Nic MA-3000 User manual

Mercury Collection Tube Heating Furnace Unit

for MA-3000

RH-MA3

Instruction Manual

NIC-600-2208-04

Nippon Instruments Corporation

Instruction Manual MA-3000+RH-MA3 NIC-600-2208-04

Instruction Manual

Mercury Collection Tube Heating Furnace Unit

RH-MA3

Contents

1. INTRODUCTION............................................................................................................. 1

1.1. Safety precautions................................................................................................... 1

1.1.1. Meaning of safety alert symbols....................................................................... 1

1.1.2. Installation precautions..................................................................................... 1

1.1.3. Precautions with maintenance ......................................................................... 1

2. SYSTEM OUTLINE......................................................................................................... 2

2.1. Operation ................................................................................................................. 3

2.2. Part names and functions........................................................................................ 4

3. SPECIFICATIONS .......................................................................................................... 7

3.1. Equipment specifications......................................................................................... 7

3.2. Installation Environment........................................................................................... 7

4. EQUIPMENT INSTALLATION........................................................................................ 8

4.1. Equipment installation and connection.................................................................... 8

5. MEASUREMENT............................................................................................................ 9

5.1. Measurement Operation Flowchart......................................................................... 9

5.2. Equipment needed to make measurements.......................................................... 10

5.3. Preparing to make measurements......................................................................... 10

5.4. Measurement..........................................................................................................11

5.4.1. Setting the measuring conditions....................................................................11

5.4.2. Setting the table conditions ............................................................................ 12

5.4.3. Creating a calibration curve............................................................................ 13

5.4.4. Measuring an unknown sample (collection tube)........................................... 16

5.4.5. Interrupting the measurement........................................................................ 19

5.4.6. Terminating the measurement........................................................................ 19

6. MAINTENANCE............................................................................................................ 20

6.1. Inspection items..................................................................................................... 20

Instruction Manual MA-3000+RH-MA3 NIC-600-2208-04

6.1.1. Daily inspections............................................................................................. 20

6.1.2. Annual inspections ......................................................................................... 21

6.2. Failures during measurement................................................................................ 22

6.2.1. Reduced peak sensitivity................................................................................ 22

6.2.2. No standard gas repeatability......................................................................... 23

6.2.3. Incorrect blank values..................................................................................... 24

6.3. Parts replacement.................................................................................................. 25

6.3.1. Washing the coupling, joint, and gas scrubbing bottle................................... 25

6.3.2. Replacing the RH2 heater mercury collection tube........................................ 26

6.3.3. Regenerating collection tube 65L................................................................... 26

6.3.4. Fuse replacement........................................................................................... 27

6.3.5. Replacing the air pump (P2) tube................................................................... 28

7. CONTACT..................................................................................................................... 30

Instruction Manual MA-3000+RH-MA3 NIC-600-2208-04

1

1. Introduction

1.1. Safety precautions

1.1.1. Meaning of safety alert symbols

Warning

Indicates that incorrect handling could result in death or severe injury to

the operator.

Caution

Indicates that incorrect handling could pose a specific potential hazard

resulting in injury to the operator or damage to property.

1.1.2. Installation precautions

Warning

•Ensure to connect the earth wire in preventing electric shocks.

1.1.3. Precautions with maintenance

Warning

•Ensure to turn OFF the power supply before doing any maintenance or it could

result in an electric shock.

Caution

•Before doing maintenance work on the heater section ensure to turn off the

power switch and wait until the heater cools down to room temperature. Failure to

observe this could result in the operator suffering a burn.

•Exercise caution when handling any of the glass parts. Failure to observe this

could result in them being damaged.

•Do not turn on or off the power of the MA-3000 main unit while any buffer solution

is present. Failure to observe this could result in a backflow of the buffer solution,

thus disabling use of the collection tube.

Instruction Manual MA-3000+RH-MA3 NIC-600-2208-04

2

2. System Outline

The RH-MA3 is the collection tube heating furnace for use with the MA-3000, and an

optional unit for use in measuring any mercury collected by the MA-3000 in a 160L mercury

collection tube in LPG, natural gas or atmospheric air.

It is strongly recommended that this manual be carefully read before using the system in

thereby maximizing its potential performance.

This Instruction Manual covers the operation and maintenance of the RH-MA3.

Please read the MA-3000 Instruction Manual as well.

Instruction Manual MA-3000+RH-MA3 NIC-600-2208-04

3

2.1. Operation

The machine is fully controllable from the MA-3000. It introduces carrier gas into the

detection section via an optional pump located at the rear of the RH-MA3.

The machine heats the mercury collection tube with heater RH1 (H6) in thus liberating the

gas collected by the collector, and then removes any acidic gases via the gas scrubbing

bottle.Any excess moisture in the dehumidifying bottle is then removed, and any mercury

selectively re-collected and condensed in RH2 (H7). After collecting the mercury the

machine heats RH2 in thus liberating any mercury gas and introduces it into the detection

section before measuring its absorbance.

Cooling fan

Electronic cooler

T-joint with septum with collection tube 65L

Mercury collection tube

Carrier gas

Cooling fan

Heater

(RH2)

To MA-3000

Heater

(RH1)

Instruction Manual MA-3000+RH-MA3 NIC-600-2208-04

4

2.2. Part names and functions

Inside the RH-MA3 cover

No.

