T2AL00LML3SWA

Alarm; left side only

General purpose

Pre-wired

T2AL00LML3STA

Alarm; left side only

General purpose

Terminal

T2AL00LML3RWA

Alarm; left side only

Micro-switch

Pre-wired

General purpose contact

Micro-switch contact

AC (V)

DC (V)

Minimum Load

DC (V)

Minimum Load

Volts

(V)

Amperes (A)

Volts

(V)

Amperes (A)

Volts

(V)

Amperes (A)

Resistive

Load

Inductive

Load

Resistive

Load

Inductive

Load

Resistive

Load

480

─

─

250

─

─

100 mA @ 15 Vdc

30

0.1

1 mA @ 5 Vdc

250

3

2

125

0.4

0.05

125

3

2

30

3

2

Internal Accessories

14

TemBreak PRO P_BE-UM-001-EN V1.3.0

Shunt Trip

A shunt (normally de-energized) can be installed to trip the MCCB by applying voltage to the shunt coil.

Part Number

Rated voltage

Connection Type

AC (V)

DC (V)

T2SH00LA10T

110

─

Terminal

T2SH00LA20T

230…240

─

Terminal

T2SH00LA40T

400…415

─

Terminal

T2SH00LD01T

─

12

Terminal

T2SH00LD02T

─

24

Terminal

T2SH00LD04T

─

48

Terminal

T2SH00LD10T

─

110

Terminal

T2SH00LD20T

─

230

Terminal

T2SH00LA10WA

110

─

Pre-wired cage clamp

T2SH00LA20WA

230…240

─

Pre-wired cage clamp

T2SH00LA40WA

400…415

─

Pre-wired cage clamp

T2SH00LD01WA

─

12

Pre-wired cage clamp

T2SH00LD02WA

─

24

Pre-wired cage clamp

T2SH00LD04WA

─

48

Pre-wired cage clamp

T2SH00LD10WA

─

110

Pre-wired cage clamp

T2SH00LD20WA

─

230

Pre-wired cage clamp

Rated voltage

AC (V)

DC (V)

100…120

200…240

380...450

12

24

48

100…120

200…240

Excitation current (mA)

16.0

16.0

6.2

160.0

124.0

32.0

14.0

12.0

Under Voltage Trips

A UVT (normally energized) can be installed to trip the MCCB removing voltage from the UVT coil.

Part Number

Rated voltage

Compatible MCCB

Connection Type

Notes

AC (V)

DC (V)

3P

4P

T2UV00LA10NT

110

─

All

P160 / 250

Terminal

Instantaneous

T2UV00LA20NT

230…240

─

All

P160 / 250

Terminal

Instantaneous

T2UV00LA40NT

400…440

─

All

P160 / 250

Terminal

Instantaneous

T2UV00LD02NT

─

24

All

P160 / 250

Terminal

Instantaneous

T2UV00LD10NT

─

110

All

P160 / 250

Terminal

Instantaneous

T2UV00LD20NT

─

230

All

P160 / 250

Terminal

Instantaneous

T2UV00LA10DS

110

─

All

P160 / 250

Terminal

Time Delay 500ms

T2UV00LA24DS

230…240

─

All

P160 / 250

Terminal

Time Delay 500ms

T2UV00LA45DS

440…450

─

All

P160 / 250

Terminal

Time Delay 500ms

T2UV00LD02DS

─

24

All

P160 / 250

Terminal

Time Delay 500ms

T2UV00LD10DS

─

110

All

P160 / 250

Terminal

Time Delay 500ms

T2UV00LD24DS

─

230

All

P160 / 250

Terminal

Time Delay 500ms

T2UV00LA10DL

110

─

─

P400 / 630

Terminal

Time Delay 500ms

T2UV00LA24DL

230…240

─

─

P400 / 630

Terminal

Time Delay 500ms

T2UV00LA40DL

380…415

─

─

P400 / 630

Terminal

Time Delay 500ms

T2UV00LA45DL

440…450

─

─

P400 / 630

Terminal

Time Delay 500ms

T2UV00LD02DL

24

─

P400 / 630

Terminal

Time Delay 500ms

T2UV00LD10DL

110

─

P400 / 630

Terminal

Time Delay 500ms

T2UV00LD24DL

230

─

P400 / 630

Terminal

Time Delay 500ms

T2UV00LA10NWA

110

─

All

P160 / 250

Pre-wired cage clamp

Instantaneous

T2UV00LA20NWA

230…240

─

All

P160 / 250

Pre-wired cage clamp

Instantaneous

T2UV00LA40NWA

440…450

─

All

P160 / 250

Pre-wired cage clamp

Instantaneous

T2UV00LD02NWA

─

24

All

P160 / 250

Pre-wired cage clamp

Instantaneous

T2UV00LD10NWA

─

110

All

P160 / 250

Pre-wired cage clamp

Instantaneous

T2UV00LD20NWA

─

230

All

P160 / 250

Pre-wired cage clamp

Instantaneous

Rated Voltage

AC (V)

