NIOX MINO User manual

ENGLISH

NIOX MINO®

External Quality Control

User Manual

Note!

This manual is an appendix to the NIOX MINO®User Manual.

It describes the optional external Quality Control procedure for

NIOX MINO. Please refer to the NIOX MINO User Manual for more

information.

1

Warning! ........................................................... 2

External Quality Control procedure (QC) ...... 2

Switching QC on/off.......................................... 2

Selection and qualication of QC testers.......... 3

QC measurement ............................................. 3

View stored QC results..................................... 4

View QC information......................................... 4

Reset QC tester................................................ 5

Alerts codes...................................................... 5

Display buttons and symbols ............................ 5

Table of contents

External Quality Control User manual 000186

(EPM-000158), version 04, December 2016, for

instruments with software version from 2005

to 20XX, 22XX and 23XX. X can be any number

between 0 and 9. The version number for your

instrument can be seen in the Information menu,

see NIOX MINO®User Manual.

Information in this document is subject to change.

Amendments will be made available by Aerocrine

AB as they occur.

• NIOX MINO is CE-marked according to In Vitro

Diagnostic Device Directive 98/79/EC and

approved for clinical use in EEC countries.

• NIOX MINO is 510(k) cleared, K101034, by FDA.

• NIOX MINO is RoHS compliant.

• Copyright © 2016 Circassia AB, Solna, Sweden.

• NIOX MINO®and NIOX®are registered

trademarks of Circassia AB.

• Circassia is a registered trademark of Circassia

Limited

2

Warnings!

• Handle the NIOX MINO®instrument as stated

in the NIOX MINO User Manual and in this

manual. Aerocrine accepts no responsibility

for damaged equipment or faulty results, if

the equipment is not used according to the

manuals mentioned above.

• Do not use a damaged NIOX MINO instrument

or damaged components

• Use only the power supply unit provided.

• Keep the instrument out of water. Ensure

that no liquid is spilled or dripped on the

instrument.

• Do not heat or dispose of the instrument or

Sensor in re. Please refer to the "Handling of

used/expired products" section.

• Take care not to drop the instrument or subject

it to strong impact.

• It is recommended not to use NIOX MINO

in the proximity of areas where volatile

substances such as organic uids or

disinfectants are being used. Special attention

should be paid to aerosols and disinfection

baths (either open vessels or ultrasonic baths).

• NIOX MINO should not be used adjacent to or

stacked with other equipment.

• The NIOX MINO Sensor contains chemicals

that could be harmful if swallowed.

• Touch only the grey cap when exchanging the

Sensor.

• Do not clean the sensor. Cleaning of the

Sensor with ethanol or similar disinfectant

might destabilize it for a non-predictable time

period.

• Keep the Sensor out of water! Ensure that no

liquid is spilled or dripped on the Sensor.

• The NO scrubber contains potassium

permanganate and should be disposed of as

hazardous waste in accordance with the local

waste disposal regulations.

• When selecting an accessory for your NIOX

MINO please keep in mind that an accessory

not recommended by Aerocrine may result in

loss of performance, damage to your NIOX

MINO, re, electric shock, injury or damage to

other property. The product warranty does not

cover product failure or damage resulting from

use with non-approved accessories. Aerocrine

takes no responsibility for health and safety

problems or other problems caused by the use

of accessories not approved by Aerocrine.

• No modication of the NIOX MINO instrument

or the Sensor is allowed.

Please refer to the NIOX MINO User Manual

for Cautions.

External Quality Control

procedure (QC)

In addition to internal checks and self tests

of NIOX MINO, the external Quality Control

procedure provides the user with further

condence that the system is operating within its

specications.

The external Quality Control consists of two

parts. One positive control from a qualied staff

member with a stable F

e

NO value providing a

normal biological

FeNO

sample, and a negative

control consisting of a NO free gas sample,

generated from ambient air. NIOX MINO will

allow for one daily QC measurement that will

not affect the number of remaining tests on the

NIOX MINO Sensor. (During the rst 20 days of

instrument start-up, a maximum of four QC testers

can be qualied without impact to the number of

remaining tests on the Sensor.)

