4.3 - Transmitter to be used for programming

procedures

• Procedures that can only be completed with a Nice “ERA P” or “ERA W”

transmitter having the PRG and ESC keys, or with transmitters equipped

with a STOP key.

• All the programming procedures must be completed by selecting a single

channel on the transmitter.

• The programming procedure must be performed exclusively with a transmitter

memorised in “Mode I” (see procedure B.1 - A.1 - C.1).

• If the transmitter used for programming controls multiple automation units, you

must select the “unit” corresponding to the automation you are programming before

sending a command during a procedure.

4.3.1 - Report messages sent by the motor

The motor repeats the report message on the status of the installation by performing

some brief movements when a movement is commanded. To understand the signifi-

cance of these movements read Table A.

TABELLA A – Movement signals

No. of MOVEMENTS Meaning

0 movements (START & STOP) = 2 limit switches programmed

1 movement (START & STOP) = 1 limit switch programmed

2 movements (START & STOP) = no limit switch programmed

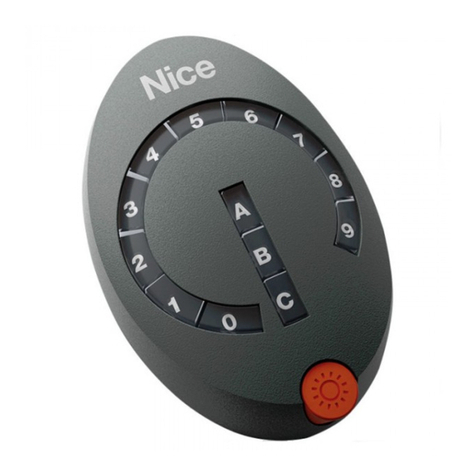

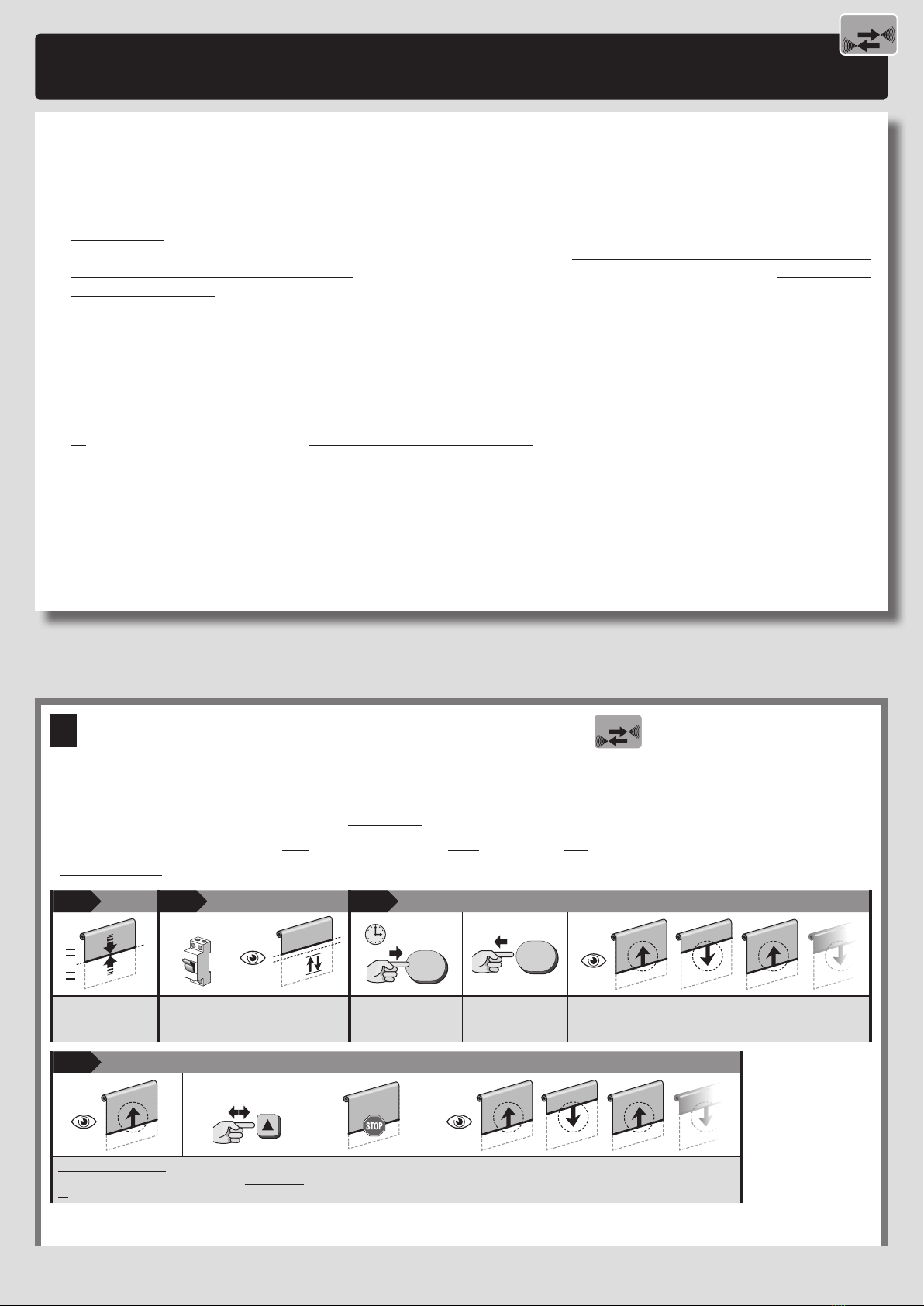

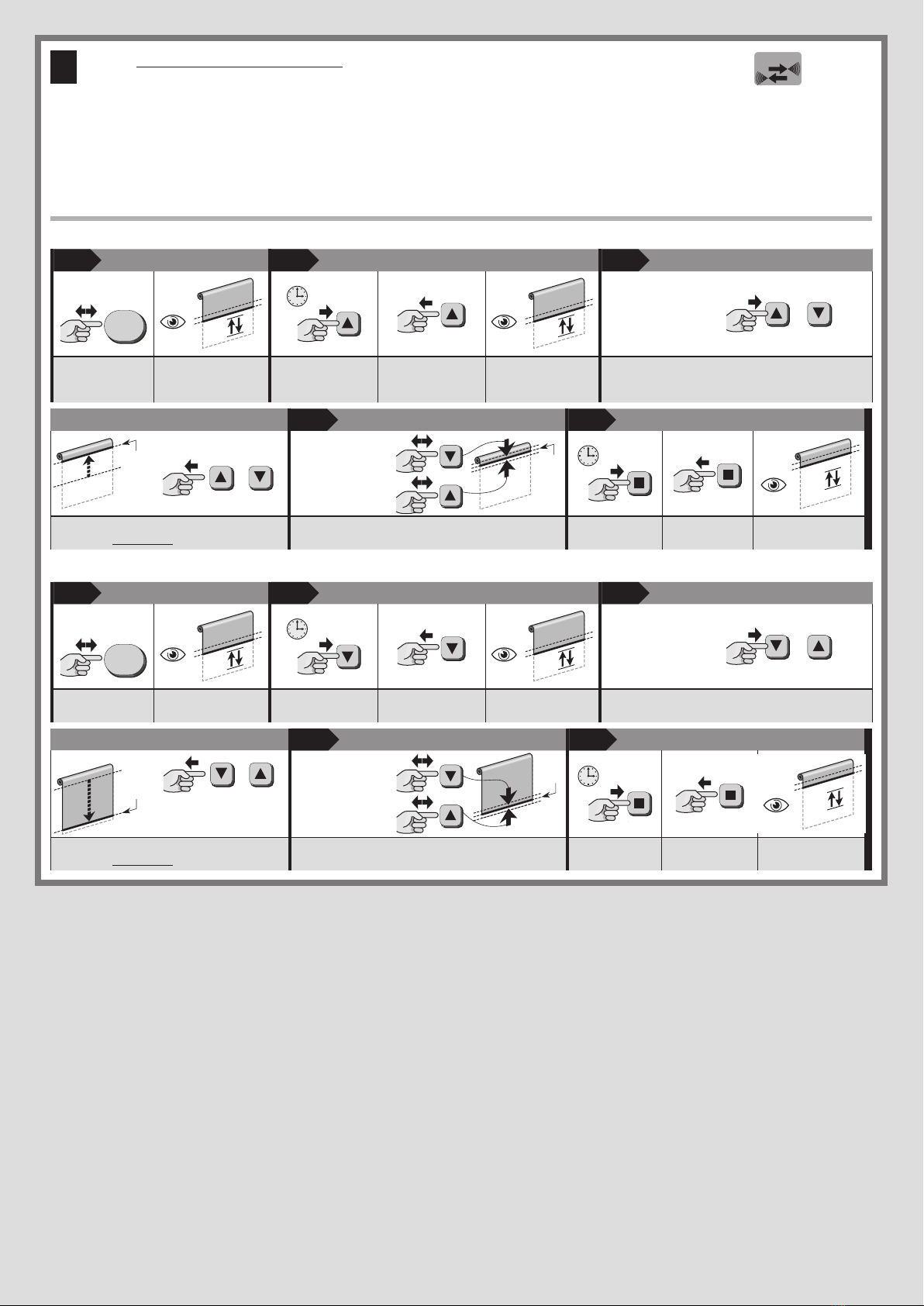

4.4 - Positions in which the roller shutter stops

