Nibco NIP-2AW series Manual

AHEAD OF THE FLOW®

www.nibco.com

NIBCO INC. WORLD HEADQUARTERS • 1516 MIDDLEBURY ST. • ELKHART, IN 46516-4740 • USA • PH: 1.800.234.0227

TECH SERVICES PH: 1.888.446.4226 • FAX: 1.888.234.0557 • INTERNATIONAL OFFICE PH: +1.574.295.3327 • FAX: +1.574.295.3455

www.nibco.com

1

®

INSTALLATION, OPERATION, and MAINTENANCE GUIDE

NIBCO Wall Mount Indicator Posts

Series NIP-2AW

• NIBCO Series NIP-2AW Wall Mount Indicator Posts are designed and manufactured to:

• Operate non-rising stem (NRS) post indicator valves (PIV) located through building walls

• Operate multi-turn post indicator valves (PIV) with an operating range from 10 to 50 turns

• Visually indicate if the valve is in the OPEN or SHUT position

• Provide a means to lock the valve into a desired position

(usually OPEN)

NIBCO Indicator Posts are listed by Underwriters

Laboratories Inc. (UL), Underwriters Laboratories Inc. for use

in Canada (C-UL), and approved by Factory Mutual Research

Corp. (FM).

It is important to follow the instructions below to assure

proper installation and safe trouble-free operation. Failure

to follow these instructions may result in reduced product

performance and may cause loss of manufacturer’s warranty.

1. Application

1.1 NIBCO Indicator Posts are primarily used with multi-turn non-rising stem (NRS) post indicator valves (PIV) controlling water

supplies to sprinkler, deluge, water spray, foam, and standpipe systems used in fire protection service.

1.2 NIBCO Indicator Posts are designed for outdoor service and are coated with electrostatically applied fusion bonded epoxy

resin to resist corrosion.

1.3 NIBCO Indicator Post view targets are adjustable to accommodate valves of various sizes.

1.4 NIBCO Indicator Posts are shipped for use with “left-hand” (counter-clockwise) opening valves.

1.5 NIBCO Indicator Posts are designed to allow the attachment of a Control Valve Supervisory Switch for electronic monitoring

of the OPEN valve position. Simply follow the instructions provided with the Supervisory Switch for proper installation and

operation.

1.6 NIBCO Wall Indicator Posts are designed to attach directly to the exterior of the building wall; four ¾” holes on a 10½”

diameter bolt circle.

1.7 Indicator Posts should be inspected on a regular basis.

WINDP-0617

© 2017, NIBCO INC.

