2 – ENGLISH

ENGLISH

Translation of the original instructions in full

CONTENTS

GENERAL SAFETY WARNINGS AND

PRECAUTIONS

1

1 GENERALSAFETYWARNINGSANDPRECAUTIONS

1.1 GENERAL WARNINGS

a

WARNING! Important safety instructions. Observe

all the instructions as improper installation may

cause serious damages.

a

WARNING! Important safety instructions. It is im-

portant to comply with these instructions to ensure

personal safety. Store these instructions carefully.

a

According to the latest European legislation, an

automated device must be constructed in conform-

ity to the harmonised rules specied in the current

Machinery Directive, which allow for declaring the

presumed conformity of the automation. Conse-

quently, all the operations for connecting the prod-

uct to the mains electricity, its commissioning and

maintenance must be carried out exclusively by a

qualied and expert technician.

a

In order to avoid any danger from inadvertent re-

setting of the thermal cut-off device, this appliance

must not be powered through an external switching

device, such as a timer, or connected to a supply

that is regularly powered or switched off by the cir-

cuit.

WARNING! Please abide by the following warnings:

–Before commencing the installation, check the “Prod-

uct technical specications”, in particular whether this

product is suitable for automating your guided part.

Should it not be suitable, do NOT proceed with the in-

stallation.

–The product cannot be used before it has been com-

missioned as specied in the “Testing and commis-

sioning” chapter.

–Before proceeding with the product’s installation,

check that all the materials are in good working order

and suited to the intended applications.

–The product is not intended for use by persons (includ-

ing children) with reduced physical, sensory or mental

capacities, nor by anyone lacking sufcient experience

or familiarity with the product.

–Children must not play with the appliance.

–Do not allow children to play with the product’s control

devices. Keep the remote controls out of reach of chil-

dren.

–The system’s power supply network must include a dis-

connection device (not supplied) with a contact open-

ing gap permitting complete disconnection under the

conditions envisaged by Overvoltage Category III.

–During the installation process, handle the product with

care by avoiding crushing, impacts, falls or contact

with liquids of any kind. Do not place the product near

sources of heat nor expose it to open ames. All these

actions can damage the product and cause it to mal-

function, or lead to dangerous situations. Should this

occur, immediately suspend the installation process

and contact the Technical Assistance Service.

1 GENERAL SAFETY WARNINGS AND PRECAUTIONS . . . . . 2

1.1 General warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Installation warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 PRODUCT DESCRIPTION AND INTENDED USE. . . . . . . . . . 3

2.1 List of constituent parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1 Pre-installation checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

