Nic Mercury/RH-PE User manual

Mercury collection-tube heating furnace

for the PE-1

Mercury/RH-PE

Instruction manual

NIC-600-2113-03

Nippon Instruments Corporation

Table of contents

RH-PE –Mercury collection-tube reheating furnace for the PE-1 i

No.600-2113-03

Mercury collection-tube reheating furnace for the PE-1:

“Mercury/RH-PE”

Instruction manual

Table of contents

1. Introduction.....................................................................................................................2

1.1. Safety precautions ..................................................................................................... 2

1.1.1. Safety symbols ....................................................................................................2

1.1.2. Installation precautions ........................................................................................2

1.1.3. Servicing precautions ..........................................................................................2

1.2. Equipment overview...................................................................................................3

2. Principles.........................................................................................................................4

2.1. Operation ................................................................................................................... 4

2.2. Description of each component.................................................................................. 5

2.2.1. RH-PE .................................................................................................................5

3. Specifications .................................................................................................................7

3.1. Equipment specifications............................................................................................ 7

4. Installing the equipment.................................................................................................7

4.1. Installation conditions ................................................................................................. 7

4.1.1. Installation environment....................................................................................... 7

4.2. Installation/connection................................................................................................ 7

5. Measurement...................................................................................................................8

5.1. Measuring operation flow chart .................................................................................. 8

5.2. Measurement necessities........................................................................................... 9

5.3. Preparation for measurement.....................................................................................9

5.3.1. Startup .................................................................................................................9

5.3.2. Starting the software in Windows......................................................................... 9

5.4. Measurement ........................................................................................................... 10

5.4.1. Setting measurement mode............................................................................... 10

5.4.2. Setting the tabulation conditions........................................................................ 11

5.4.3. Preparing the calibration curve .......................................................................... 12

5.4.4. Measuring the content of mercury collection tube ............................................. 14

5.4.5. Measurement sequence .................................................................................... 16

5.4.6. Measurement interruption.................................................................................. 16

6. Maintenance..................................................................................................................16

6.1. Criteria for judging equipment failure and troubleshooting ....................................... 16

6.1.1. Degradation of peak sensitivity.......................................................................... 17

6.1.2. Standard gas measurement is not reproducible. ............................................... 18

6.1.3. Abnormal blank value ........................................................................................ 19

6.2. Carrying out maintenance ........................................................................................ 20

6.2.1. Checking for leakage ......................................................................................... 20

6.2.2. Washing the coupling, joint, and gas washing bottle ......................................... 20

7. Contact ..........................................................................................................................21

1. Introduction

2Mercury/RH-PE ‒Mercury collection-tube reheating furnace for the PE-1

No.600-2113-03

1. Introduction

1.1. Safety precautions

1.1.1. Safety symbols

Warning

Denotes that incorrect handling may pose a specific potential hazard,

resulting in serious injury or death to the operator.

Caution

Denotes that incorrect handling may pose a specific potential hazard,

resulting in minor or moderate injury to the operator and/or damage to

property.

1.1.2. Installation precautions

Warning

Ensure the ground wire is connected so as to prevent electric shocks.

1.1.3. Servicing precautions

Warning

Before servicing, disconnect the power supply or electric shock may occur.

Caution

Before servicing the heater section turn off the power switch and wait until the

heater has cooled down to approximately room temperature. Failure to observe

this could result in being burnt.

Be careful when working with the equipment and touching any parts made of

glass. Failure to observe this may result in damage occurring.

Only qualified persons should change the calibration curves. Using the wrong

calibration curve will result in incorrect results being obtained.