DC (V)

100…120

200…240

380…450

24

100…120

200…240

Excitation current (mA)

1.3

1.1

2.0

22.0

9.0

3.7

15

TemBreak PRO P_BE-UM-001-EN V1.3.0

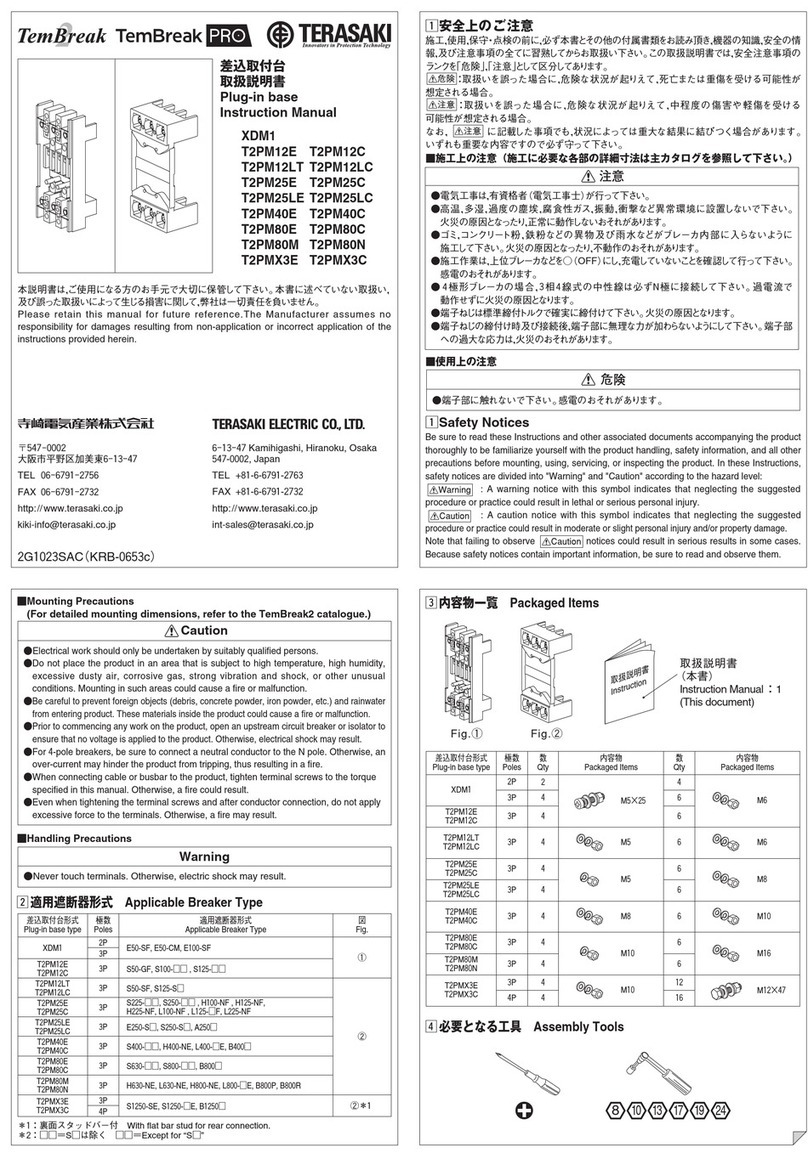

Plugs & Ports

The P_BE circuit breaker is equipped with specific connectors for connecting interfacing devices and accessories.

Port

Description

PTA

Used to connect the PTA output contact to send the pre-trip alarm over a local signalling circuit.

Located on the outside left-hand side of the MCCB.

MIP

Maintenance Interface Port –for temporary connection to OCR testing, servicing, and maintenance tools.

Located to the right of the embedded display front cover.