Name

Function

Remarks

1

T-joint

(with septum)

(Used to charge standard gas)

S1031-6103-11

2

Mercury collection

tube 160L

Tube used to collect mercury as the

measurement target

160 mm long

3

Heater (RH1)

Heater used to heat the mercury

collection tube (H6)

4

Union

FLW-30-6U-S

5

Gas scrubbing

bottle

Removal of acidic gases etc.

N-1062-0801-401

6

Roller clamp

IUC-56-655-02

7

Dehumidification

bottle

Water removal

N-1062-0801-401

8

Electronic cooler

Cools the gas scrubbing bottle and

dehumidifying bottle

9

Reducing elbow

FLW-30-6UE4-C

10

Collection tube 65L

Removes any mercury in the carrier

gas

S1016-3401-00

Instruction Manual MA-3000+RH-MA3 NIC-600-2208-04

5

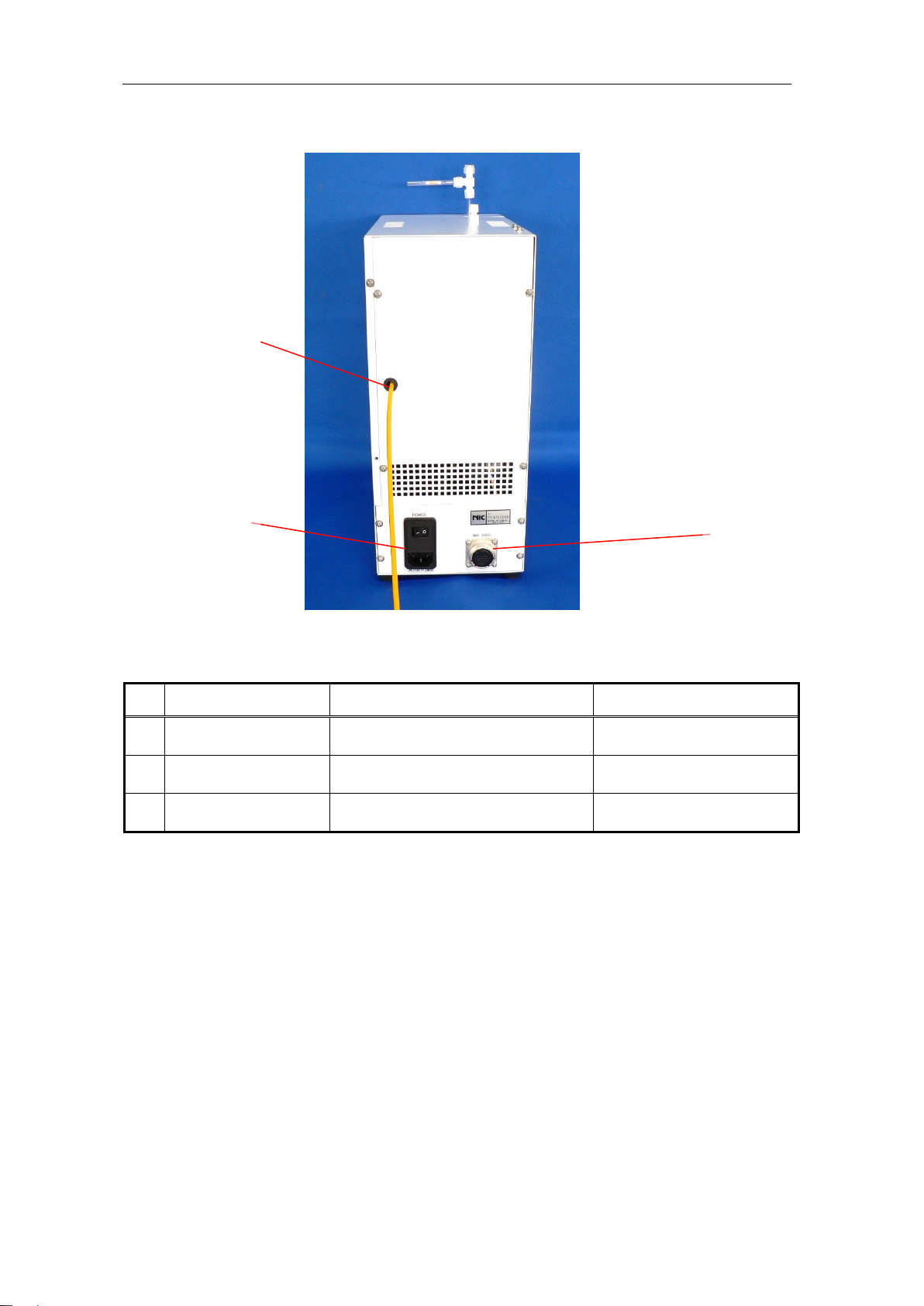

Rear of RH-MA3

No.

Name

Function

Remarks

11

Teflon pipe

(Φ4×Φ2)

Connects to the optional MA3

unit.

70 cm (standard)

12

AC INLET

Power supply port with power

switch

Includes built-in 4Afuse

13

MA-3000

connection terminal

Terminal for connection to

MA-3000

⑬

⑪

⑫

Instruction Manual MA-3000+RH-MA3 NIC-600-2208-04

6

Right side face of RH-MA3

No.

