NIPPON POP RIVETS AND FASTENERS PRL550 User manual

PRL550

Rivet Tool

PRL550

Instruction Manual

This rivet tool is exclusively for pop rivets.

Read this manual thoroughly before using the rivet tool, and keep it in a handy place

where rivet operator can refer to it any time.

NIPPON POP RIVETS AND FASTENERS LTD.

PRL550

Contents

SafetyPrecautions ・・・・・ 1

1.Nameofparts ・・・・・ 3

2.Outline ・・・・・ 4

3.Dimensionaldrawing ・・・・・ 5

4.Preparation for use ・・・・・ 6

5.Precautions for use ・・・・・ 7

6.Howtouse ・・・・・ 8

7.MaintenanceandInspections ・・・・・ 10

8.Troubleshooting ・・・・・ 16

9.Partslist ・・・・・ 17

10.Cross-sectional diagram of PRL550 ・・・・・ 19

PRL550

- 1 -

Ssfety Precautions (1/2)

●Read the following “Safety Precautions” thoroughly before using the rivet tool, and use the tool correctly,

following the instructions included in the instruction manual.

●Cautions are divided into the following:

WARNING Erroneous handling could cause death or serious injury.

CAUTIONErroneous handling could cause personal injury or damage.

●After reading the manual, keep it in a handy place where rivet operators can refer to it any time.

●Use this tool only when setting standard pop rivets.

(See the catalog of pop rivets for selecting rivets.)

WARNING

1. Use the tool with an air pressure of 0.5-0.6 MPa.

◇Exceeding the specified air pressure could damage the tool, resulting in accident or injury.

2. Do not use or operate this tool while pointing at any person. Do not look into the tool from the front or back.

◇If rivets or ruptured mandrels pop out, it could cause an accident or serious injury (losing eyesight, etc.).

3. Always wear protective goggles (JIS T8147 specification product) during use.

◇If rivets or ruptured mandrels pop out, it could cause an accident or serious injury (losing eyesight, etc.).

Take special care with BHM and peel-typerivets since it is specified that mandrelheads may pop out.

See the catalog of pop rivets for details.

4. Be sure to attach the collector without damage. When removing the collector, be sure to separate the coupler to

stop the supply of compressed air.

Do not supply compressed air while the collector is detached:

◇

Doing so could cause the ruptured mandrels to pop out, resulting in an accident or serious injury (losing

eyesight, etc.).

5. Check whether individual parts are damaged or not: If there is a damaged part, stop using the tool and ask for a

repair.

◇Using the damaged tool as is could cause an accident or injury.

6. Securely connect the compressed air supply block.

◇If the screws at the connection section do not fit in or the threaded insert margin is insufficient, the coupler,

hose, etc. could come off during use, resulting in an accident or injury.

※For names of parts, see P.3.

PRL550

- 2 -

Safety Precautions (2/2)

CAUTION

1. When this tool is disassembled for maintenance and/or parts replacement, and then reassembled, be sure to

separate the coupler or perform similar actions to stop supply of compressed air.

◇If the tool is disassembled or reassembled while compressed air is being supplied, parts could pop out, oil

could jet out, or the tool could move unexpectedly, resulting in an accident or injury.

2. Securely tighten the fill-screw when using the tool.

◇

Using the tool with the fill-screw loosened or removed could cause oil to jet out, resulting in an accident or

injury.

3. Do not operate the tool with the nose housing removed:

◇

Doing so could cause your fingers to be caught, etc., resulting in injury.

4. Use only the parts supplied or specified by use.Attach the parts that suit the rivets to be used.

◇

Neglecting the above could not only cause the tool to fail to deliver full performance, but abnormal operation

could result in an accident or injury.

5. Do not modify this tool without our permission.

◇

Unauthorized modification could cause abnormal operation, resulting in an accident or injury.

6. Leave maintenance of this tool to qualified persons who understand the functions and mechanism. Qualified

persons should follow the instructions described in the instruction manual and take great care during the work.

◇

If unauthorized persons who do not have knowledge or techniques perform maintenance, the tool will not only

fail to deliver full performance, but it could also result in an accident or injury.

7. Contact us for repair of this tool.

◇

Contact your dealer or us for repair of the tool:

If unauthorized persons who do not have knowledge or techniques on servicing perform repair, the tool will

not only fail to deliver full performance, but it could also result in an accident or injury.

8. Keep the handle grip dry and clean without oil or grease adhering.

◇Oil or grease could cause the tool to slip from your hand and fall.

9. Do not scatter ruptured mandrels on the floor.

◇ Ruptured mandrels are dangerous since they have sharp points. Persons stepping on mandrels are likely to

slip, and could fall.

10. Please organic solvent do not adhere to the Handle front, the Handle rear, the collector body, and

the collector cover (These materials are polycarbonates).

◇ Parts etc. dash out by damaging the above-mentioned parts, and the accident and the trouble

might be owed.

11. Be careful of exhaust air from the Exhaust vent.

◇

Do not bring your face (especially eyes) to the Exhaust vent, since it occasionally discharges foggy air

intensively. Be careful: Exhaust air could contaminate surrounding objects.

Foggy air containing oil or moisture could be discharged mainly depending on the status of compressed air

supplied.

※For names of parts, see P.3.

PRL550

1. Names of Parts

Mandrel guide

Pulling head

Inside

Jaw case Jaw pusher

Jaw pusher spring

Jaws

Collector

- 3 -

Fill screw

Grip

Shutter Nose piece

Nose housing

BodyMandrel

Rivet

Trigger

Handle rear

Handle front

Handle

Exhaust vent

Chamber

Coupler (Plug)

Coupler

(Socket)

Hose

R-joint

(Thread size: Rc1/4)

Warning label

Not attached

(See P.6)

Fig.1-1

PRL550

2. Out line

The PRL550 series sre compact and light weight air-hydraulic rivet tools capable of setting POP rivets for

φ3.0~4.0mm. This tool has MCS (Mandrel Collection System) as standard equipment to vacuum broken

mandrels automatically after setting rivets.

1.Specification

Select the model according to the rivet size and conditions of use.

