Nickel-Electro Clifton Series User manual

Hotplates & Stirrers

THE Clifton RANGE

Round and Rectangular Boiling Baths

with Energy Regulator

1000ER and 1100ER Series

PDF created with pdfFactory Pro trial version www.software-partners.co.uk

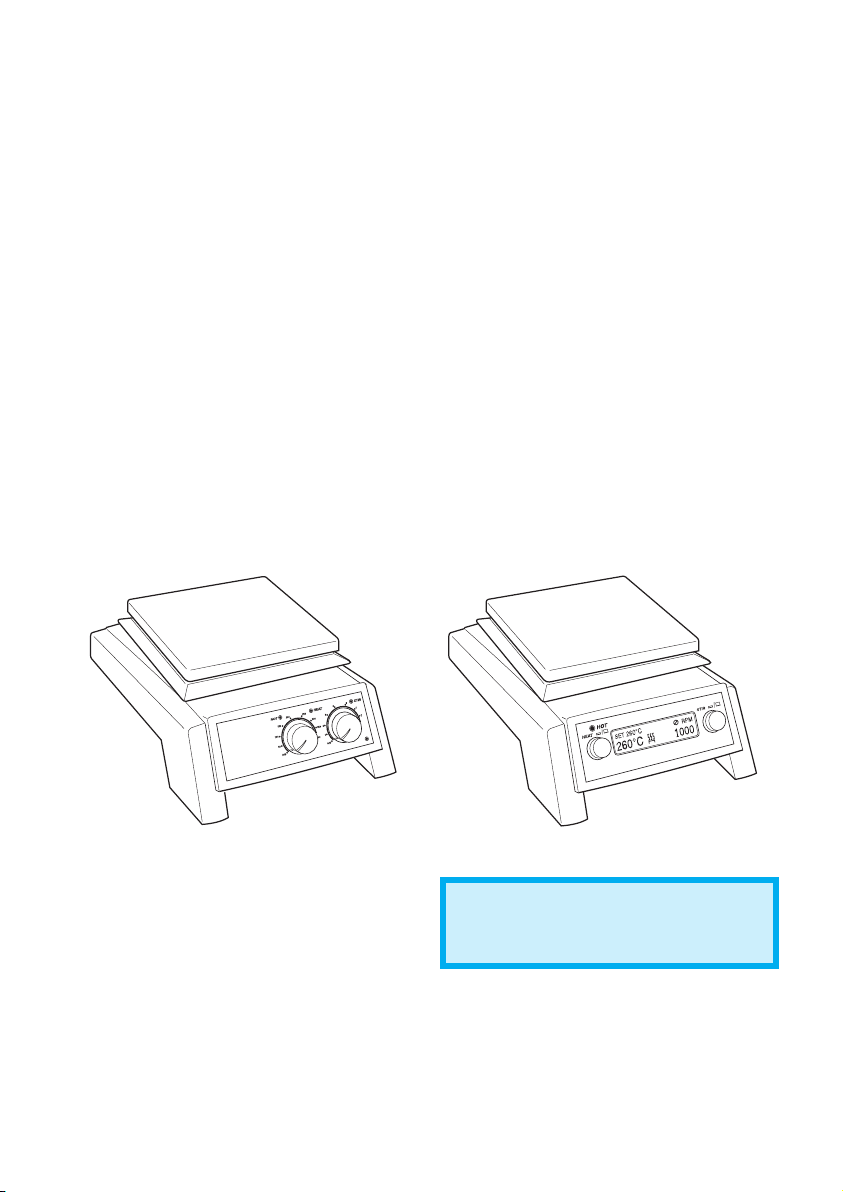

MSH-1 MSH-1D MSH-3

CH-1E CHS-1E CHS-2E

Analogue models

Figure

2 - Rear view

IEC socket

Retort rod fitting

Figure

1 - Front view

‘Hot’ warning light

Heater on light

Stirrer

on

light

Mains on light

‘Hot’ warning light

IEC socket

External probe

socket

Retort rod fitting

Digital display

Stirrer control

Heater control

Digital models

Figure

3 - Front view

Figure

4 - Rear view

The Clifton Range - 3 Year Warranty 2High Quality Products at Affordable Prices

Thank you for purchasing this Clifton product. To get the best performance from the

equipment, and for your personal safety, please read these instructions carefully before use.