Name

Function

Remarks

14

Heater (RH2)

Heater used to heat the mercury

collection tube (H7)

15

Mercury collection

tube PE1

Recollects and condenses any mercury

L100mm

S1085-0820-00

16

Reducing union

Connection between collection tube and

Teflon tube

FLW-30-6RU4-S

⑭

⑮

⑯

Instruction Manual MA-3000+RH-MA3 NIC-600-2208-04

7

3. Specifications

3.1. Equipment specifications

Carrier gas:............................Indoor purified air

Sample:.................................160L mercury collection tube

Measurement range:.............0.01~1000ng

Dimensions and Weight:.......150W×280D×420mmH, 7kg

Source voltage:.....................Single-phase AC, 100 to 260V, 50/60Hz (3-pin socket)

Voltage source capacity:.......0.5kVA

Quality of power supply:........Should be free of any surges, harmonics, noise, etc.

3.2. Installation Environment

Room temperature:...............15 to 35°C

Vibration:...............................No vibrations strong enough to be felt by the human

body.

Dust and Fumes:...................Clean atmospheric environment free of fumes, dust, and

anything else that could affect the measurement. (No

smoking)

Installation space:..................1000W x 800D (mm) or larger with a rigid foundation and

capable of supporting a weight of about 60kg.

Other:.....................................Ensure to install the unit in a place out of direct sunlight

and not exposed to any air from air conditioners or

blowers.

Special notes:........................Ensure to not install the system in any place where

volatile halide reagents such as organic chlorine

solvents are handled. In addition, avoid installing it

anywhere those gases could be present.

Instruction Manual MA-3000+RH-MA3 NIC-600-2208-04

8

4. Equipment installation

4.1. Equipment installation and connection

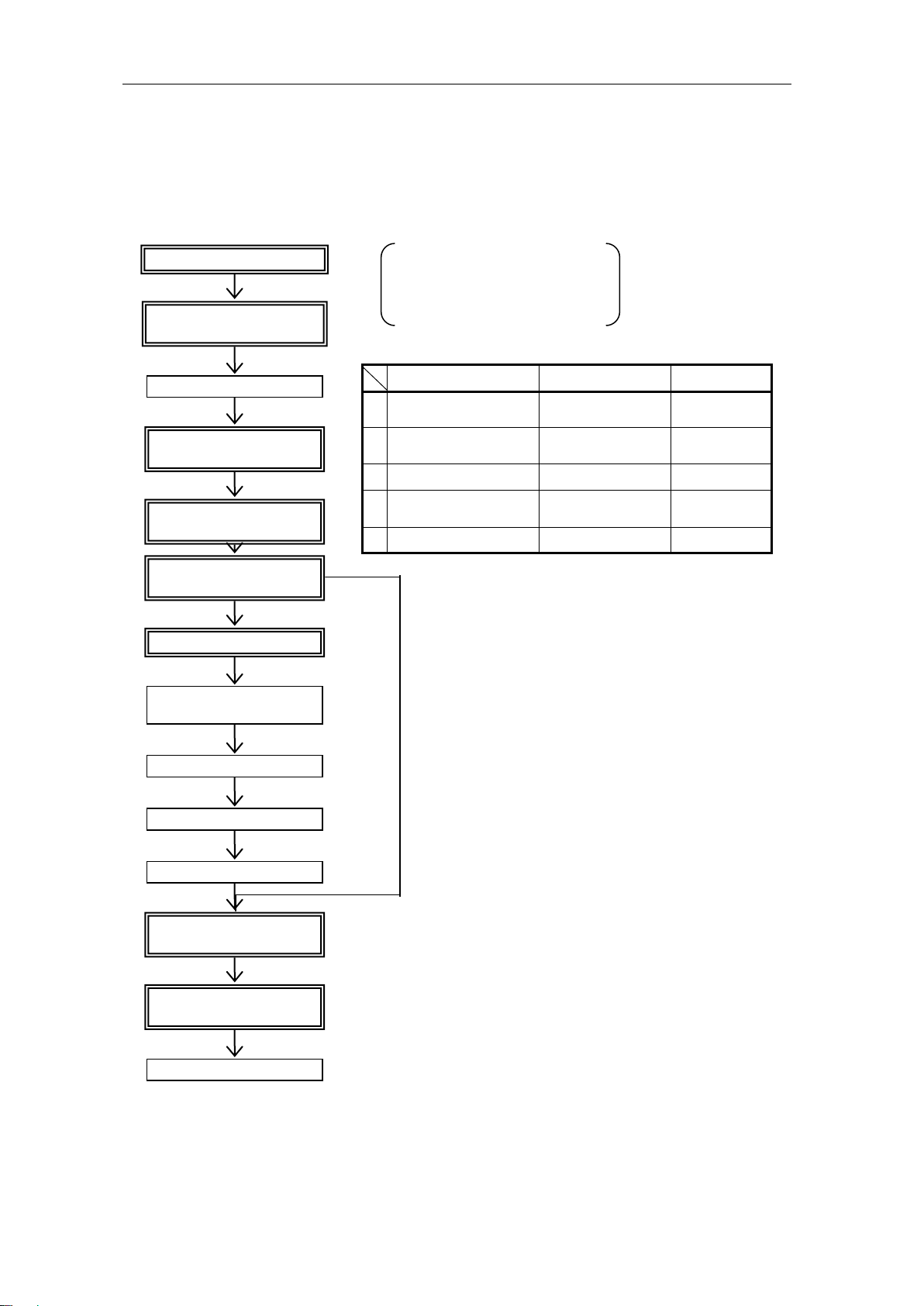

(1) Remove the right side plate by loosening the 2 screws at the rear.

(2) Draw the yellow tube through the hole into the back panel before connecting it

to the collection tube of the recollection furnace using the reducing Teflon joint

FLW-30-6RU4-S.