PATENT #US 9,541,218

AHEAD OF THE FLOW®

www.nibco.com

NIBCO INC. WORLD HEADQUARTERS • 1516 MIDDLEBURY ST. • ELKHART, IN 46516-4740 • USA • PH: 1.800.234.0227

TECH SERVICES PH: 1.888.446.4226 • FAX: 1.888.234.0557 • INTERNATIONAL OFFICE PH: +1.574.295.3327 • FAX: +1.574.295.3455

www.nibco.com

2

®

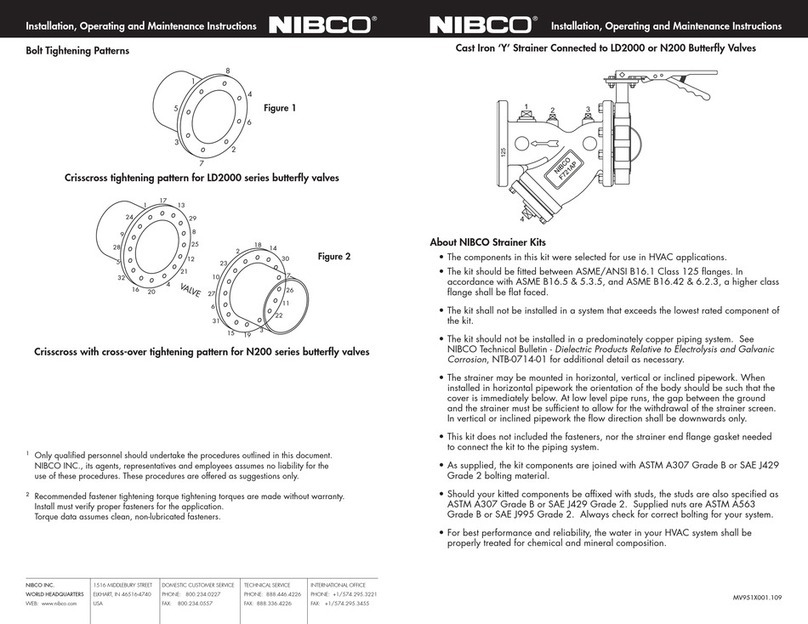

2. Indicator Post Selection

2.1 NIBCO Indicator Posts are designed to work with 4” thru 16” size NIBCO Resilient Wedge Gate Valves (RWGVs) and 4” thru

12” sizes NIBCO Iron Body Bronze Mounted (IBBM) Gate Valves. See Table 1 and Fig. 1 for valve dimensional data. They

will also work with any manufacturers non-rising stem Post Indicator Valve (PIV) that operates from 10 to 50 turns, and a

maximum operating torque of 900 ft·lbs.

DIMENSIONAL DATA FOR NIBCO RWGV AND IBBM GATE VALVES

VALVE

SIZE

NIBCO RESILIENT WEDGE GATE VALVES

(RWGV)

NIBCO IRON BODY BRONZE MOUNTED

GATE VALVES (IBBM)