1. Introduction

RH-PE –Mercury collection-tube reheating furnace for the PE-1 3

No.600-2113-03

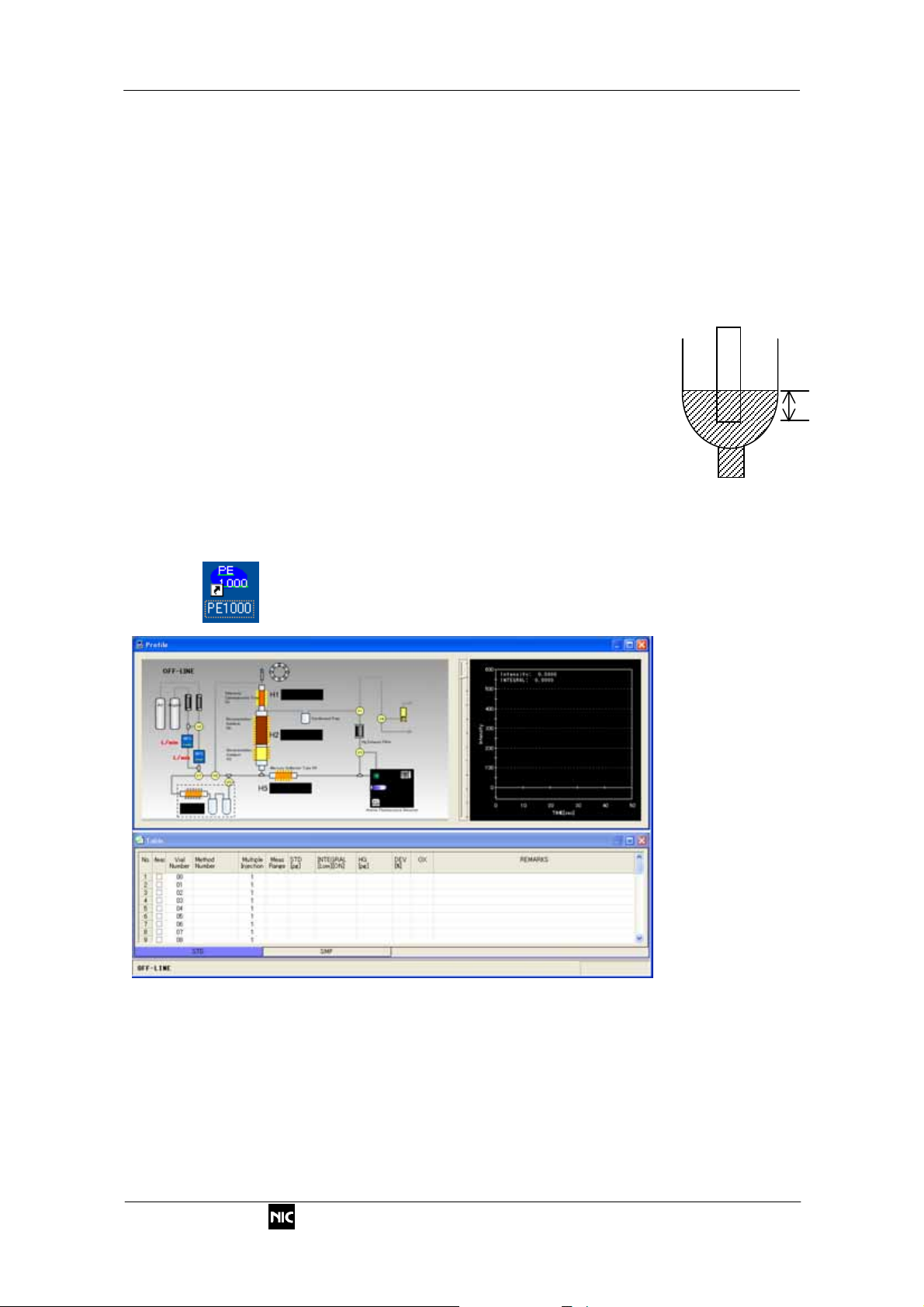

1.2. Equipment overview

The Mercury/RH-PE, the mercury collection-tube heating furnace for the PE-1, is an

optional device for measuring mercury in the 160L mercury collection tube collected from

LPG, natural gas, the air, etc. with the PE-1.

In order to fully utilize the capabilities of the equipment ensure you thoroughly read this

instruction manual prior to use.

Fig. 1: RH-PE

2. Principles

4Mercury/RH-PE ‒Mercury collection-tube reheating furnace for the PE-1

No.600-2113-03

2. Principles

2.1. Operation

This equipment is completely controlled from the PE-1. Selecting “RH” as the method,

inserting the mercury collection tube—which separately collects mercury—into the heater,

and then commencing measurement automatically switches the pathway with a solenoid

valve built in the PE-1. Heating the heater releases mercury from the mercury collection

tube, and then the gas is washed in the gas washing bottle, dehumidified in the

dehumidifying bottle, and then transferred to the PE-1. The mercury collection section in

the PE-1 is heated to release and atomize the mercury again and then detected using the

atomic fluorescence spectroscopy at a wavelength of 253.7 nm in the fluorescence cell of

the detector.

