Ningbo YTD-35 Operation instructions

YTD-35 DRUM LIFTER &TRUCK

●riginal instruction

●peration Manual

Ningbo Ruyi Joint Stock Co. , Ltd.

Add:656 North Taoyuan Road Ninghai,Zhejiang China

YTD350 Operation Manual

- 1 -

elcome to choose YTD-35 Drum Lifter&Truck

A

Alarm

Please pay attention to the following cautions before you use this truck:

1. The operating instruction manual should be read seriously before operation, and the performance of the drum truck should be known, examine the truck carefully and make sure it

is normal every time before you use it, it is forbidden to use faulted truck..

2. YTD350 drum lifter & truck can only be used indoors with flat and solid ground, it is forbidden to be used in corrosive environment such as acid/alkali.

3. When the drum lifter & truck holding a drum is being moved, keep the drum off the highest position.( notice: the drum can not be rotated and lifted or lowered at the same time

during this process) Examine if the inner active overhead has fallen down or not, it is all right to keep a necessary clearance between the drum and the ground.

4. Make sure that the whole weight of the drum and materials in it are not more than the maximum rated load.

5. During operation, don’t put your hand and foot in front of this product or under the drum.

6. Don’t use this product on inclined ground with a inclination angle more than 8 degree.

7. During operation, keep your hand or other objects off the lifting chain, staple bolt or active overhead.

8. Examine the oil gauge bore in the reducer, make sure there is enough lubricant in it, add a little light engine oil and butter at each running position as well as the oil-fulfill choke to

make each part run safely and reliably.

I. Usage

YTD350 drum lifter & truck is designed to be used in many industrial fields to lift, carry drums and evert and discharge in 360 degree, it is specially applicable for the drums with

diameter of 600 mm and 900 mm high, it is a kind of machine with high lifting load and unloading and short range, lifting goods by manual hydraulic pressure, and it has mechanical

rotating device. Because it doesn’t produce fire and electromagnetism, it is especially applicable to motor load and unloading and the load and unloading of flammable and fire

forbidden goods in workshop, storage, dock, station, goods fields and so on, there are several characteristics of this product such as steady lifting and dropping, flexible rotation, easy

operation etc., the universal wheel has braking device, it works safely and reliably, so it is a ideal facility to reduce work intension, advance production efficiency and realize safe load

and unloading.

YTD350 Operation Manual

- 2 -

II. Main technological parameters:

III. Operation Manual

Manufacturer's type designation

YTD-35

Load capacity/rated load

Q(kg)

350

Load centre distance

c(mm)

570

Wheelbase

Y(mm)

1115

Service weight

kg

131

Tyre size,front

(mm)

φ80x36

Tyre size rear

(mm)

φ147x40

Height,mast lowered

h1(mm)

1270/1490

Lift

h3(mm)

1945/2385

Height,mast extended

h4(mm)

2100/2640

Height,lowered

h13(mm)

385

Overall length

l1(mm)

1520

Overall width

b1(mm)

1050

Distance between fork-arms

b5(mm)

840

Ground clearance,laden,below mast

m1(mm)

22

Aisle width for pallets 1000x1200 crossways

Ast(mm)

1720

Aisle width for pallets 800x1200 lengthways

Ast(mm)

1805

Turning radius

Wa(mm)

1200

Lift speed,laden/unladen

m/s

22

Lowering speed,laden/unladen

m/s

手控

YTD350 Operation Manual

- 3 -

1. Before you use it, add gear oil into reducer, make oil level between the marks;

2. To lift the drum, you just have to push the truck to the drum, open the staple bolt in front of the facility to the limited position, push it to the drum, make the opening position be

tightly and contrapuntally appressed to the center of the drum (notice: during the contraposition, make sure the cover of the drum is located dead ahead), lock the staple bolt by the

handle of the clamp, however, don’t hoop too much and make it flat. Before lift the drum, step on the brake of the universal wheel, fix the truck, and the drum will be lifted by

stepping on the hydraulic cylinder pedal at the right-back of the product or pulling the lifting handle of the jack;

3. To convey the drum, if the universal wheel is braked, firstly loosen the brake, adjust the height of the drum and make it 2 -3 inches above the ground (50mm-75mm). Alarm:

don’t move the drum when it is at the highest position. Then push or pull the truck to the necessary place. Alarm: don’t park the truck holding a drum on a slope. If this

case happens, it might cause automatic rolling of the truck and lead to property loss or personnel injury;

4. To rotate the drum, screw off the cover and exchange a special cover with unidirectional valve before the drum leaves the ground, after it is lifted, turn the handle at the input of

the redactor, rotate the drum and discharge, rock the handle, the drum can be rotated clockwise or anticlockwise and discharge in any angle.