TURNS

TO OPEN

A B 1/2 PIPE OD TURNS

TO OPEN

A B 1/2 PIPE OD

INCH MM INCH MM INCH MM INCH MM INCH MM INCH MM

4” 13 13.46 342 10.12 257 2.40 61 9 14.13 359 10.47 266 2.40 61

6” 15.7 17.01 432 13.78 350 3.45 88 13.5 18.54 471 16.30 414 3.45 88

8” 17.3 20.47 520 17.32 440 4.53 115 17.5 22.13 562 18.11 460 4.53 115

10” 21.4 23.82 605 20.71 526 5.50 140 30.3 25.75 654 21.89 556 5.50 140

12” 25.3 27.01 686 23.86 606 6.60 168 38.3 29.49 749 24.57 624 6.60 168

14” 44 31.81 808 28.58 726 7.65 194

16” 50 34.21 869 30.98 787 8.70 221

Table 1

Fig. 1

AHEAD OF THE FLOW®

www.nibco.com

NIBCO INC. WORLD HEADQUARTERS • 1516 MIDDLEBURY ST. • ELKHART, IN 46516-4740 • USA • PH: 1.800.234.0227

TECH SERVICES PH: 1.888.446.4226 • FAX: 1.888.234.0557 • INTERNATIONAL OFFICE PH: +1.574.295.3327 • FAX: +1.574.295.3455

www.nibco.com

3

®

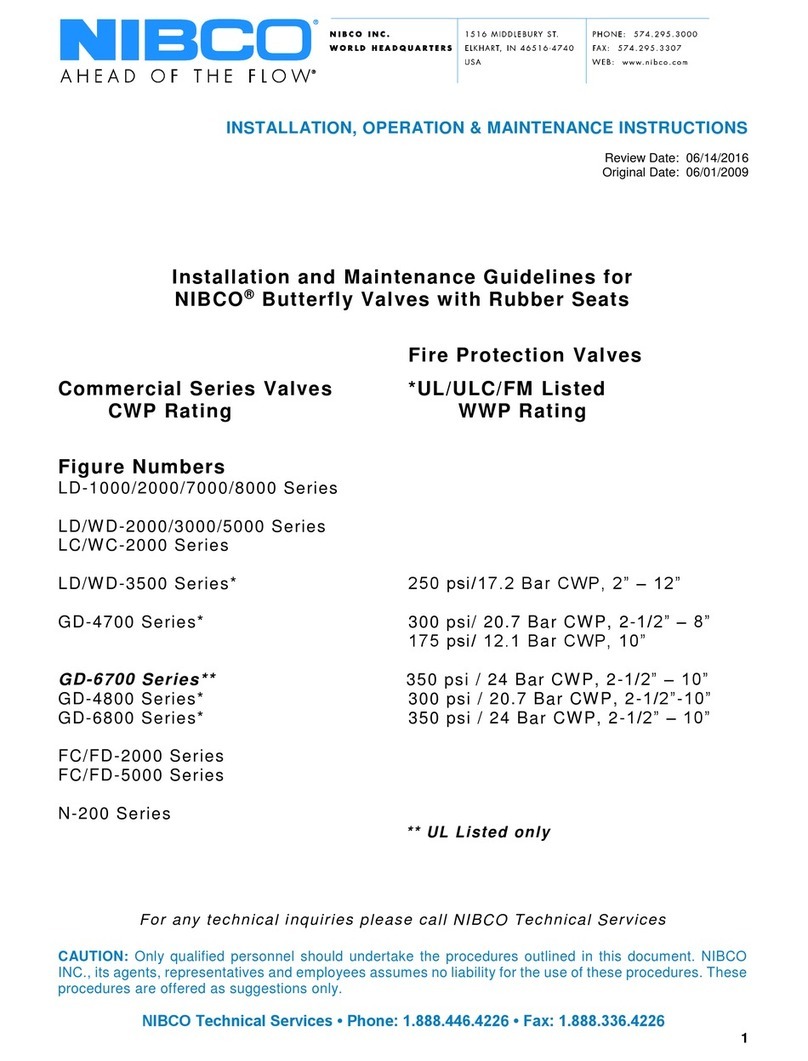

3. Installation of Wall Mount Style Indicator Post

3.1 Fully OPEN the gate valve to which the Indicator Post is being attached.

3.2 Remove 1” square Operating Rod (26) with attached Coupling (25) from Indicator Post by sliding it out from bottom, See Fig. 2.

3.3 Insert Operating Rod (26) thru exterior wall and fully engage Coupling onto Operating Nut of Valve as shown in Fig. 3. Mark

the Operating Rod (26) at a distance of 12¼” from exterior face of wall. Remove Operating Rod (26) from wall and cut-off

the top section of the 1” square Rod at location you just marked. Remove any sharp edges from the Rod with a file.

3.4 Reinstall the shortened Operating Rod (26) into the Wall Indicator Post by sliding it into the 1” square pocket in bottom side,

See Fig. 2.

3.5 Lift Wall Indicator Post assembly and insert Operating Rod (26) thru exterior wall and fully engage Coupling (25) onto Operating

Nut of valve as shown in Fig. 4. Rotate and Orient Wall Post assembly until desired location of View Windows is obtained.

Align and level Operating Rod with valve Operating Nut then mark position of 4 wall mounting holes thru Flange (27).

3.6 Remove Wall Indicator Post assembly from the wall. Drill exterior wall as marked for appropriate size (customer supplied)

mounting bolts.

3.7 Reinstall Wall Indicator Post assembly onto wall making sure the Coupling (25) is fully engaged on Operating Nut of valve.

Secure Post assembly to wall with 4 bolts.

Table 2

WALL MOUNT STYLE INDICATOR POST PARTS LIST

NO. DESCRIPTION MATERIAL SPECIFICATION QTY.