automatically

The electronic system that controls the roller shutter’s movement at all times can au-

tomatically stop the movement when the roller shutter reaches a certain position pro-

grammed by the installer. The programmable positions are (fig. 4):

– position “0” = UPPER (fully wound roller shutter);

– position “1” = LOWER (fully unwound roller shutter);

– position “H” = INTERMEDIATE (partially open roller shutter).

4

When the limit switches are not programmed yet, the roller shutter can be moved only

in the “hold-to-run” mode, i.e. keeping the control key pressed for the desired dura-

tion of the manoeuvre; the movement stops as soon as the user releases the key.

However, after programming the limit switches, briefly pressing the appropriate key

will start the roller shutter and it will stop moving automatically as soon as the roller

shutter reaches the required position.

To adjust the distances “0” and “1” various procedures are possible; to choose the

appropriate one, take into account the supporting structure of your roller shutter (see

the summary in the table).

WARNING! – If you want to again adjust again the height of the limit switches

adjusted previously, consider the following:

– If you would like to adjust them with an alternative procedure different

from the one used previously, you must FIRST delete the heights by fol-

lowing procedure B.7, A.6 or C.4.

– If you wish to adjust the same procedure used previously, you need not

delete them.

The programming of the limit switches simultaneously combines the two directions

of rotation of the motor to the respective shutter raising key (▲) and shutter lowering

key (▼) of the control device (initially, when the limit switches are not programmed

yet, the combination is random and it can happen that when pressing the ▲key, the

roller shutter moves down instead of up, or vice versa).

4.5 - General warnings

• The limit switch must be adjusted after installing the motor in the roller shutter and

connecting it to the power supply.

• Comply strictly with the time limits indicated in the procedures: after releasing a key,

you have 60 seconds to press the next key indicated in the procedure; otherwise,

when the time is up, the motor will perform 6 movements to communicate cancel-

lation of the procedure in progress.

• During programming the motor performs a certain number of brief movements

as a “response” to the command sent by the installer. Count these movements

regardless of their direction. The movements are indicated in the procedures with a

number followed by the symbol .