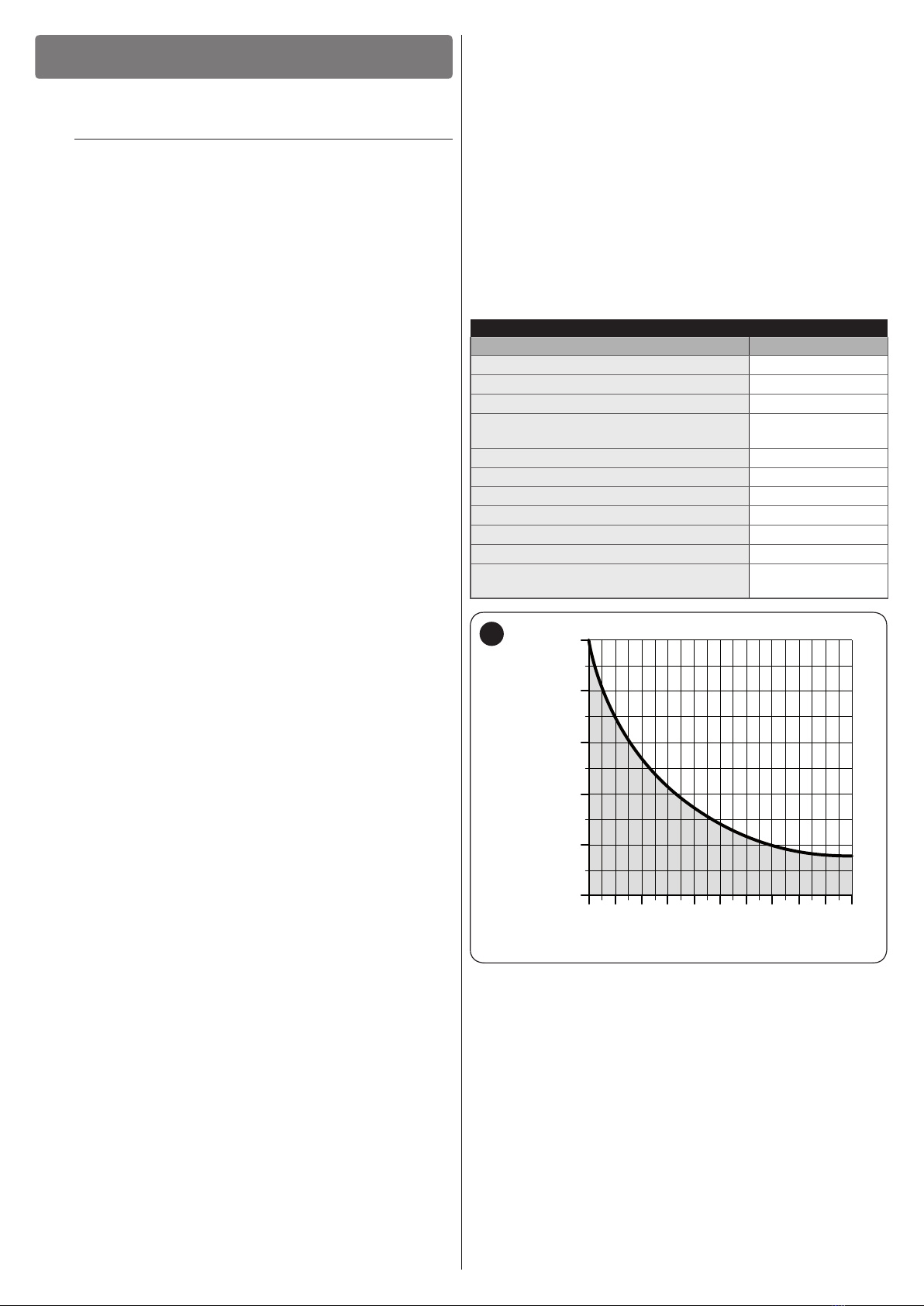

3.2 Product usage limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2.1 Product durability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

