Safety Warnings and Guidelines

1. Important information for safe use

Users should understand how to use this instrument before operating. Please

read this manual carefully prior to operation.

Any improper operation may cause injury. Please read this manual

carefully and operate safely according to the guidelines.

2. Operation and Maintenance

The operation and maintenance of the instrument should comply with the basic

guidelines and warnings below. Incorrect operation or maintenance will have

detrimental effects on the life, performance, and safety features of the instrument.

The instrument is a normal indoor instrument which conforms to

classⅠof the GB 4793.1 standard.

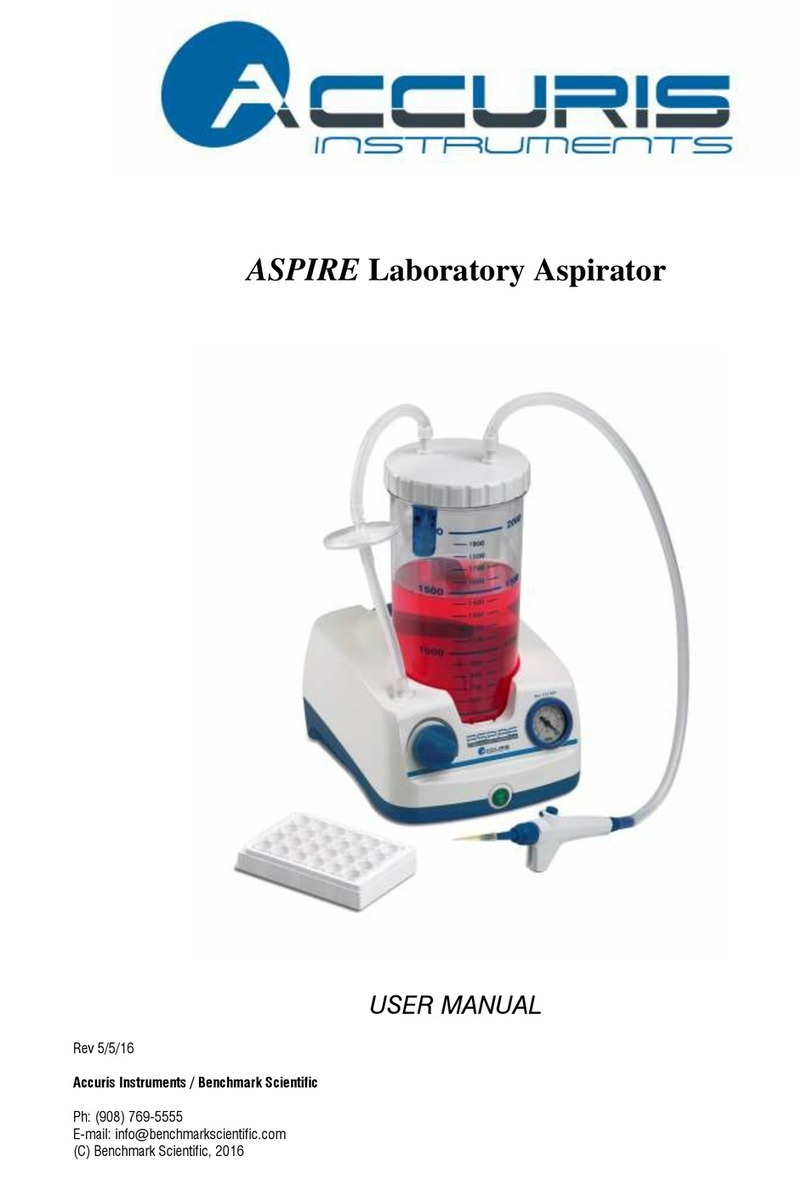

This instrument is designed for use in a laboratory

environment. The device must be operated by skilled

laboratory personnel with appropriate training.

To prevent injury or voiding the warranty, the operator should not

attempt to repair the instrument without explicit guidance from

Accuris Instruments. If service is required, please contact Accuris

Instruments or your local distributor for repair.

Before powering on, confirm that the voltage used meets the electrical

requirements of the instrument as stated on the rating plate. If the

electric cord is damaged, replace it with the same type of cord. Hold the

socket firmly before pulling the plug from an outlet. Do not pull the

electric cord.

The temperature of the heating block can be high; please do not touch

it while it is in use to prevent injury.

The instrument should be installed in an environment of standard room

temperature, low dust, low humidity, and away from direct sunlight,

electromagnetic interference, and heat sources. Do not block the vents

on the instrument.

Always power off the instrument when you are finished using it. Unplug

the power cord and cover the instrument with a cloth or plastic sheet to

prevent excessive dust from entering the housing.