Table of Contents

§

1INTRODUCTION ........................................................................................................ 1-1

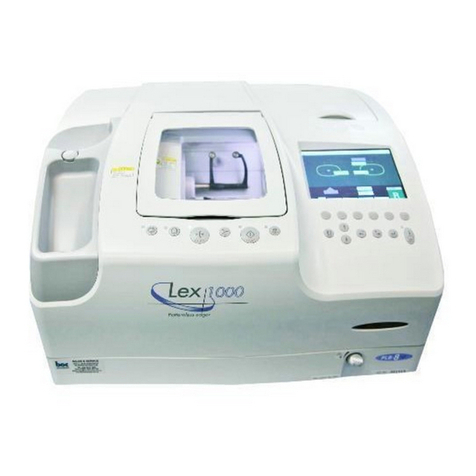

1.1 Outline of the Product ................................................................................................. 1-1

1.2 Symbol Information .................................................................................................... 1-2

§

2SAFETY ........................................................................................................................ 2-1

2.1 Cautions during Use ................................................................................................... 2-1

2.2 Storage ......................................................................................................................2-3

2.3 Transport ................................................................................................................... 2-3

2.4 Installation .................................................................................................................. 2-4

2.5Wiring ........................................................................................................................ 2-5

2.6 After Use ................................................................................................................... 2-5

2.7 Maintenance and Check ............................................................................................. 2-5

2.8 Disposal ..................................................................................................................... 2-7

2.9 Labels ........................................................................................................................ 2-8

2.10 Safety Function ...................................................................................................... 2-10

§

3CONFIGURATION ..................................................................................................... 3-1

§

4OPERATING PROCEDURES .................................................................................... 4-1

4.1 Operation Flow ......................................................................................................... 4-1

4.2 Preparation ............................................................................................................... 4-3

4.3 Tracings .................................................................................................................... 4-4

4.3.1 Tracing frames ................................................................................................. 4-4

4.3.1.1 Tracing both rims ................................................................................ 4-4

4.3.1.2 Tracing single rim ............................................................................... 4-5

4.3.1.3 Semiauto tracing.................................................................................. 4-5

4.3.1.4 Tracing goggle type frames ................................................................. 4-6

4.3.2 Tracing pattern ................................................................................................ 4-7

4.3.3 Tracing dummy lens ........................................................................................ 4-8

4.3.4 Tracing during processing ............................................................................. 4-10

4.3.5 Stopping tracing ............................................................................................ 4-10

4.3.5.1 Stopping frame tracing ...................................................................... 4-10

4.3.5.2 Stopping pattern or dummy lens tracing ........................................... 4-10

4.4 Layouts ................................................................................................................... 4-11

4.4.1 Selecting processing conditions and inputting layout data ........................... 4-11

4.4.2 Inputting height from lens outline ................................................................. 4-14

4.4.2.1 Layout of bifocal lens ........................................................................ 4-15

4.4.2.2 Layout of progressive power lens ..................................................... 4-16

4.4.3 Eye point layout ............................................................................................ 4-17

4.5 Blocking Lenses ..................................................................................................... 4-18

4.5.1 Blocking in active mode................................................................................ 4-18

Page