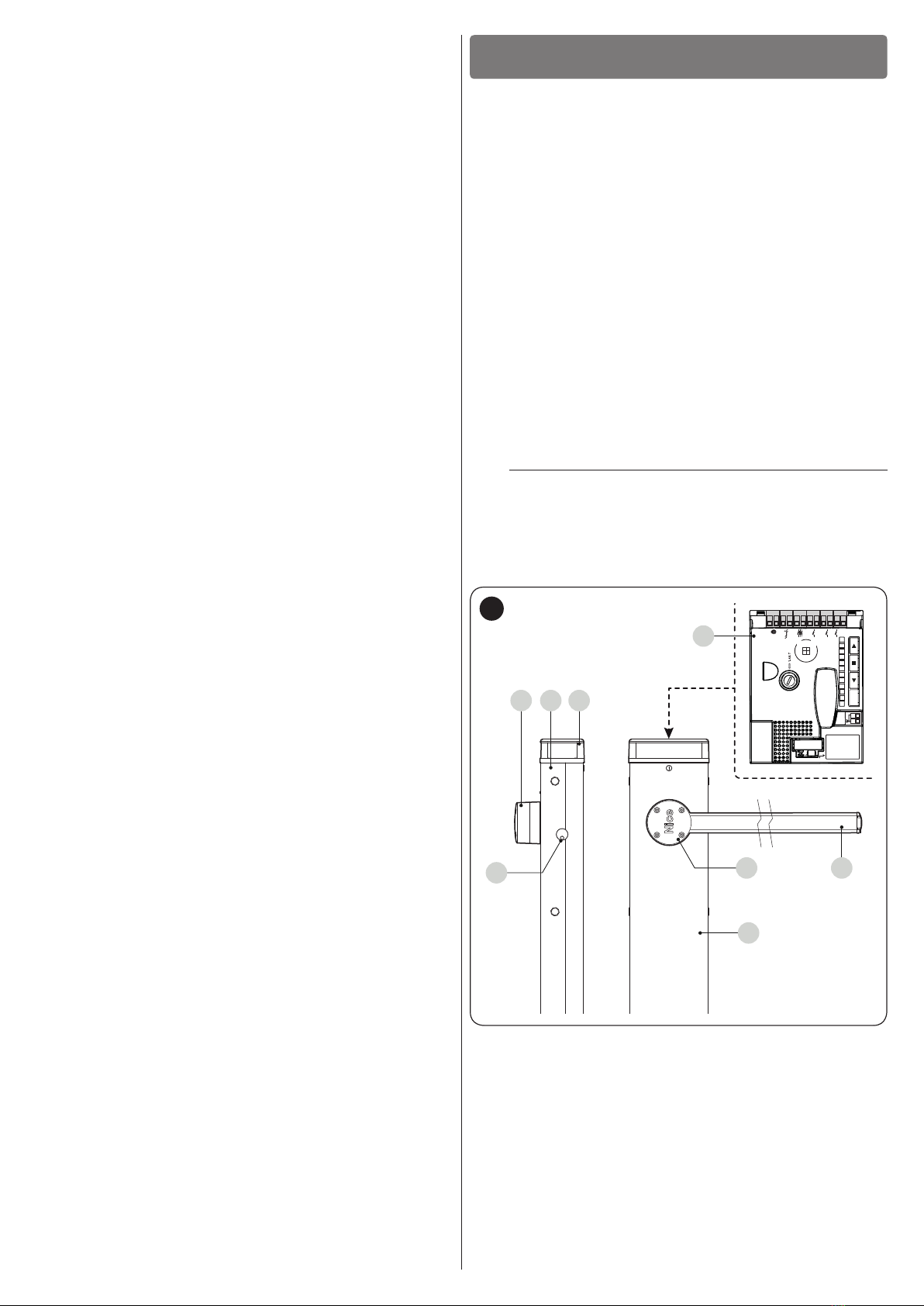

3.3 Product identification and overall dimensions. . . . . . . . . . . 5

3.4 RECEIPT OF THE