1 UPPER BODY DUCTILE IRON ASTM A536 Gr. 65-45-12 1

2 CAP DUCTILE IRON ASTM A536 Gr. 65-45-12 1

3 T-HEAD BOLT, CAP STEEL, ZINC PLATED ASTM A105 2

4 NUT, CAP STEEL, ZINC PLATED ASTM A105 2

5 OPERATING STEM BRONZE ASTM B584 C84400 / B62 C83600 1

6 RETAING RING, STEM STAINLESS STEEL ASTM A276 S30400 1

7 LEADING BOGIE BRONZE ASTM B584 C84400 / B62 C83600 1

8 TARGET PLATE, OPEN ALUMINUM ASTM B26 2

9 TARGET PLATE, SHUT ALUMINUM ASTM B26 2

10 EXTENSION PLATE STEEL, PAINTED BLACK ASTM A1008 2

11 TARGET ROD BRASS ASTM B16 C36000 2

12 VIEW WINDOW POLYCARBONATE COMMERCIAL 2

13 GASKET, WINDOW RUBBER ASTM D2000 EPDM 2

14 GUARD, WINDOW CAST IRON ASTM B124 Gr. B 2

15 HANDWHEEL DUCTILE IRON ASTM A536 Gr. 65-45-12 1

16 EYEBOLT, HANDWHEEL FORGED STEEL, ZINC PL. ASTM A105 1

17 WASHER, H.W. RETAINER STEEL, ZINC PLATED COMMERCIAL 1

19 SCREW, HEX HEAD CAP STAINLESS STEEL S30400 4

20 WASHER STAINLESS STEEL S30400 4

21 SCREW, SLOTTED FLAT HD. STAINLESS STEEL S30400 4

22 PLUG, 1/2" PIPE STEEL, ZINC PLATED COMMERCIAL 1

23 U-BOLT FORGED STEEL ASTM A105 1

24 COTTER PIN STAINLESS STEEL S30400 1

25 COUPLING, OPERATING ROD DUCTILE IRON ASTM A536 Gr. 65-45-12 1

26 OPERATING ROD STEEL ASTM A105 1

27 FLANGE, THREADED DUCTILE IRON ASTM A536 Gr. 65-45-12 1

37 SCREW, SOCKET HD. SET STAINLESS STEEL S30400 6

Fig. 2

AHEAD OF THE FLOW®

www.nibco.com

NIBCO INC. WORLD HEADQUARTERS • 1516 MIDDLEBURY ST. • ELKHART, IN 46516-4740 • USA • PH: 1.800.234.0227

TECH SERVICES PH: 1.888.446.4226 • FAX: 1.888.234.0557 • INTERNATIONAL OFFICE PH: +1.574.295.3327 • FAX: +1.574.295.3455

www.nibco.com

4

®

Fig. 3

Fig. 4

INSTALLATION LAYOUT

AHEAD OF THE FLOW®

www.nibco.com

NIBCO INC. WORLD HEADQUARTERS • 1516 MIDDLEBURY ST. • ELKHART, IN 46516-4740 • USA • PH: 1.800.234.0227

TECH SERVICES PH: 1.888.446.4226 • FAX: 1.888.234.0557 • INTERNATIONAL OFFICE PH: +1.574.295.3327 • FAX: +1.574.295.3455