Clifton hotplates and stirrers are designed to operate under the following conditions:-

❖For indoor use only

❖Use in a well ventilated area

❖Ambient temperature range +5°C to +40°C

❖Altitude to 2000m

❖Relative humidity not exceeding 80%

❖Mains supply fluctuations not exceeding 10% of nominal

❖Overvoltage category II IEC60364-4-443

❖Pollution degree 2 IEC664

❖Use with a minimum distance all round of 200mm from walls or other items

If the equipment is not used in the manner described in this manual the protection provided by the

equipment may be impaired.

Electrical Installation

THIS EQUIPMENT MUST BE EARTHED

Before connection please ensure that the line supply corresponds to that stated on the

rating label.

Power requirements:

Model Wattage Model Wattage

CH-1E 550W MSH-1 750W

CHS-1E 550W MSH-1D 750W

CHS-2E 1200W MSH-3 3 x 700W

There is an IEC socket at the rear of the instrument for connection to the mains supply, (see figure 2).

The unit is supplied with two mains leads fitted with IEC plugs for connection to the instrument.

One has a U.K. 3 pin plug and the other has a 2 pin “Shuko” plug for connection to the mains.

Choose the lead appropriate for your electrical installation and discard the other.

Should neither lead be suitable, take the lead with the U.K. plug and replace the plug with a suitable

alternative. See the enclosed instruction sheet for advice on how to carry out this procedure.

Should the mains lead require replacement a cable of 1mm2of harmonised code H05W-F connected

to an IEC 320 plug should be used.

IF IN DOUBT CONSULT A QUALIFIED ELECTRICIAN

The mains lead should be connected to the instrument BEFORE connection to the mains supply.

NOTE that when connected to the mains supply a green neon light on the front of the unit

illuminates, (see figure 1).

The Clifton Range - 3 Year Warranty 3High Quality Products at Affordable Prices

The Clifton Range - 3 Year Warranty 4High Quality Products at Affordable Prices

Operation

Heating, analogue models

The control knob labelled on the front panel controls the heat output and hence the plate

temperature. It is graduated with an approximate temperature scale. This scale refers to the

temperature of the top plate and not to the temperature of the contents of the vessel being heated,

When the heat is switched on an amber pilot light illuminates, (see figure 1).

When the surface becomes too hot to touch a red warning light on the front panel will begin to

flash, (see figure 1). This will continue to flash while the plate temperature is above 50°C so long

as the unit remains connected to the electricity supply.

WARNING: The top surface of the instrument may be HOT In free air a surface temperature of

450°C can be achieved on the ceramic top models and 325°C on the metal top models. Do not

leave heaters switched on when not in use.

Stirring, analogue models

The control knob labelled on the front panel controls the stirrer speed. When switched on an

amber pilot light illuminates, (see figure 1).

The knob is graduated with an arbitrary 1-9 scale. Turning the knob to a higher number increases the

stirrer speed.

Heating, digital models

Ensure that the external temperature probe is NOT connected to the instrument.

The control knob on the left hand side of the display controls the heating function.

To switch on the heating function briefly press and release the knob. Repeat to turn off the heating

function.

When switched on the display will show actual plate temperature at the bottom of the screen and the

set temperature directly above. The heating icon will show , indicating that the displayed

temperatures are those of the plate surface.

The plate temperature can be selected and controlled to a resolution of 1°C.

To increase the set temperature turn the knob clockwise until the required setting is shown in the

display. To decrease the setting turn the knob anti-clockwise.