(Table 2-1)

Model Weight

(kg) Length B

(mm) Height

(mm) Storoke

(mm) Air pressure

(MPa)

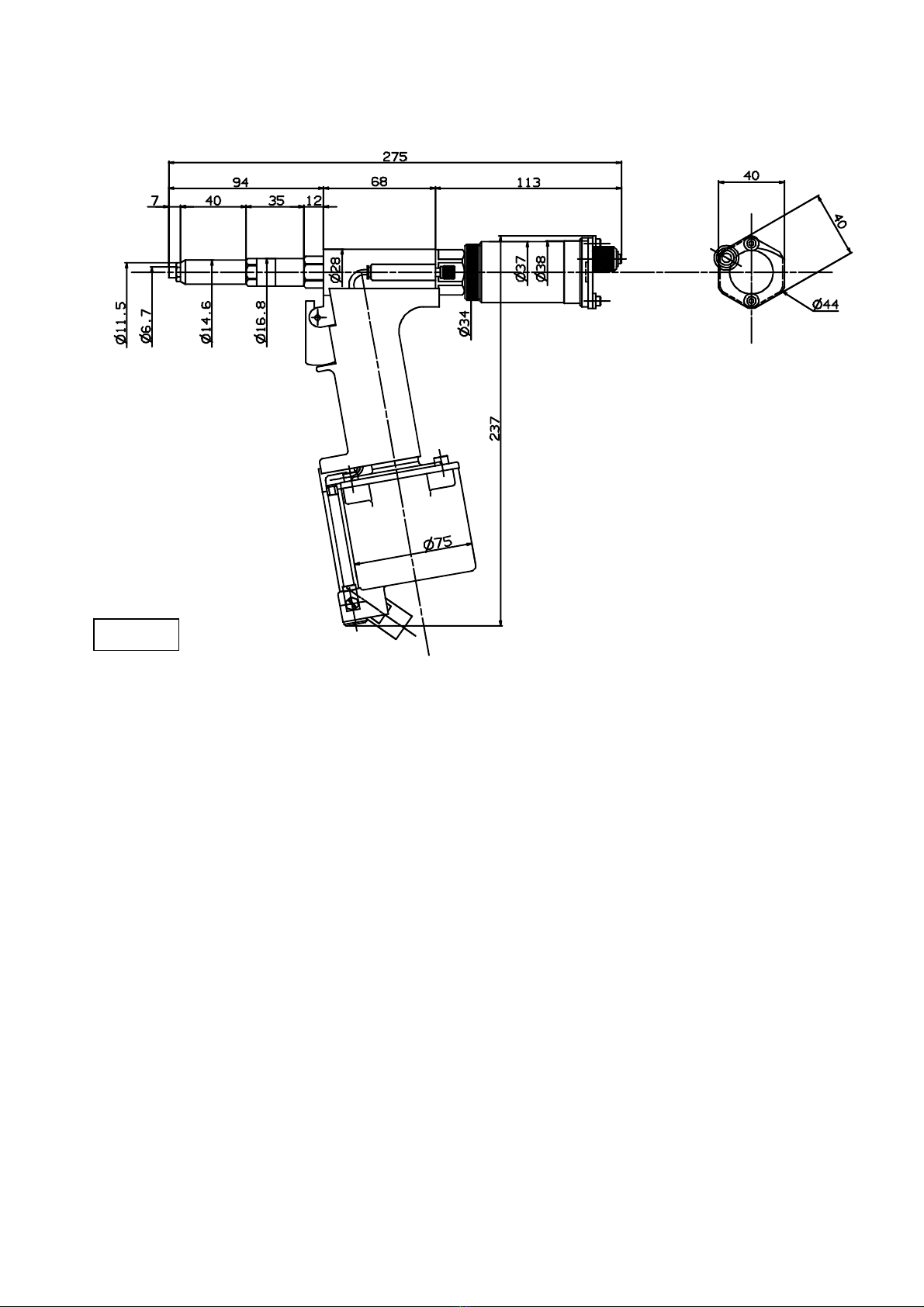

PRL550 0.89 275 237 18.0 0.5〜0.6

2.Nosepiece (Table 2-2)

Use an appropriate nosepiece according to the type and size of rivet.

Using different size nosepiece may cause faultily rivet setting or tool malfunctions.

(Table 2-2) Rivet Nose piece

Rivet dia.

(φmm) Rivet name Mandrel

dia.

(φmm)

Product

No. Hole dia.

(φmm) Remark

3.0 TAP/D(K)30M-BS PAD30M-ABS(HR/CC)

A6D30M-HR/CC SD30M-BS

TAP/D(K)4-BS(SSBS) TAP/D(K)4-SW

TAP/D4-BHM AD4-BS/LF

TCP/D-BS(BSB)

1.83

AD(K)4-ABS TAP/D(K)4-HR

SD(SSD)4-BHM

SD(K)4-BS SSD(K)4-BS(SSBS)

SSD4-SSH

1.93

PRN041 2.2 Std.

Equipment

SD(K)4-HR SSD(K)4-HR(SSHR) 2.10 PRN04K 2.4 Option

AD(K)4 AD4-SSH CD4 1.63 PRN042 1.8 Option

3.2

AD4-AH 1.83 PRN043 2.0 Option

TAP/D(K)5-BS *TAP5-SSBS

TAP/D(K)5-SW

TAP/D5-BHM AD5-BS/LF

TAP/D(K)5-HR

AD5-TL TCP/D5-BSB

2.28

AD(K)5-ABS *SD(K)5-BS 2.41

PRN051 2.7 Accessory

CD5 *AD(K)5 *AD5-SSH 2.18 PRN052 2.4 Option

4.0

AD5-AH 2.28 PRN053 2.5 Option

Mandrel dia.

Body dia.

Stam

p

Hole dia.

* : The air pressure of 0.55MPa or more is necessary.

- 4 -

PRL550

3. Dimensional Drawing

PRL550

- 5 - Fi

g

.3-1

PRL550

4. Preparation for use

(1) Make sure that Nosepiece that suits the rivets used are attached: If incompatible

parts are attached, replace them with those specified to suit the rivets used (see Table

2-2 on P. 4).

(See P.14 for Replacing Nosepiece.)

(2) Attach the coupler (AN500-72) to R-Joint block of rivet tool, to supply compressed air.

Install the air filter and regulator between Compressors and rivet tool, and adjust the

pressure of air supplied to 0.5-0.6 MPa.

Fig. 4-1

A

ir filter

Regulator

Hos

e

Coupler (Socket)

Recommended internal dia.

: at least 6mm

(Recommended)

NITTO KOUKI20SH

20SM

20SF

Compressor

R-Joint

(Rc 1/4)

Coupler (Plug)

AN500-72

NotAttached

Use the hose with the pressure at normal temperature (maximum) of a

t

least 0.7 MPa, and suitable for environment where the tool is used.

(Example: Consider oil resistance, wear resistance, etc.)

WARNING

(3) Confirm whether the shutter shuts. Turn the shutter to the right, and shut in case of

the opening. (see Fig4-2)

(4) The Valve shutter must revolve to the left one-twice, open, and operate MCS.

(see Fig.4-2)

Shutter

Fig.4-2

V

alve shutter

Collector

Operate MCS

Revolve to the left one-twice Shut

When the amount of the opening of th

e

V

alve shutter is insufficient, the mandre

l

might not be able to be collected.

Shut the Valve shutter (Screw in unti

l

stopping), and stop MCS when you do no

t

do rivetting.

*

*

- 6 -

PRL550

- 7 -

5. Precautions for use

(1) Air pressure used

Use the rivet tool with an air pressure of 0.5-0.6 MPa.

If the specified air pressure is exceeded, the tool could break, resulting in an accident

or injury. If the air pressure is lower than that specified, it may not be possible to

setting rivets.

Use the regulator to adjust the air pressure to optimum value. (see P.6)

(2) Using air filter

Moisture or dust contained in compressed air could affect the life of rivet tool: Use an

air filter. (See P.6)

(3) Nosepiece

Use an appropriate nosepiece according to the type and size of rivet.