Notice: Port images are representative only. Locations differ slightly for the various ampere frame sizes

16

TemBreak PRO P_BE-UM-001-EN V1.3.0

Installation

Precautions

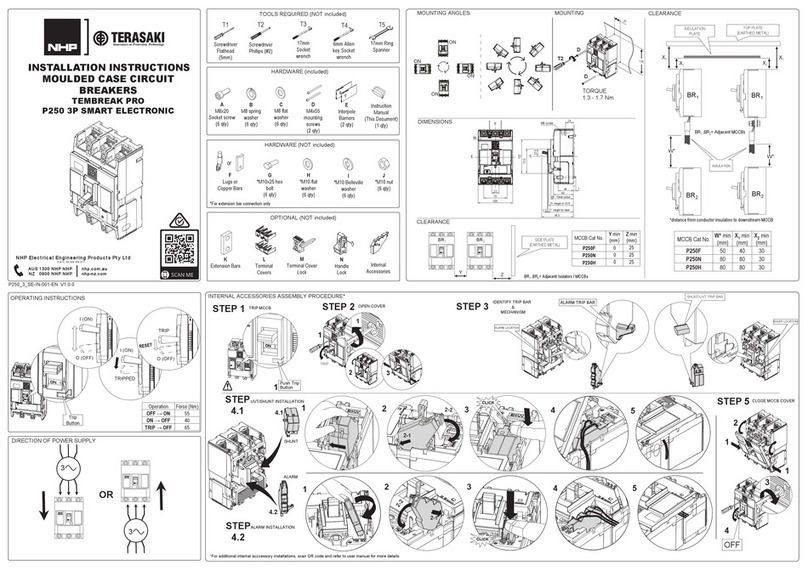

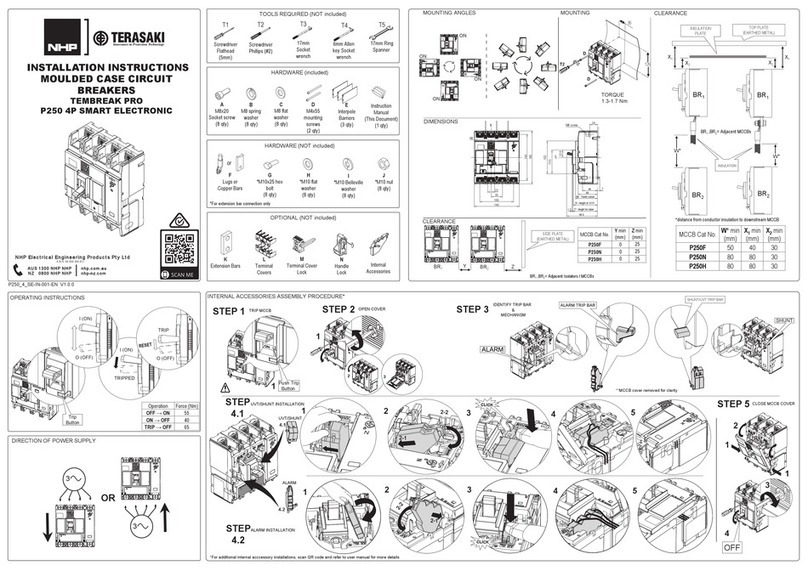

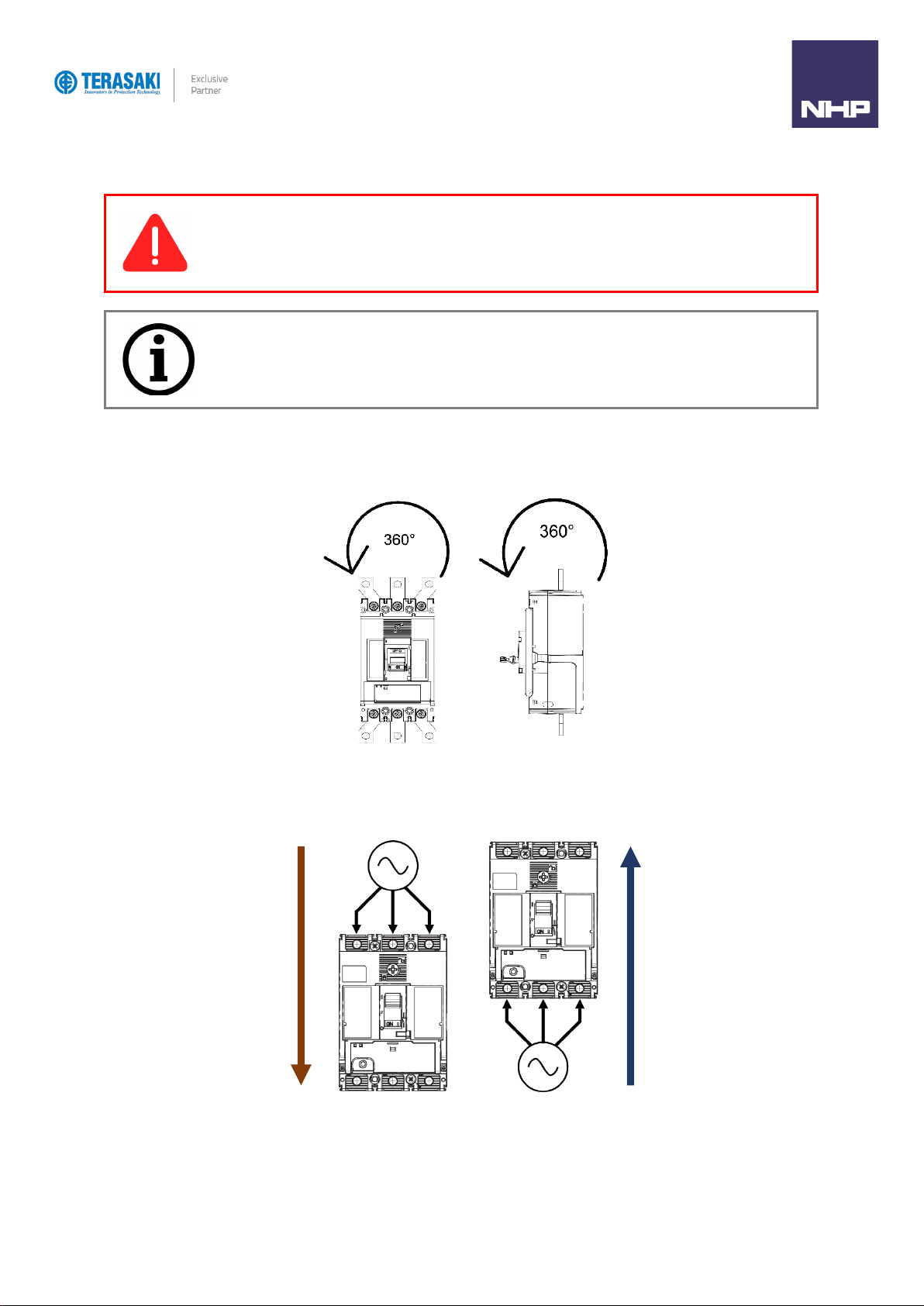

Mounting Angles

TemBreak PRO MCCBs may be mounted at any angle without affecting performance.

Direction of Power Supply

Power supply may be fed in either direction with respect to the MCCB without affecting performance.

WARNING: To prevent electrical shock and damage to equipment, disconnect and isolate power source

upstream of the MCCB before installing or servicing the MCCB including its connected accessories.

Notice: To ensure correct performance, and integrity of equipment, the installation instructions and

recommendations provided herein shall be respected. Refer to the respective user manual and installation

instructions provided with the MCCB and associated accessories.

Positive (+)

Forward/Normal

Supply

Negative (−)