*Lightly tighten it by hand before retightening 1/6

turn with a spanner.

(3) Connect a Teflon tube between the gas scrubbing bottle and the collection tube.

(4) Connect the MA-3000 and the RH-MA3 with the attached interlock cable.

(5) Connect the power cord to the RH-MA3 before plugging it into a wall outlet.

(6) Connect the yellow Teflon tube of the RH-MA3 to the IN port of valve V4 of the

optional unit at the rear of the MA-3000.

* The joint at top of RH-MA3 is used only when the

optional reducing vaporization unit RD-5+SC-5 of

MA-3000 is connected at the same time.

Instruction Manual MA-3000+RH-MA3 NIC-600-2208-04

9

5. Measurement

5.1. Measurement Operation Flowchart

Start the equipment

Stabilize the optical unit

Input the measurement

conditions

Start measurement

Heat the mercury collection

tube

Measurement

Cooling

Repeat

Purge the carrier gas

Replace mercury collecting

tube

Set the measurement

method to "heating furnace"

Drain the gas scrubbing

solution

Charge the gas scrubbing

solution

Measuring section MA-3000

Personal computer

Collection tube heating furnace

RH-MA3

Operation

Status name

Time

1

Collection tube heating

RH1 ATOMIZE

240 seconds

(Default value)

2

Sample gas

replacement

PURGE1

30 seconds

3

Measurement

MEASURE

60 seconds

4

Equipment purging after

measurement

MEASURE PURGE

30 seconds

5

Cooling

COOL

30 seconds

Set the measurement

method to "HEATING"

End

Instruction Manual MA-3000+RH-MA3 NIC-600-2208-04

10

5.2. Equipment needed to make measurements

(1) pH = 6.86 standard buffer solution

(2) Mercury standard gas box (MB-1)

(3) Gas tight syringe

5.3. Preparing to make measurements

(1) Verify the gas scrubbing bottle of the RH-MA3 contains no solution.

Note) Do not turn on or off the power of the MA-3000 main unit while any gas

scrubbing solution is present.

Failure to observe this could result in a backflow of the gas scrubbing

solution, thus disabling use of the collection tube.

(2) Start the MA3win control software.

(3) Turn on both the power switches of the MA-3000 and the RH-MA3.

(4) Set the optional unit setting of MA-3Win to "RH".

Select "System" - "Setup" from

the menu bar to open the

window.

(5) Charge the gas scrubbing solution.

①Open the roller clamps of both the gas scrubbing bottle and

the dehumidifying bottle, and fill the gas scrubbing bottle

with pH=6.86 standard buffer solution and distilled water at

a ratio of 1:1.

②Ensure the amount of the gas scrubbing solution is at a level

of about 20 mm higher than the end of the air outlet.

③Close the roller clamps of both the gas scrubbing bottle and

the dehumidifying bottle.