(see Table 2-2 on P.4)

Using different size nosepiece may cause faultily rivet setting or tool malfunctions.

(4) Hydraulic oil

Use specified hydraulic oil.

Select the hydraulic oil from Table 5-1: Other oil could cause malfunctions.

(Table5-1)specifiedoil

Oil company Name

Idemitsu Kosan Daphne Hydro 68A

Mobil Sekiyu Mobil DTE 26

Cosmo Sekiyu Cosmo Orpheus 68

Esso Sekiyu Telesso 68

Nippon Petroleum FBK R068

Mitsubishi Oil Diamond Lub R068 (N)

Showa Shell Sekiyu Shell Oil C68

(5) Discard mandrels collected in the Collector

Discard mandrels collected in the collector before the accommodation capacity of

collector is not exceeded (Table 6-1 on P.9).

(Note) Exceeding the maximum capacity may damage the MCS or cause mandrels to

become stuck inside the tool.

(6) Plastic parts (Handle front, Handle rear, Collector)

Organic solvent do not adhere to the Handle front, the Handle rear, the collector body,

and the collector cover (These materials are polycarbonates).

Use the soapless soap when washing it.

PRL550

6. How to use the PRL650

- 8 -

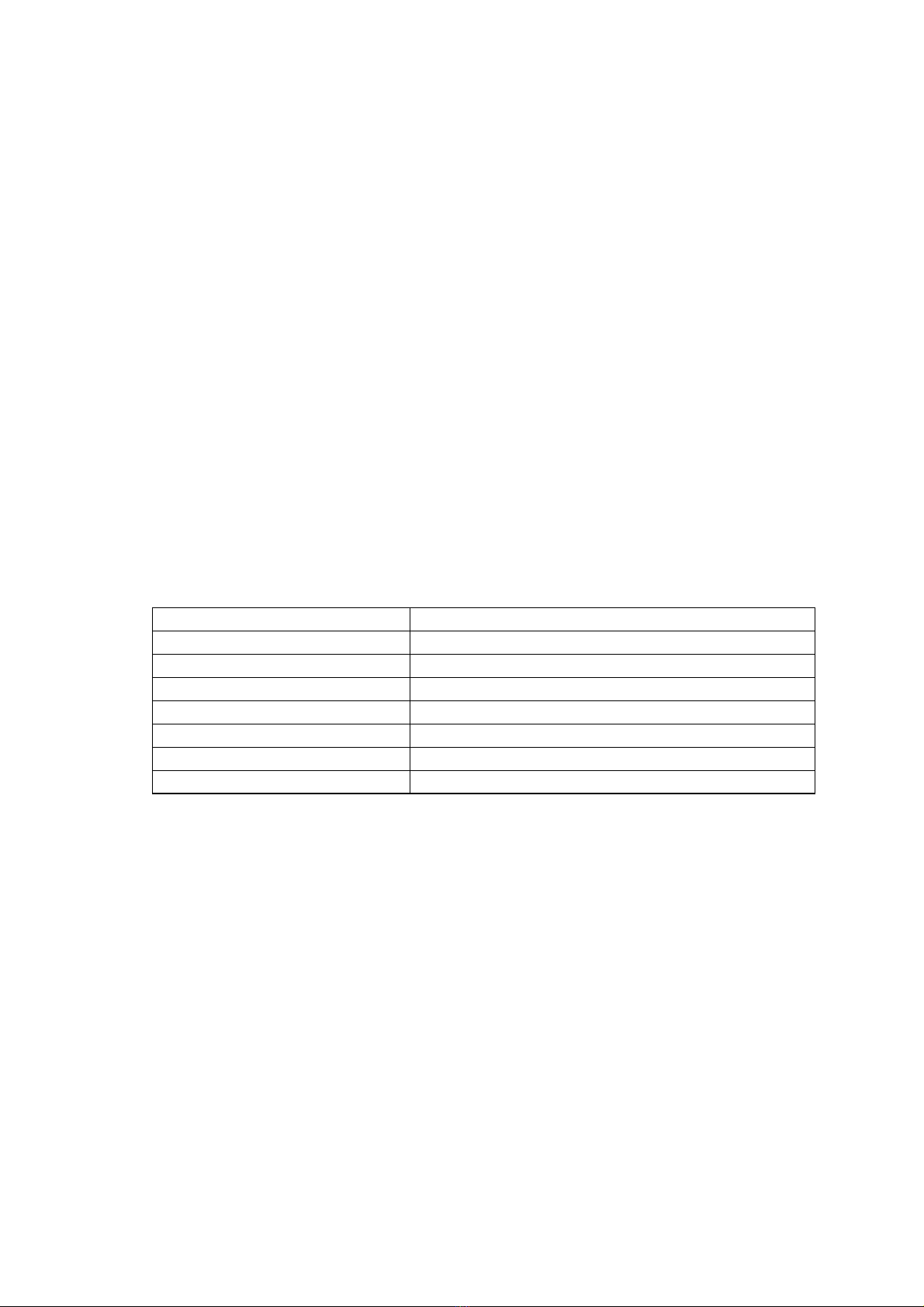

6-1 Setting rivets

(1) Insert mandrel into the nosepiece and attach a

rivet, and then insert the rivet body into the hole

in the lower base metal. (Fig. 6-1)

The rivet is attracted by MCS

into the nosepiece.

Or insert the rivet body into the hole in the lower

base metal, bring the rivet tool to the rivet, and then

insert the mandrel into the nosepiece. (Fig. 6-2)

(2) Push the rivet tool against the base metal at right

angles, and then pull the trigger while the base

metals to be joined and the rivet flange and

nosepiece are in close contact: The mandrel

ruptures and the rivet is set to join base metals.

(Fig. 6-3)

Trigger

Pull

Right angle

Close contac

t

Fig. 6-3

Ruptured mandrel

Trigger

Release

Collector

Base

Metal

Nose

p

iec

e

Body Mandrel

Fig. 6-1

Fig. 6-2

Base metal

Body Nosepiece

Mandrel

Fig. 6-4

(3) Release the rivet tool from the base metal, and then

release the trigger. (Fig. 6-4)

The ruptured mandrel is attracted by MCS, and is

collected in the Collector.

*Discard mandrels collected in the collector before the

accommodation capacity of collector is not exceeded

(Table 6-1 on P.9).

(4) After making sure that the mandrel has

been ejected, proceed with subsequent

joining.

※ See the catalog of pop rivets for selecting rivets and setting diameter of hole in lower base metal.

PRL550

6-2 Discard mandrel

Discard mandrels collected in the collector before the accommodation capacity of Collector

is not exceeded. (Table 6-1)

(Table 6-1) The accommodation capacity of Collector

Nominal dia.

of rivet Mandrel dia. Accommodation capacity

φ3.2 φ1.63

φ1.83

φ1.93 120

φ2.10

φ2.18 100

φ4.0

φ2.28

φ2.41 70

<Method for use>

The Shutter opens when the Shutter is turned to the left with the Grip pulled, and the

mandrel is discarded from this opening.

