NieRuf EV01 User manual

Operating instructions

Solenoid valve, series

Type EV01, MV01

Type MV02

Type EV03, MV03

Type EV04, MV04

Type EV05, MV05

Type EV06, MV06

Type EV07, MV07

Type EV08, MV08

Type EV09, MV09

Type FV01

Imprint

2/23 OPERATING INSTRUCTIONS FOR METAL SOLENOID-VALVES Index: 0

Imprint

Manufacturer NieRuf GmbH

Zeppelinstr. 11

74354 Besigheim

Germany

Phone: +49 (0) 7143 96669 00

Fax: +49 (0) 7143 96669 01

E-mail: info@nieruf.de

Website: www.nieruf.de

Published by NieRuf GmbH

Printed by NieRuf GmbH

Translation These operating instructions in English are a translation of the

original German operating instructions. Operating

instructions in other languages are also translations of the original

German operating instructions. In the event of discrepancies

between the different versions, the information contained in the

original operating instructions in German shall apply.

Read carefully before use.

Store in a safe place for future reference.

Subject to technical modifications.

Table of contents

3/23 OPERATING INSTRUCTIONS FOR METAL SOLENOID-VALVES Index: 0

Table of contents

1 About these instructions .................................................................................................................... 5

1.1 Target group ................................................................................................................................ 5

1.2 Other applicable documents ....................................................................................................... 5

1.3 Guarantee .................................................................................................................................... 5

1.4 Warning notices and symbols ..................................................................................................... 6

2 General safety instructions ................................................................................................................ 7

2.1 Intended use ................................................................................................................................ 7

2.2 General safety instructions ......................................................................................................... 7

2.2.1 Duties of the operator .......................................................................................................... 7

2.2.2 Duties of the personnel ........................................................................................................ 8

2.3 Special dangers ............................................................................................................................ 8

2.3.1 Duties of the personnel ........................................................................................................ 8

3 Design and function ............................................................................................................................ 9

3.1 Type label .................................................................................................................................... 9

3.2 Description .................................................................................................................................. 9

3.3 Design and dimensions .............................................................................................................. 10

3.3.1 Type EV01 and MV01 ......................................................................................................... 10

3.3.2 Type MV02 ......................................................................................................................... 10

3.3.3 Type EV03 and MV03 ......................................................................................................... 10

3.3.4 Type EV04 and MV04 ......................................................................................................... 11

3.3.5 Type EV05 and MV05 ......................................................................................................... 11

3.3.6 Type EV06 and MV06 ......................................................................................................... 11

3.3.7 Type EV07 and MV07 ......................................................................................................... 12

3.3.8 Type FV01 ........................................................................................................................... 12

3.3.9 Type EV08 and MV08 ......................................................................................................... 12

3.3.10 Type EV09 and MV09 ....................................................................................................... 12

4 Transport, storage and disposal ....................................................................................................... 13

4.1 Unpacking .................................................................................................................................. 13

4.2 Transport ................................................................................................................................... 13

4.3 Storage ...................................................................................................................................... 13

4.4 Disposal ..................................................................................................................................... 13

5 Installation and connection .............................................................................................................. 14

5.1 Preparing the installation .......................................................................................................... 14

1 About these instructions

4/23 OPERATING INSTRUCTIONS FOR METAL SOLENOID-VALVES Index: 0

5.1.1 Checking conditions of use ................................................................................................. 14

5.2 Planning pipelines ..................................................................................................................... 14

5.2.1 Designing pipelines ............................................................................................................. 14

5.3 Fitting the valve to a pipeline .................................................................................................... 15

5.3.1 Threaded connection ......................................................................................................... 15

5.3.2 Connection with flange ...................................................................................................... 15

5.4 Electrical connection ................................................................................................................. 16

5.4.1 Plug assignment .................................................................................................................. 16

5.5 Carry out a pressure check ........................................................................................................ 16

6 Operation ......................................................................................................................................... 17

6.1 Commissioning .......................................................................................................................... 17

7 Maintenance and repairs ................................................................................................................. 18

7.1 Maintenance ............................................................................................................................. 18

7.2 Repairs ....................................................................................................................................... 18

7.2.1 Removing valves ................................................................................................................. 19

7.2.2 Replacing solenoid coils ...................................................................................................... 19

7.3 Spare parts ................................................................................................................................ 20

7.4 Returns ...................................................................................................................................... 20

7.5 Packaging ................................................................................................................................... 20

8 Fault elimination .............................................................................................................................. 21

9 Appendix .......................................................................................................................................... 22

9.1 Technical data ........................................................................................................................... 22

9.2 Circuit diagrams ......................................................................................................................... 22

9.2.1 Circuit diagrams Type EV01 /-03 and MV01 /-02 /-03 ....................................................... 22

9.2.2 Circuit diagrams Type EV04 /-05 /-07, MV04 /-05 /-07 and FV01 ...................................... 22

9.2.3 Circuit diagrams Type EV06 and MV06 .............................................................................. 22

9.2.4 Circuit diagrams Type EV08 /-09 and MV08 /-09 ............................................................... 22

9.3 Declaration of conformity ......................................................................................................... 23

1 About these instructions

5/23 OPERATING INSTRUCTIONS FOR METAL SOLENOID-VALVES Index: 0

1 About these instructions

These instructions

§ Are part of the valve

§ Are applicable for Series EV01-03-04-05-06-07-08-09, MV01-02-03-04-05-06-07-08-09 und

FV01.

§ Describe the safe and correct operation of the valve

§ Are available for downloading from the website

1.1 Target group

Operator

§ These instructions must be kept available at the place of use, including for future

applications.

§ Employees must be encouraged to read and observe these instructions.

§ Additional country-specific or plant-specific regulations and rules must be observed.

Personnel

§ Skilled workers with additional qualifications for installing the respective pipeline system.

§ Electrician

§ Read these instructions as well as all other applicable documents.

1.2 Other applicable documents

§ Data sheet

If not available, the data sheet must be requested from the manufacturer.

1.3 Guarantee

NieRuf GmbH accepts no liability if operators or third parties:

§ Disregard this document

§ Do not use the product properly

§ Carry out interventions of any type whatsoever to the product (alterations, modifications,

etc.)

Malfunctions that can be attributed to contamination or wear, as well as wearing parts (e.g. seals),

are not covered by the warranty.

1 About these instructions

6/23 OPERATING INSTRUCTIONS FOR METAL SOLENOID-VALVES Index: 0

1.4 Warning notices and symbols

DANGER

High risk

Denotes an imminent danger that will result in serious injuries or

death if not avoided.

WARNING

Medium risk

Denotes a possibly dangerous situation that may result in serious

injuries or death if not avoided.

CAUTION

Low risk

Denotes a possibly dangerous situation that may result in slight or

minor injuries if not avoided.

NOTE

Instruction

Denotes a possibly dangerous situation that may cause damage to

property if not avoided.

2 General safety instructions

7/23 OPERATING INSTRUCTIONS FOR METAL SOLENOID-VALVES Index: 0

2 General safety instructions

NOTE

Liability

The manufacturer accepts no liability for damage resulting from the

failure to observe the complete documentation.

2.1 Intended use

§ The valve must be used exclusively for shutting off pipelines carrying suitable media

§ Observe the operating limits

§ Use the armature exclusively for media that are free of solid matter

2.2 General safety instructions

NOTE

Information

Read and observe the following regulations before carrying out any

activities.

2.2.1 Duties of the operator

Safety-conscious working

§ Only operate the valve if it is in technically flawless condition, for its intended application and

keeping safety and potential dangers in mind in accordance with these instructions.

§ Ensuring adherence and supervision:

- Intended use

- Statutory or other safety and accident-prevention regulations

- Safety regulations for handling dangerous substances

- Applicable standards and directives of the respective country of use

§ Supply personal protective equipment

2 General safety instructions

8/23 OPERATING INSTRUCTIONS FOR METAL SOLENOID-VALVES Index: 0

Personnel qualifications

§ Make sure that personnel tasked with carrying out activities using the valve have read and

understood these instructions and all other applicable documents before starting work,

especially safety, maintenance and repair information.

§ Manage the responsibilities, competencies and supervision of personnel.