20mm

Instruction Manual MA-3000+RH-MA3 NIC-600-2208-04

11

5.4. Measurement

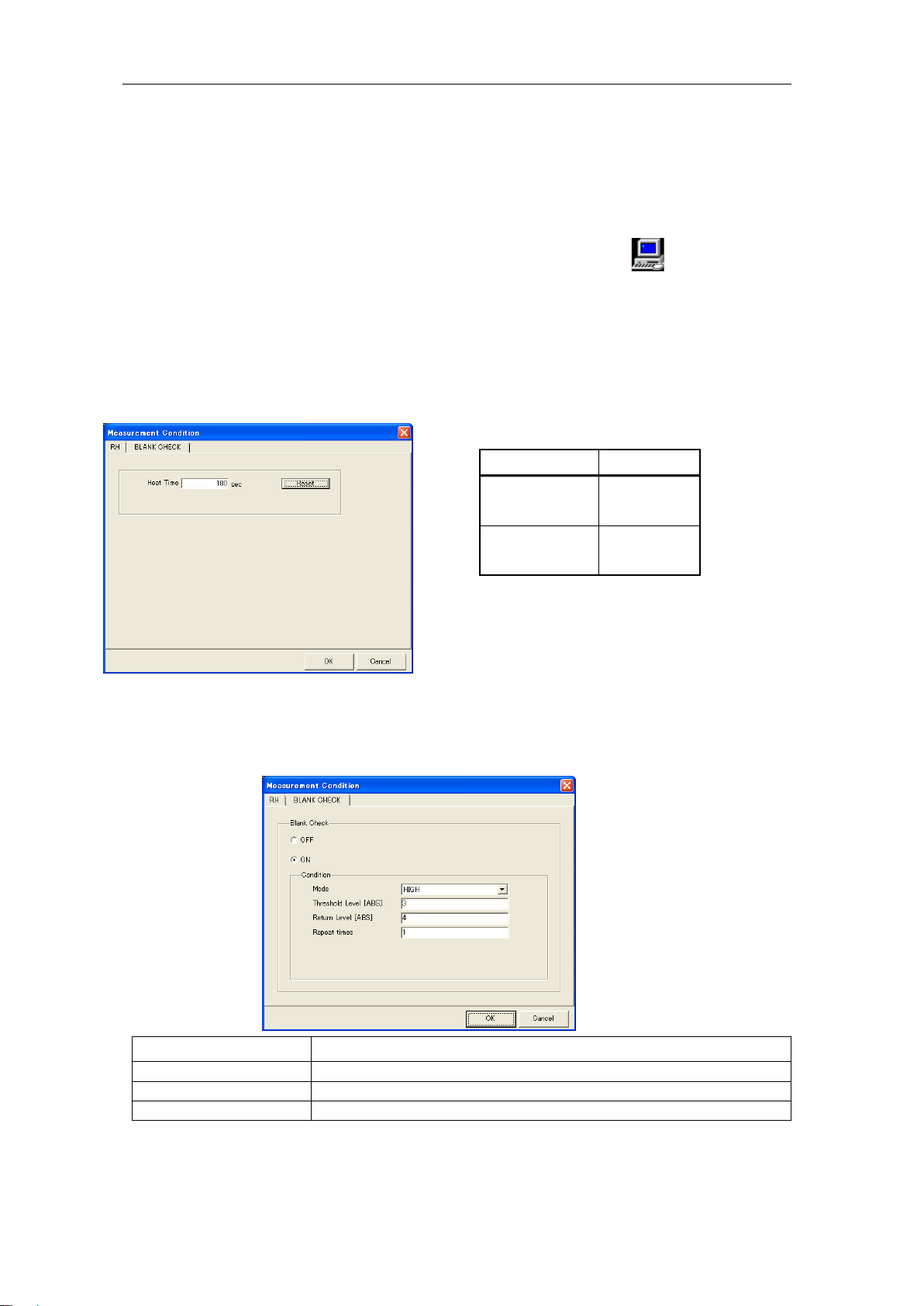

5.4.1. Setting the measuring conditions

Select “Run” - “Measurement Condition”from the menu or click the icon, and then

set the measuring conditions.

RH Heat Time

The time during which the heater (RH1) of the mercury collecting section will be

heated can be set. (Default value: 240 seconds)

If you measure the high concentration Hg, 240 seconds of RH Heat Time may not be

enough. Please extend the Heat Time.

BLANK CHECK

If an ABS higher than the setting is detected with the measurement of an unknown

sample, the measurement sequence is automatically executed again to reduce the

system blank.

Mode

Select whichABS: LOW or HIGH is used in the determination.

Threshold Value [ABS]

Executed if the measured value reaches a higher value.

Return Value [ABS]

Ends if the measured value reaches a lower value.

Repeat times

Max. 10

* Not executed when measuring standard samples.

Hg

Heat Time

~10ng

(LOW range)

240 sec

~1000ng

(HIGH range)

420 sec

Indication of Heat time

*If you measure the ambient air, 180

seconds of Heat Time is enough.