PRODUCT. . . . . . . . . . . . . . . . . . . . . . . . 5

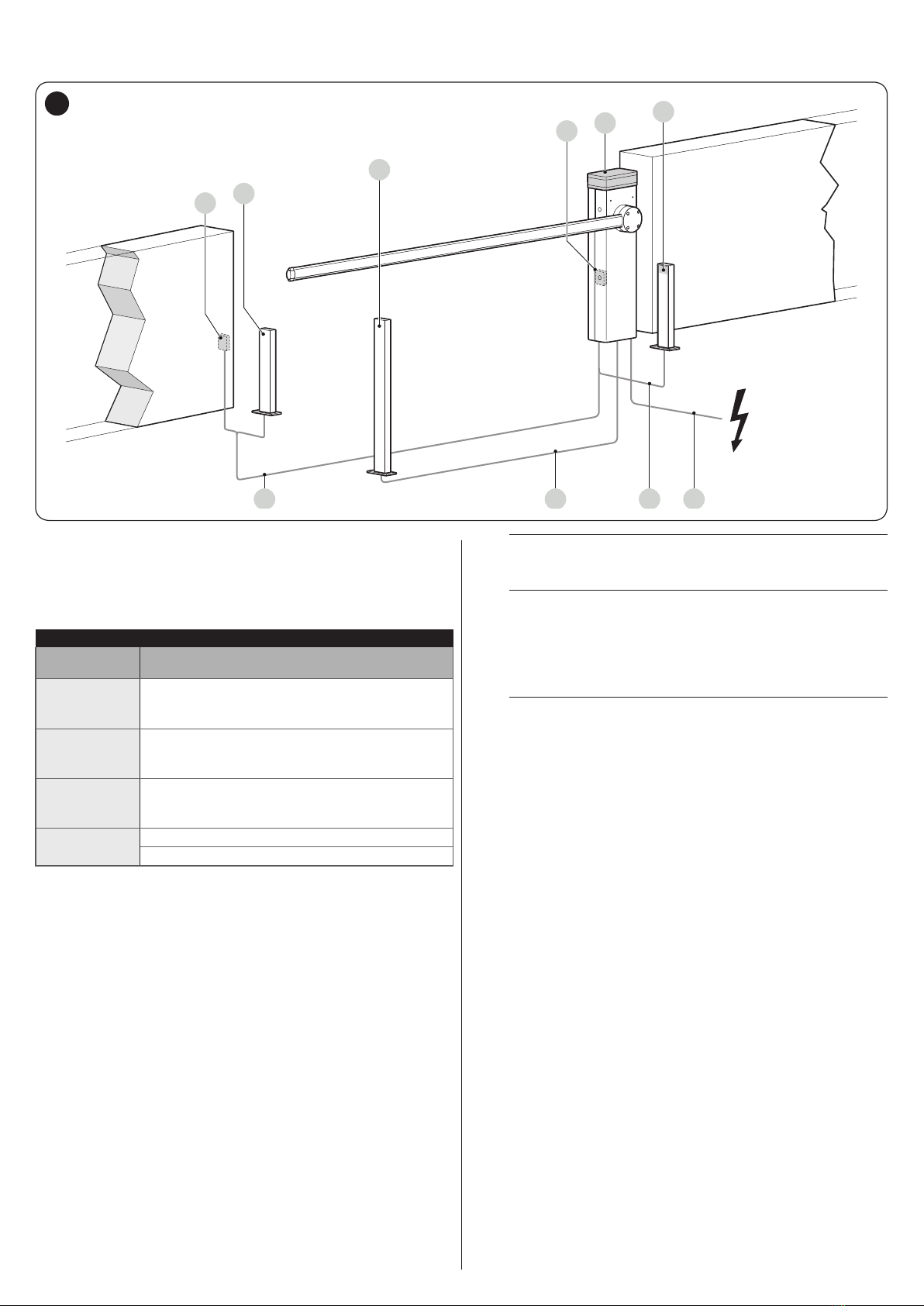

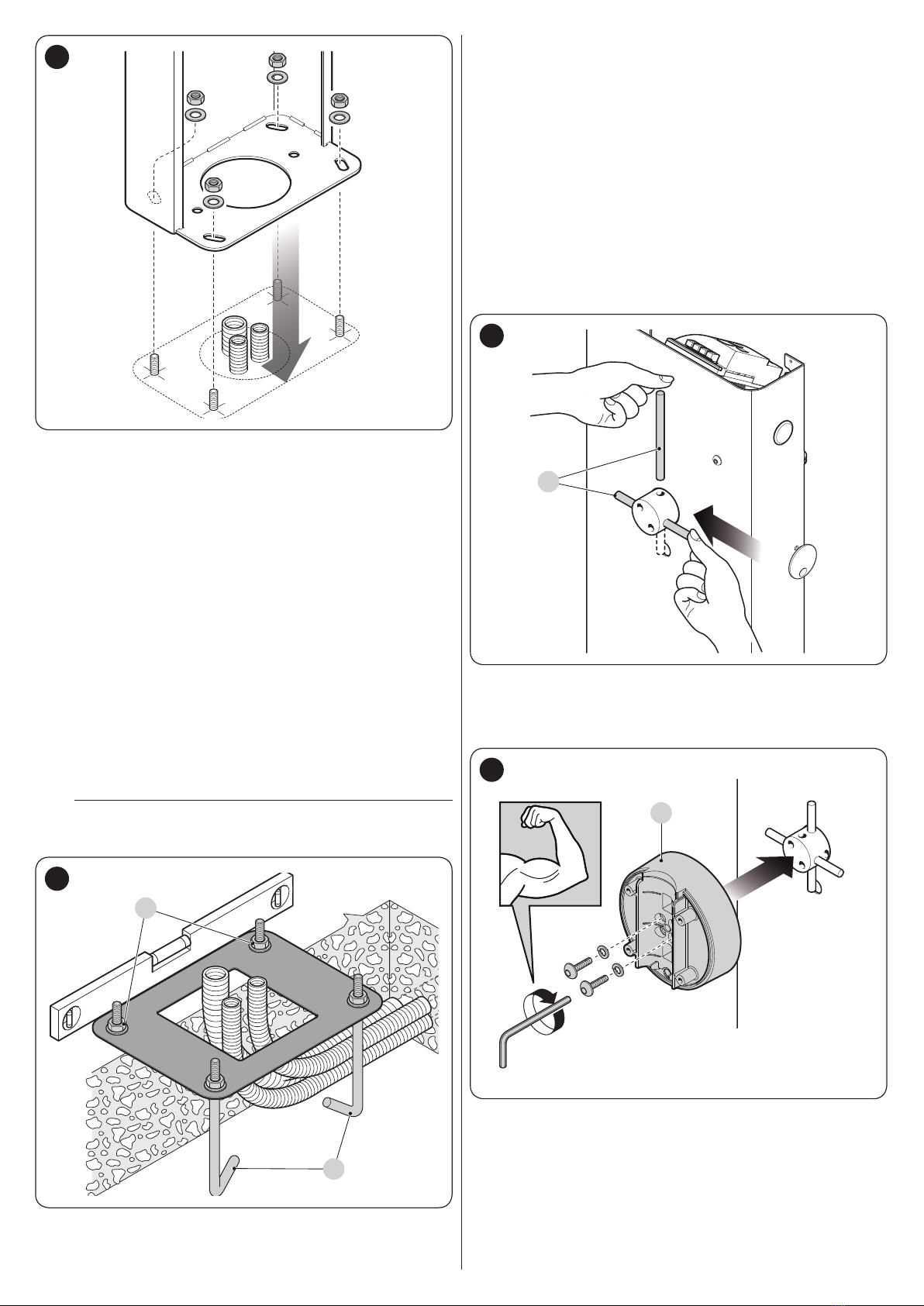

3.5 Pre-installation works. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.6 Adjusting the boom gate . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

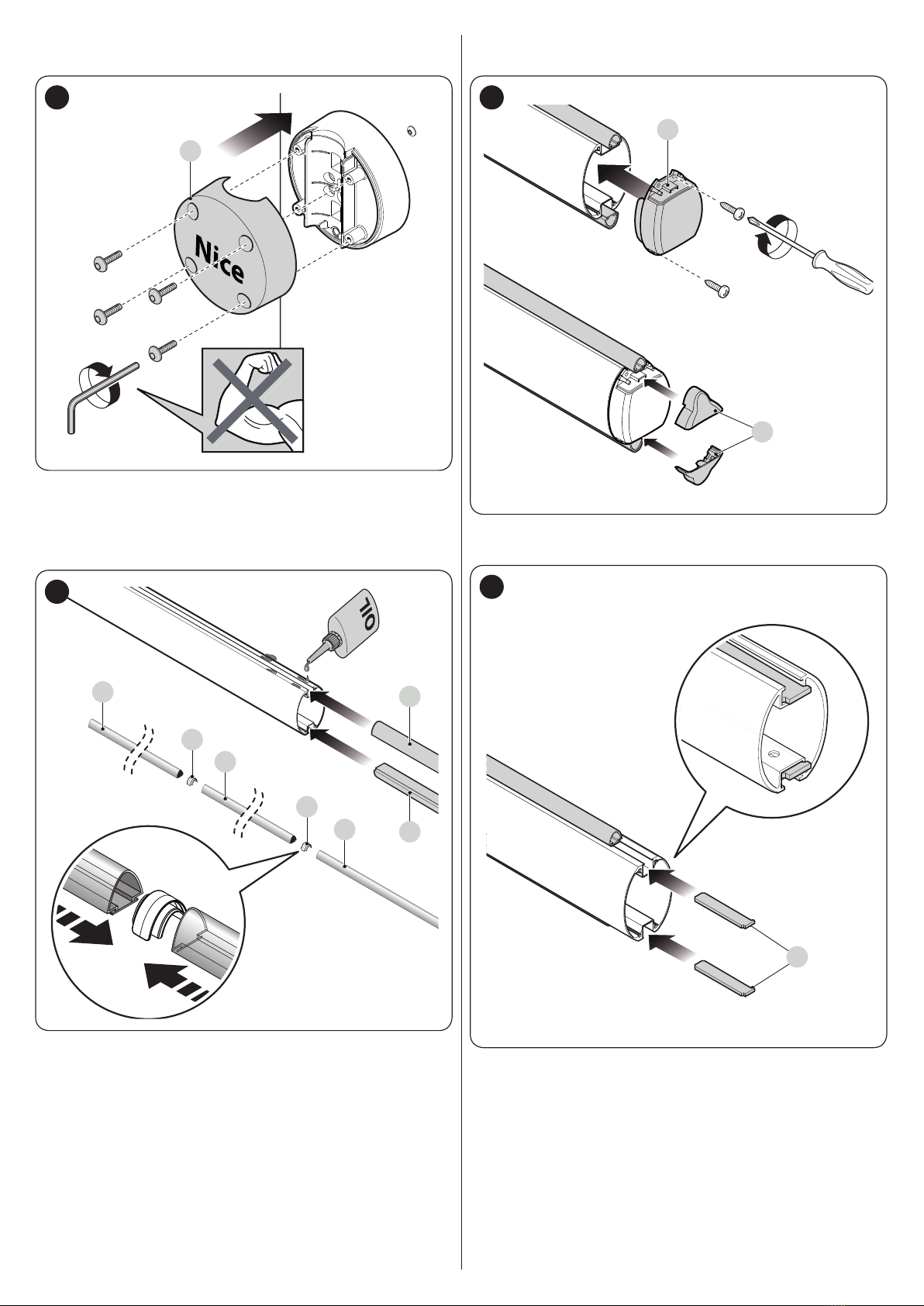

3.7 Installing the gearmotor. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

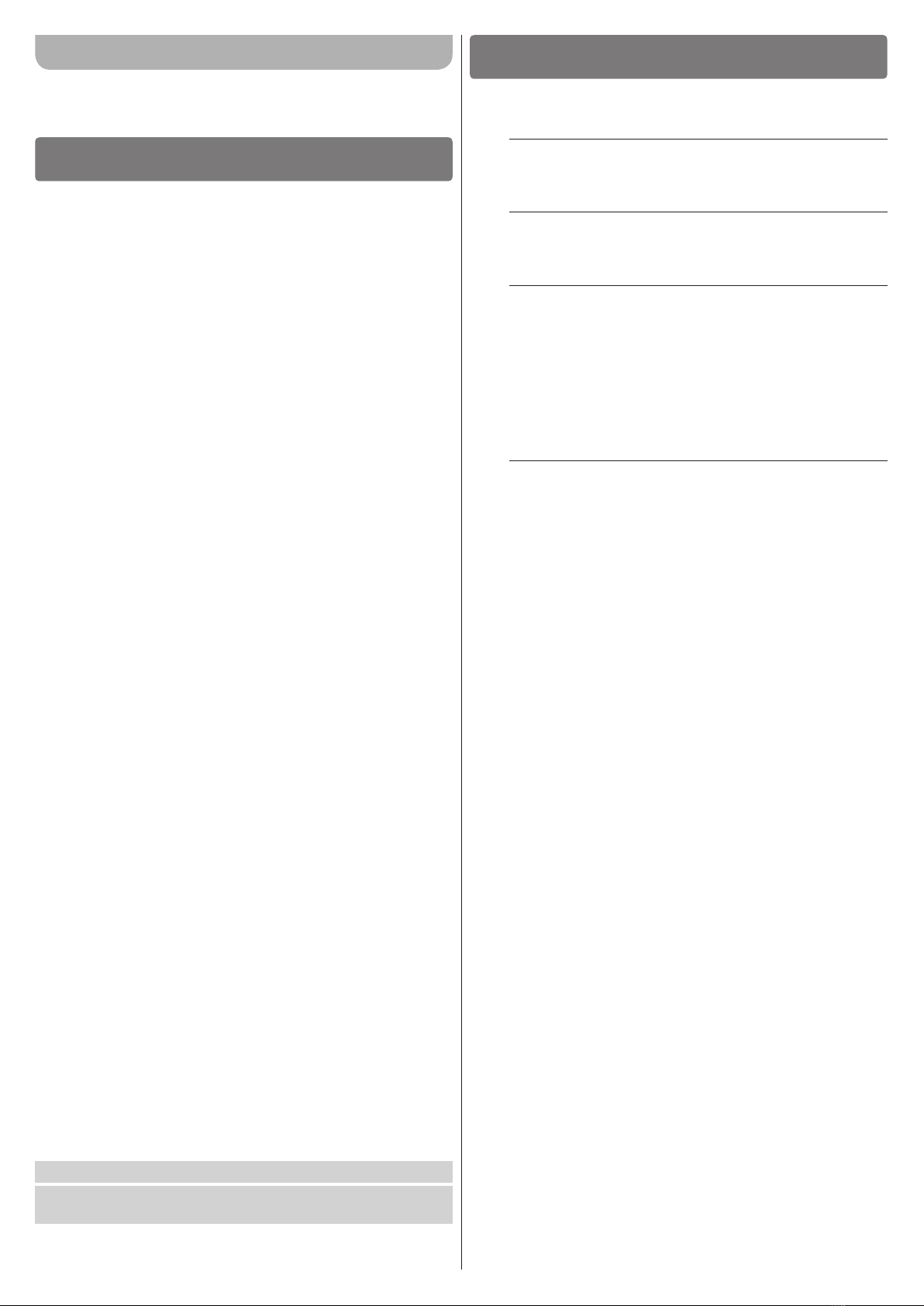

3.8 Installing the boom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.9 Adjusting the mechanical limit switches . . . . . . . . . . . . . . 11

3.10 Boom balancing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.11 Manually unlocking and locking the gearmotor. . . . . . . . . 12

4 ELECTRICAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Preliminary checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Wiring diagram and description of connections . . . . . . . . 13

4.2.1 Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2.2 Description of connections . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Addressing of devices connected with the BlueBUS

system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 FINAL CHECKS AND START-UP. . . . . . . . . . . . . . . . . . . . . . 14

5.1 Power supply connection . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 Device learning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.3 Learning of the mechanical stop positions . . . . . . . . . . . . 15

5.4 Checking the boom’s movement . . . . . . . . . . . . . . . . . . . . 15

5.5 Connecting other devices . . . . . . . . . . . . . . . . . . . . . . . . . 16

6 TESTING AND COMMISSIONING . . . . . . . . . . . . . . . . . . . . . 16

6.1 Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.2 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7 PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.1 Using the programming buttons . . . . . . . . . . . . . . . . . . . . 18

7.2 Level 1 programming (ON-OFF) . . . . . . . . . . . . . . . . . . . . 19

7.2.1 Level 1 programming procedure . . . . . . . . . . . . . . . . . 19

7.3 Level 2 programming (adjustable parameters) . . . . . . . . . 20

7.3.1 Level 2 programming procedure . . . . . . . . . . . . . . . . . 20