Fig. 2: Flow chart

Cooling fan

Electronic cooler

Heater

From PE-1

To PE-1

Mercury collection tube

Carrier gas

Dehumidifying bottle

Gas washing bottle

2. Principles

RH-PE –Mercury collection-tube reheating furnace for the PE-1 5

No.600-2113-03

2.2. Description of each component

2.2.1. RH-PE

Fig. 3: Inside the RH-PE with the cover open

Fig. 4: Rear view of the RH-PE

l

11

e

f

k

g

d

c

h

j

i

2. Principles

6Mercury/RH-PE ‒Mercury collection-tube reheating furnace for the PE-1

No.600-2113-03

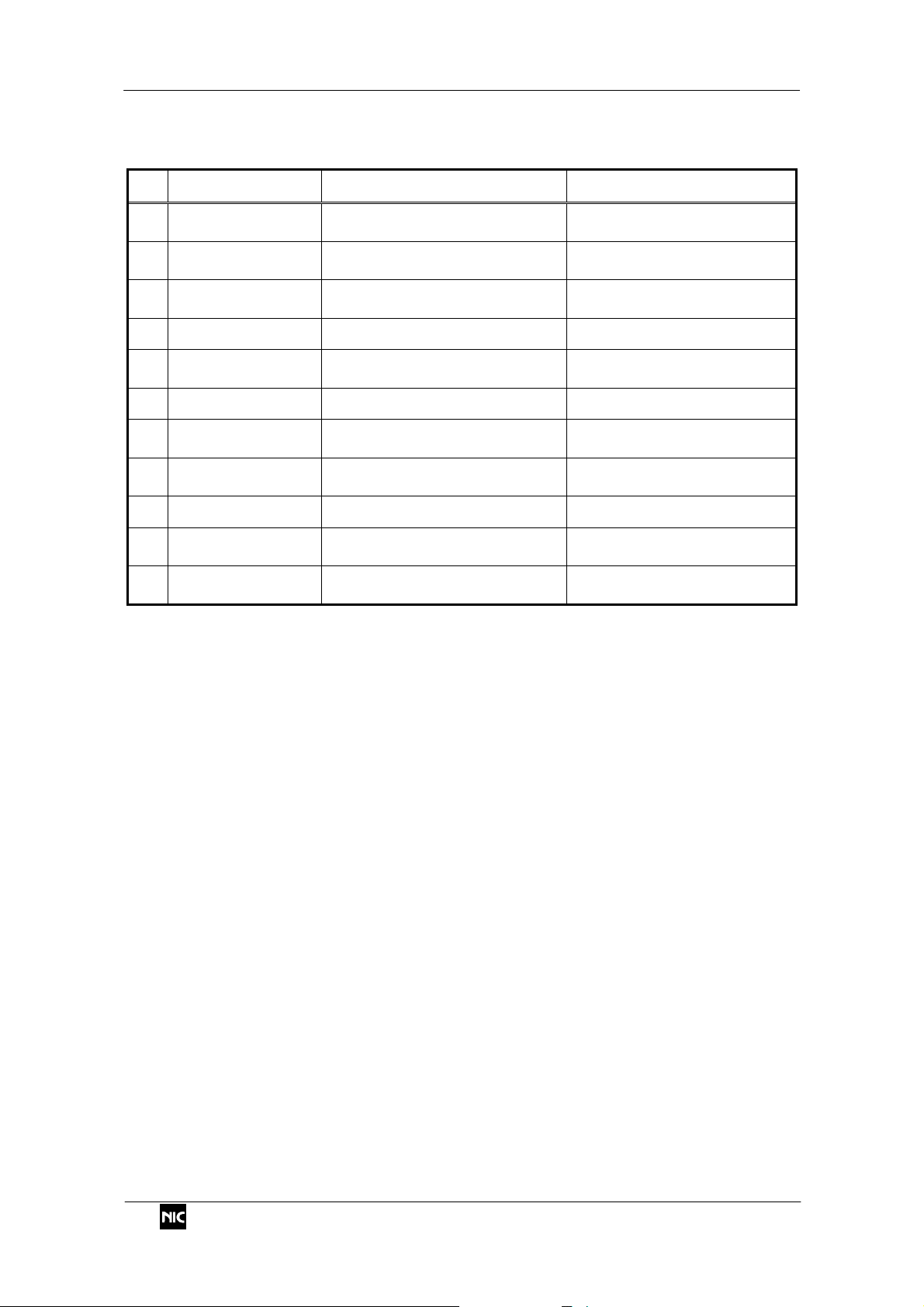

Table 1: Description of each part of the RH-PE

No. Name Function Remarks

1 Joint with a

septum

A septum for injecting the

standard gas is built in.

Carrier gas is supplied from

the PE-1.

2 Mercury collection

tube

Mercury collection tube whose

content is to be measured

3 Heater Heater for heating the mercury

collection tube

4 Rubber coupling

5 Gas washing bottle Removes moisture, tar, acid

gas, etc.

Approximately 2 cm of

(1+1)buffer solution of pH 7

6 Roller clamp

7 Dehumidifying

bottle Removes moisture

8 Electronic cooler Cools the gas washing bottle

and dehumidifying bottle

Cools down with an electronic

cooling device

9 Elbow joint

10 AC INLET Power connector with a power

switch A 5A fuse is built in.

11 PE-1 connection

terminal Terminal for PE-1 connection This terminal connects to the

PE-1 with a special cable.

3. Specifications

RH-PE –Mercury collection-tube reheating furnace for the PE-1 7

No.600-2113-03

3. Specifications

3.1. Equipment specifications

Carrier gas :Purified dry air (supplied from the PE-1)

Samples :160L mercury collection tube

Dimensions and weight :150 W x 177 D x 350 H mm, 6 kg

Power voltage :Single phase 100 to 260 VAC, 50/60 Hz (3-pin socket)

Power capacity :0.3 kVA

Power quality :No surges, harmonics, noise, etc.

4. Installing the equipment

4.1. Installation conditions

4.1.1. Installation environment

Room temperature :15°C to 35°C

Vibration :Avoid any vibrations that the human body can strongly

sense.

Dust and dirt :Maintain a clean atmosphere without any smoke, dust, or

other factors that can adversely affect measurements.

Please also refrain from smoking anywhere near.

Installation space :A minimum area of 1,000 mm wide x 800 mm deep is

necessary. Ensure a firm foundation (without any wobble)

capable of bearing approximately 60 kg.

Others :Avoid direct exposure to sunlight and air from air

conditioners, fans, etc.

Special notes :Never place the equipment anywhere volatile

halogen-based reagents such as organochlorine solvents

are used. In addition, avoid anywhere such gases may be

present.

4.2. Installation/connection

(1) Place the RH-PE to the left of the PE-1.

(2) Connect the supplied signal cable between the PE-1 and RH-PE.

(3) Connect the power cable to the RH-PE.

(4) Connect the supplied Teflon tubes (one yellow tube and one transparent tube) between the

PE-1 and RH-PE.