The unit will now begin to heat until the set temperature is reached and then will hold the plate at

this value. The actual plate temperature is continuously displayed at the bottom of the screen. When

the set temperature is reached an alarm will sound. When the plate surface is too hot to touch (>

50°C) a red warning light on the front panel will begin to flash. This will continue to flash while

the plate temperature is above 50°C even after the heating function is turned off.

WARNING: The top surface of the instrument may be HOT. In free air a

surface temperature of 450°C can be achieved on the ceramic top CHS-1E model and 325°C

on the metal top MSH-1D model. Do not leave heaters switched on when not in use.

Use as a Stirrer

The control knob on the right hand side of the front panel controls the stirrer speed.

To switch on the stirring function briefly press and release the knob. Repeat to turn off the stirring

function When switched on the icon on the display will revolve and the display will show the set

speed.

Turning the knob clockwise increases speed from 100rpm to 1300rpm. Turning the knob

anti-clockwise decreases the speed.

The Clifton Range - 3 Year Warranty 5High Quality Products at Affordable Prices

Use as a Temperature Controller using the External Probe CHS-1E, MSH-1D only

These units are supplied with a temperature probe to allow direct control of liquid temperature.

NOTE: Before attaching probe, mains supply must be turned off.

To use the probe first insert the connector into the socket on the rear of the instrument (see fig 2)

and place the probe into the vessel containing the liquid. Switch on the heating function by briefly

depressing the control knob. The heating icon in the display will show indicating that the displayed

temperatures are those of the liquid rather than the plate surface.

When switched on the display will show actual liquid temperature at the bottom of the screen and

the set temperature directly above.

The liquid temperature can be selected and controlled to a resolution of 1°C.

To increase the set temperature turn the knob clockwise until the required setting is shown in the

display. To decrease the setting turn the knob anti-clockwise.

The unit will now begin to heat until the set temperature is reached and then will hold the liquid at

this value. The actual liquid temperature is continuously displayed at the bottom of the screen.

Note that the maximum liquid temperature is limited to 200°C.

Guidance Notes

1. For optimum temperature control please ensure the contents of the beaker are stirred adequately.

2. Keep the unit out of strong drafts.

3. Allow the temperature adequate time to stabilise.

Safety Advice

❖Do not use the instrument to heat flammable liquids

❖Never lift or carry the instrument until it has been switched off and allowed to cool for at least 30

minutes. The hot warning light will give guidance.

❖The unit should be carried using both hands with the fingers under the side edges.

❖Never move or carry the unit with containers on the top plate or while still connected to the mains

supply.

❖There is a danger of liquid spillage if containers are over-filled and stirred at high speed. Always

build stirrer speed slowly and never stir more rapidly than necessary.

❖NEVER place a cold glass vessel onto a hotplate which is already hot.

Cleaning and Care

Before attempting cleaning:-

Ensure that the top is cool, disconnect from the mains electricity supply.

The metal casing should be cleaned using a damp cloth and a mild detergent solution.

Ceramic top units:

A damp cloth will normally remove most types of contamination. For more difficult stains a domestic

cream cleanser is recommended.

Cleaning is made easier if spillages are attended to promptly. In any case, spillages of alkali,

phosphoric acid and hydrofluoric acid MUST be removed immediately as these chemicals can

attack and damage the glass ceramic. Ensure that the appropriate safety precautions are

observed.

During cleaning and general operation take care not to scratch the surface of the top plate as this

could result in subsequent thermal breakage.

WARNING: A ceramic top which is scratched, chipped, chemically etched or damaged must not

be used.

The Clifton Range - 3 Year Warranty 6High Quality Products at Affordable Prices

Metal top units:

The metal top plate should be cleaned using a damp cloth and a mild detergent solution.

Cleaning is made easier if spillages are attended to promptly. In any case, spillages of acids

and alkalis MUST be removed immediately as these chemicals can attack and damage the

the surface of the aluminium alloy. Ensure that the appropriate safety precautions are

observed.

Preparation of Media

Take particular care when heating liquids having a high viscosity. Viscous liquids can act as thermal

insulators and can cause thermal breakage of the glassware. This is very important with media

solutions as the viscosity will usually increase as the temperature rises.