7.4 Special functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.4.1 “Always open” function . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.4.2 “Move anyway” function . . . . . . . . . . . . . . . . . . . . . . . . 22

7.4.3 “Maintenance notice” function . . . . . . . . . . . . . . . . . . . 22

7.5 Verifying the number of manoeuvres completed. . . . . . . . 22

7.6 Manoeuvre counter resetting. . . . . . . . . . . . . . . . . . . . . . . 23

8 TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . 23

8.1 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.7 Memory deletion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.3 Signalling through warning light . . . . . . . . . . . . . . . . . . . . 24

8.2 Anomaly log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.4 Signals on the control unit . . . . . . . . . . . . . . . . . . . . . . . . . 25

9 FURTHER DETAILS (Accessories). . . . . . . . . . . . . . . . . . . . 27

9.1 Modifying the STOP input configuration . . . . . . . . . . . . . . 27

9.2 Connecting an SM-type radio receiver . . . . . . . . . . . . . . . 27

9.3 EDSP digital selector and proximity reader for ETPB

transponder cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9.4 Connecting the boom lights (optional accessory). . . . . . . 28

9.5 Connecting the warning light or traffic light. . . . . . . . . . . . 29

9.6 Connecting and installing the back-up battery . . . . . . . . . 29

9.7 Connecting the Oview programmer . . . . . . . . . . . . . . . . . 30

9.8 Connecting the Solemyo solar energy system . . . . . . . . . 30

10 PRODUCT MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . 31

11 PRODUCT DISPOSAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

12 TECHNICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . 32

13 CONFORMITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

INSTRUCTIONS AND WARNINGS FOR THE USER . . . . . . 35

MAINTENANCE SCHEDULE (to be handed to the end

user). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37