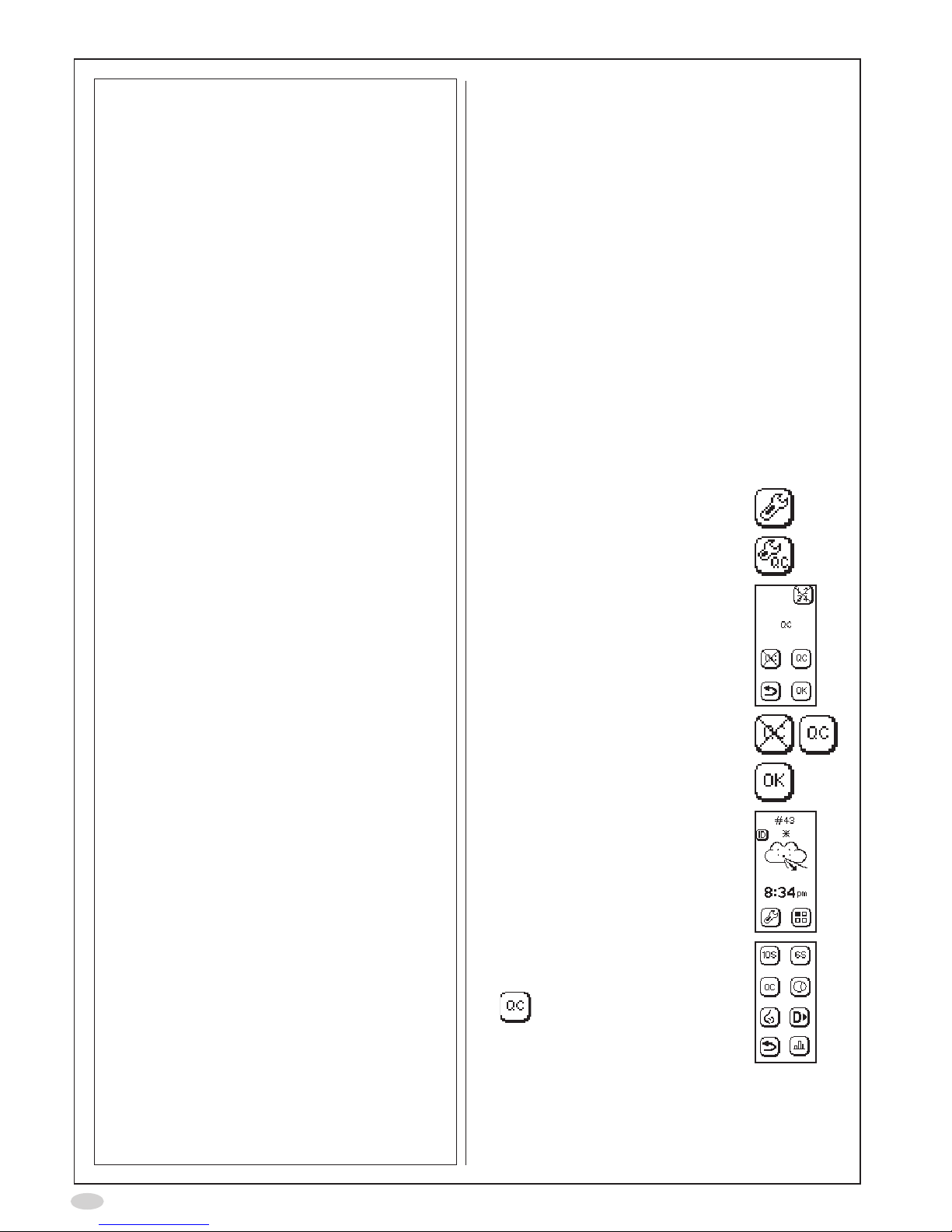

Switching QC on/off

1. Select Settings

2. Select QC settings

3. The QC settings are shown

4. Use the buttons to deactivate or

activate QC measurement

5. Select OK to accept the changes

The main screen shows a twinkling

asterisk to indicate that QC is on

and a daily QC measurement has

not been performed.

The mode screen shows a QC

measurement mode button for

starting a QC measurement

3

Selection and qualication of QC testers

A minimum of one individual (two individuals are

recommended) needs to qualify for this procedure.

Identify a third individual as a back-up, if possible.

Identify the staff members who will perform the

Quality Control and meet the following criteria

• Over 18 years of age.

• No ongoing cold or known airway disease.

• Non-smoker.

• Expected stable

FeNO

values between 5 and

40 ppb.

• Preferably no allergies (except seasonal, see

below) or asthma.

A QC tester will be qualied over the course of

three days.

Note!

If the most recent QC measurement is

older than 30 days, then the qualication

is suspended and the QC tester needs

to re-qualify according to the qualication

procedure.

Perform three QC measurements, one per

day within seven days, according to the QC

measurement section, in order to qualify a QC

tester.