❖Check that the stirring action is sufficient to agitate the whole of the liquid. Unstirred areas in the

liquid can result in uneven heat transfer and “hot spots” in the glassware. This can induce thermal

stress and so cause failure.

❖Check the stirring action regularly to ensure that it remains adequate as the viscosity of the solution

increases.

❖Always use the largest magnetic follower possible and, if necessary, use a mechanical overhead

stirrer.

❖Do not use glass vessels with thick walls, e.g. Pyrex Heavy Duty Ware or standard beakers and flasks

having capacities of 5 litres or greater.

❖NEVER heat glass bottles on a hotplate.

❖Ensure that the heat is built up slowly to avoid localised overheating.

❖Ensure the glassware is completely free from scratches or other defects.

❖Place the hotplate in a tray large enough to contain the liquid in the event of glassware failure.

❖Wear the appropriate safety clothing - e.g. gloves, goggles, protective apron etc.

Accessory

A rod is available to support apparatus used with the instrument. The instrument is equipped with a

fitting on the rear to accept the support rod (see figure 2). To fit the rod to your instrument, first

isolate from the mains supply and allow to cool. Then simply screw the threaded end of the support

rod into the fitting on the rear of the instrument.

Servicing and Repair

This product range does not require any routine servicing.

Note: There are no internal user replaceable parts.

In the event of product failure it is recommended that any repair is only undertaken by suitably

qualified personnel. For advice or to receive a service manual please contact the Service Department

of Nickel-Electro Ltd.

Only spare parts supplied by Nickel-Electro Ltd or its agent should be used. Fitting of non-approved

parts may affect the performance of the safety features of the instrument and void warranty.

Note: The magnetic stirrer drive utilises strong magnets.

If in doubt, please contact the Service Department of;

Nickel-Electro Ltd, Oldmixon Crescent, Weston-Super-Mare, North Somerset BS24 9BL

Tel: +44 (0)1934 626691 Fax: +44 (0)1934 630300

The Clifton Range - 3 Year Warranty 7High Quality Products at Affordable Prices

Warranty

Nickel-Electro warrants this instrument to be free from defects in material and workmanship, when

used under normal laboratory conditions, for a period of three (3) years. In the event of a justified

claim Nickel-Electro will replace any defective component free of charge.

This warranty does NOT apply if,

1. A ceramic top has broken due to mechanical impact, scratching, chipping or chemical etching.

2. Any repair has been made or attempted other than by Nickel-Electro or its agent.

Stirrer Hotplates

NICKEL-ELECTRO Ltd.

Manufacturers of laboratory, medical and clinical equipment.

Oldmixon Crescent, Weston-Super-Mare,

North Somerset, BS24 9BL, United Kingdom

Tel: +44 (0)1934 626691

Fax: +44 (0)1934 630300

Email: [email protected]