When setting rivet, turn the Shutter to the right and shut.

(Fig. 6-5)

Turn left

Collector

Pull

Fig. 6-5

- 9 -

PRL550

7. Maintenance and Inspections

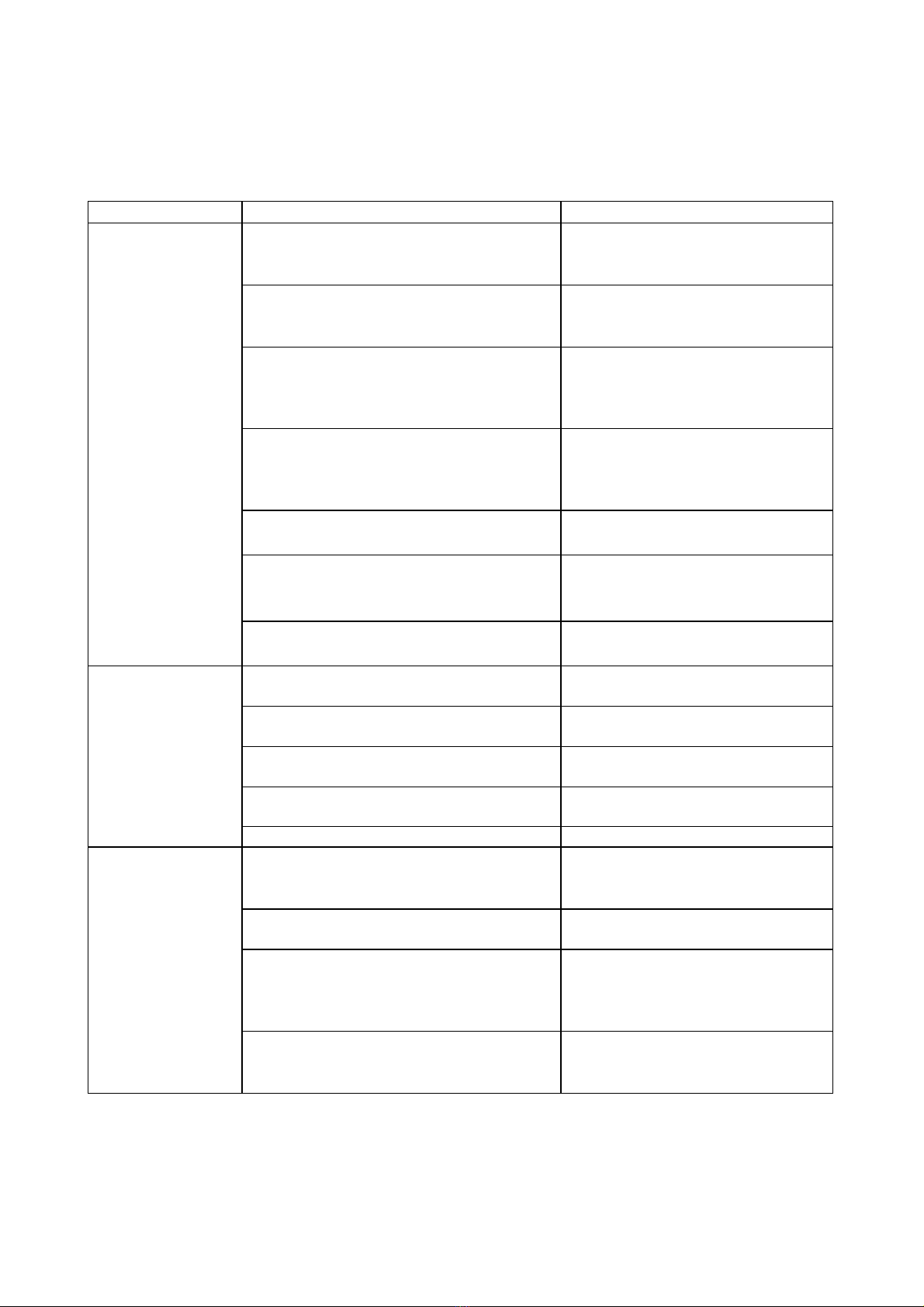

(Table 7.1)

No Item Purpose

7-1 Spraying lubricant into the Jaws ・Maintains proper Jaws operation and extends the service life.

7-2 Cleaning the tip parts ・To remove metal particles and prevent slippage of Jaws or being caught

・To prevent early wear on Jaws and Jaws case

7-3 Greasing the Jaw case ・To remove metal particles and prevent slippage of Jaws or being caught

・To prevent early wear on Jaws and Jaws case

7-4 Exchange of Hydraulic oil ・To restore stroke

7-5 Replacing Nosepiece ・To match the rivets used

・Because of damage

7-6 Replacing Jawpusher ・Because of damage

7-7 Replacing Jaws ・To match the rivets used

7-8 Replacing Ejector complete ・Recovery when MCS function has become degraded

7-1. Spraying lubricant into the Jaws

Lubricating and rust-proofing agents (CRC type) should be sprayed into the Nosepie

cehole approximately every 2,000 rivets in order to maintain proper Jaws operation.

Always close the Valve shutter when spraying the Jaws.

(If the Jaws are spraying with the air connected, the lubricating oil will be drawn in

to the MCS and miss the Jaws.)

Manufacturer Product neme

Kure Industries Inc. CRC5-56

Three Bond Inc. 1801B

Musashi Holtz Inc. Holtz Top Oil

MH241

Lesupi Inc. Pikka

(Reference)

Nosepiece

(PRN-□)

Spray oil Fig. 7-1

7-2. Cleaning the tip parts

Clean the tip parts regularly (two or three times per month). After setting 10,000 rivets,

metal powder will adhere to the tip parts causing tool action to deteriorate and the Jaws

to slip or catch. Continuing operation under these conditions will shorten the service life of

the Jaws and other tip parts.

(1) Loosen the Nose housing with a wrench and remove it.

(2) Loosen the Jaw case from the Pulling head with wrentches.

(3) The parts which will come off are shown (Fig. 7-2). Clean these parts and the Nose

housing with kerosene or similar oil. In addition, blow air through the Pulling head and

Nose housing to clean them.

- 10 - Fig 7-2

Nose housing

Jaw case

Pulling hesd

Jaw pusher Mandrel guide

Jaws Jaw pusher spring

PRL550

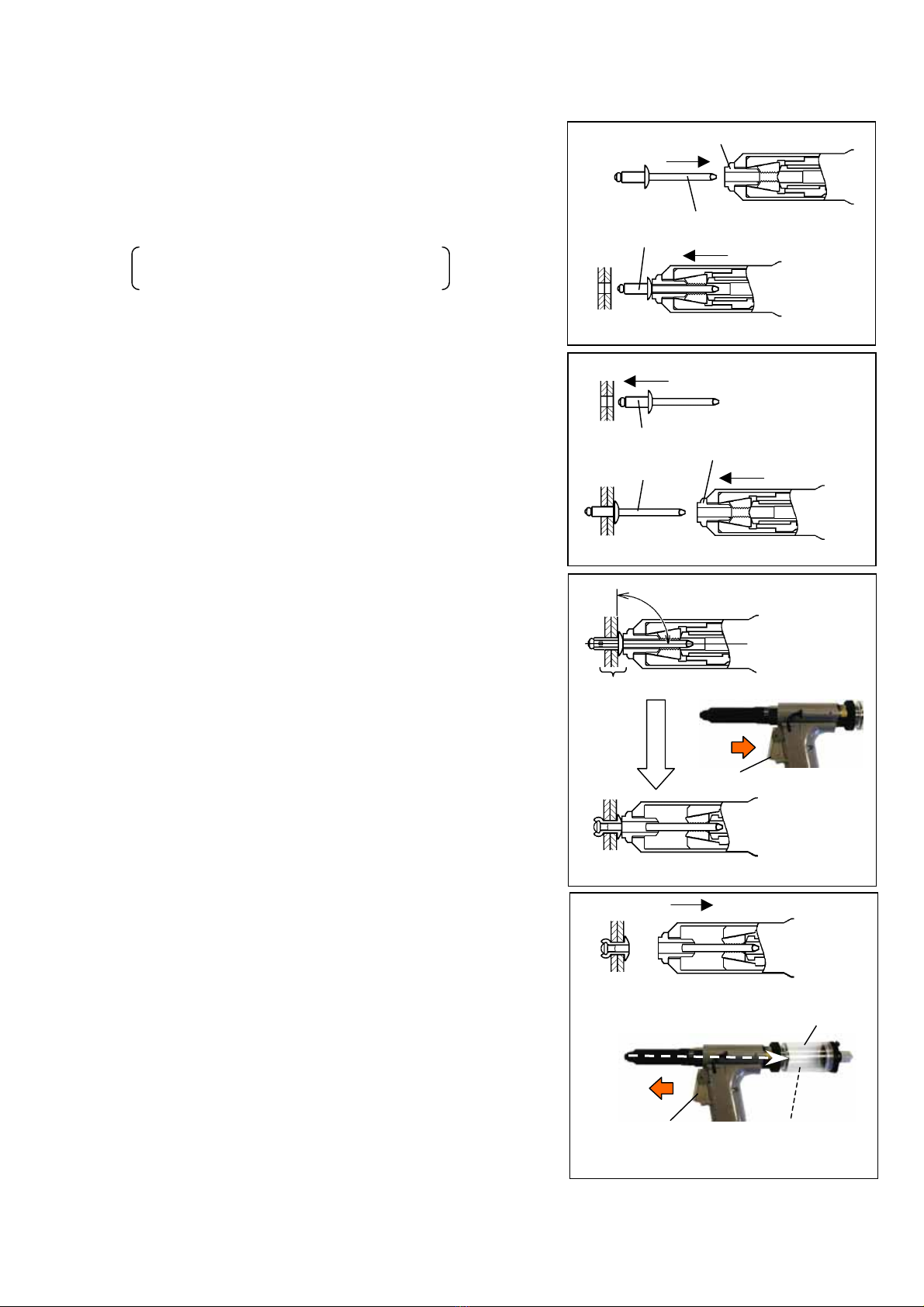

7-3. Greasing the Jaw case

When Jaws slipping or catching occurs earlier in the spraying lublicant into the Jaws,

grease inside of Jaw case.

Catching: After a rivet is setting, the jaw is caught by the jaw case and does not open, and

the mandrel cannot be ejected.

<Procedure>

(1) Clean the tip parts according to P.10 7-2.

(2) Reassemble the parts by the reverse procedure to disassembly. Grease the inside of jaw case (surface

that is in contact with jaw) sufficiently before reassembly (see Fig. 7-3): Molybdenum disulfide type is

recommended.

Jaw case (section)

Grease (2~3mm thick)

Fig. 7-3

- 11 -

PRL550

7-4. Exchange of Hydraulic oil

When hydraulic oil is down and the stroke is low (one trigger operation does not allow

riveting), exchange the hydraulic oil by the following procedure:

If stroke is low immediately after hydraulic oil is exchanged, seal has worn:Ask for repair.

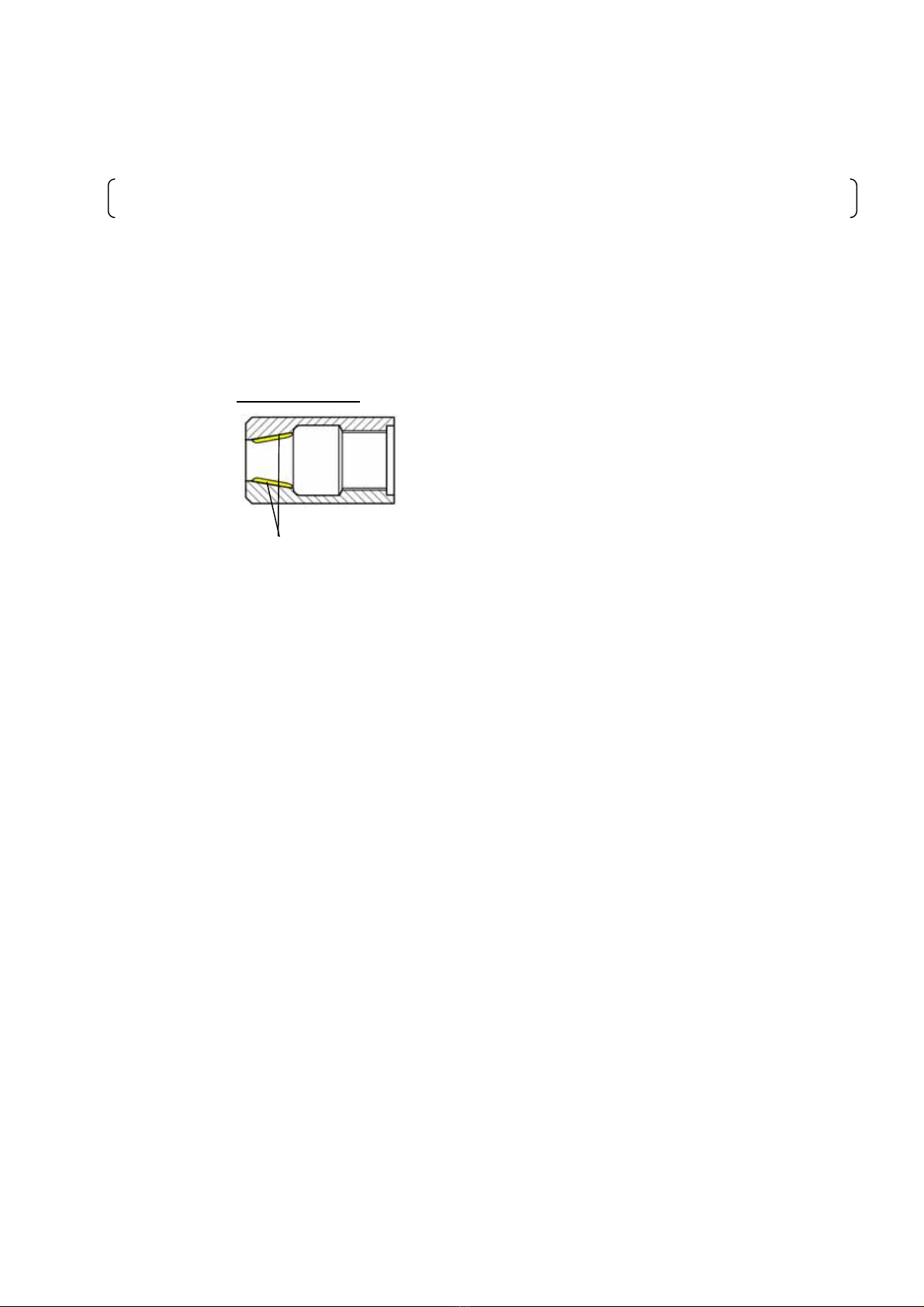

<Procedure>

(1) Cut off supply of compressed air by separating the coupler.