Yellow Teflon tube

transparent Teflon tube

5. Measurement

8Mercury/RH-PE ‒Mercury collection-tube reheating furnace for the PE-1

No.600-2113-03

5. Measurement

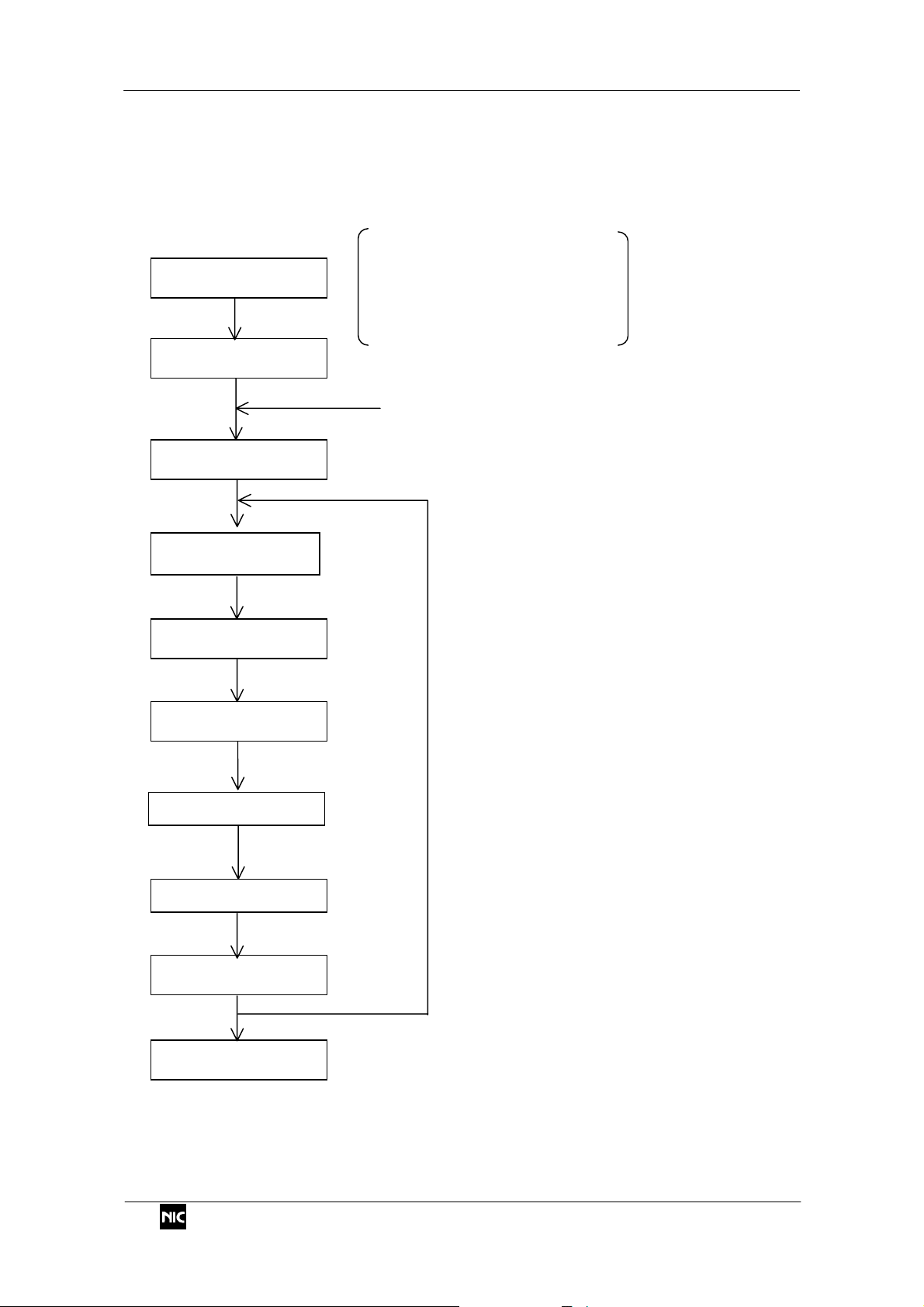

5.1. Measuring operation flow chart

Loop

Set the mercury collection

tube

Measuring section: PE-1

Sample changer: HT-300A

Personal computer

Reheating furnace: RH-PE

POWER ON

Optical system stabilizes

Input of measurement

conditions

Measurement starts

Heating of the mercury

collection tube

Measurement

Cooling

Termination

Injection of gas washing solution

Purge with argon gas

5. Measurement

RH-PE –Mercury collection-tube reheating furnace for the PE-1 9

No.600-2113-03

5.2. Measurement necessities

(1) Standard buffer solution of pH 6.86

(2) Mercury standard gas box MB-1 (for calibration)

5.3. Preparation for measurement

5.3.1. Startup

(1) Turn on the POWER switches of the PE-1,

the PC, and the RH-PE.

(2) Open both the roller clamps for the gas

washing bottle and the dehumidifying bottle,

and pour the standard buffer solution of pH

6.86 (1+1) and distilled water into the gas

washing bottle at a ratio of 1:1.

Ensure the gas washing solution level is

approximately 20 mm above the air outlet.

(3) Close both the roller clamps for the gas

washing bottle and the dehumidifying bottle.

5.3.2. Starting the software in Windows

Click the icon on the desktop to start the PC software (PE1000Win).

The message "STAND-BY xx:xx" appears at the upper left of the screen for 20 minutes

while the optical system and the temperature of heaters stabilizes.

