INSTRUCTION MANUAL

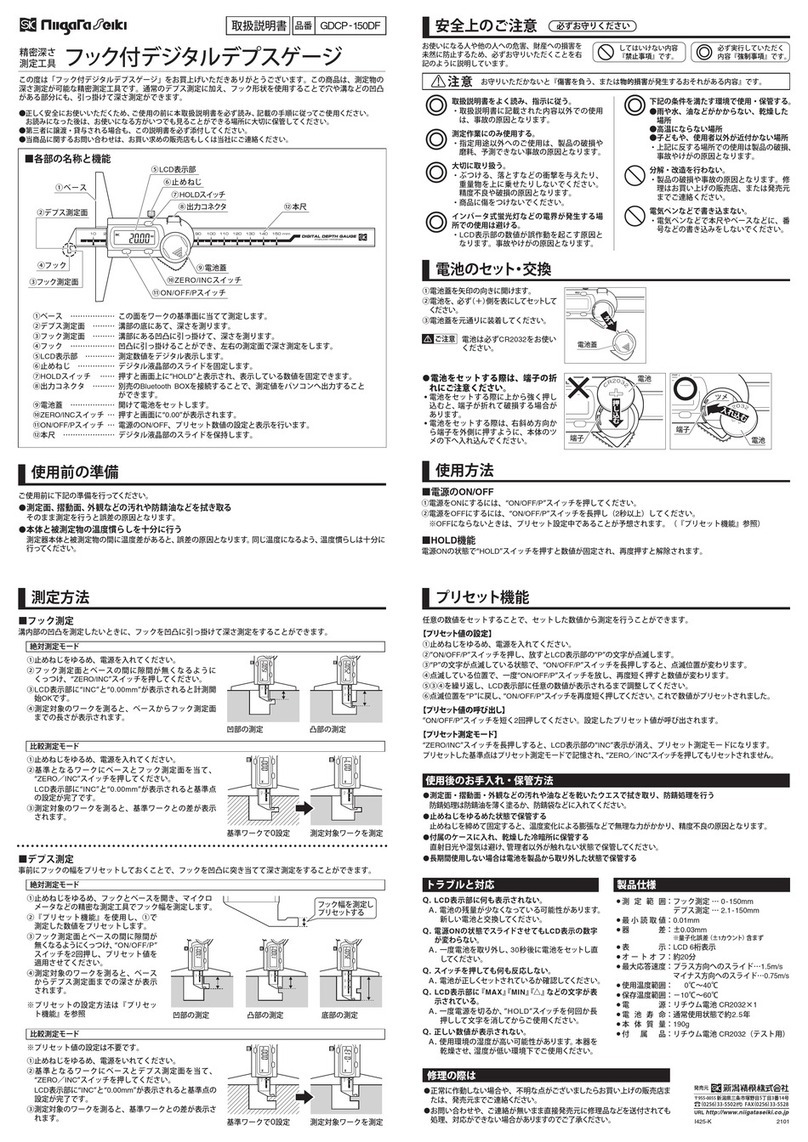

■HOW TO USE – Detecting reference position

Precision

Alignment

■APPLICATIONS・FEATURES

CAUTION

Do not pull apart Tip and Shank of instrument.

Make sure chips do not get on the moving surfaces of the

Stylus Center.

Use care not tofeed Stylus Center too far into Workpiece.

If possible, repeat process 2-3 times, and do not rely on

one reading.

Only use as directed. Improper use may cause accident or injury.

●

●

●

●

●

Mount the Stylus Center into the chuck

and offset the Tip slightly so there is

some wobble as it turns. Begin rotation

of the spindle.

For use with CNC, milling, and other precision positioning applications.

Finds reference position with 2μm accuracy.

Easy to use, quickly references off edge of workpiece.

●

●

●

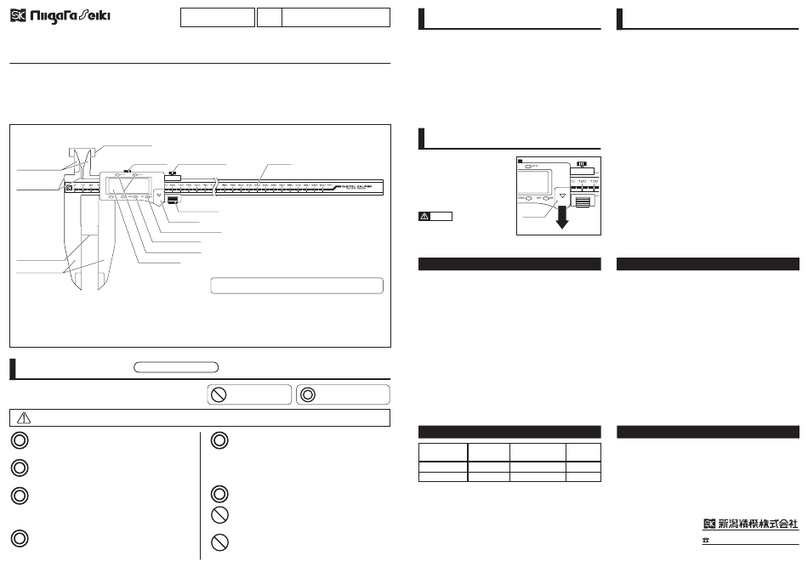

■SPECIFICATIONS

Tip

Chuck

Stylus Center

■

PARTS IDENTIFICATION

SR-10

φ10mm

Within ±2μm

High carbon chrome bearing steel

56g 57g55g 56g

SR-104 SR-104LSR-102

φ4×5・φ10mm

φ4×10・φ10mm

φ2×5・φ10mm

82mm 88.5mm 88.5mm 93.5mm

φ10mm

450〜600min-1

1

With Stylus Center rotating, gradually

bring the Stylus and workpiece together.

As it comes close to the edge reference

position, the Stylus will stop wobbling

and runout will decrease.

2

With additional feed, the Tip of the Stylus Center

will grab onto the face of the workpiece and shift

(“slide”, or “kick”) as shown.

This transition occurs when the Stylus Center is

accurately positioned at the edge.

The reference point for the edge of the workpiece

is offset by ½ the diameter of the Tip. (※)

※Stylus:φ2・・・1mmfeed φ4・・・2mmfeed φ10・・・5mmfeed

3

Slide

φ10Tip

Shank

Tip

Slow approach

Fine feed

Model:SR-**<combined>

Thank you for buying the Niigata Seiki Stylus Center (Edge Finder).

For proper operation, please read this manual thoroughly and follow the procedures described.

※Model SR-104 shown.

Tip

Shank

Length

RPM

Repeatability

Weight

Material

Model No.

Niigata Seiki Co., Ltd.

5-3-14, Tsukanome, Sanjo, Niigata, Japan, 955-0055

Tel. : +81-256-33-5522 Fax. : +81-256-33-5518

URL http://www.niigataseiki.co.jp

STYLUS CENTER