A mean value is calculated from the three

measurements that must be between 5-40 ppb

for the QC tester to be qualied. The following

QC measurement on the fourth day must be

within ±10ppb from the mean value and the NO

Scrubber result < 5 ppb. Once the Quality Control

has been completed the instrument is ready

for clinical use. The next moving mean value is

calculated when the QC tester performs a QC

measurement following at least 7 days.

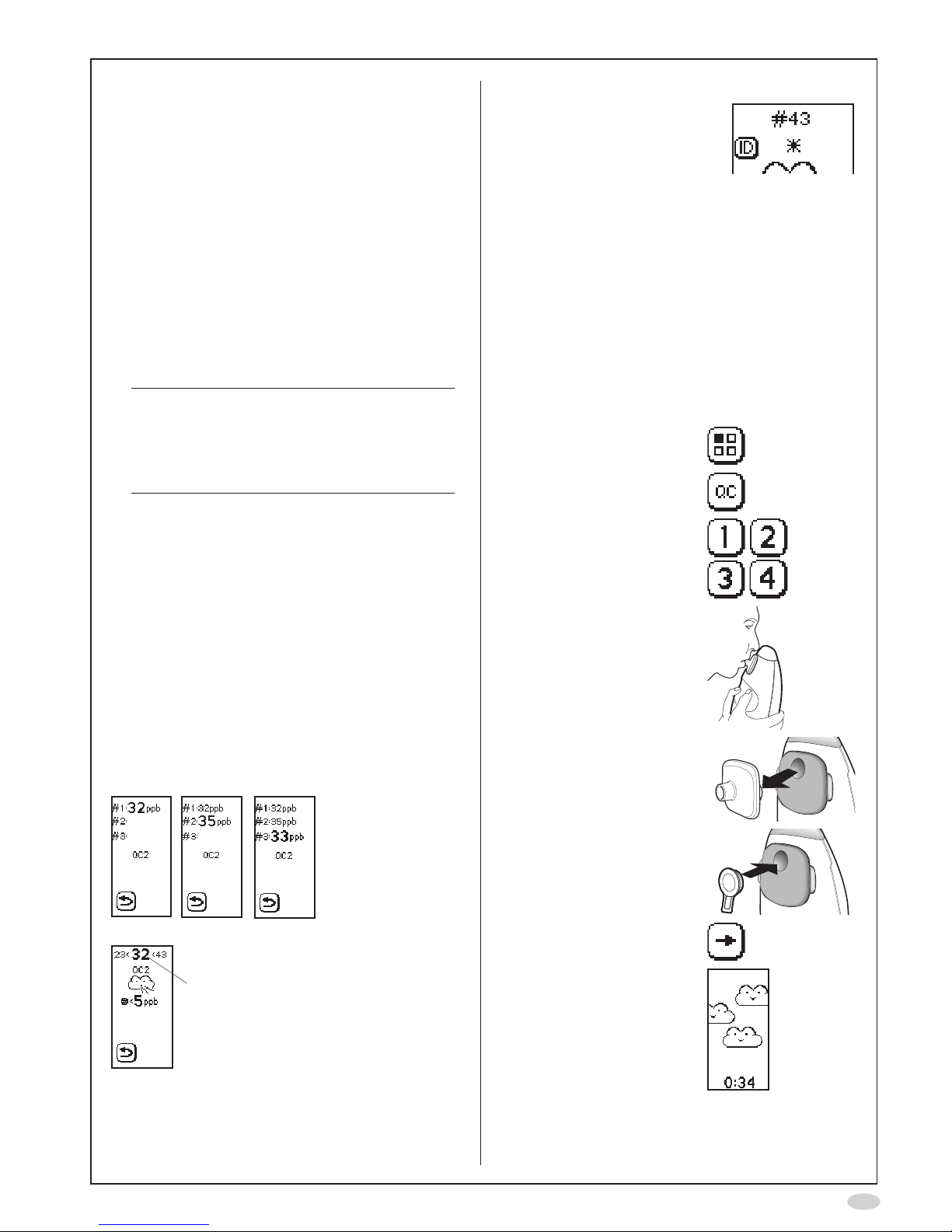

Result screens for the QC tester qualication

Day 1 Day 2 Day 3

After day 3

Positive control result:

FeNO

value and limits

(mean value +/- 10 ppb)

QC measurement

The instrument will prompt for a

daily QC procedure by showing

a twinkling asterisk on the

display.

Always consider the following in order to obtain

reliable results.

Before any measurement:

• Avoid nitrate rich food within 3 hrs before the

measurement.

• Avoid any strenuous exercise at least 1 hour

before the measurement.