www.nickel-electro.co.uk

www.nickel-electro.co.uk

This manual suits for next models

6

Table of contents

Popular Cooktop manuals by other brands

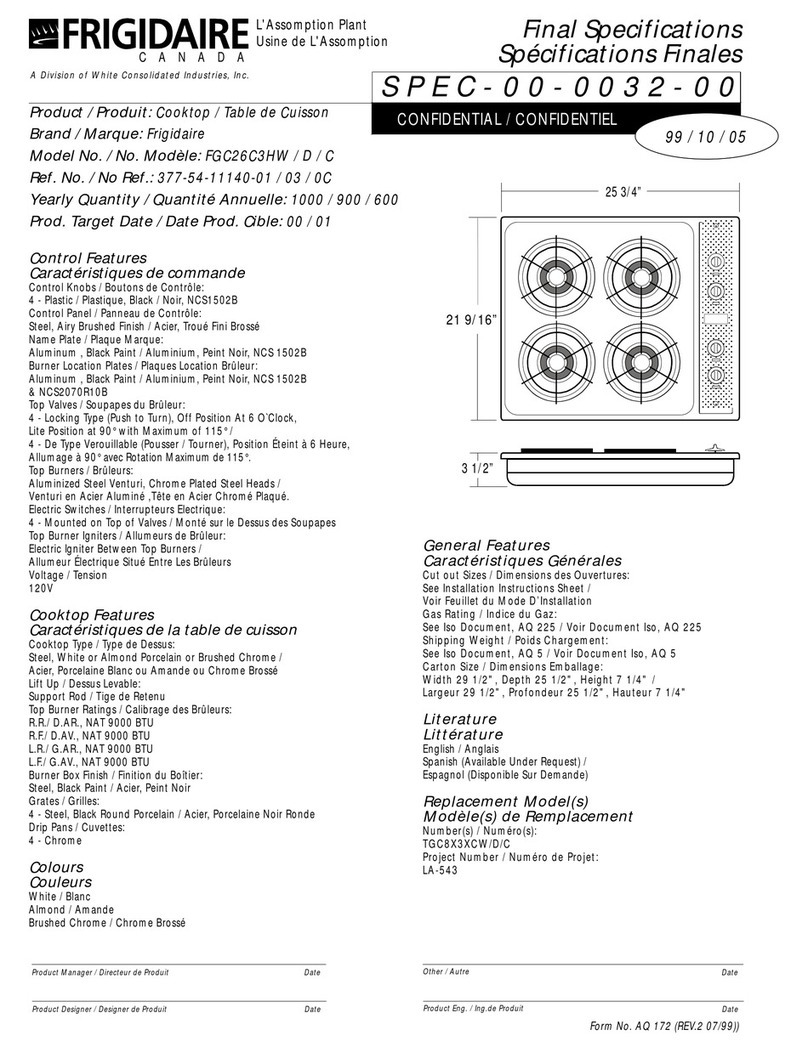

Frigidaire

Frigidaire FGC26C3HW specification

Panasonic

Panasonic KY-E227E Operating & installation instructions