Instruction Manual MA-3000+RH-MA3 NIC-600-2208-04

12

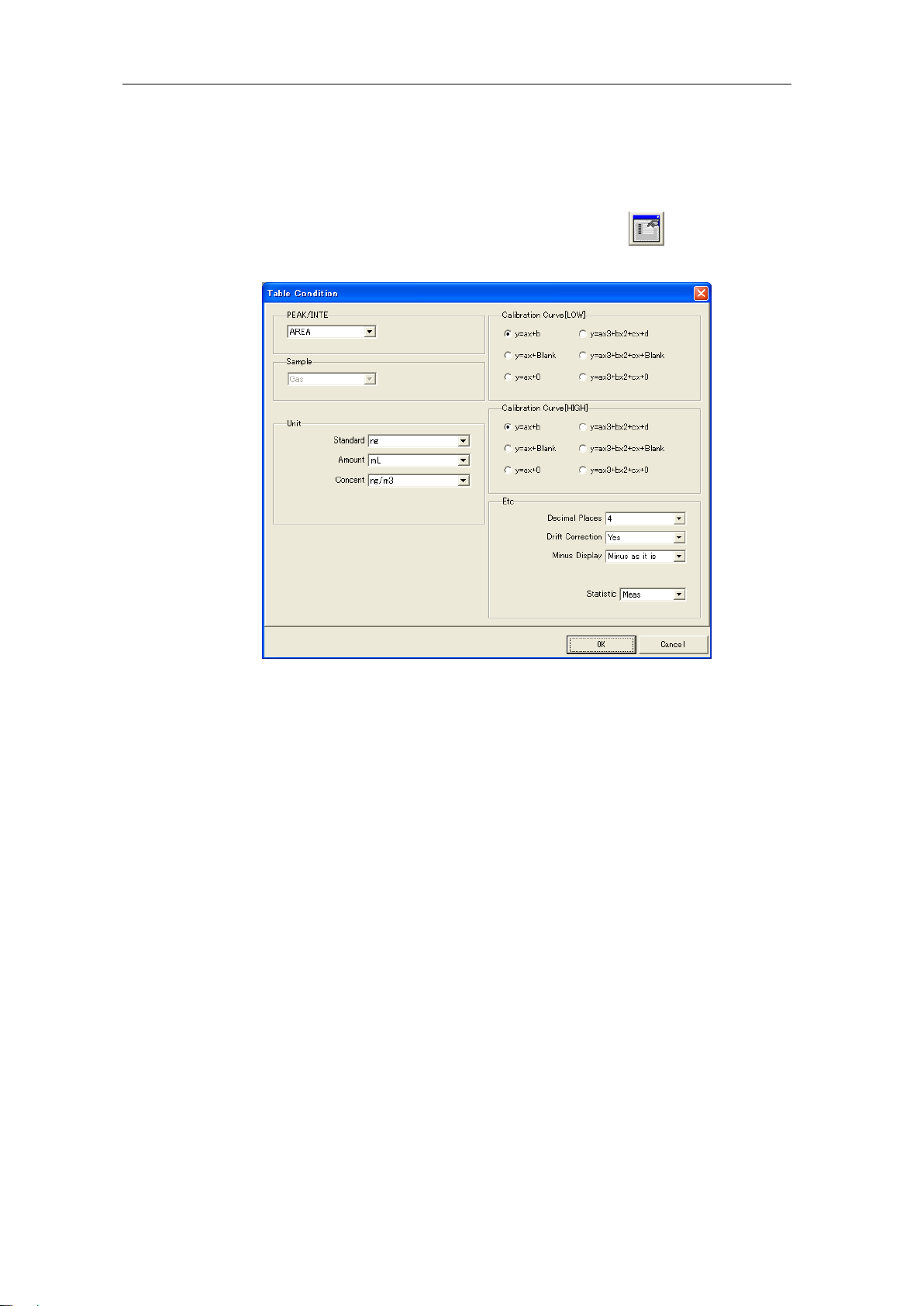

5.4.2. Setting the table conditions

Select “Run” - “Measurement Condition”from the menu or click the icon, and then

set the table conditions.

*Select the Calibration Curve according to the official method and the curve passing

through the blank (+Blank) with measurements of trace quantities of mercury close

to the blank value enable the best measurement results.

Instruction Manual MA-3000+RH-MA3 NIC-600-2208-04

13

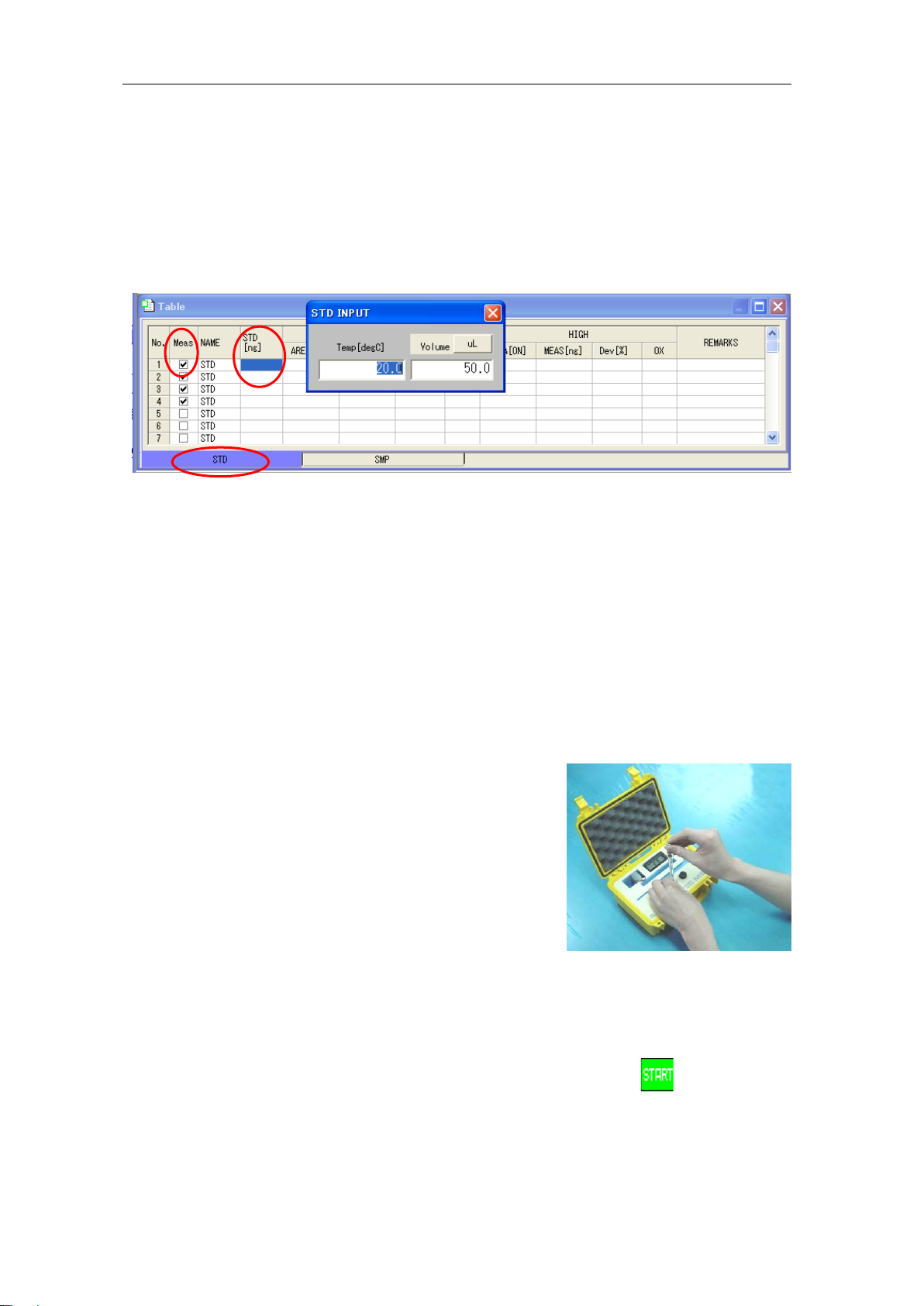

5.4.3. Creating a calibration curve

(1) Set the standard sample on the “Table” screen. Click the “STD” tag.

(2) Check the "Meas" field.

(3) Input a standard value.

Click the "STD" field to open the "STD INPUT" window. Input the thermometer

reading and volume of the sample of the standard gas box. The amount of mercury

will then be calculated automatically and input.