www.nibco.com

5

®

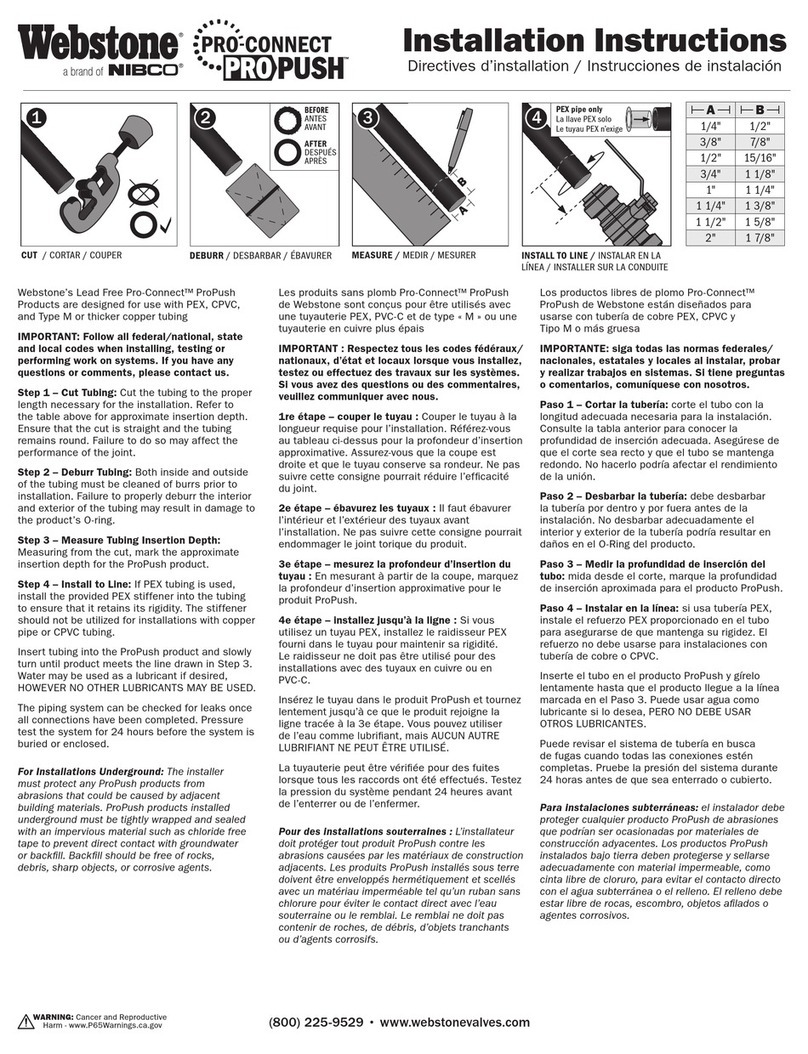

4. OPEN and SHUT Target Adjustment

4.1 All NIBCO Indicator Posts are shipped for use with “left-hand” (counter-clockwise) opening valves.

4.2 Remove 2 Nuts (4) and 2 T-Head Bolts (3) that secure Cap (2) to Indicator Post. See Fig. 2.

4.3 Grasp Cap (2) and remove from Indicator Post by lifting upward until Target assembly is clear.

4.4 Target Plates (8 & 9) must be positioned with the OPEN Plate (8) above the SHUT Plate (9) for “left-hand” (counter-clockwise)

opening valves. See Fig. 5.

TARGET ASSEMBLY PARTS LIST

NO. DESCRIPTION MATERIAL SPECIFICATION QTY.

7 LEADING BOGIE BRONZE ASTM B584 C84400 / B62 C83600 1

8 TARGET PLATE, OPEN ALUMINUM ASTM B26 2

9 TARGET PLATE, SHUT ALUMINUM ASTM B26 2

10 EXTENSION PLATE STEEL, PAINTED BLACK ASTM A1008 2

11 TARGET ROD BRASS ASTM B16 C36000 2

21 SCREW, SLOTTED FLAT HD. STAINLESS STEEL S30400 4

37 SCREW, SOCKET HD. SET STAINLESS STEEL S30400 6

Table 3

Fig. 5

NOTE: Only half of

assembly is shown

AHEAD OF THE FLOW®

www.nibco.com

NIBCO INC. WORLD HEADQUARTERS • 1516 MIDDLEBURY ST. • ELKHART, IN 46516-4740 • USA • PH: 1.800.234.0227

TECH SERVICES PH: 1.888.446.4226 • FAX: 1.888.234.0557 • INTERNATIONAL OFFICE PH: +1.574.295.3327 • FAX: +1.574.295.3455

www.nibco.com

6

®

4.5 Position OPEN Target Plates (8) so they are in the full upward position for “left-hand” (counter-clockwise) opening valves.

Secure OPEN Target Plates (8) by tightening Screws (37a). See Fig. 6.

4.6 Determine the number of turns required to fully open the valve. See Table 1 for NIBCO valves. You should always confirm

actual turns required to open the valve by counting them.

4.7 Using Table 6, choose the closest “Number of Turns to Open Valve” and the corresponding “Distance Between Targets”

dimension “X”.