Reverse Supply

Installation

17

TemBreak PRO P_BE-UM-001-EN V1.3.0

Clearances

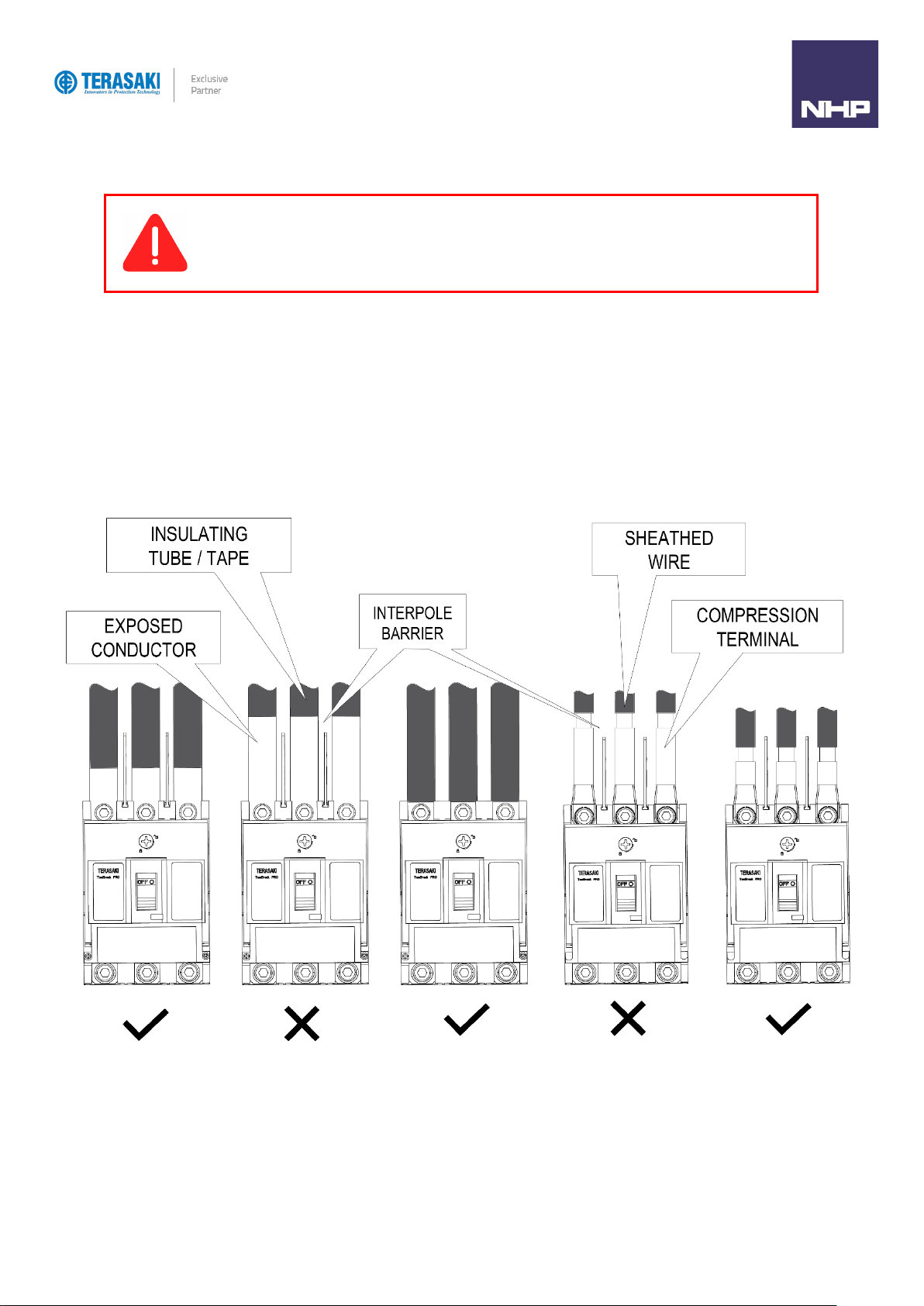

Phase to Phase and Earth

Interruption of large currents during fault or normal switching operation produces ionised gases and arcing materials which expelled from the vents at the top

of the MCCB. These ionised gases are highly conductive, concentrated, and at an elevated temperature when it exits the MCCB via the arc vents. Care

must be taken to avoid an arcing fault from occurring due to the presence of concentrated ionised gases creating a conductive path between exposed

conductors. Incoming conductors must therefore be insulated the full length up to the terminal opening of the MCCB, ensuring bare conductors are not

exposed directly to concentrated ionised gases. This also applies to the attached busbars supplied as part of the MCCB.

Interpole barriers or terminal covers may be used to achieve creepage and clearance requirements. Conductors must not impede the flow of ionised gas

and allow it to clear and disperse safety. Interpole barriers are supplied as standard with Terasaki MCCBs for the line side only. 2 barriers with 3P MCCBs

and 3 with 4P MCCBs. In cases where two different MCCB types are installed one above the other, the insulation distance between the two models should

be as for the lower model.

WARNING: Exposed conductors including terminals at attached busbars must be insulated to avoid possible

short-circuit or earth faults due any foreign matter coming into contact with the conductors.

Installation

18

TemBreak PRO P_BE-UM-001-EN V1.3.0

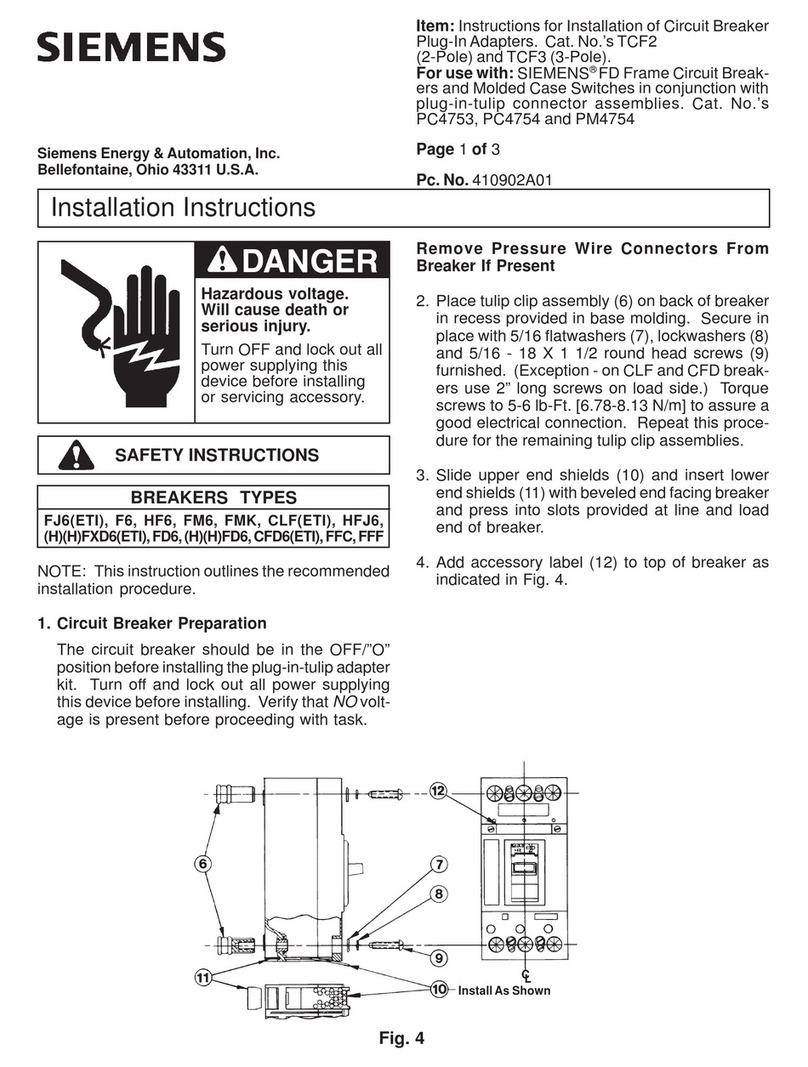

Insulating Distance

When earth metal is installed within proximity of the breakers, the correct insulating distance must be maintained, (refer to Minimum Clearance).

This distance is necessary to allow the exhausted arc gases to disperse. This could include the mounting plate or side panel within a switchboard.

Minimum Clearance

Below illustrates the minimum clearance that must be maintained.

Dim.

Description

MCCB Cat. No.

Distances (mm)

A

B1

B2

C

D

E

A

Distance from lower breaker to open charging part of terminal on

upper breaker (front connection) or the distance from lower

breaker to upper breaker end (rear connection and plug-in type)

P160F

50

10

10

0

25

^

P160N / H / D

75

45

25

0

25

^

P250F

50

40

30

0

25

^

B1

Distance from breaker end to ceiling (earthed metal)

P250N / H / D

80

80

30

0

25

^

B2

Distance from breaker end to insulator

P400F / N / H / D

100

80

60

0

80

^

C

Clearance between breakers

P400S

120

120

80

0

80

^

D

Distance from breaker side to side plate (earthed metal)

P630F / N / H / D

100

80

60

0

80

^

E

Length of insulation over exposed conductors.

P630S

120

120

80

0

80

^

^ Insulate the exposed conductor until it overlaps the moulded case at the terminal, or the terminal cover.