Preferably do not perform a measurement in case

of:

• Ongoing cold.

• Acute seasonal allergy.

1. Select Mode

2. Select QC mode

3. Select QC tester number

(each QC tester must

select an individual

number)

4. Perform a normal

FeNO

measurement according

to the NIOX MINO user

manual

5. Remove the patient lter

6. Immediately attach the

QC plug

7. Select the Forward icon

on the display

8. Wait for the analysis to be

completed and the test

result to be displayed

(approximately 5 minutes)

4

9. The QC measurement

result is displayed

Note!

During the qualication

days of a new QC

tester the result is

displayed as presented

Day 1-3.

Day 1 Day 2 Day 3

A. Positive control result:

FeNO

value and

limits (mean value

+/-10ppb)

B. QC tester number

C. Negative control result

(should be < 5 ppb)

After day 3

A

B

C

10.Remove the QC plug

Repeat the QC measurement if the positive and/

or the negative controls fail. If QC fail persists,

discontinue use of NIOX MINO®and contact

your local Aerocrine representative or Aerocrine

Customer Support.

Note!

If the daily Quality Control

is not successfully

performed, or if the results

from the QC are outside

limits, an asterisk will be

displayed beside every

measurement value

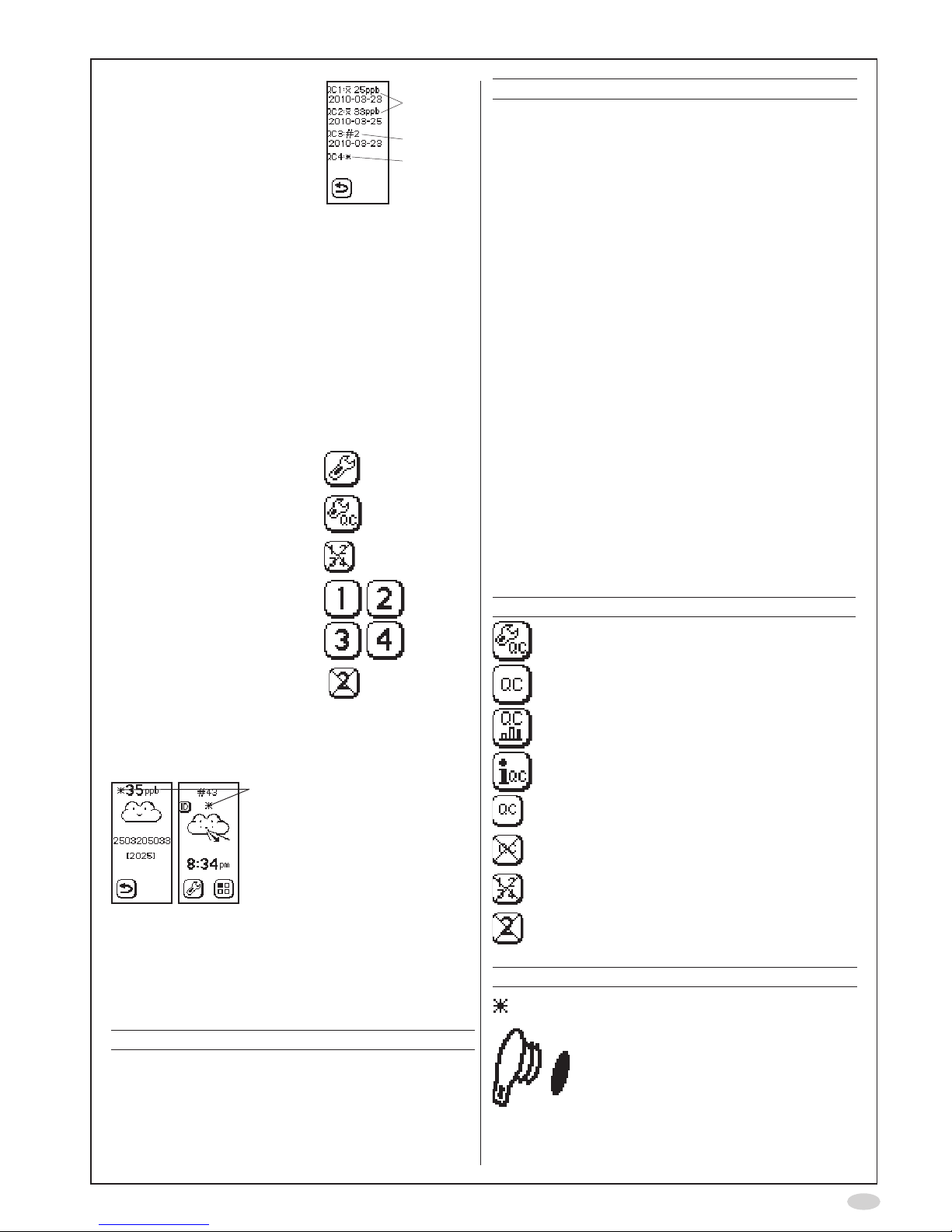

View stored QC results

All previous QC results are stored in the instrument

and can be viewed at any time by using the

following procedure:

1. Select Mode

2. Select QC

3. Select QC measurement

results

4. The latest stored

measurement is displayed

A. Positive control result:

FeNO

value and

limits (mean value

+/-10ppb)

B QC tester number

C. Negative control result

(should be < 5 ppb)

D. QC sequence number

E. Time and date of

measurement

A

B

C

D

E

The qualication results

can also be displayed

A. QC tester qualifying

result

B QC tester number

C. QC sequence number

A

B

C

5. Use the previous and next

buttons to step through

the results

6. Select Return to go back

to the Mode screen

View QC information

QC tester information is stored in the instrument.

1. Select Mode

2. Select QC

3. Select QC info

5

4. The QC information is

displayed:

A. Mean QC

FeNO

value

and latest moving

mean date for QC

testers 1 and 2

B. Ongoing qualication,

position in QC

measurement

sequence for

QC tester 3, and

latest qualication

measurement date

C. The QC tester 4 is not

qualied

A

B

C

Reset QC tester

This procedure will delete the data for the selected

individual

1. Select Settings

2. Select QC setup

3. Select Reset QC tester

4. Select the QC tester to be

reset

5. Select the crossed-over

number to conrm reset

of desired user ID

Alerts codes

Asterisk shown.

The instrument has not been

veried by a daily QC –

Perform a QC measurement.

Alert messages and other information are shown

as codes at the top of the instrument display. The

table below provides the recommended actions to

be taken for an alert code. If alert persists, contact

your local Aerocrine representative or Aerocrine

Customer Support.

Code Action

QC alerts

A50 The mean value of the three qualication

results does not fall between 5-40 ppb.

Restart the QC tester qualication from

qualication day 1.

Code Action

A51 There has been an attempt to perform

several QC measurements on the

same day with the same test person.

Wait one day and perform the next QC

measurement.

A52 Moving mean value out of range.

Restart the QC tester qualication from

qualication day 1.

A53 NO Scrubber result over 5 ppb. Check

that the QC Plug was attached when

instructed. Restart the QC measurement.

If continuously shown replace the NO

Scrubber.

A54 Daily QC result lower than 5 ppb. Restart

measurement with test person who has

FeNO

higher than 5 ppb.

A55 Daily QC result higher than 40 ppb.

Restart measurement with test person

who has

FeNO

lower than 40 ppb.

A56 Failure to press the QC plug forward

button in time (within 1.30 min.). Repeat

the QC measurement and make sure to

press the forward button after the QC

plug is inserted.

Display buttons and symbols

Button Description

QC settings

QC measurement

Stored QC measurement results

QC info

External QC on

External QC off

Reset QC tester

Conrm QC tester reset

Symbol Description

The instrument has not been veried

by a daily QC

Insert the QC plug

000186 (EPM-000157), version 04, December 2016, for instruments with SW from 2005 to 20XX, 22XX and 23XX

Circassia AB, an ISO 13485 certified company

Circassia AB, Råsundavägen 18, SE-169 67 Solna, Sweden

Phone: +46 8 629 07 80, Fax: +46 8 629 07 81, E-mail: nioxxtechsupport@ircassia.com

www.niox.com.

NIOX MINO®is CE marked according to European In Vitro Diagnostic Device Directive 98/79/EEC

Copyright ©2016 Circassia AB, Solna, Sweden.

Circassia is a registered trademark of Circassia Limited

NIOX MINO®and NIOX®are registered trademarks of Circassia AB.

Patents:

Circassia’s NIOX products are protected by a number of patents in the US, Europe and a range of other

countries.

A NEW DIMENSION IN ASTHMA CARE

Information in this document is subject to change.

Amendments will be made available by Circassia AB as they occur.

© Copyright 2016: Circassia AB, SOLNA, Sweden.

Based on the company’s intellectual property, Circassia develops and

commercializes product for the monitoring of nitric oxide (NO) as a marker

of inflammation, to improve the management and care of patients with

inflammatory disease in the airways.

Other manuals for MINO

1

Table of contents

Other NIOX Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual