8

3 About the product

3.1 General

The domestic hot water heat pump has been designed and produced according to all relevant

EU guidelines (please also refer to the EEC-declaration of conformity).

3.2 Scope of delivery

• Domestic hot water heat pump with built-in control.

• Manual including installation guidelines, operating instructions and technical data.

3.3 Product description

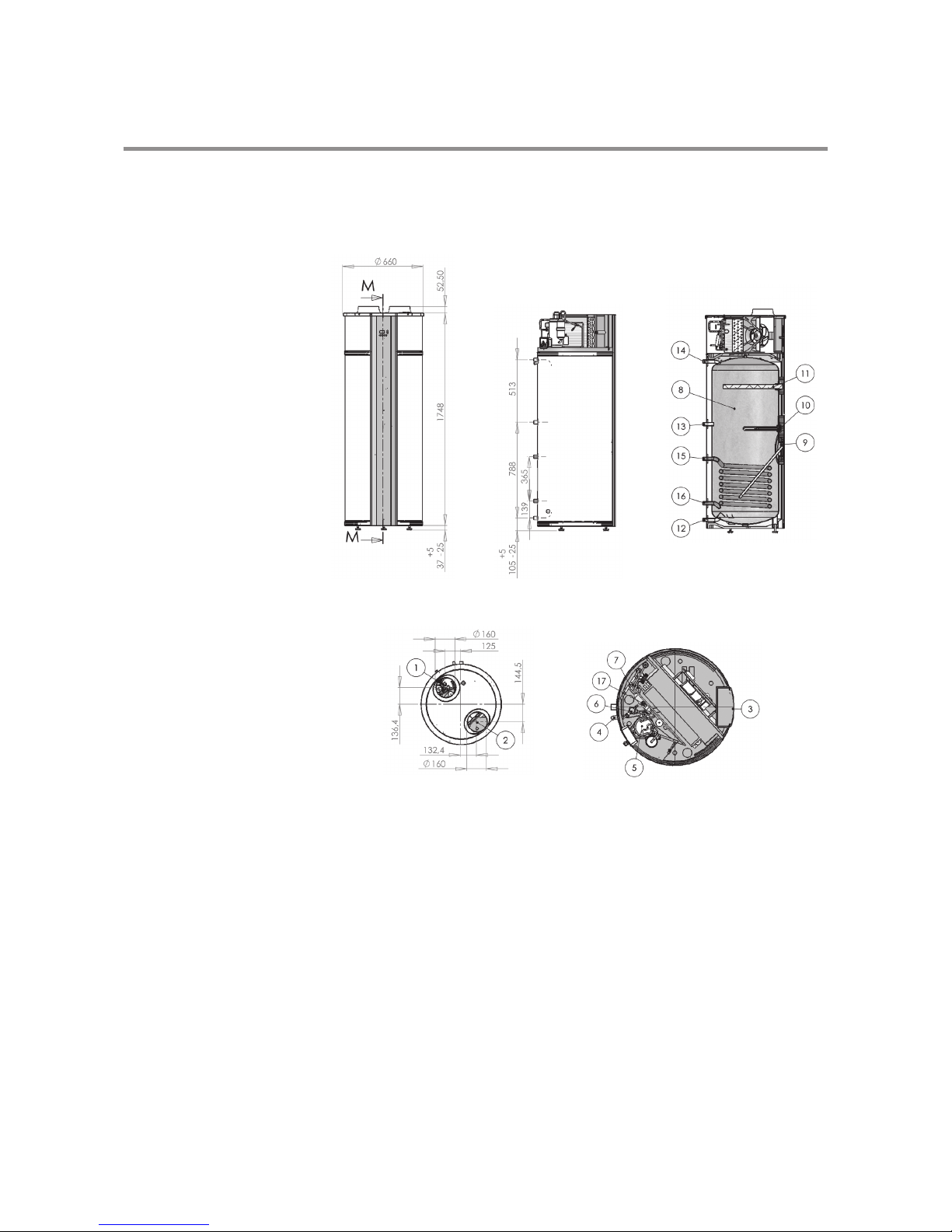

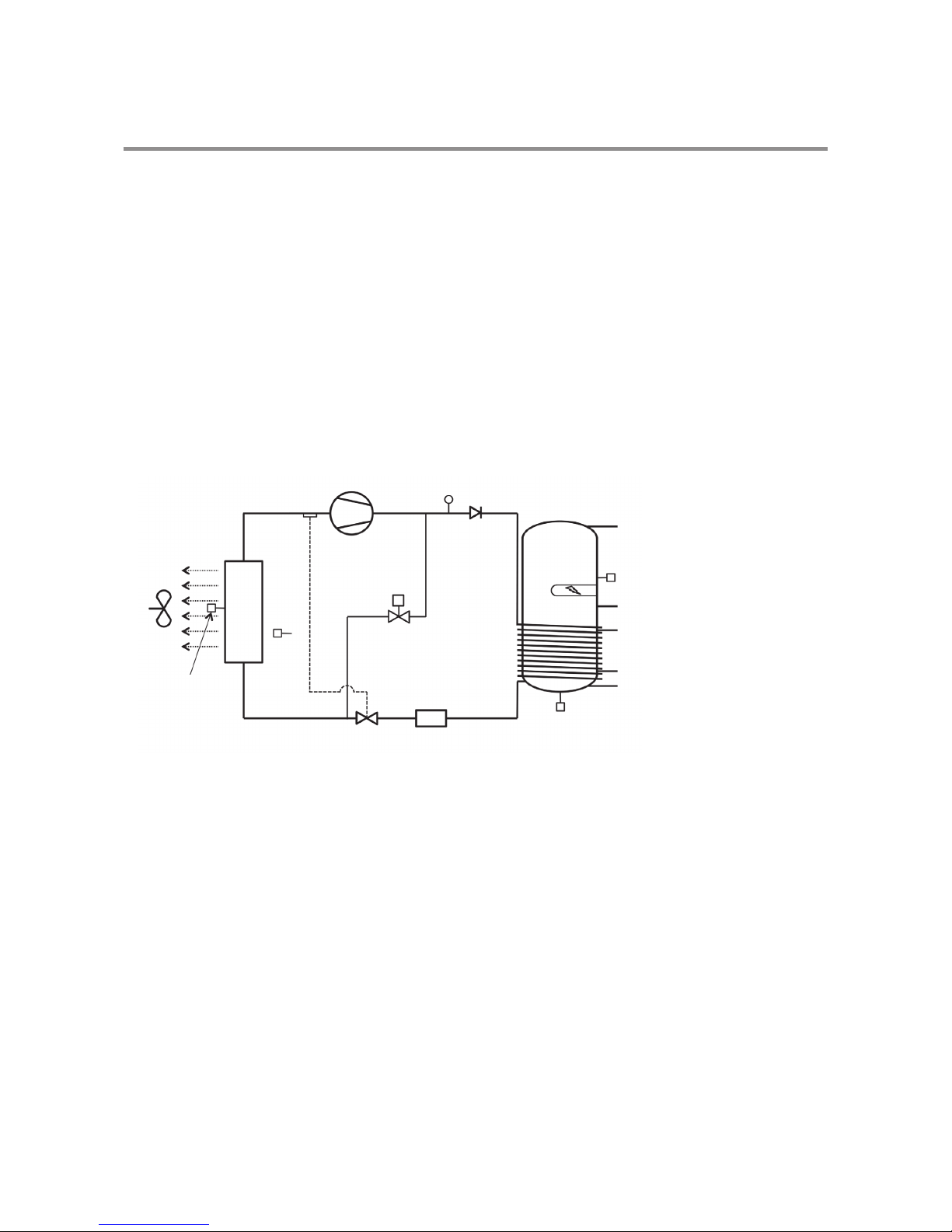

The NIBE MT-WH 2029-F/1FS is a domestic hot water heat pump, ready made for installation.

It consists of cabinet, components for refrigerant, air and water circuits as well as control panel,

and control and monitoring equipment designed for automatic operation.

The NIBE MT-WH 2029-F/1FS uses the heat from the extract air to produce hot water. At peak

times extra heat can be supplied through an integrated electrical immersion heater of 1.5 kW.

There is a sensor pocket in the water tank in which an external thermostat or sensor (diameter 6

mm) from an external control can be mounted.

The application area and operating principles of the heat pump are specified in this manual.

3.4 Operation of the NIBE MT-WH 2029-F/1FS

The control starts the compressor when hot water is needed. The compressor operates until the

water in the water tank reaches the set temperature. Usually, the NIBE MT-WH 2029-F/1FS can

produce enough hot water to cover the need of a household of 4 persons.

If the NIBE MT-WH 2029-F/1FS is not able to produce enough domestic hot water, an electrical

immersion heater integrated in the water tank can be activated.This way more domestic hot

water can be produced. It is possible to set the temperature to which the electrical immersion

heater should heat the water. The electrical immersion heater should only be used when there is

a need, as it consumes significantly more energy that the compressor.