5. To let the drum fall down, move the uninstall handle, oil return valve is open, under the action of gravity of the goods and fork, working oil in the piston-cylinder goes back into

the tank through oil return valve, the piston rod and fork fall to the lowest position, after the drum falls to the ground or tray, you just have to open the staple bolt and then pull the

truck off the drum. Alarm: when the goods is falling down, the operation of the handle of the oil return valve should be slow and light to prevent sudden fall when falling

down too rapidly and cause unsafe result. When the goods is falling down rapidly, the oil return valve can not be shut down suddenly because the inertial acceleration in

the rapid falling process will produce strong force to damage the facility and goods if it is shut down suddenly.

IV Structural features

YTD350 drum lifter & truck consists of hydraulic system, framework and rotary mechanism, etc.

This truck needs manual hydraulic pressure jack (hydraulic equipment) as power to lift goods. Push, pull or transit the goods by men. There is an oil return valve in the hydraulic

equipment, and the falling speed of fork is controlled by handle. It also makes the hydraulic system act correctly, safely and reliably. The upright mounting is welded of high quality

profiled bar; and it has high rigidity and intension. The rear wheel needs a universal wheel with brake device, then it can rotate freely and turn portably and flexibly. Both of the front

wheels and rear wheels are installed onto the axle by ball bearings, so they can run flexibly. The wheels are made from nylon; and they are not only wear resistant and durable, but also

bring little damage to working floor.

VWork condition

The condition in which YTD350 drum lifter & truck works should accords with those followings: 1.Work circumstance temperature:-25℃~+40℃。

2.Circumstance relative humidity should be less than 90%RH。

3.Work in circumstance with no rain and noxious gases.

4.Work in rooms with flat, hard ground.

VI. Maintenance explanations

1. The oil should be clean and enough.

YTD350 Operation Manual

- 4 -

2. Before work, please check the condition of the truck and make sure that there is no relaxing part.

3. Goods should be distributed uniformly at the folk and no over loading.

4. After work, unload the weight part, which is not allowed putting at the fork for a long time.

5. Every month, lubricate the truckle and chain with butter through oil-fulfill choke. Light oil should be injected to the move part of the machine in order to operate it steadily.

VII. The failures which could happen during work and the fixing methods

Serial

Number

Failure

Reason analysis:

Fixing methods

1

The rising height does not reach

the design requirement

Lack of oil

Fulfill the oil tank, open the screw, and fulfill the tank with clean oil till reaching

oil hole, then

2

Pull the handle but the fork does not

work.

1. The viscosity of work oil is too high or there is no oil

Change the oil or fulfill the tank with oil as fixed.

2. The impurity of the oil makes the oil valve does not close well

Clean the impurity or change the oil

3. Fuel outlet valve、unloading handle、draught spring do not work; or

are not at the lowest shut off position or are blocked by other thing.

Check if the draught spring works well and does the unloading handle at the

lowest shut off position; clean the impurity.

4. The positions of unloading handle、Fuel outlet valve are not right

Readjust the position of unloading bolt

3

The fork can not move down after

moving up

1. Unloading handle is not adjusted well.

2. Leaning load of the piston is too high that permanent deformation

happened.

3. The fork frame, idler wheel are blocked.

Adjust, repair or change the piston staff according unloading handle at the lowest

shut off position;

Repair or change the bearing

4

Greasing or oil leaking

1. Sealing gaskets are damaged or do not work

2. Exceptional part has some tiny fracture or small perforation.

3. The screw-joint parts are loosened or sealing gasket does not press

well.

Change new Sealing gaskets, examine and change new parts.

Examine and tighten.