20mm

Fig. 6: Gas washing solution level

5. Measurement

10 Mercury/RH-PE ‒Mercury collection-tube reheating furnace for the PE-1

No.600-2113-03

5.4. Measurement

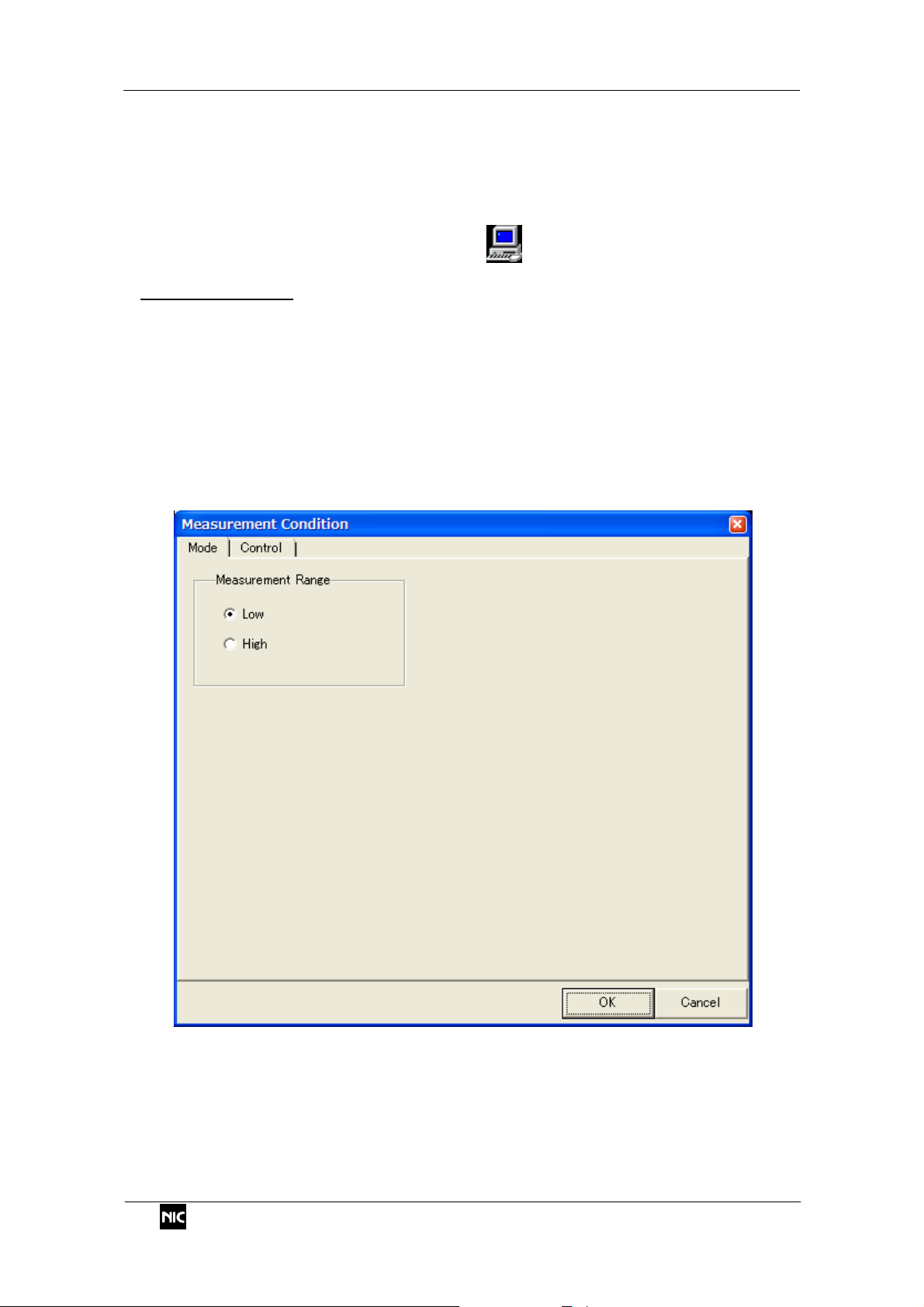

5.4.1. Setting measurement mode

Select [Run]-[Mode] from the menu, or click the icon to set the measurement mode.

Measurement mode

Set the heating speed of the mercury collection section for measurement in accordance

with the weight of the mercury.

A guideline for that is as follows:

LOW: 0 to 10 ng (Low concentration)

The heater H5 of the mercury collection section heats up at full power, and the

mercury gas is quickly discharged into the fluorescence cell.

HIGH: 0 to 100 ng

The heater H5 of the mercury collection section slowly heats up, and the mercury gas

is gradually discharged into the fluorescence cell.