Admiral

Admiral A3875XRA Use and care

Frigidaire

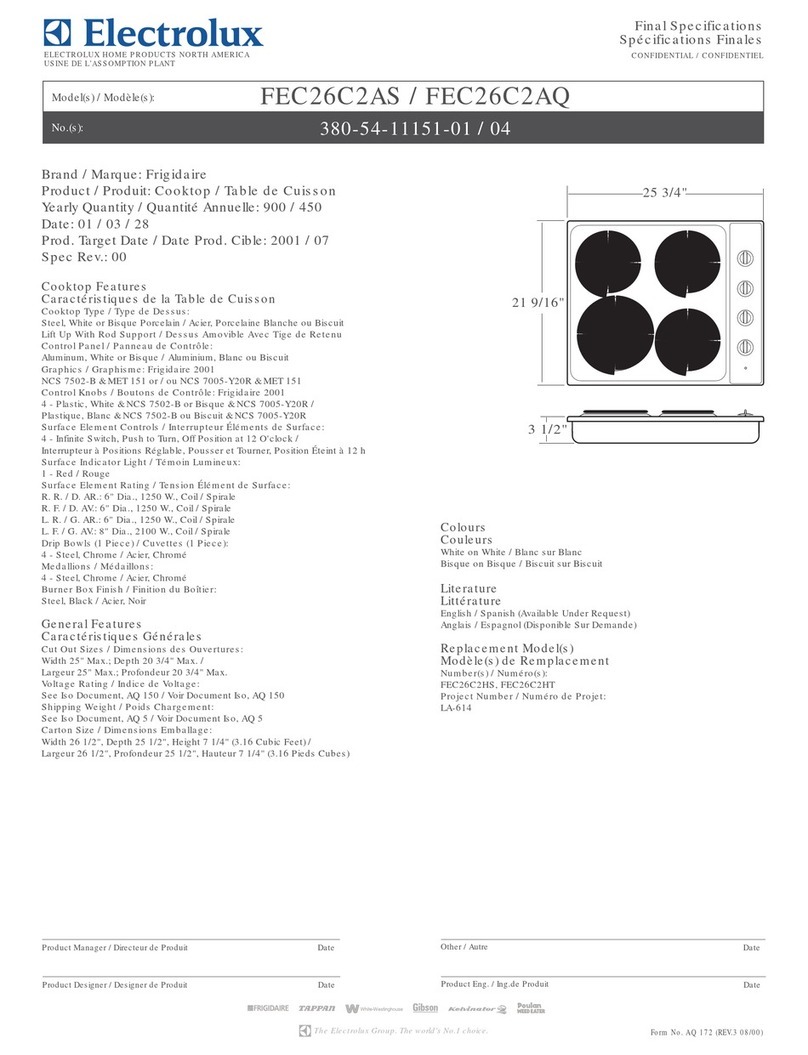

Frigidaire FEC26C2AS - 26" - Coil Electric Cooktop Specifications

Blomberg

Blomberg CTE 30400 Use & care manual

Hoover

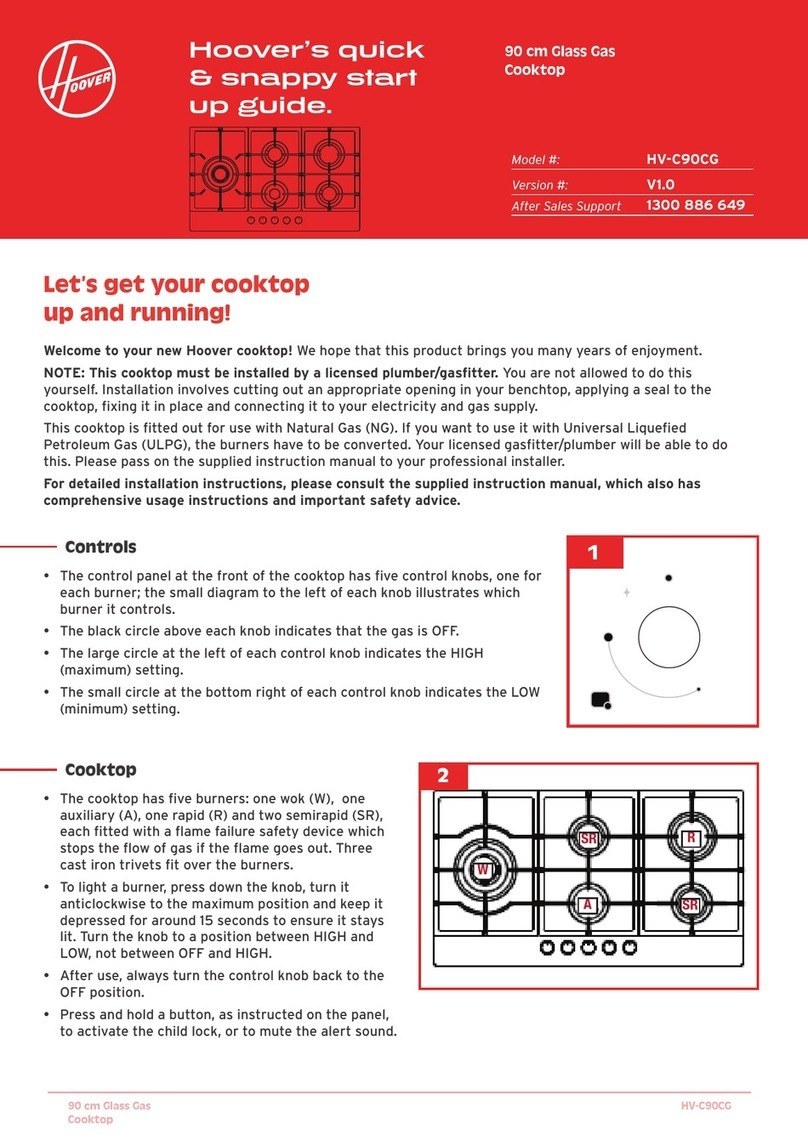

Hoover HV-C90CG quick start guide