YTD350 Operation Manual

- 5 -

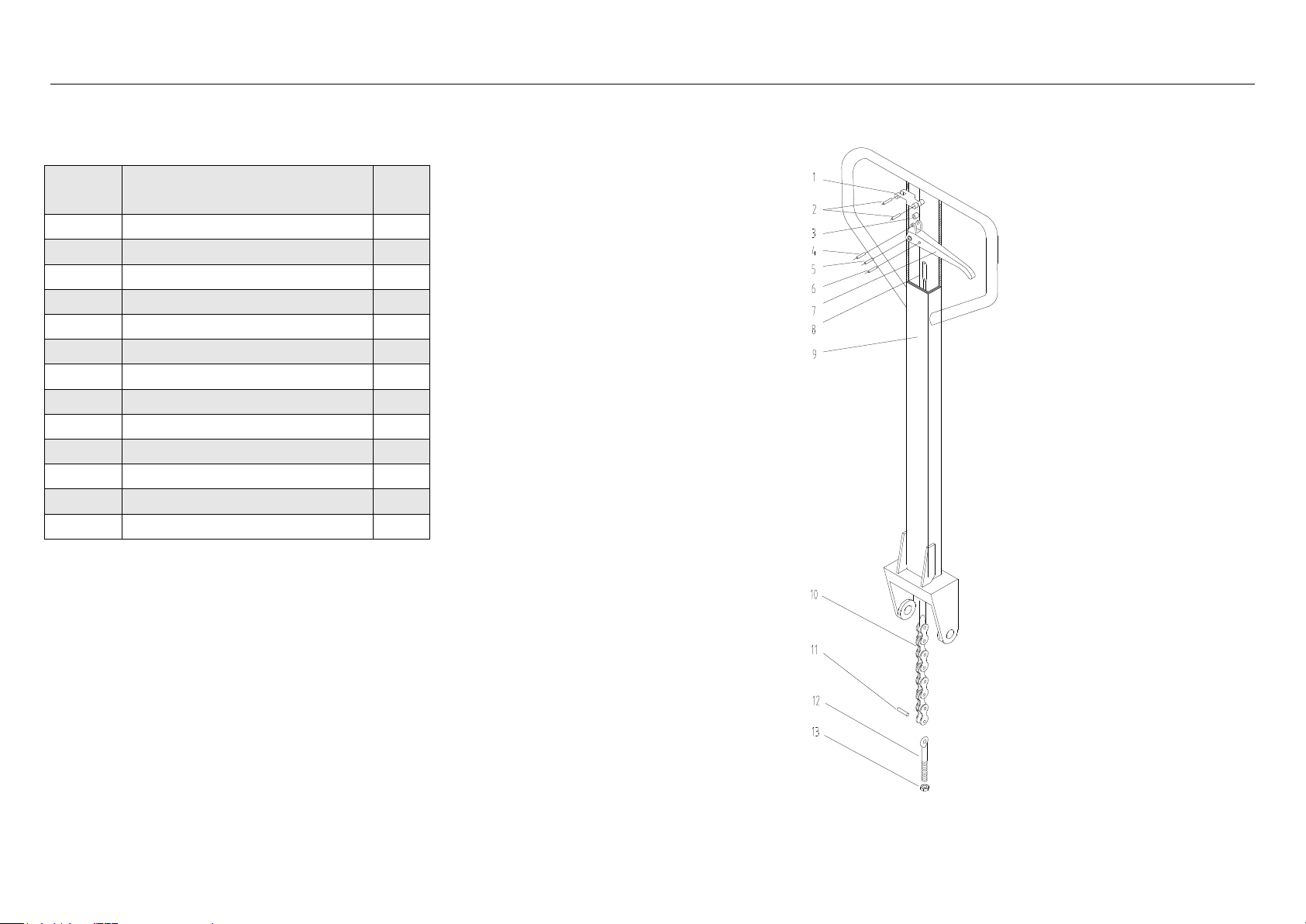