5. Measurement

RH-PE –Mercury collection-tube reheating furnace for the PE-1 11

No.600-2113-03

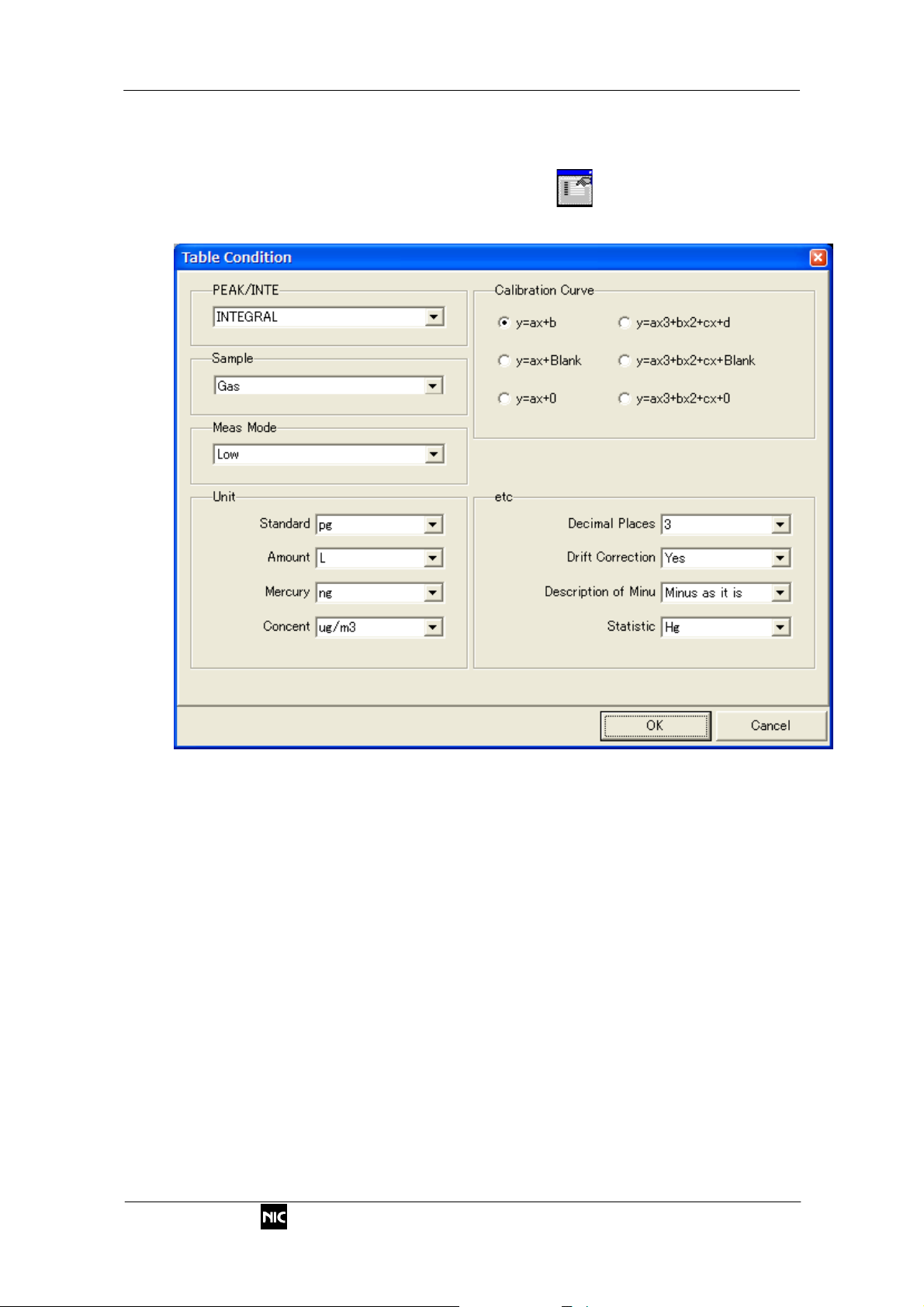

5.4.2. Setting the tabulation conditions

Select [File]-[Table Condition] from the menu, or click the icon to set tabulation

settings.