(The unit can be changed between "mL" and "uL" by clicking "uL" at the right of the

“Volume”field.)

* The initial blank measurements will result in high values. Make measurements

repeatedly before adopting a value after theABS has stabilized.

(4) Sample the gas from the standard gas box using a syringe. When sampling ensure

to move the piston up and down 2 or 3 times to ensure a good fit before collecting

the required amount of the sample.

* The temperature in the gas box not having stabilized will negatively affect the

reproducibility. Do not place the gas box anywhere exposed to airflow from an air

conditioner or other fans.

(5) Select “Run”- “Measurement start” from the menu or click the

icon to start the

measurement.

The measurement can also be started by pressing the F5 key on the keyboard.

(2)

(1)

(3)

Instruction Manual MA-3000+RH-MA3 NIC-600-2208-04

14

(6) Inject the sampled gas through the septum in one stroke.

* Injecting the gas before the start of

measurement will result in an incorrect

measurement.

(7) At the end of measurement the following message will display.

(8) After the measurement the calibration curve will be automatically updated.

The "OX" field can be used to select whether to adopt the calibration curve or not.

* In some cases the characters in the calibration curve

graph can turn red and "WARNING" display, as shown

in the left figure.

In this case the calibration curve will have fallen outside

the specified value range. Verify that there was no error

in the input of the amount of mercury or with the

equipment.

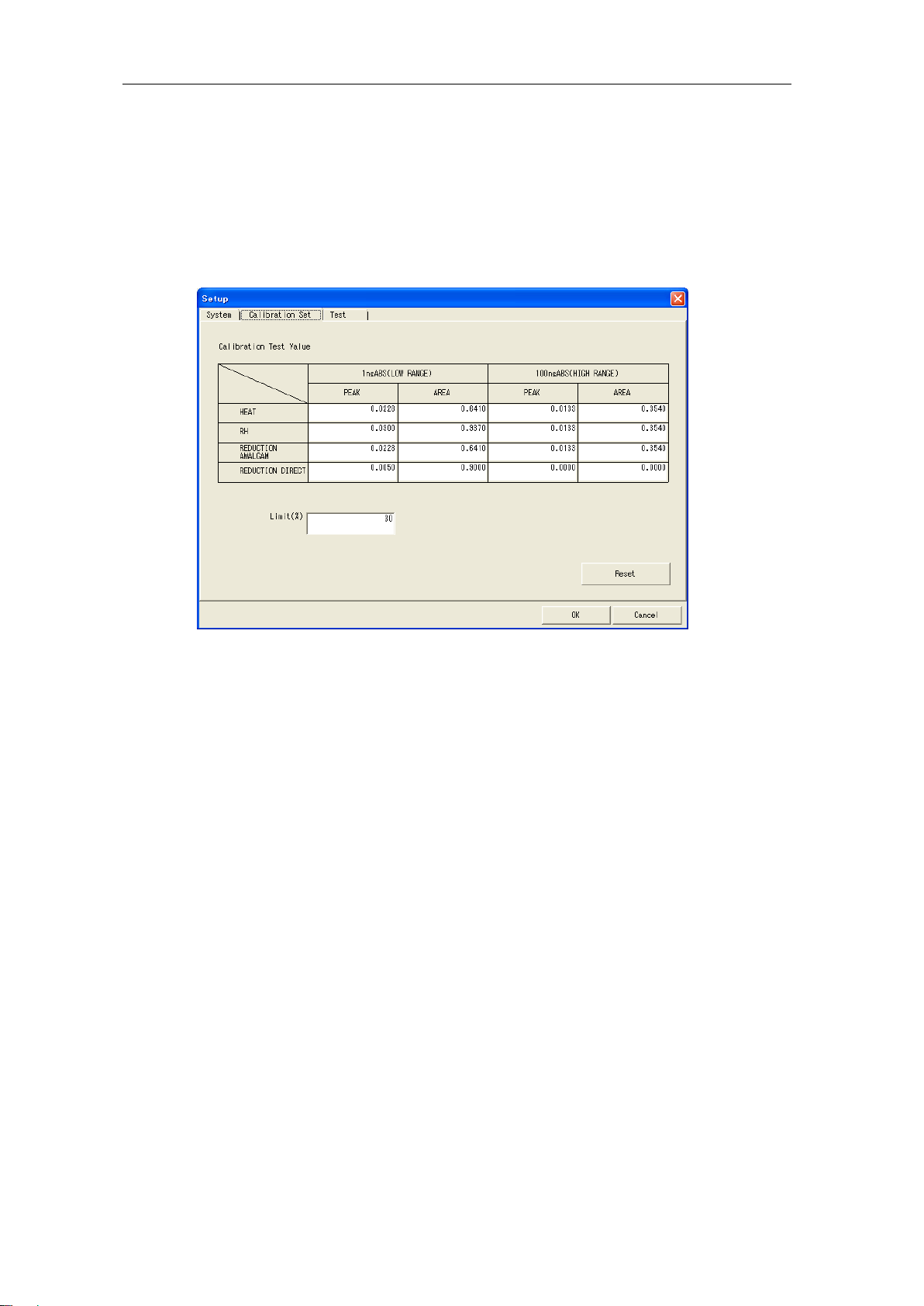

* The specified value can be changed from "Setup" -

"Calibration set".

(9) When measuring without interruption return to (2). Repeat the procedure the

required number of times.

Instruction Manual MA-3000+RH-MA3 NIC-600-2208-04

15

Setting the calibration curve

Set the accept/reject criteria for the calibration curve.