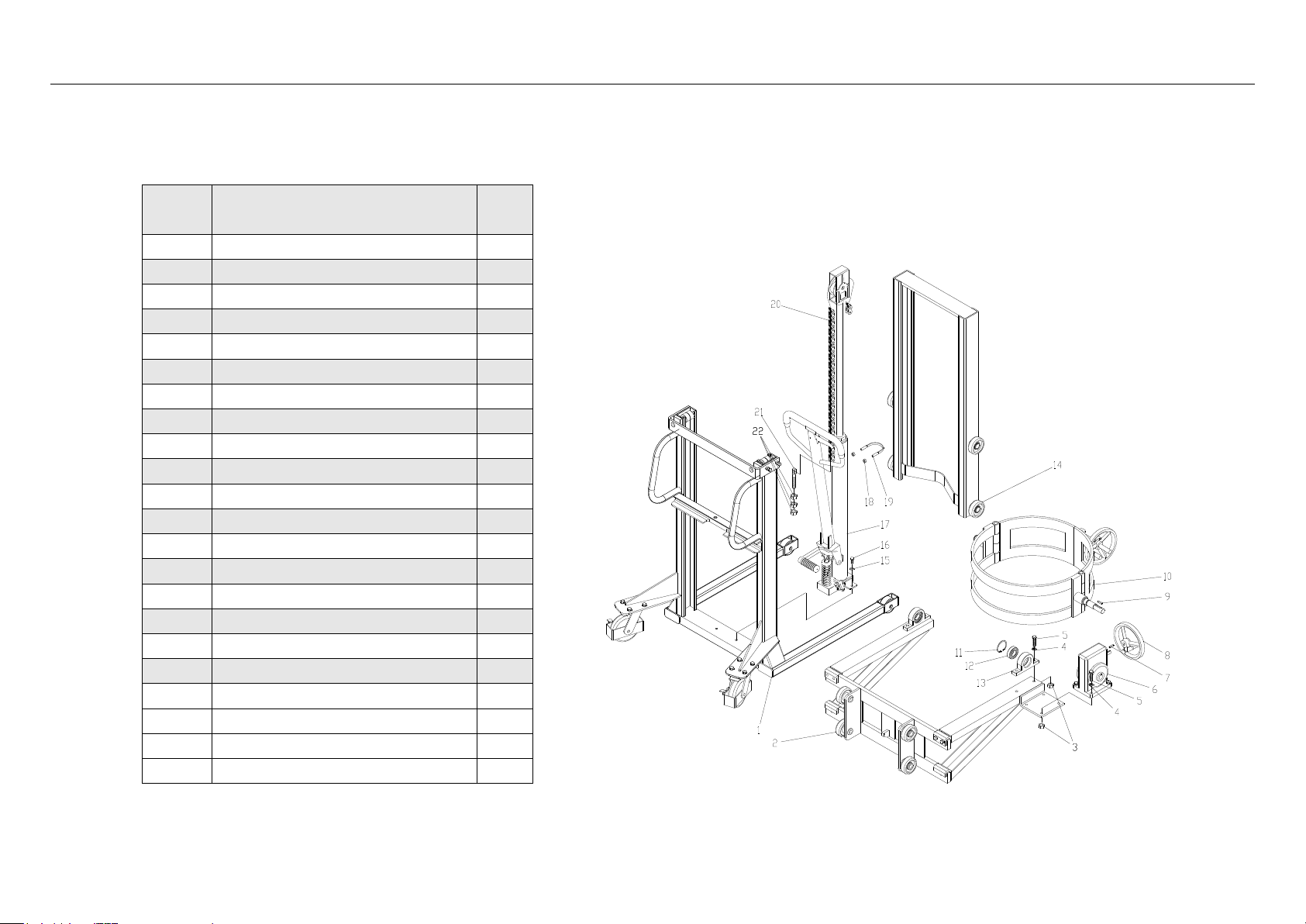

VIII. Blast figure:

1. handle:

Serial

number

Name

Number

1

Locating tab

1

2

Elastic pinø4×32

2

3

Idler wheel

1

4

Elastic pinø4×20

1

5

Elastic pinø6×32

1

6

Elastic pinø4×20

1

7

Knob

1

8

Draught staff

1

9

Handlebar

1

10

Chain

1

11

Pin

1

12

Ball head bolt

1

13

Locknut

1

YTD350 Operation Manual

- 6 -

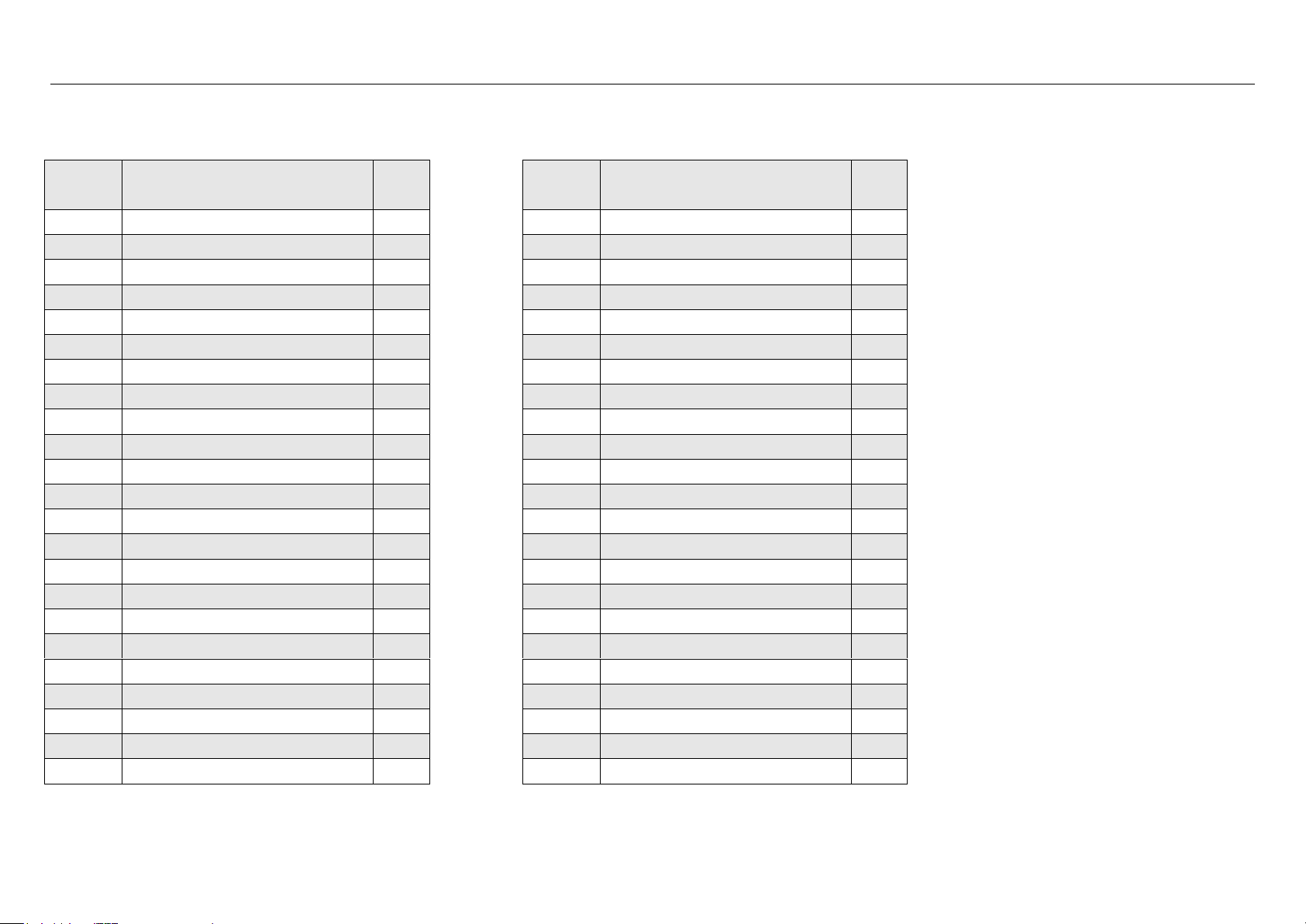

2. Jack:

Serial

number

Name

Number

1

Hexagonal nutm6

2

2

Bolt m6×25

3

Lever board

1

4

F iring pin

1

5

Otype ring ø4.87×1.8

2

6

Firing pin spring

1

7

Firing pin valve seat

1

8

Compound gasketø20

2

9

Otype ring ø12.5×2.65

2

10

Steel ballø8

1

11

Boltm8×50

1

12

Nut m8

1

13

Pinø3×15.7

1

14

Valve seat500

1

15

Steel ballø5

1

16

Pin

1

17

Valve seat spring

1

18

Compound gasketø10

1

19

Plug

1

20

Compound lining 1220

1

21

Compound lining 2017

2

22

Pressing frame

1

23

Elastic pinø4×24

1

YTD350 Operation Manual

- 7 -

Serial

number

Name

Number

24

Pin with hole

1

25

Press wheel

1

26

Elastic pin ø5×35

1

27

Pressing frame bearing pin

1

28

Draught spring

1

29

Handle

1

30

O type ring ø22.4×2.65

1

31

Pump cylinderø18

1

32

Sealing ringø18

1

33

Dust ring ø18

1

34

Big spring

1

35

Pump core ø18

1

36

Big spring seat

1

37

O type ring ø65×3.55

1

38

Cylinder

1

39

O type ring ø 7.5×2.65

2

40