5. Measurement

12 Mercury/RH-PE ‒Mercury collection-tube reheating furnace for the PE-1

No.600-2113-03

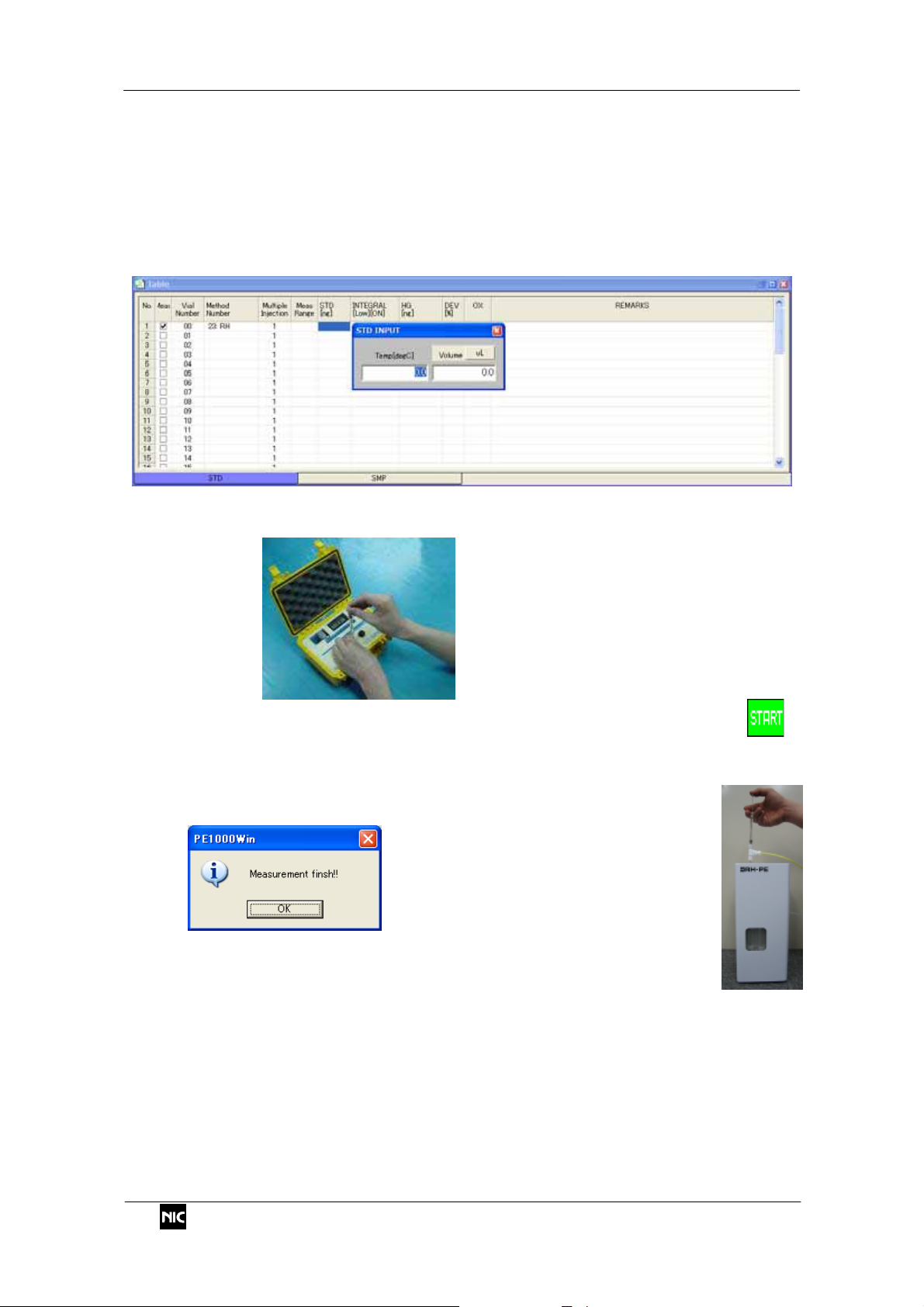

5.4.3. Preparing the calibration curve

(1) The settings for the standard sample are made in the Table window. Check the

“Meas” (measurement) field, and select “23:RH” in the “Method Number” field.

(2) Click the “STD” (standard value) field, and enter the temperature indicated by the

thermometer on the standard gas box and then also enter the amount to be

extracted. The mercury weight is then automatically calculated and entered.

(3) Extract gas from the standard gas box with a syringe. Move the piston up and down

several times to ensure smooth movement, and then extract the required amount of

gas.

(4) To commence measurement, select [Run]-[Start] from the menu, or click the

icon.

Alternatively, press F5 on the keyboard to start measurement.

(5) Inject the extracted gas through the septum in one stroke.

(6) The following message appears when the measurement is complete.

(7) To continue measurement, return to step (2) and repeat the procedure

as necessary.

5. Measurement

RH-PE –Mercury collection-tube reheating furnace for the PE-1 13

No.600-2113-03

(8) The calibration curve is automatically updated on completion of measurement.

Whether the sample is used for the calibration curve is specified in the “{X” field.

The type of calibration curve etc can be changed in the tabulation conditions

settings.

5. Measurement

14 Mercury/RH-PE ‒Mercury collection-tube reheating furnace for the PE-1

No.600-2113-03

5.4.4. Measuring the content of mercury collection tube

(1) Make the setting for an unknown sample in the Table window. Check the “Meas” field,

and select “23:RH” in the “Method Number” field.

(2) Insert the mercury collection tube to be measured into the coupling from the top of the

RH-PE in such a way that its narrow section is pointed downward (is on the lower end).

(3) Connect the joint with the septum to the upper end of the mercury collection tube

(4) To commence measurement, select [Run]-[Start] from the menu, or click the

icon.

Alternatively, press F5 on the keyboard to start measurement.

(5) The following message appears when measurement is complete.

Remove the joint with the septum from the measured mercury collection tube, and pull

it out of the RH-PE.

(6) To continue measurement, return to step (1) and repeat the procedure as necessary.

Gas flow

Narrow

section

5. Measurement

RH-PE –Mercury collection-tube reheating furnace for the PE-1 15

No.600-2113-03

(7) Entering the amount of the collected sample into the “SVOL [L]” (sample volume) field

after measurement automatically calculates the concentration.

The units used in the Table window can be changed in the tabulation conditions setting.

5. Measurement

16 Mercury/RH-PE ‒Mercury collection-tube reheating furnace for the PE-1

No.600-2113-03

5.4.5. Measurement sequence

To commence measurement, select [Run]-[Start] from the menu, or click the icon.

Alternatively, press F5 on the keyboard to start measurement.

The measurement sequence proceeds as follows:

Operation Status name Period

1 Heating of the

collection tube SAMPLE 120 seconds

2 Ar substitution 1 PURGE1 30 seconds

3 Ar substitution 2 PURGE2 30 seconds

4 Ar substitution 3 PURGE3 10 seconds

5 Ar substitution 4 PURGE4 30 seconds

6 Measurement MEASURE Period specified in the measurement parameter

7 Cooling COOL 30 seconds

5.4.6. Measurement interruption

To interrupt the measurement, select [Run]-[Stop] from the menu or click the icon.

Clicking the icon terminates operation on completion of the current measurement.

Clicking the icon immediately starts the cooling process, and the equipment

returns to READY status when cooling has completed.

6. Maintenance

6.1. Criteria for judging equipment failure and troubleshooting

Listed below are criteria for judging whether the equipment is operating properly or not.

(If the equipment does not satisfy any of these criteria, take the appropriate measures

given in "Troubleshooting" described in Sections 6.2.1 to 6.2.3.)

(1) A blank value should be low (0.01 ng or less). →6.1.3

(2) After a standard mercury gas is measured, the blank value should not significantly

increase. (As a guide it should be approximately 1% or less of the mercury measured

right before.) →6.1.3

(3) When a standard mercury gas is repeatedly measured its reproducibility should be

within ±3%. →6.1.2

(4) A calibration curve drawn using a standard mercury gas should be linear with a

variation of ±5% or less. →6.1.2

(5) When a calibration curve is drawn for a low mercury weight region (1 ng or less), the

y-intercept of the curve should not be negative. →6.1.1

(6) When a standard sample is measured before and after measurement for the collection

tube, the difference between the measured values should be within the measurement

error. →6.1.1

(7) The intensity of fluorescence should be at least 70% of that at the time of delivery.