§ Only qualified technical personnel are to be permitted to carry out the following work:

- Installation, repair and maintenance work

- Work on the electrical system

§ Only allow trainee personnel to work on the valve under the supervision of qualified

technical personnel

WARNING

Unqualified personnel

Improper handling can result in serious personal injuries or damage

to property. The work described here must only be carried out by

qualified personnel.

2.2.2 Duties of the personnel

§ Instructions on the valve itself should be observed and kept in a legible state, e.g. type label.

§ Only work on the valve if the following prerequisites are met:

- System is drained

- System is flushed

- System is de-pressurised

- System is cooled

- System is secured against reactivation

§ Do not make modifications to the device

2.3 Special dangers

2.3.1 Duties of the personnel

§ When handling dangerous media (e.g. hot, flammable, explosive, toxic, harmful,

environmentally hazardous), always observe the safety regulations governing the handling of

dangerous substances.

§ During all work on the valve, wear personal protective equipment.

§ Leakages and residues must be safely contained and disposed of in an environmentally-safe

manner.

3 Design and function

9/23 OPERATING INSTRUCTIONS FOR METAL SOLENOID-VALVES Index: 0

3 Design and function

3.1 Type label

Layout of the type label:

1 Article

2 Connection

3 Nominal diameter, voltage, function

4 Medium temperature

5 Pressure range

6 Commission number

7 Serial number

3.2 Description

The metal valve is a seat valve fitted with a diaphragm seal and is used for opening and closing

pipelines. It is fully automatic and glandless and therefore practically maintenance-free.

§ Available as normally closed (NC) or normally open (NO) variants.

§ Connector complies with DIN EN 175301-803 form A.

o Types EV01 / -09 and MV01 / -09 with DIN EN 175301-803 form B

§ Flow direction as per direction arrow on the valve body.

§ Valves are not suitable for back pressure.

§ Fitting position:

- Solenoid coil ideally at the top.

- Fit valve horizontally or vertically into the line.

Type EV01 /-03 and MV01 /-02 /-03

The valve is a direct-controlled seat valve. No differential pressure is required for opening or closing.

Type EV04 /-05 and MV04 /-05

The valve is servo-controlled and requires a differential pressure to open and close.

Type EV04/MV04 requires a differential pressure of 0.1 bar between the inlet and outlet.

Type EV05/MV05 requires a differential pressure of 0.5 bar between the inlet and outlet.

Type EV06 /-07, MV06 /-07 and FV01

The valve is servo-controlled with positive lift. No differential pressure is required for opening and

closing.

Type EV08 /-09 and MV08 /-09

The valve is a direct-controlled seat valve. No differential pressure is required for opening or closing.