- 12 -

(2) Remove Collector and Nose housing.

(3) Pull out the Tube from Joint while evenly pushing the ring

of open of the Joint by the finger. (Fig. 7-4)

(4) Remove the cap screws (4 pcs) with 4mm hexagonal wrench.

(Fig. 7-5)

Fig.7-6

A

ir piston

assembly

Chamber

(5) Do Chamber up, and remove Chamber.

Pull outAir piston assembly.

Discard Hydraulic oil in the Sleeve. (Fig. 7-6)

Tub

e

Join

t

Fig. 7-5

Cap screw (4pcs)

4mm

Hexagonal wrench

Remov

e

Fig. 7-4

(6) Inject the specified oil (see Table 5-1 on P.7) into the sleeve (hole in which the air piston

assembly was inserted), until the oil surface is the same of Backup ring.

(Fig. 7-7)

H

y

draulic oil

Sleev

e

Sleev

e

Oil surface is sam

e

of Backup ring. Backup ring

Specified oil

Fig. 7-7

PRL550

(7) Loosen Fill screw about 3mm, push and holdAir piston.

The hydraulic oil oozes out from Fill screw, and hold it, until this polluted hydraulic oil

does not come out. (Fig. 7-8)

(8) Pull out Air piston assembly, inject the hydraulic oil again according to (4), and tighten

Fill screw temporarily.

(9) After pushing Air piston assembly, and making the piston move 5-6 times by the hand,

pull outAir piston assembly again, and confirm the oil side. (Fig. 7-9)

Repeat (8) and (9) when the oil side has fallen or air mixes.

Dirty oil

Fill screw

Push and Hold

A

ir piston assembl

y

Making the pisto

n

move 5-6 times by th

e

hand.

Fig. 7-9

Fig. 7-8

(10) After the injection of the hydraulic oil is completed, reassemble Air piston assembly and

Chamber.

Grease inside of Chamber before reassembling.

Assemble it in the reverse order of disassembly.

Fill screw

Remove

Fig.7-10

(11) Loosen Fill screw, and remove an extra hydraulic oil and air (bubble).

Tighten Fill screw after it leaves it until the hydraulic oil does not come out. (Fig.7-10)

- 13 -

(12) Assemble Nose housing and Collector.

*Do not allow any dust or metal particle to enter the hydraulic oil or chamber during

disassembly and reassembly.

PRL550

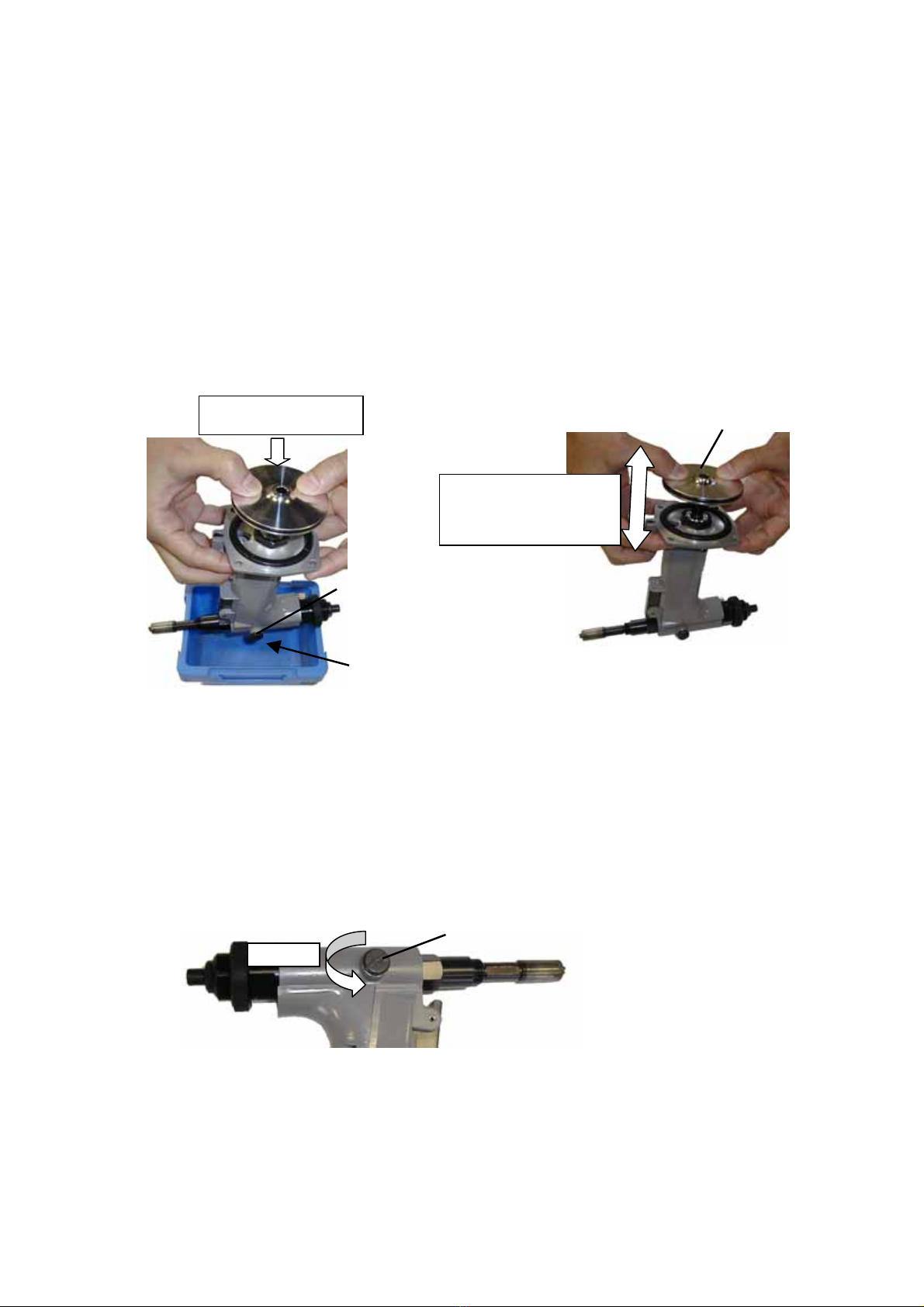

7-5. Replacing Nosepiece

Use the specified Nosepiece to match the rivets used (see Table 2-2 on P.6).