Installation

19

TemBreak PRO P_BE-UM-001-EN V1.3.0

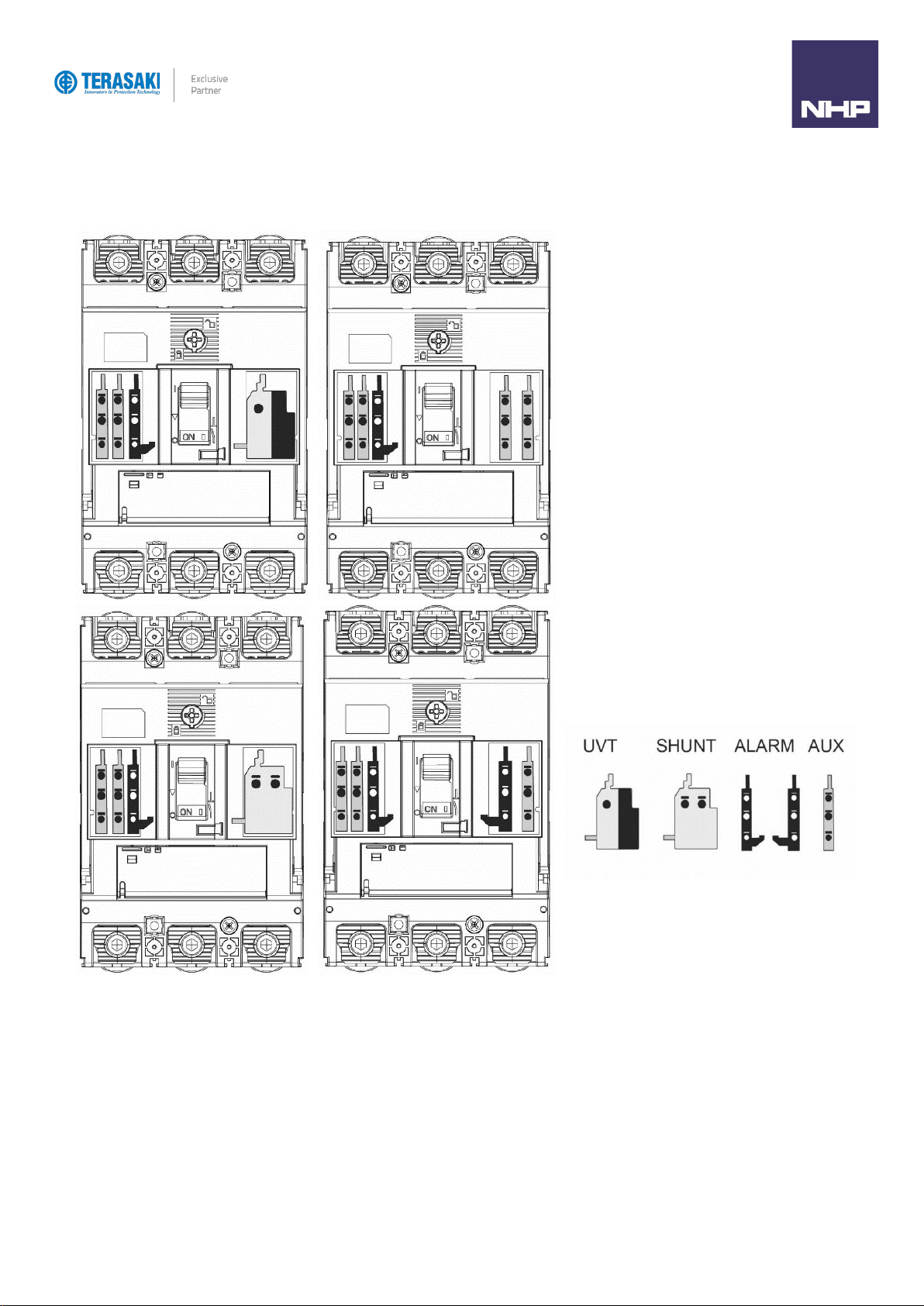

Internal Accessory Mounting Locations

P160, P250 and P400/630 frame sizes have different internal mounting locations for auxiliary contacts, alarm contacts, shunts and, UVTs.

Left-side and right-side mounting locations are independent and accept unique combinations. For example, shunts and UVTs may only be mounted on the

right side, whereas auxiliary and alarm contacts may be mounted on either left or right side.

Refer to the following illustrations for each frame size listing the various possible internal accessories combinations.