Oil stopper

1

41

Compound lining 2012

2

42

Rectangle sealing ring

1

43

Steel ballø6.5

1

44

Safety valve seat

1

45

Safety valve spring

1

46

Safety valve adjusting screw

1

Serial

number

Name

Number

47

Safety valve protect jacket

1

48

Piston staff

1

49

Sealing ringø31.5

1

50

Oil tank

1

51

Top cap

1

52

O type ring ø31.5×3.55

1

53

Dust ring ø31.5

1

54

Bolt m12×25

1

55

Elastic shield ring for axisø20

2

56

Sprocket shaft

1

57

Elastic shield ring for hole ø47

1

58

Bearing60204

1

59

Sprocket wheel

1

60

Sprocket wheel cover

1

61

O type ring ø47.5×3.55

1

62

Steel ballø4

1

YTD350 Operation Manual

- 8 -

3. Cans clamp components:

Serial

number

Name

Number

1

Clamp1

1

2

Connection pin

2

3

Clamp2

1

4

Inner-hexagonal round-head bolt

m8x50

1

5

Embedded plasticlocknutm8

1

6

Screw

1

7

Clamp3

1

8

Hand-clamping wheel

1

YTD350 Operation Manual

- 9 -

4. Fork frame components:

Serial

number

Name

Number

1

Fastening boltm16×50

4

2

Steel ball ø19

4

3

Bearing80207

4

4

Elastic shield ring for axis ø35

4

5

Big block

4

6

Elevating platform

1

7

Fork frame 1

1

8

Spring gasket12

6

9

Hexagonal boltm12×35

6

10

Fork frame 2

1

YTD350 Operation Manual

- 10 -

5. Inner upright frame components:

Serial

number

Name

Number

1