If Nosepiece is damaged, replace it.

<Procedure>

(1) Use spanner to remove Nosepiece from Nose housing. (Fig. 7-11)

Nosepiece

Nose housing

Remove

Fig. 7-11

(2) Tighten specified Nosepiece to Nose housing firmly.

7-6. Replacing Jawspusher

If Jaw pusher is damaged, replace it.

<Procedure>

Remove used Jaw pusher by the procedure in 7-2 (P.10).

7-7. Replacing Jaws

Use specified jaw to match the rivets used (see Table 2-2 on P.6).

If jaw is damaged or slips immediately after cleaning (teeth are worn), replace it.

<Procedure>

(1) Remove used Jaw by the procedure in 7-2 (P. 10).

(2) Before installing new jaw, clean the tip parts and grease the Jaw case (see 7-2 on P.10

and P.11).

7-8. Replacing Ejector complete

When Ejector nozzle is worn out, or the force is weak, mandrels are not being collected,

and replace Ejector complete.

(Notes)

Check the following before replace Ejector complete: If the applicable defective

phenomenon is found, perform appropriate troubleshooting. (See P.17)

a) Supplied air pressure is low.

b) Mandrel collector is full

c) Mandrel ejection tube is clogged with ruptured mandrels.

d) Jaw pusher and nosepiece are clogged with ruptured mandrels.

If the attraction force is weak after troubleshooting, replace Ejector complete.

- 14 -

PRL550

<Procedure>

(1) Cut off supply of compressed air by separating the coupler.

(2) Remove Collector. Collector lock nut is held by the hand, turn Collector in the left, and

remove it. (Fig. 7-12)

Remove

Collector lock nu

t

Collector

Fig. 7-12

(3) Remove Collector lock nut and Valve shutter. (Fig. 7-13)

(4) Remove End cap with wrench. (Fig. 7-14)

Collector lock nut

V

alve shutter

Fig. 7-13

End cap

Return spring

Fig. 7-14

(5) Pull out Ejector complete by the hand. (Fig. 7-15)

(6) Replace it for new Ejector complete.

Spread grease before assembling. (Fig. 7-16)

Fig. 7-15

Ejector complete

Fig. 7-16

Ejector complete

S

p

read

g

rease

WARNING

Do not rivet during this adjustment since compressed air is being supplied.

Also at this time, do not insert a rivet or ruptured mandrel from the nosepiece.

◇If you do, the rivet or ruptured mandrel will pop out because of the compressed air,

which could cause an accident or serious injury (losing eyesight, etc.).

- 15 -

PRL550

- 16 -

8. Troubleshooting

(If you cannot fix the tool after checking the content of this secton, send it to your supplier or

one of our offices for repair.)

Symptom Cause Troubleshooting

1.Parts are incompatible.

Nosepiece is not compatible with rivets

used.

Replace the parts with compatible

ones. (see P.4)

2.Loose parts

Nosepiece, Nose housing, Jaw case are

loose.

Use wrench to securely tighten

them.

3.Damaged parts

Jaw, Nosepiece (section in contact with

Jaw), Jaw pusher or Jaw pusher spring is

damaged.

Replace the damaged parts.

(See P.11)

4.Dirt in Nose housing

Metal particles have accumulated in

Nose housing, which causes defective

opening of Jaw.

Clean nose housing, jaw, etc.

(see P.10)

5.Jaw and jaw case are poorly lubricated.

Defective lubrication causes catching. Clean and grease the point end

parts, such as jaw. (see P.10,11)

6.Excessive hydraulic oil

After hydraulic is replenished, surplus

hydraulic oil and air are not removed.

Loosen the fill-screw and eliminate

surplus hydraulic oil and air.

(see P.13)

Rivet cannot be

inserted into

Nosepiece.

Or mandrel cannot

be ejected after

riveting.

7.Clogging in jaw pusher

Mandrels are clogged in the jaw pusher. Remove the jaw pusher and remove

the clogged objects. (See P.10)

1.Shortage of supplied air pressure. Adjust the supplied air pressure.

(see P.6)

2.The amount which shuts Valve shutter or

opens is insufficient. Open Valve shutter. (see P.6)

3. Ccollector is full of mandrels. Discard the mandrels from

Collector. (see P.9)

4.Mandrels are clogged in Jaw pusher Remove Jaw pusher, and removed

clogged mandrels. (see P.10)

Mandrels cannot

be collected by

MCS

(Attractive force is

weak).

5.Wear-out of Ejector nozzle Replace Ejector complete.(see P.15)

1.Parts are incompatible.

Nosepiece is not compatible with rivets

used.

Replace the parts with compatible

ones. (see P.4, P.14)

2.Shortage of supplied air pressure. Adjust the supplied air pressure.

(see P.6)

3.Slippage of jaw

Metal particles are clogged in jaw teeth

or teeth are worn, and the jaw cannot

catch mandrels, causing slippage.

Clean the jaw.

If fault is not corrected after

cleaning, replace the jaw. (see P.10)

One trigger

operation does not

allow riveting.

4.Stroke is too low

Hydraulic oil is short or air enters,

causing low stroke.

Exchange hydraulic oil. (see P.12)