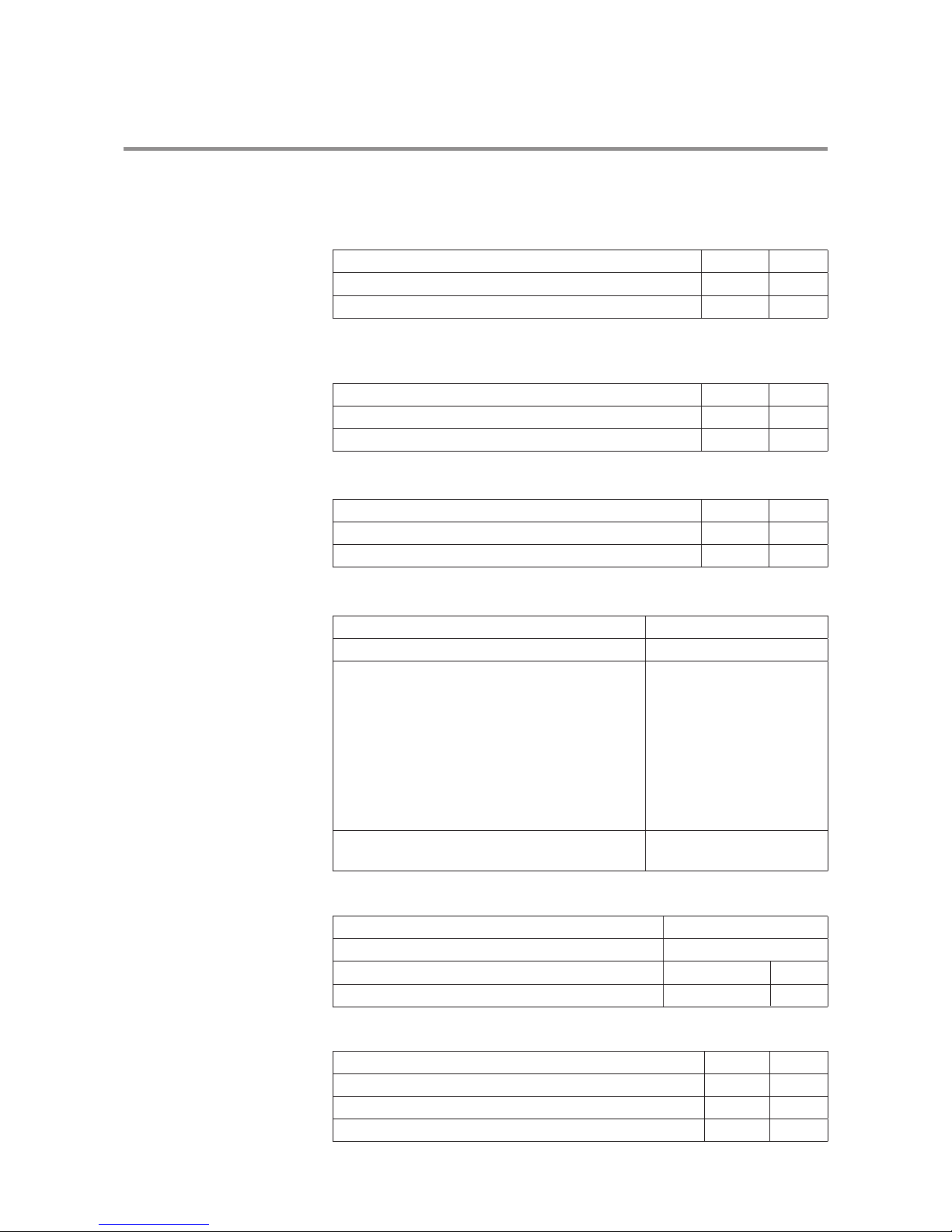

3.5 Technical data

Domestic hot water heat pump NIBE MT-WH 2029-F/1FS

Diameter without pipe connections mm Ø660

Height mm 1837

Weight without water, F/1FS kg 120/126

Electrical connections V/Hz 230/50 (L1, N, G)

Fuse size A13 (10)

Refrigerant / quantity -/kg R134a /1.1

Ingress Protection rating -IP 21

Electrical immersion heater (supplementary heat) kW 1.5

Any work carried out on

this unit must only be done by

skilled personnel.

Take all necessary precautions to

avoid accidents.