6

RL75-2 / Manual

Titgemeyer / 10344EN1121 / 1

English

5. Special safety advice

The riveting tool is exclusively designed

for setting Lockbolts and structural blind

rivets. The Customer bears individual re-

sponsibility for each and every change

of the riveting tool!

ATTENTION!

— Use the tool only after reading and un-

derstanding the operating instructions.

— Do not operate with the tool if you

are ill, under the inuence of drugs or

alcohol.

— Do not use the tool when it is incom-

plete and when it has visible mecha-

nical defects.

— Never aim the riveting tool at people

and do not rivet without material.

— Use the riveting tool only at working

temperature ranging from 5°C to 45°C.

— Never get over the maximum limit of

input air pressure of 7 bar

— In case the provided air pressure

exceeds the max of 7 bars, use appro-

priate equipment to reduce it.

— Use only ttings and hoses for an

approved operating pressure of 10

bar in pneumatics.

— Before adjusting or replacing compo-

nents, disconnect the tool from the

compressed air supply

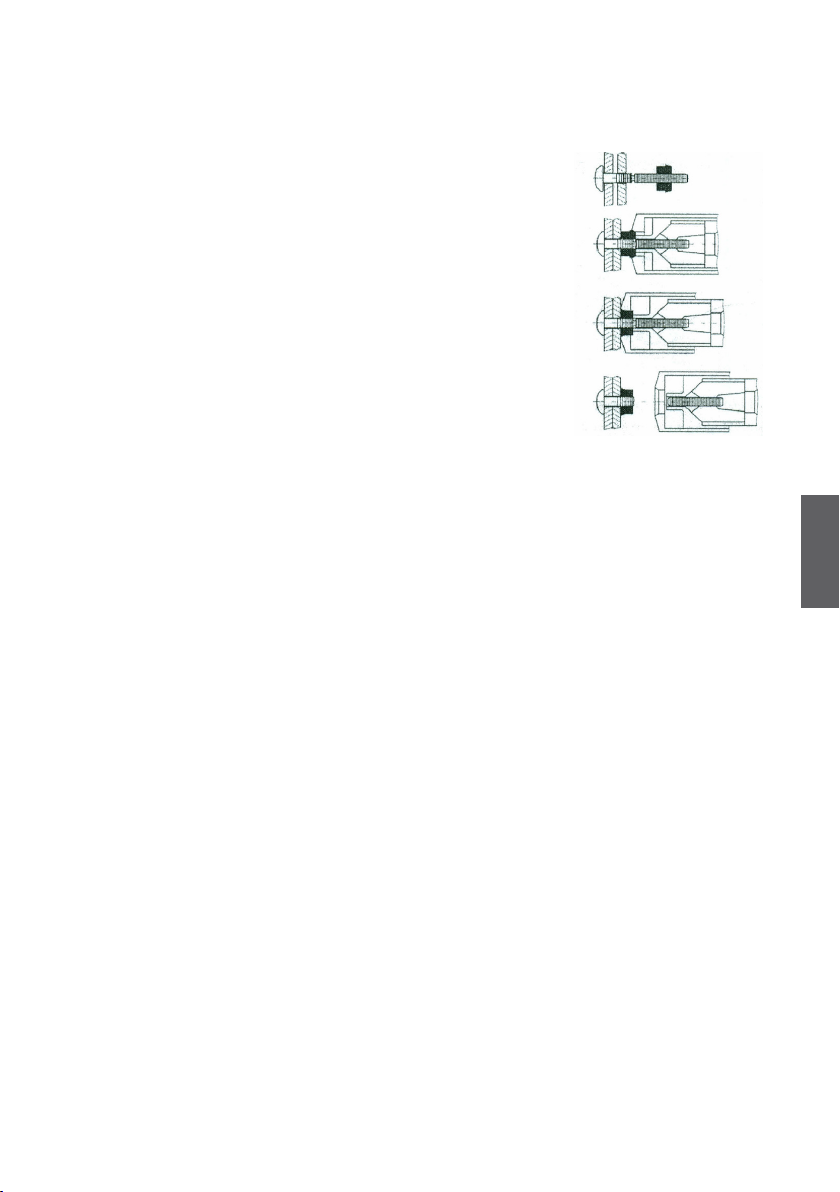

— For processing rivets, use the recom-

mended pulling head for lockbolts or

jaw case and nosepiece for structural

blind rivets accordingly.