3 Design and function

10/23 OPERATING INSTRUCTIONS FOR METAL SOLENOID-VALVES Index: 0

3.3 Design and dimensions

3.3.1 Type EV01 and MV01

3.3.2 Type MV02

3.3.3 Type EV03 and MV03

POS

Designation

Material

1

Connector

Plastic

2

Coil housing

Plastic or metal

3

Valve body

Brass or stainless steel

Seal material

NBR, EPDM or FKM

POS

Designation

Material

1

Connector

Plastic

2

Coil housing

Plastic or metal

3

Valve body

Brass

Seal material

NBR, EPDM or FKM

POS

Designation

Material

1

Connector

Plastic

2

Coil housing

Plastic or metal

3

Valve body

Brass or stainless steel

Seal material

NBR, EPDM or FKM

3 Design and function

11/23 OPERATING INSTRUCTIONS FOR METAL SOLENOID-VALVES Index: 0

3.3.4 Type EV04 and MV04

3.3.5 Type EV05 and MV05

3.3.6 Type EV06 and MV06

POS

Designation

Material

1

Connector

Plastic

2

Coil housing

Plastic or metal

3

Cover

Brass or stainless steel

4

Valve body

Brass or stainless steel

Seal material

NBR, EPDM or FKM

POS

Designation

Material

1

Connector

Plastic

2

Coil housing

Plastic or metal

3

Cover

Brass or stainless steel

4

Valve body

Brass or stainless steel

Seal material

NBR, EPDM or FKM

POS

Designation

Material

1

Connector

Plastic

2

Coil housing

Plastic or metal

3

Cover

Brass or stainless steel

4

Valve body

Brass or stainless steel

Seal material

NBR, EPDM or FKM

3 Design and function

12/23 OPERATING INSTRUCTIONS FOR METAL SOLENOID-VALVES Index: 0

3.3.7 Type EV07 and MV07

3.3.8 Type FV01

POS

Designation

Material

1

Connector

Plastic

2

Coil housing

Plastic or metal

3

Cover

stainless steel

4

Valve body

stainless steel

Seal material

NBR, EPDM or FKM

3.3.9 Type EV08 and MV08

3.3.10 Type EV09 and MV09

POS

Designation

Material

1

Connector

Plastic

2

Coil housing

Plastic or metal

3

Cover

Brass or stainless steel

4

Valve body

Brass or stainless steel

Seal material

NBR, EPDM or FKM

POS

Designation

Material

1

Connector

Plastic

2

Coil housing

Plastic or metal

3

Valve body

Brass or stainless steel

Seal material

NBR, EPDM or FKM

POS

Designation

Material

1

Connector

Plastic

2

Coil housing

Plastic or metal

3

Cover

Brass or stainless steel

4

Valve body

Brass or stainless steel

Seal material

NBR, EPDM or FKM

4 Transport, storage and disposal

13/23 OPERATING INSTRUCTIONS FOR METAL SOLENOID-VALVES Index: 0

4 Transport, storage and disposal

4.1 Unpacking

§ On receipt of the armature, unpack it, check it for signs of transport damage and ensure that

it is complete.

§ Transport damage or missing components must be reported to the manufacturer

immediately.

§ Make sure that the type label information matches the order and design data.

§ When installing the product, dispose of the packaging material in accordance with the

applicable local regulations.

4.2 Transport

§ Wherever possible, transport the valve in the original packaging

§ Lift the valve by hand for transport purposes (see data sheet for weight information)

4.3 Storage

NOTE

Improper storage can cause damage to property

Store the valve properly.

You must ensure that the storage location fulfils the necessary conditions, such as:

§ Dry

§ Frost-free

§ Free from vibrations

§ No direct sunlight

§ Storage temperature range +10°C to +50°C

4.4 Disposal

The valve must be disposed of in accordance with the applicable local regulations.

NOTE

Contamination

Plastic components may be contaminated by toxic or radioactive

media to such an extent that cleaning is not sufficient.

WARNING

Danger of poisoning and environmental damage from the medium

During all work on the armature, wear personal protective

equipment.

Prior to disposing of the valve, contain any leaking medium and

dispose of it separately in accordance with the applicable local

regulations. Medium residues in the armature must be neutralised.

Dismantle plastic parts and dispose of them in accordance with the

applicable local regulations.

5 Installation and connection

14/23 OPERATING INSTRUCTIONS FOR METAL SOLENOID-VALVES Index: 0

5 Installation and connection

5.1 Preparing the installation

5.1.1 Checking conditions of use

§ Make sure that the valve design is suitable for the intended use:

- Materials used

- Medium

§ Ensures the necessary conditions of use

- The resistance of the materials used for the body and seals against the medium

- Media temperature

- Operating pressure

§ Agree any other use with the manufacturer

5.2 Planning pipelines

5.2.1 Designing pipelines

WARNING

Danger of poisoning and environmental damage from the medium

Leakage due to leaks caused by impermissible pipeline forces.

Make sure that no tensile or compressive forces and no bending

moments act on the armature.

§ Plan pipelines with safety in mind

- Ensure there are no tensile or compressive forces

- Ensure there are no bending moments

- Compensate for changes in length caused by temperature fluctuations

- Observe the direction of flow

- Pay close attention to the fitting position and direction of the valve

- Apply suitable measures to prevent pressure surges

§ Dimensions (3.3 Design and dimensions)

§ Fit dirt traps to ensure proper functioning

5 Installation and connection

15/23 OPERATING INSTRUCTIONS FOR METAL SOLENOID-VALVES Index: 0

5.3 Fitting the valve to a pipeline

WARNING

De-pressurised fitting.

Only fit the valve to de-pressurised pipelines.

WARNING

Danger of poisoning and environmental damage from the medium

Leakage due to incorrect installation.

Installation work on the pipelines must only be carried out by skilled

workers who are trained for the respective pipeline system.