4.8 Measure and position both SHUT Target Plates (9) at dimension “X” from OPEN Target Plates (8). See Fig. 6.

4.9 Secure both SHUT Target Plates (9) by tightening Screws (37a) with an Allen wrench.

NUMBER

OF TURNS

TO OPEN

VALVE

DISTANCE

BETWEEN TARGETS

X

INCH MM

10 0.000 0.0

11 0.050 1.3

12 0.150 3.8

13 0.250 6.4

14 0.350 8.9

15 0.450 11.4

16 0.550 14.0

17 0.650 16.5

18 0.750 19.1

19 0.850 21.6

20 0.950 24.1

21 1.050 26.7

22 1.150 29.2

23 1.250 31.8

NUMBER

OF TURNS

TO OPEN

VALVE

DISTANCE

BETWEEN TARGETS

X

INCH MM

24 1.350 34.3

25 1.450 36.8

26 1.550 39.4

27 1.650 41.9

28 1.750 44.5

29 1.850 47.0

30 1.950 49.5

31 2.050 52.1

32 2.150 54.6

33 2.250 57.2

34 2.350 59.7

35 2.450 62.2

36 2.550 64.8

37 2.650 67.3

NUMBER

OF TURNS

TO OPEN

VALVE

DISTANCE

BETWEEN TARGETS

X

INCH MM

38 2.750 69.9

39 2.850 72.4

40 2.950 74.9

41 3.050 77.5

42 3.150 80.0

43 3.250 82.6

44 3.350 85.1

45 3.450 87.6

46 3.550 90.2

47 3.650 92.7

48 3.750 95.3

49 3.850 97.8

50 3.950 100.3

51 4.050 102.9

ADJUSTMENT OF TARGET PLATES

Table 4

AHEAD OF THE FLOW®

www.nibco.com

NIBCO INC. WORLD HEADQUARTERS • 1516 MIDDLEBURY ST. • ELKHART, IN 46516-4740 • USA • PH: 1.800.234.0227

TECH SERVICES PH: 1.888.446.4226 • FAX: 1.888.234.0557 • INTERNATIONAL OFFICE PH: +1.574.295.3327 • FAX: +1.574.295.3455

www.nibco.com

7

®

POSITIONING OF OPEN TARGET PLATES FOR VIEW WINDOW

STANDARD TARGET

LOCATION FOR “LEFT-HAND”

(COUNTER-CLOCKWISE)

OPENING VALVES

Fig. 6 Fig. 7

6. Positioning of Targets in View Window

6.1 Rotate Square Operating Stem (5) positioning the center of the OPEN Target Plate (8) until it is located 6¾” from the inside lip

of Cap (2). See Fig. 7.

6.2 Verify that the valve is in full OPEN position.

6.3 Reinstall the Cap (2) & Target assembly into the Upper Body (1) making sure both alignment ears on bronze Leading Boogie

(7) straddle the guides cast on the inside of the Upper Body. See Fig. 2.

6.4 Reinstall 2 T-Head Bolts (3) in Cap and secure with 2 Nuts (4).

6.5 Check to assure that the OPEN Target Plate (8) is centered in both sides of the view window.

AHEAD OF THE FLOW®

www.nibco.com

NIBCO INC. WORLD HEADQUARTERS • 1516 MIDDLEBURY ST. • ELKHART, IN 46516-4740 • USA • PH: 1.800.234.0227

TECH SERVICES PH: 1.888.446.4226 • FAX: 1.888.234.0557 • INTERNATIONAL OFFICE PH: +1.574.295.3327 • FAX: +1.574.295.3455

www.nibco.com

8

®

NO. DESCRIPTION PART NO.

3T-HEAD BOLT NP1AU10

12 VIEW WINDOW NP1AU06

13 WINDOW GASKET NP1AU09

14 WINDOW GUARD NP1AU07

15 HANDWHEEL NP2AW31

NO. DESCRIPTION PART NO.

24 COTTER PIN NP1AU21

25 OPERATING ROD COUPLING NP1AU22

26 OPERATING ROD 36" NP2AW16

26 OPERATING ROD 72" NP1AU16

26 OPERATING ROD 90" NP1AU16E

REPAIR PARTS WALL MOUNT STYLE

Table 5

7. Operation

7.1 The post indicator valve (PIV) can be opened or shut by rotating Handwheel (15) in the desired direction. To open the valve,

turn in the counter-clockwise direction as indicated on Cap (2). To shut the valve, turn in the clockwise direction. See Fig. 2.

7.2 The Target Plates (8) (9) can be visually checked in the view windows to determine if PIV is open or shut.

7.3 After installation, the PIV should be cycled to the full shut position and both view windows should be visually inspected to

assure the SHUT target plates are centered. The PIV should then be cycled to the full open position and both view windows

should be visually inspected to assure the OPEN target plates are centered.

7.4 Valve position can be secured by placing a customer supplied chain through U-bolt (23), and Handwheel (15). A customer

supplied lock can be installed into the chain and U-bolt securing Handwheel, preventing valve operation.

7.5 NIBCO Indicator Posts have provisions to add a Security Wire thru the Cap T-bolts (3) and Operating Stem (5) to prevent valve

operation.