→6.1.1

6. Maintenance

RH-PE –Mercury collection-tube reheating furnace for the PE-1 17

No.600-2113-03

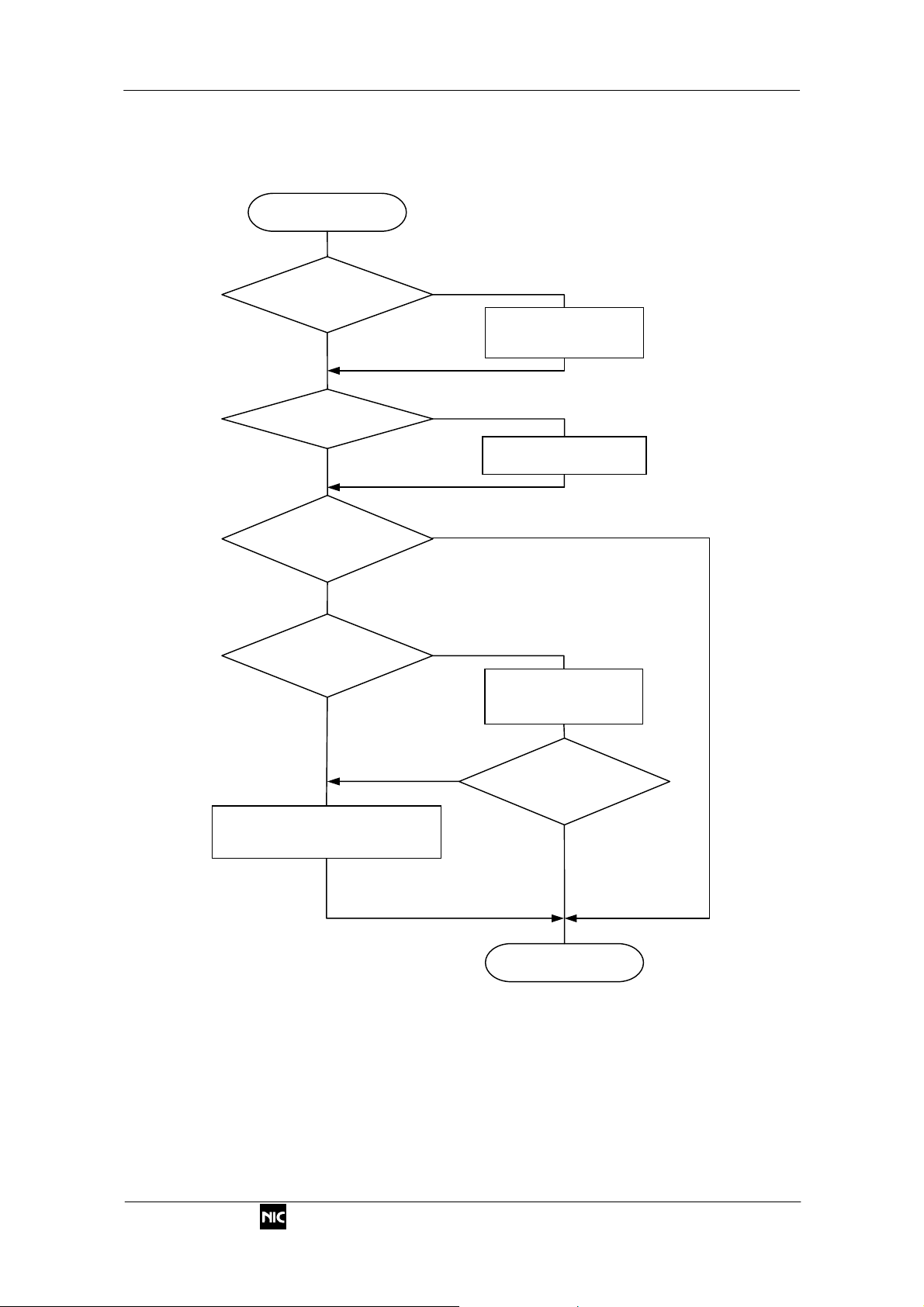

6.1.1. Degradation of peak sensitivity

Peak sensitivity has decreased or lost.

Is any carrier gas

leaking?

Has a heater cable

broken?

Has peak

sensitivity

recovered?

Has trapping

occurred in the

system?

Locate the leak and

repair it.

Replace the relevant

heater.

Has peak

sensitivity

recovered?

Wash the gas washing

bottle and the

dehumidifying bottle.

START

END

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

Carry out maintenance of the PE-1.

Wash or replace the V5, joint, Teflon

tubes, or H5 collection tube.

6.Maintenance

18 Mercury/RH-PE ‒Mercury collection-tube reheating furnace for the PE-1

No.600-2113-03

6.1.2. Standard gas measurement is not reproducible.

Is standard sample

measurement

reproducible?

Is the syringe

defective? (Leaks,

needle clogging, or

contamination)

Is the septum

contaminated?

Is any carrier gas

leaking?

Locate the leak and

repair it.

Replace the syringe.

START

END

YES

NO

YES

NO

YES

YES

Replace the septum.

Is standard sample

measurement

reproducible?

YES

Wash the gas washing

bottle, dehumidifying bottle,

joint, and coupling.

Carry out maintenance of the PE-1.

Wash or replace the V5, joint, Teflon

tubes, or H5 collection tube.

NO

NO

NO

Table of contents

Other Nic Laboratory Equipment manuals