Page

7.2.3Dressingwheel ..................................................................................................7-4

7.2.3.1Dressing................................................................................................7-4

7.2.3.2 Compound............................................................................................7-5

7.2.4 Reading the lens data.........................................................................................7-5

7.2.5Readingthedataofthedrillingadjustmentlens ...................................................7-6

7.3Calibration .................................................................................................................7-6

7.4FeelerAdjustment ......................................................................................................7-7

7.4.1Adjustingthefeelerheight ..................................................................................7-7

7.4.2AdjustingthefeelerAXIS ..................................................................................7-8

7.5SizeAdjustment........................................................................................................7-10

7.6AdjustingtheBevelPosition ...................................................................................... 7-11

7.7AXISAdjustment .....................................................................................................7-12

7.8PolishingAdjustment.................................................................................................7-13

7.8.1PolishDiff.andBeveladjustments ...................................................................7-13

7.8.2AdjustingthepolishingAXIS ...........................................................................7-14

7.8.3AdjustingthePolishSize ..................................................................................7-15

7.9Adjustment oftheSafety Bevel .................................................................................7-16

7.9.1Adjustingthe S.F.B.position............................................................................7-16

7.9.2Adjustmentof theSafety BevelAXIS ..............................................................7-17

7.9.3AdjustingtheSafetyBevelposition(Flat) .........................................................7-18

7.9.4Adjusting theSafetyBevelAXIS (Polish) .........................................................7-19

7.10GrooveAdjustment ................................................................................................7-20

7.10.1Adjustingthegroovingdepth..........................................................................7-20

7.10.2Adjustingthegrooveposition .........................................................................7-21

7.10.3Adjusting the GrooveAXIS ...........................................................................7-22

7.11DrillingAdjustment..................................................................................................7-23

7.11.1Preparationforthedrillingadjustment.............................................................7-23

7.11.2AdjustingtheHoleDiameter ..........................................................................7-24

7.11.3AdjustingtheDrillingAXISandverticalcentering ...........................................7-25

7.11.4AdjustingtheDrillZeroPoint(Z) ...................................................................7-26

7.11.5Adjusting theFront SurfaceOffset .................................................................7-27

7.11.6Adjusting thehole depth.................................................................................7-28

7.12Updating the Software ............................................................................................7-29

7.13Checking the Parameterof the BLInverter ..............................................................7-29

7.14 Test Mode .............................................................................................................7-30

7.15PositionadjustmentoftheleftmeasuringASshadingplate .......................................7-32

7.16PositionadjustmentoftherightmeasuringASshadingplate .....................................7-32

7.17Calibration ofthe touch panel..................................................................................7-33

7.18Changingtheparameters.........................................................................................7-33

§

8SUPPLEMENT .............................................................................................................8-1

8.1WiringDiagram ..........................................................................................................8-1

8.2 Connector Cable........................................................................................................8-2

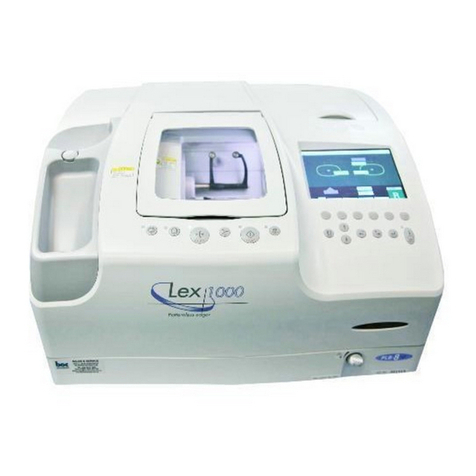

8.3Appearance................................................................................................................8-4

8.4 Labels ........................................................................................................................8-5

8.5 Error message ............................................................................................................8-7

8.6Parameter List ............................................................................................................8-8

8.7Parameter List ofInverter .........................................................................................8-14