P160 internal accessories combination

Legend

Installation

Internal Accessory Mounting Locations

20

TemBreak PRO P_BE-UM-001-EN V1.3.0

P250 internal accessories combination

Legend

Table of contents

Other NHP Circuit Breaker manuals

Popular Circuit Breaker manuals by other brands

DRIESCHER-WEGBERG

DRIESCHER-WEGBERG VSS Addition to Operation and Assembly Instructions

GE

GE MicroVersaTrip Plus Series user guide

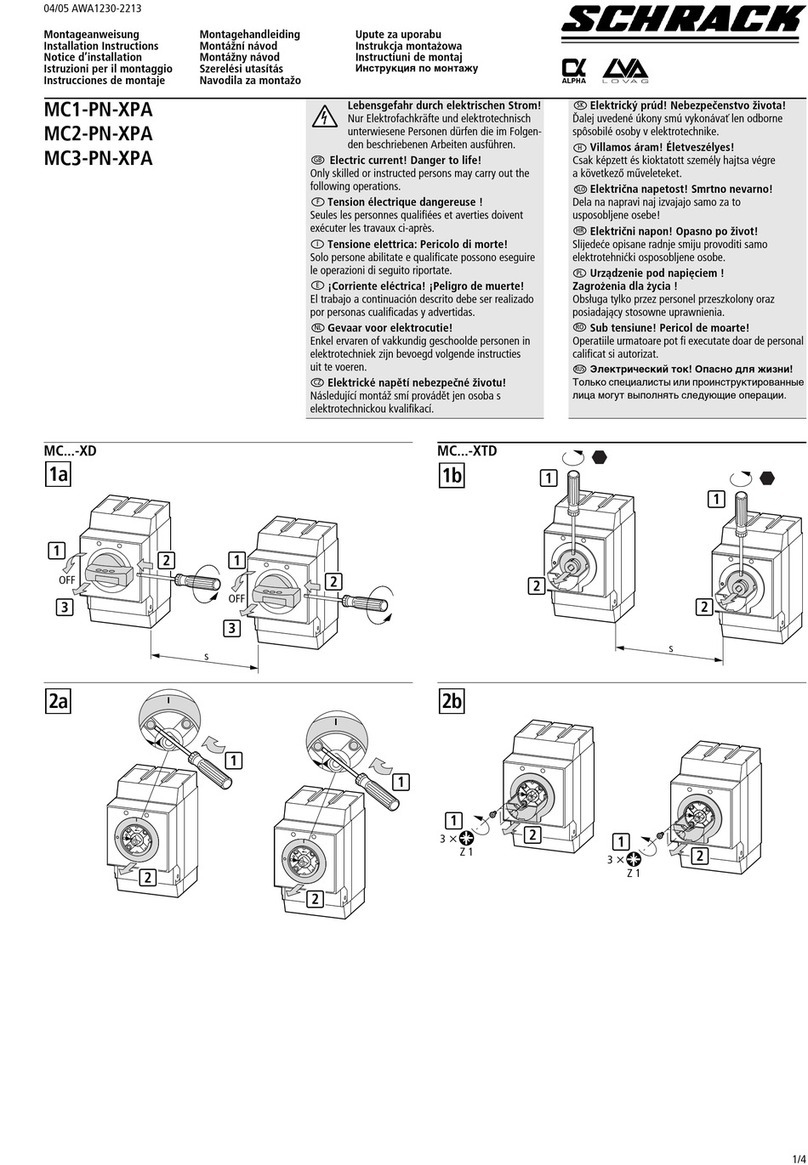

Schrack

Schrack MC1-PN-XPA installation instructions

Eaton

Eaton NOVA LBS 15 Installation and operation instructions

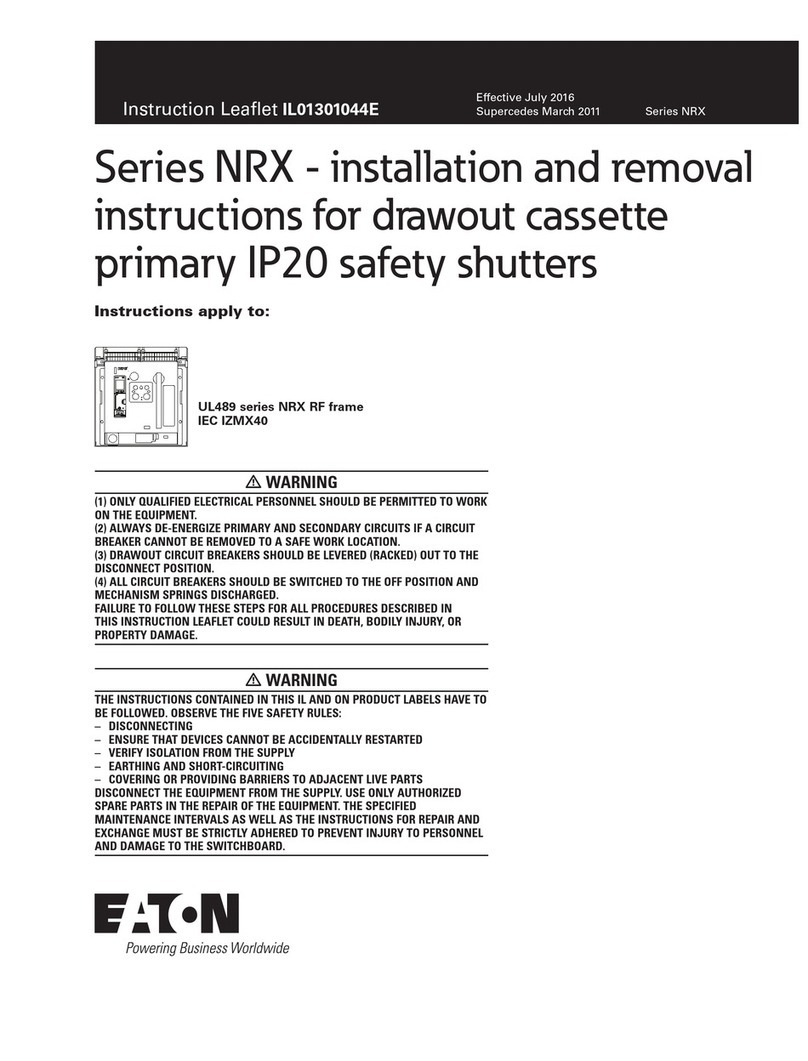

Eaton

Eaton Series NRX Instruction leaflet

ABB

ABB SACE Emax 2 operating instructions