NOTE

Improper installation of the valve can cause damage to property

Fit the armature horizontally or vertically.

Ideally, fit the armature with the solenoid coil pointing upwards.

NOTE

Contamination in the valve can cause damage to property

Make sure that no contamination can enter the armature.

Flush the pipeline with a neutral medium.

The procedure used to fit the armature is determined by the type of connection to the pipeline.

5.3.1 Threaded connection

§ Screw the threaded connection onto the pipe in accordance with the applicable standard.

§ Use suitable sealing materials depending on the design and intended purpose.

5.3.2 Connection with flange

§ Check that the sealing face is free of damage and clean.

§ Carefully align the flange in front of the threaded joint.

§ Centre the seals (use suitable sealing material).

§ Connect the valve flange and pipe flange with the seal and suitable bolts.

§ Tighten the bolts cross-wise. Use all of the flange holes!

§ Only use permissible joining elements.

5 Installation and connection

16/23 OPERATING INSTRUCTIONS FOR METAL SOLENOID-VALVES Index: 0

5.4 Electrical connection

DANGER

Danger to life due to electric shock

Only allow an electrician to work on the electrical system.

Switch off the power supply to the system and secure it to prevent it

from being accidentally switched on again.

Connect protective conductors.

§ Before making the electrical connection, check that the current type and voltage are correct

(see data sheet).

§ Make sure that the device plug connection is protected against constant moisture. If

necessary, fit a protective cover.

§ Connect the cable to the device.

§ Connect protective conductors.

§ Insert device plug into connector on the valve.

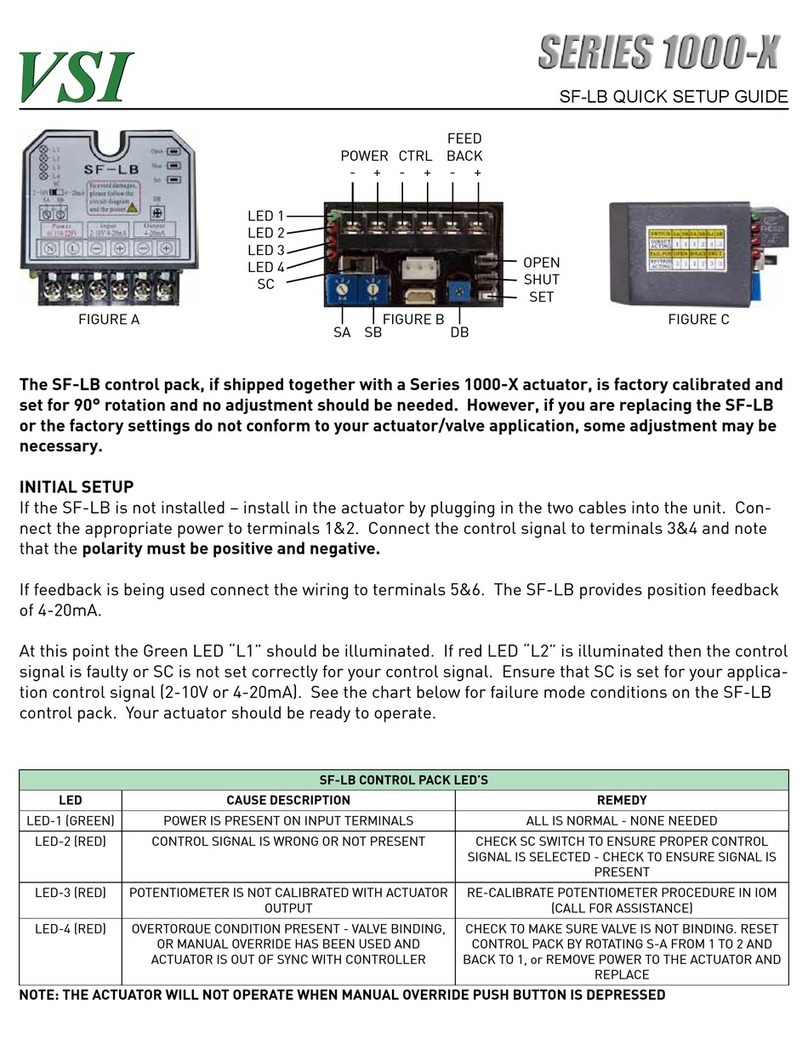

5.4.1 Plug assignment

HINWEIS

Plug

Plug according to DIN EN 175301-803.