8. Maintenance

8.1 Lubrication should be added to oil hole located in top of Operating Stem (5) on an annual basis. Note: it is necessary to

remove Eyebolt (16), Washer (17), and Handwheel (15) to expose the oil hole.

8.2 Periodic visual inspection is recommended.

8.3 Exercising (cycling) of the valve to assure proper function is recommended.

9. Repair Parts

9.1 Some specialty components are available for replacement if needed. See Table 5.

9.2 Common fasteners such as nuts, bolts, and washers are available at your local hardware.

Table of contents

Other Nibco Control Unit manuals

Nibco

Nibco Pressystem User manual

Nibco

Nibco T-103-HC Product manual

Nibco

Nibco T-413-B Product manual

Nibco

Nibco Webstone Series User manual

Nibco

Nibco LD2000 Series Assembly instructions

Nibco

Nibco LD-1000 Series Product manual

Nibco

Nibco LD-7000 Series Guide

Nibco

Nibco Webstone Pro-Connect ProPush Series User manual

Popular Control Unit manuals by other brands

SIGMA TEK

SIGMA TEK MDD 111-2 instruction manual

Kromschroeder

Kromschroeder BCU 570 operating instructions

Fantini Cosmi

Fantini Cosmi ZD NA Series quick start guide

E-Tech

E-Tech DrivE-Tech 015 Installing and operating manual

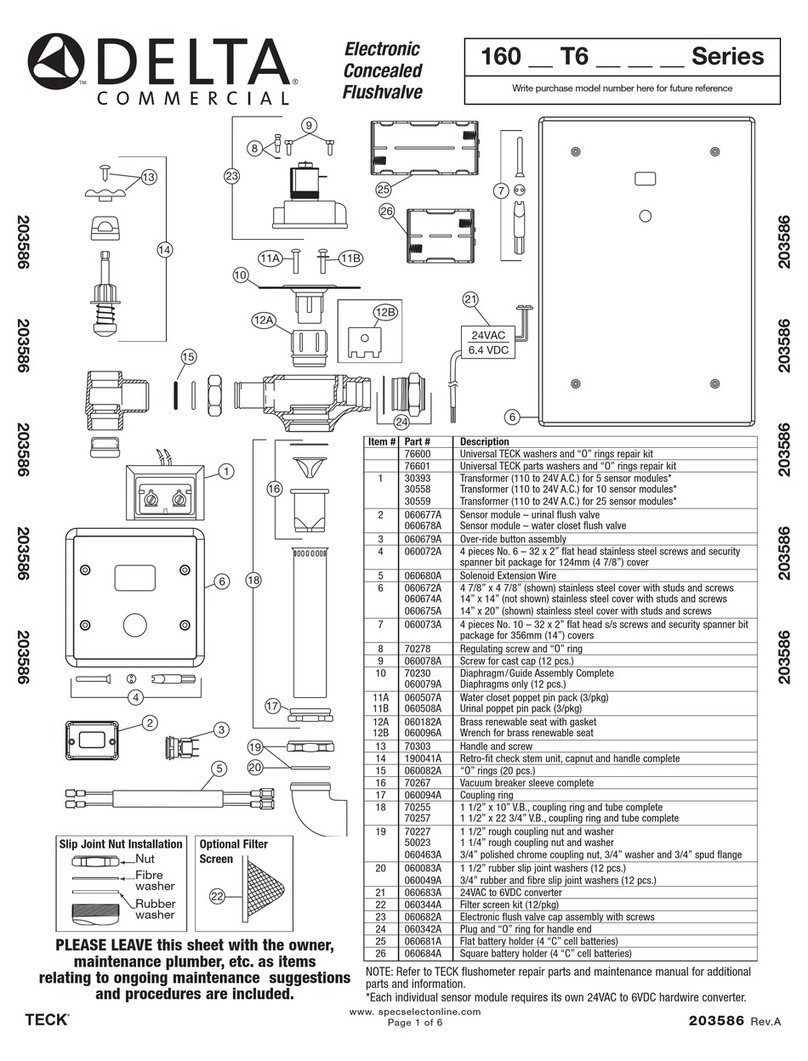

Delta

Delta 160 T6 Series installation instructions

Sferalabs

Sferalabs Exo Sense Pi user guide