Inner upright frame

1

2

Elastic shield ring for hole 72

4

3

Bearing 6207

4

4

Elastic shield ring for axis

4

5

Big block

4

YTD350 Operation Manual

- 11 -

6. Outer upright frame components:

Serial

number

Name

Number

1

Universal wheel

2

2

Hexagonal nutm10

12

3

Flat gasket ø10

8

4

Hexagonal boltm10x25

8

5

Frame

1

6

Bearing 60204

2

7

Front wheel

2

8

Shield ring for axis ø20

4

9

Front axle

2

10

Side rolling wheel

4

11

Shield ring for axis20

4

12

Side axle of rolling wheel

2

13

Hexagonal boltm10x60

4

YTD350 Operation Manual

- 12 -

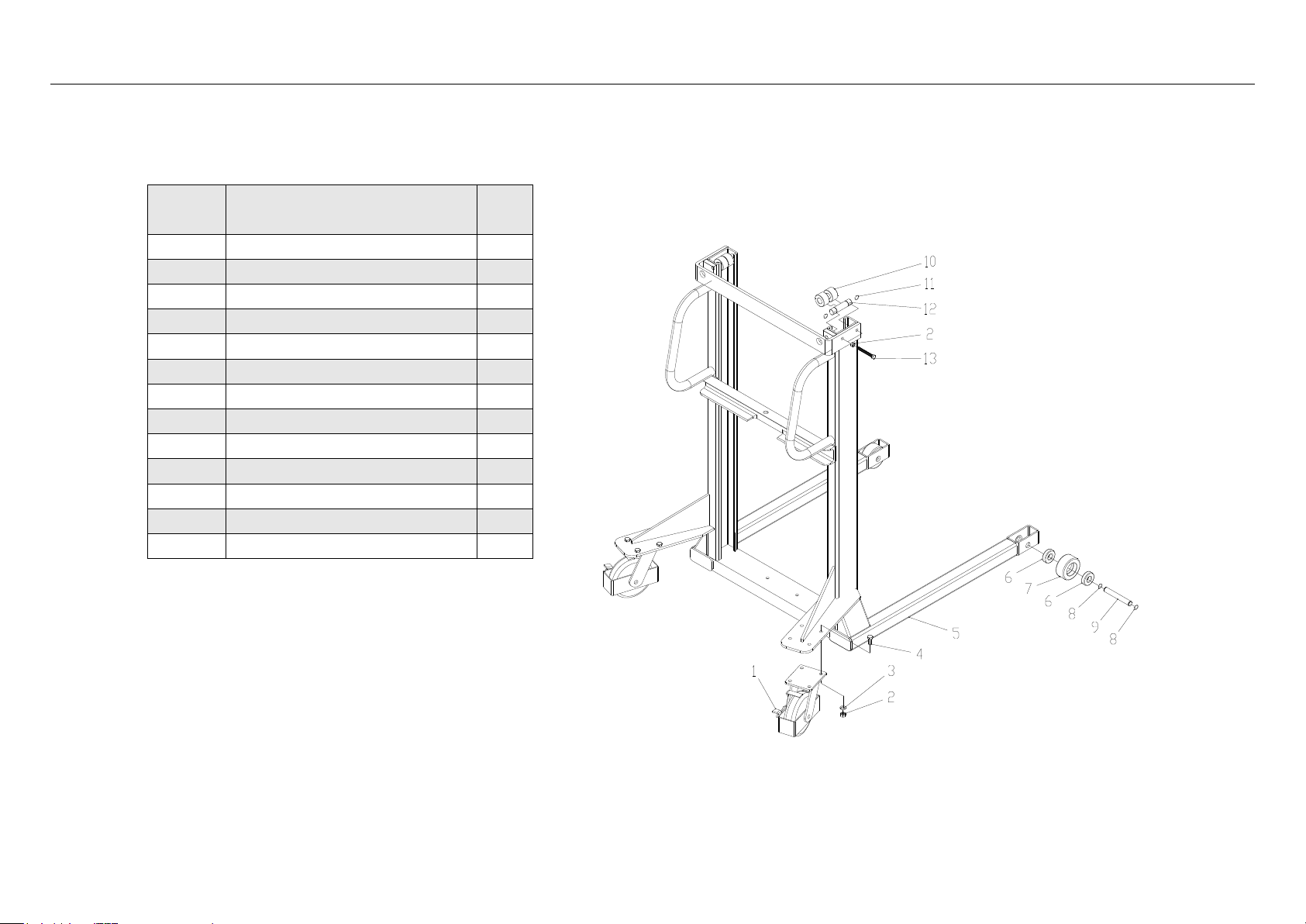

7. Assembly:

Serial

number

Name

Number

1

Outer upright frame components

1

2

Fork frame components

1

3

Hexagonal nutm12

8

4

Spring gasket12

8

5

Hexagonal boltm12x45

8

6

Worm reducer

1

7

Flat key5x35

1

8

Hand wheel of the reducer

1

9

Flat key8x40

1

10

Net guard

1

11

Fixed ring

4

12

Hexagonal boltm6×10

4

13

Clamp components

1

14

Inner upright frame components

1

15

Flat gasket ø10

2

16

Hexagonal bolt

2

17

Jack components

1

18

Locknutm10

2

19

Cylinder clamp

1

20

Chain

1

21

Screw

1

22

Hexagonal nutm16

6

YTD350 Operation Manual

- 13 -

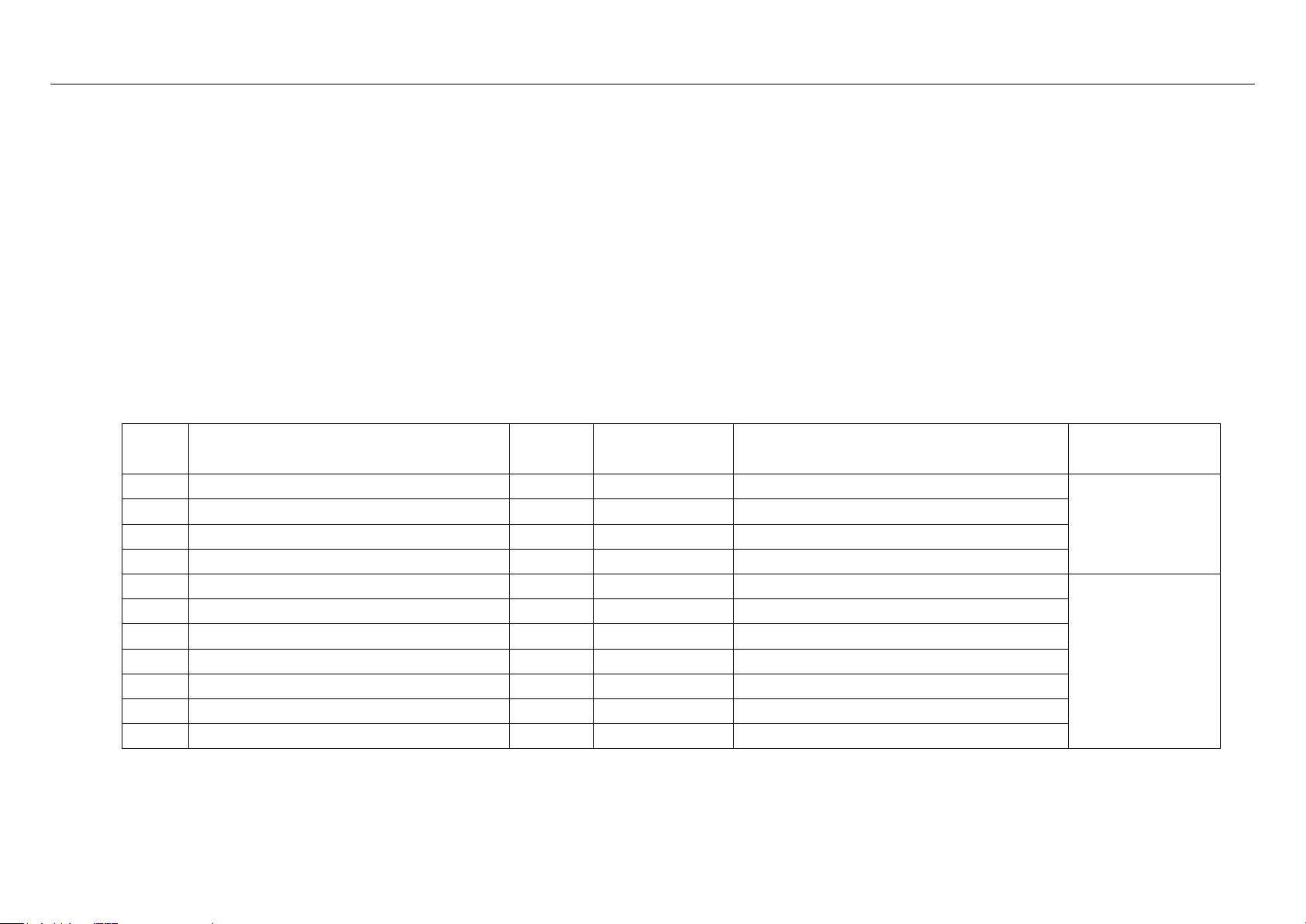

Goods list

YTD350 drum lifter & truck

Receiving company: Product serial number:

Contract number: Product date:

Serial

number

Name

Number

Net weigh(kg)

The exterior size(length ×width ×height)

Remark

1

Ytd350 can- pallet trucks

1 piece

200

1520×1050×1270

The whole

machine part

2

Instructions of ytd350 can-pallet trucks

1 piece

3

Conformity certificate

1 piece

4

Goods list

1 piece

6

Assembled ringφ20

2 pieces

The jack part

7

O type sealing ringφ47.5×3.55

1 piece

8

O type sealing ringφ65×3.55

1 piece

9

UHS sealing ringφ18

1 piece

10

UHS sealing ringφ31.5

1 piece

11

DHS dust ringφ18

1 piece

12

DHS dust ringφ31.5

1 piece

Popular Lifting System manuals by other brands

ARJO HUNTLEIGH

ARJO HUNTLEIGH MAXI LITE Instructions for use

EZ Carrier

EZ Carrier EZCLA user manual

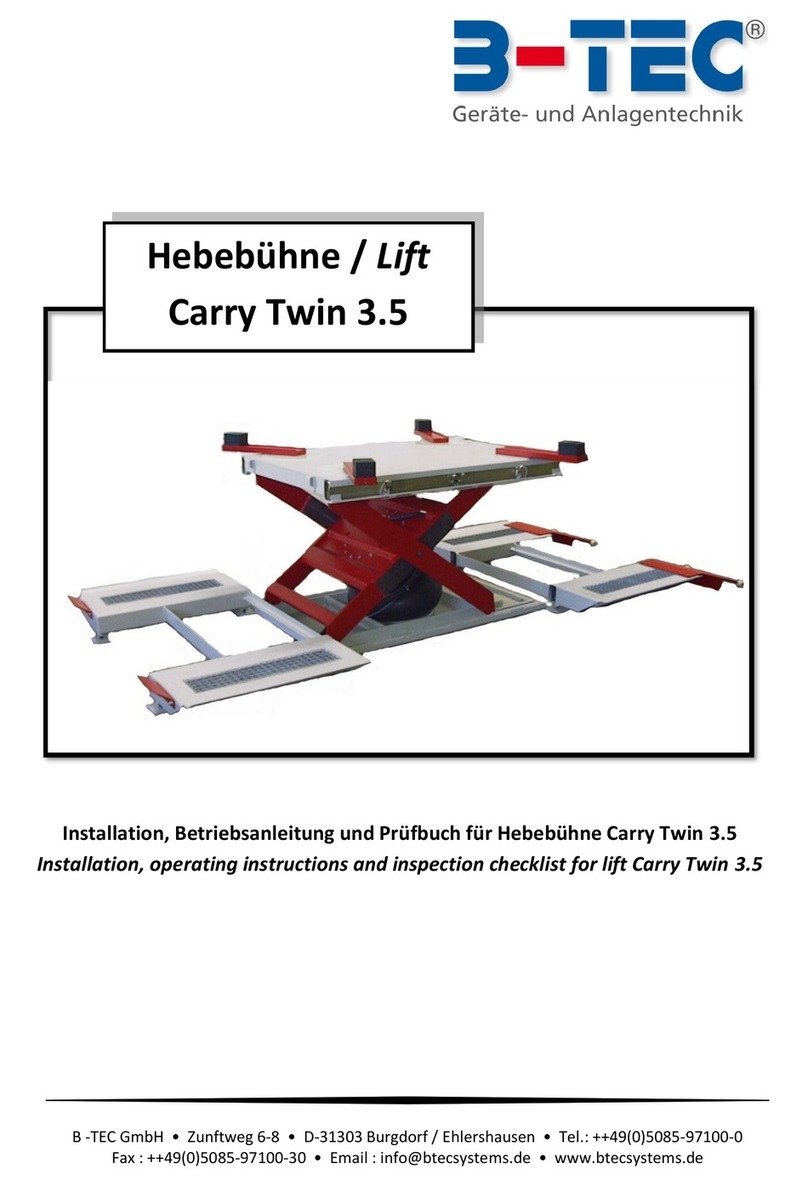

B-TEC

B-TEC Carry Twin 3.5 Installation, operating instructions and parts list

Ravas

Ravas iForks Service manual

Romedis

Romedis Symphonie Aqua operating instructions

Harmar Mobility

Harmar Mobility AL001 owner's manual