— Always use personal protective clothing.

— Tool not in current use must not be con-

nected to the compressed air supply

— Use the tool only for riveting

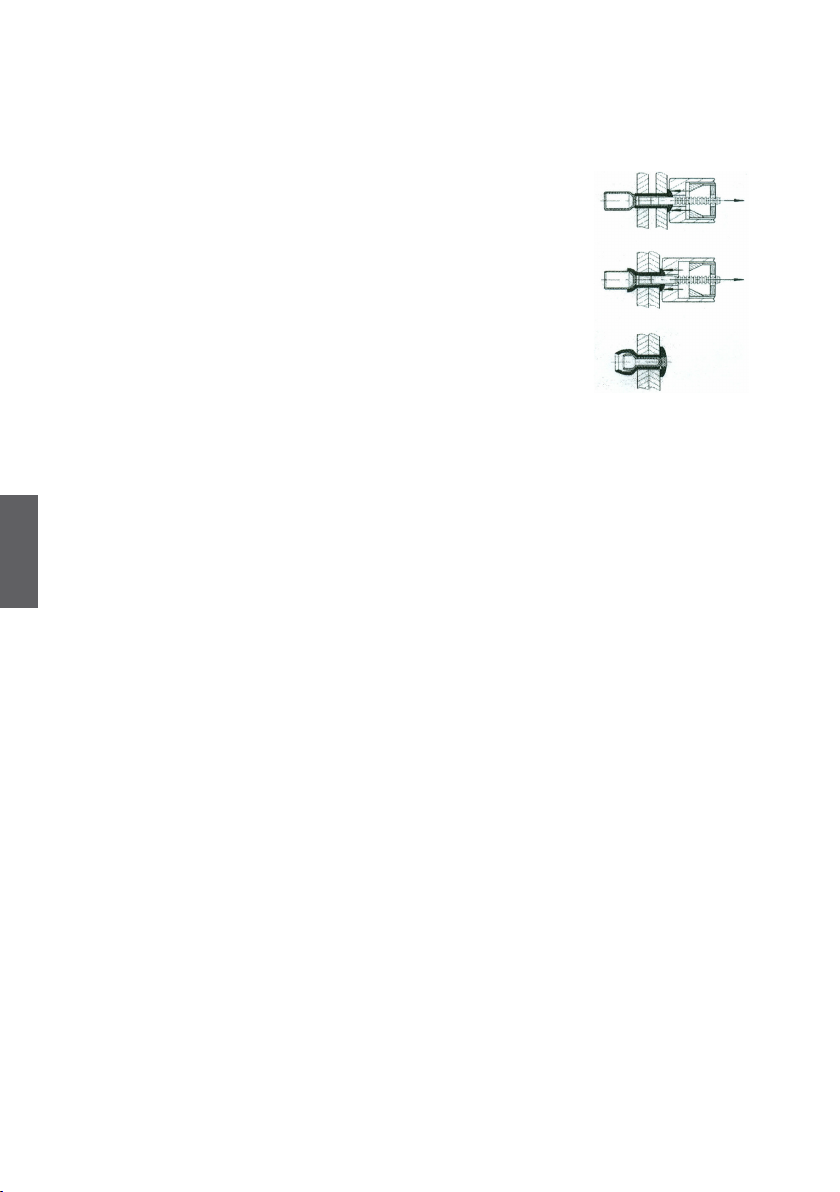

— Do not use the tool without assem-

bled rubber cover (5).

— The riveting tool must not be carried

or lifted by the air hose

ATTENTION!

Make sure that the riveting tool is

always equipped with the rubber cover

(5) for catching the rivet mandrels, other-

wise there is a high risk of injury.

NOTE

The Manufacturer bears no liability for

damages incurred due to incorrect repair

or due to using spare parts from other

sources.

The warranty is deemed invalid in case

of any repairs have been performed on

the riveting tool, leading to the damage

of the riveting tool or the seals.