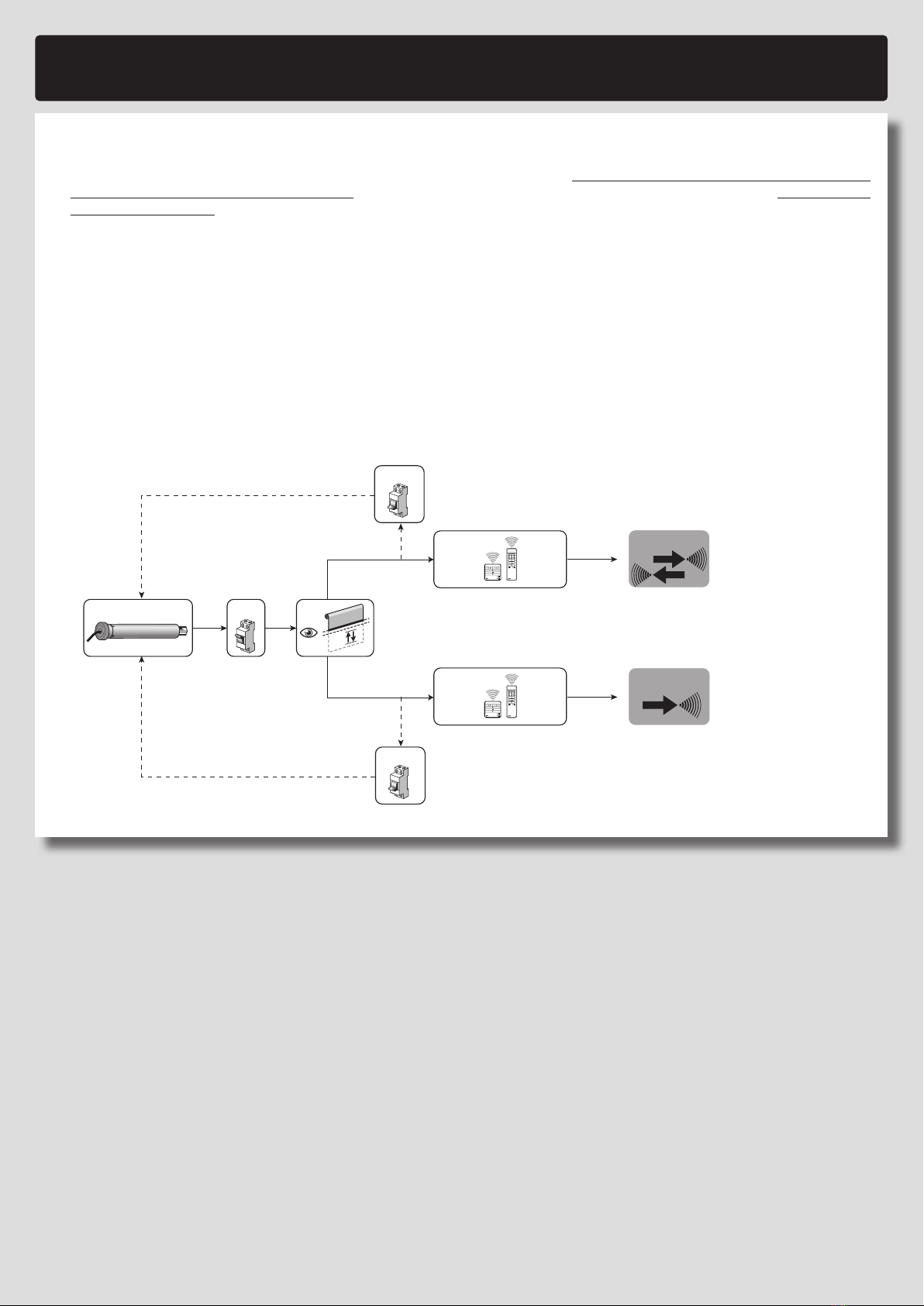

4.6 - Important warnings for memorising the radio

transmitters

• To select transmitter compatible with the motor’s receiver, refer to the “Nice

Screen” catalogue, which is also available on www.niceforyou.com.

• When the motor’s memory does not contain any transmitter, to memorise the

FIRST transmitter, perform the “Communication mode configuration procedure

(ONE-WAY or TWO-WAY)” and subsequently use only one of the following pro-

cedures: B.1 (motor configured as ONE-WAY); A.1 (motor configured as TWO-

WAY); C.1 (motor configured as ONE-WAY and OLD generation transmitter lack-

ing the PRG and ESC keys). If instead one or more transmitters have already been

memorised, to memorise SUPPLEMENTARY transmitters use one of following

procedures only: B.5 (motor configured as ONE-WAY); A.5 (motor configured as

TWO-WAY); C.2 (motor configured as ONE-WAY and OLD generation transmitter

lacking the PRG and ESC keys).

4.6.1 - Two procedures to memorise the keys of a transmitter

There are two categories of transmitter memorisation procedures:

A - Procedures which memorise the buttons in “Mode I”

(“Standard mode”)

They are procedures B.1 - B.5.1 (motor configured as ONE-WAY); A.1 -

A.5 (motor configured as TWO-WAY); C.1 - C.2.1 (motor configured as

ONE-WAY and OLD generation transmitter lacking the PRG and ESC

keys). These allow you to memorise all buttons at the same time, so that

each button corresponds to a basic motor command in a standard fashion.

B - Procedures which memorise the buttons in “Mode II”

(“Custom mode”, only applicable when the motor is con-

gured for ONE-WAY communications

These are procedures B.5.2, A.5 and C.2.2. These allow you to memorise

individual buttons and map them to any of the commands given in the mo-

tor’s “list of commands” (this list is given in each procedure). The button and the

command are selected by the installer, as required by the installation.

4.6.2 - Number of transmitters that can be memorised (only

applicable when the motor is configured for ONE-WAY

communications)

You can memorise 30 transmitters, if these are all memorised in “Mode I”, or you

can memorise 30 single commands (keys) if they are all memorised in “Mode II”.

The two modes can coexist up to a maximum limit of 30 memorised units.

4.6.3 - Number of transmitters that can be memorised (only

applicable when the motor is configured for TWO-WAY

communications)

You can memorise 30 transmitters.

5– English