1 Supply voltage

2 Supply voltage

3 Protective earth conductor

5.5 Carry out a pressure check

NOTE

Medium pressure check

Carry out the pressure check using a neutral medium (e.g. water).

§ Pressurise the valve. When doing so, ensure that:

- Test pressure < permissible system pressure

- Test pressure < 1.5 PN

§ Check that the valve is leak-tight.

6 Operation

17/23 OPERATING INSTRUCTIONS FOR METAL SOLENOID-VALVES Index: 0

6 Operation

6.1 Commissioning

The valve must be correctly assembled and connected.

WARNING

Danger of poisoning and environmental damage from the medium

Leakage due to leaks caused by impermissible pipeline forces.

Make sure that no tensile or compressive forces and no bending

moments act on the armature.

NOTE

Overheating will destroy the alternating voltage solenoids

When commissioning the valve equipped with an alternating voltage

solenoid, make sure that the solenoid coil is mounted on the plunger

guide.

§ On the Types EV04-05 and MV04-05, make sure that the required differential pressure is

applied between the valve inlet and valve outlet.

§ After it is first exposed to pressure and operating temperatures, check that the valve is leak-

tight.

7 Maintenance and repairs

18/23 OPERATING INSTRUCTIONS FOR METAL SOLENOID-VALVES Index: 0

7 Maintenance and repairs

WARNING

Risk of injury and poisoning by media

During all work on the valve, wear personal protective equipment.

7.1 Maintenance

§ Visual and functional inspection (quarterly):

- No change in normal operating states

- Leak-tightness

- No unusual operating noises and vibrations

§ If necessary, clean valve with a damp cloth.

NOTE

Adjust maintenance intervals

The maintenance intervals must be adjusted in line with the

applicable operating conditions. This is the responsibility of the

operator.

7.2 Repairs

DANGER

Danger to life due to electric shock

Only allow an electrician to work on the electrical system.

WARNING

Risk of injury and poisoning due to dangerous or hot media

During all work on the valve, wear personal protective equipment.

Any medium leaks must be safely contained and disposed of in an

environmentally-safe manner.

WARNING

Risk of injury during disassembly work

Wear protective gloves; components can become extremely sharp as

a result of wear or damage.

Components fitted with springs must be removed with great care as

the spring tension can cause components to be hurled out.

7 Maintenance and repairs

19/23 OPERATING INSTRUCTIONS FOR METAL SOLENOID-VALVES Index: 0

7.2.1 Removing valves

§ Make sure that:

- System is drained

- System is flushed

- System is de-pressurised

- System is cooled

- System is secured against reactivation

§ Remove valve from the pipeline.

§ If necessary, decontaminate valve.

- Empty spaces in the valve may still contain medium.

7.2.2 Replacing solenoid coils

3

4

5

2

1

1. Loosen bolt (1) and remove device plug (2) from the valve.

2. Unscrew nut (3) and remove washer (4).

4. Remove solenoid coil (5). Dispose of faulty solenoid coil.

5. Fit new solenoid coil (5).

6. Refit the individual parts in reverse order.

7. Connect armature to power supply (5.4 Connecting the armature to the power supply).

8. Conduct pressure check (5.5 Conducting the pressure check).

7 Maintenance and repairs

20/23 OPERATING INSTRUCTIONS FOR METAL SOLENOID-VALVES Index: 0

7.3 Spare parts

§ Keep the following information ready for ordering spare parts.

- Valve type

- Article number

- Nominal pressure and diameter

- Materials of body and seals

§ Only use spare parts supplied by NieRuf GmbH.

7.4 Returns

§ Seal all valve openings (e.g. with protective film).

§ A clearance declaration must be completed and enclosed with the returns.

7.5 Packaging

NOTE

Unsuitable packaging

The valve may be damaged if unsuitable packaging is used.

Always use the original packaging and handle the product with care.

NieRuf GmbH accepts no responsibility for damage caused by the use of unsuitable packaging!

This manual suits for next models

17

Table of contents