Calculate an ABS of 1ng or 100ng backward from the created calibration curve and

determine whether to accept or reject the calibration curve on the basis of the

deviation from the setting value.

ABS of Calibration Test Value

Reference values for PEAK and AREA for each measuring method and the medium

value of 1ng for a LOW range and 100ng for a HIGH range are installed.

Limit of Deviation between Values (%)

If the deviation between the value from the backward calculation and the setting value

falls out of this range, the arithmetic expression of the calibration curve will turn red

and a warning will be displayed.

Instruction Manual MA-3000+RH-MA3 NIC-600-2208-04

16

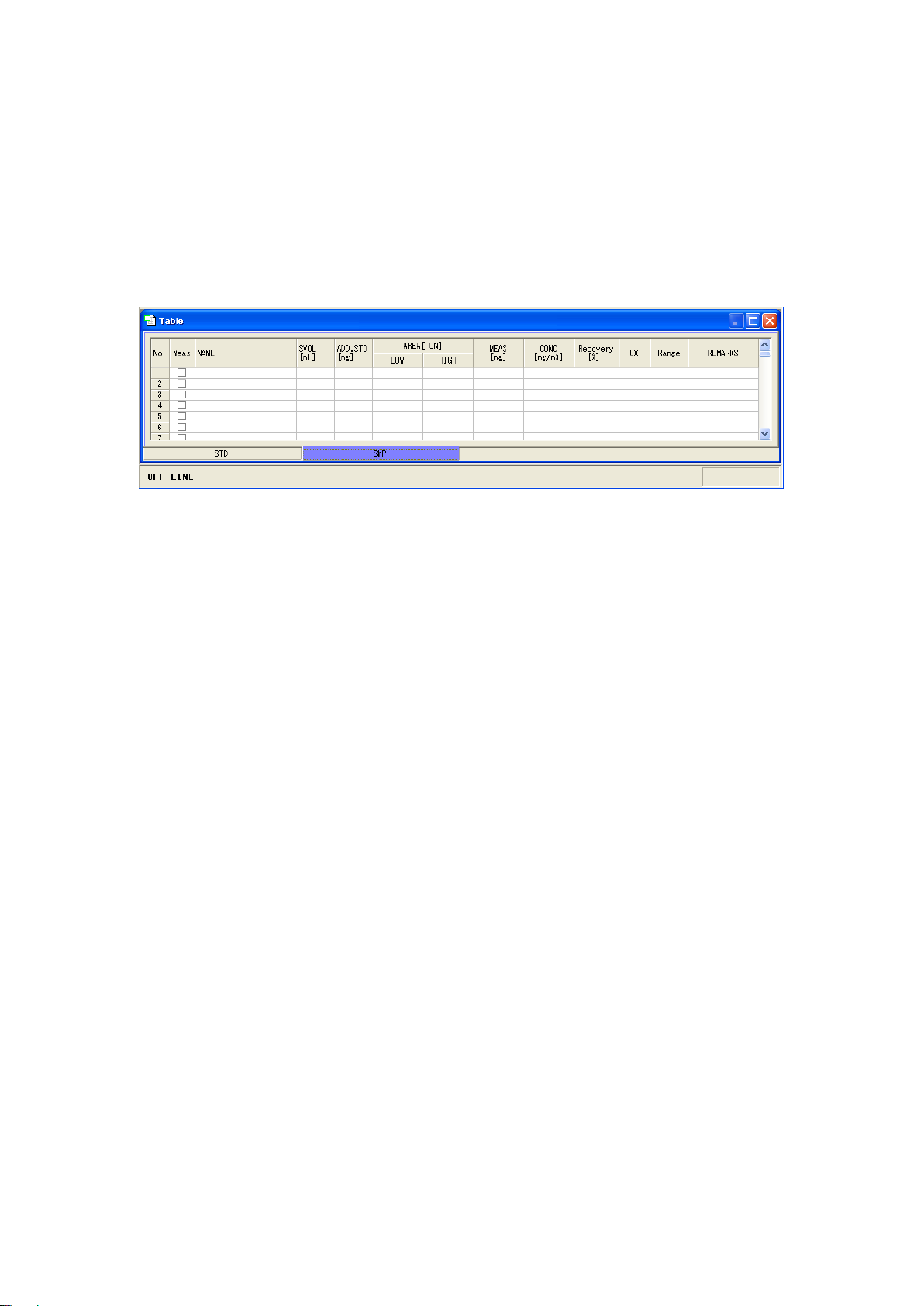

5.4.4. Measuring an unknown sample (collection tube)

(1) Change “Table” to “SMP”. Click the “SMP” tag.

(2) Check in the "Meas" field.

(3) Input the sample name in the "Name" field. Or select "Travel Blank" or "Operation

Blank".

Travel Blank : Used when a collection tube handled in the same manner as

sample collection tubes but not used for sampling is measured

and the measured value is then assumed as the correction

value.

Operation Blank : Used when a collection tube in the same washing lot as the

collection tube used for the sample measurement is measured

and the measured value is then assumed as the correction

value.

(4) Input the sample amount.

(5) Remove the collection tube.

Instruction Manual MA-3000+RH-MA3 NIC-600-2208-04

17

Open the front panel of the RH-MA3, loosen the joint

fixing the collection tube in place under the collection

tube heating furnace (RH1), and then pull out.

Other manuals for MA-3000

2

This manual suits for next models

1

Table of contents

Other Nic Laboratory Equipment manuals