PRL550

- 17 -

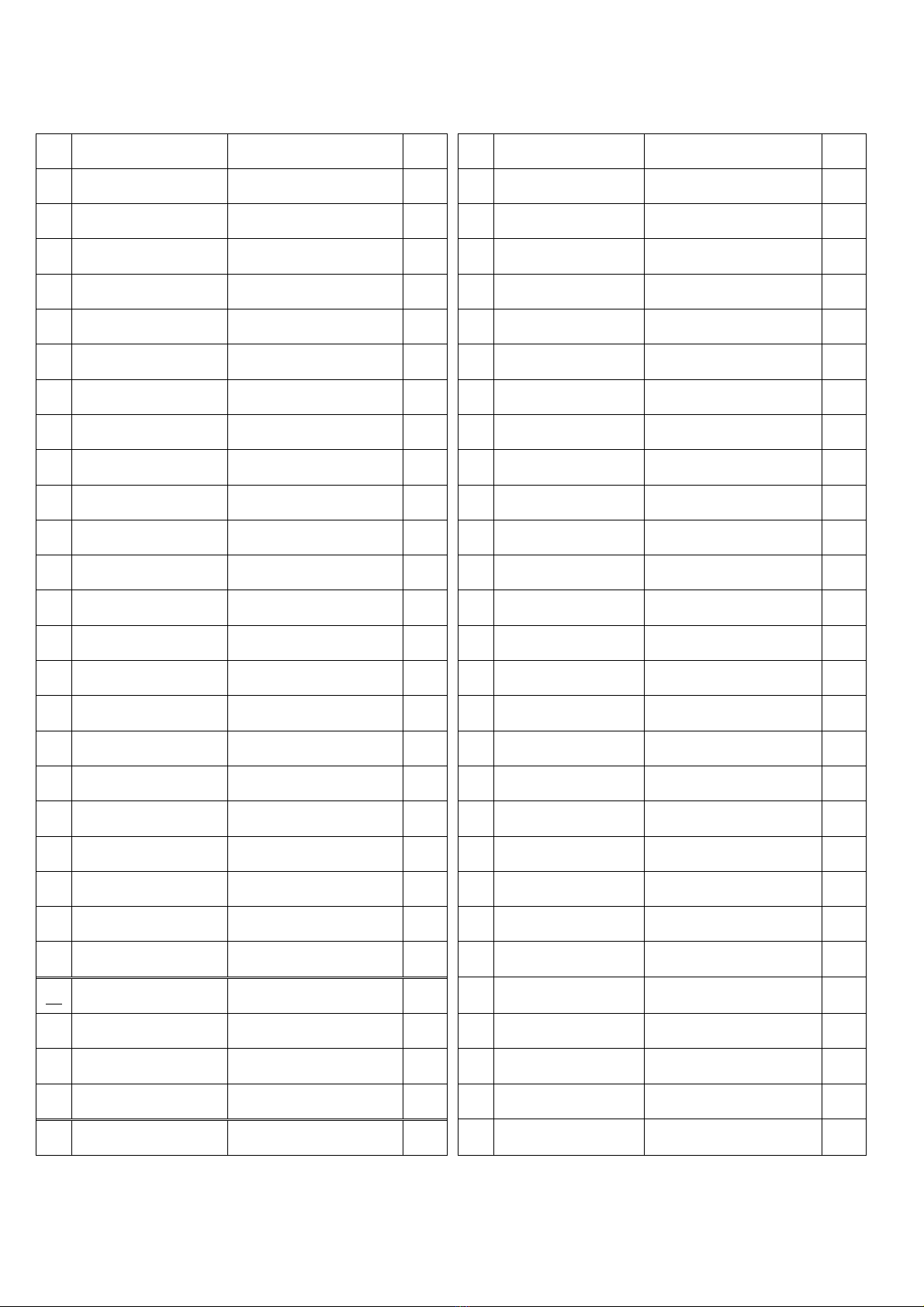

9. Parts List

No. 品番 品名 員数 No. 品番 品名 員数

1 PRN041 Nose piece 1 31 PRL600-64 O-ring P4(U) 2

2 PRL550-01 Jaws 1set 32 PRL600-29A

A

ir tube 4×71 1

6 PRL550-12 Nose housing 1 33 PRL600-28A Joint PCC4M6M 1

7 PRL550-02 Hydraulic piston 1 34 PNT600-80 O-ring S3(1A) 1

8 PRL550-03 Housing adapter 1 35 PL1500i-27A

V

alve shutter 1

9 PRL500-05 Scraper SER9 1 36 PRL600-24 O-ring P5(U) 1

10 PRL500-06A Rod seal case 1 37 PRL600-45A Sleeve upper 1

11 PRL500-07 O-ring P16(U) 2 38 PRL600-46 O-ring P10A(U) 1

12 PRL500-08 BU-ring T2P9(PT) 1 39 PRL500-20 Handle rear spacer 2

13 PRL500-09 Penta seal PS9 1 40 PRL600-48A Handle rear 1

15 PRL500-10 BU-ring T2P16(PT) 1 41 PRL600-70A Handle front 1

16 O-RING-1017 O-ring 1 42 PRL650-14 Sleeve lower 1

17 PRL550-04 Handle upper 1 43 PRL600-80 Pan head screw M3×16 4

18 PRL500-12 Return spring 1 44 PRL600-53B Handle lower 1

19 PRL550-05 End cap 1 45 PRL650-15 Bumper 1

20 PRL500-33 Lock nut 1 46 SA-18 Penta seal PS11.2 1

21 PNT600-60 O-ring S6(1A) 1 47 SA-17 BU-ring T2P11.2(PT) 1

22 PRL550-06 Ejector guide 1 48 PRL550-14 Camber 1

23 PRL550-07 Jaw case 1 49 O-RING-C0630G(1A) O-ring 1

24 PRL550-08/5 Jaw pusher 1 50 PRL650-17

A

ir piston 1

26 SPG5135 Jaw pusher spring 1 51 PRL550-15 Ram 1

27 PRL550-09/5 Mandrel guide 1 52 PRL600-62 Cap 1

28 PRL550-10 Pulling head 1 53 PRL600-63 O-ring S8(1A) 1

29 PRL550-11/5 Ejector 1set 54 PRL600-97

V

alve sprin

g

5082 1

29a PRL650-10/5 Ejector nozzle 1 55 PRL600-65A

V

alve lower 1

29b PRL650-11 Ejector lock 1 56 PRL500-28

Va

lve rod 1

29c PRL550-13/5 Ejector body 1 57 PRL600-68A

V

alve upper 1

30 PNT600-21 Fill screw 1 58 PRM530-43 Spring pin 3×10 2

PRL550

- 18 -

No. 品番品名員数 No. 品番品名員数

59 PRL600-69

V

alve pusher 1 71 PRL500-68A Collector 1set

60 PRL650-19 Sleeve lock nut 1 71a PRL500-36 Collector body 1

61 PRL650-20 Sleeve washer 1 71b PRL500-37A

A

dapter 1

62 PRL600-71 Trigger wire 1 71c PRL500-42A Shutter spacer 2

63 PRL600-72A Trigger 1 71d PSL600CJ-30 Cap screw M3×8 2

64 PRL600-73 Spring pin 3×18 1 71e PRL500-38A Shutter 1

65 PRL600-74 Cap screw M5×12 4 71f PRL500-39A Shutter washer 1

66 PRL500-64A Tube assembly 1set 71g PRL500-40A Pin case 1

66a PRL600-75A Joint PL4M5M 1 71h PRL600-102A Pin case cap 1

66b PRL500-31A Tube 1 71i PRL500-41A Shutter pin 1

66c PRL600-77 Nipple LN-M5-M5 1 71j PRL600-103 E-ring E4 1

66d PRL600-78 Joint LH-FM5-M5 1 71k PRL600-39A Grip 1

67 PRL650-21 RJ-spacer 1 71l PRL600-40A Shutter spring 5113 1

68 PNT600-44A R-joint 1 Accessory

69 PL1500i-22A R-joint adapter 1 PRN051 Nose piece 1

70 PNT600-42 O-ring S9(1A) 2

A

N50

0

-72 Couppler 20PM 1

PRM530-48 Hexagonal wrench 4mm 1

Instruction manual 1

オプション

PRL650-OSV OS-valve 1set

Table of contents

Popular Rivet Tools manuals by other brands

Gesipa

Gesipa taurus 1 Operating manual with spare parts list

Degometal

Degometal GO 3312 SAFETY INSTRUCTIONS AND DIRECTIONS FOR USE

Arconic

Arconic MARSON MP-4V manual

Marson

Marson Integra-Fuse M39075 Operation guide

Milwaukee

Milwaukee M12 BPRT Original instructions

Ingersoll-Rand

Ingersoll-Rand 127 Product information