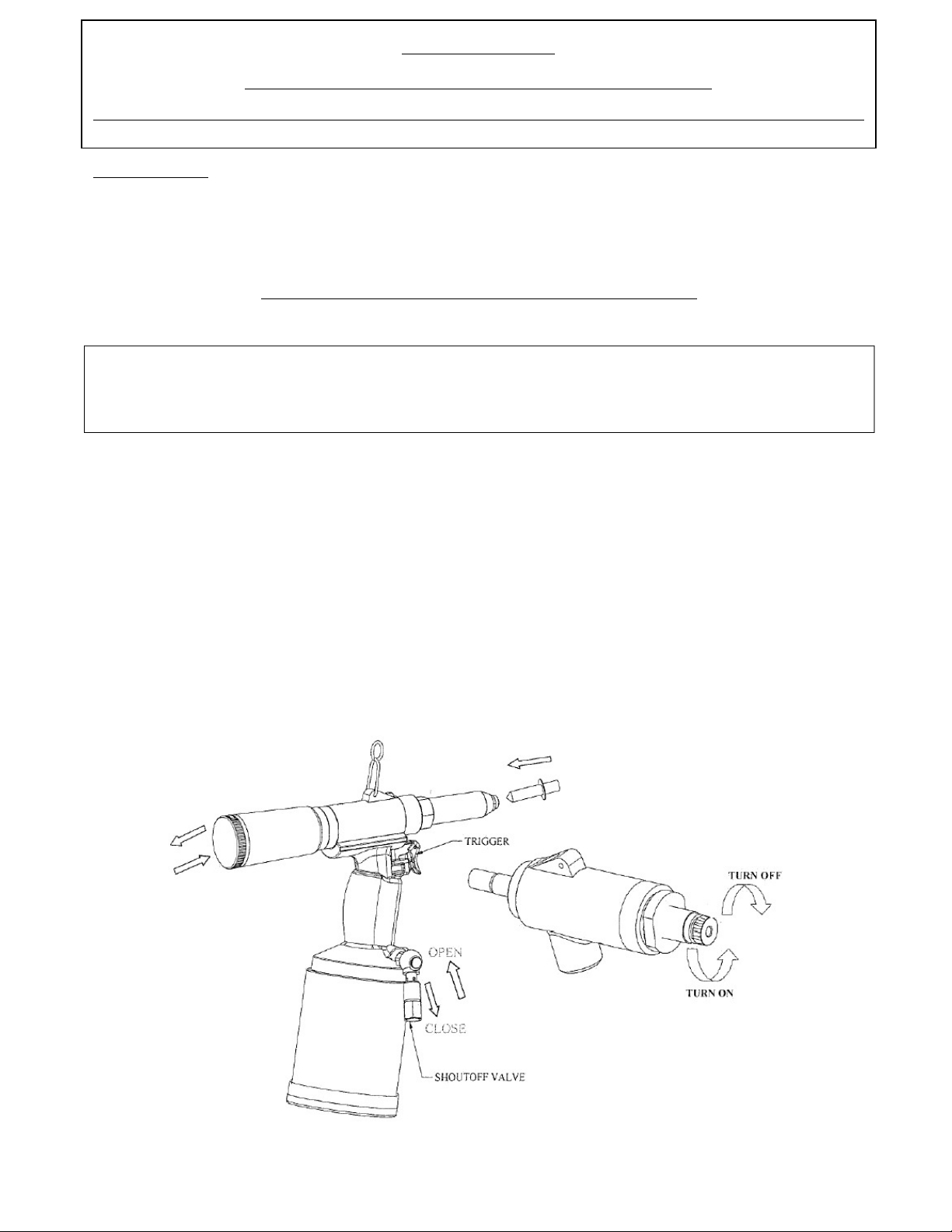

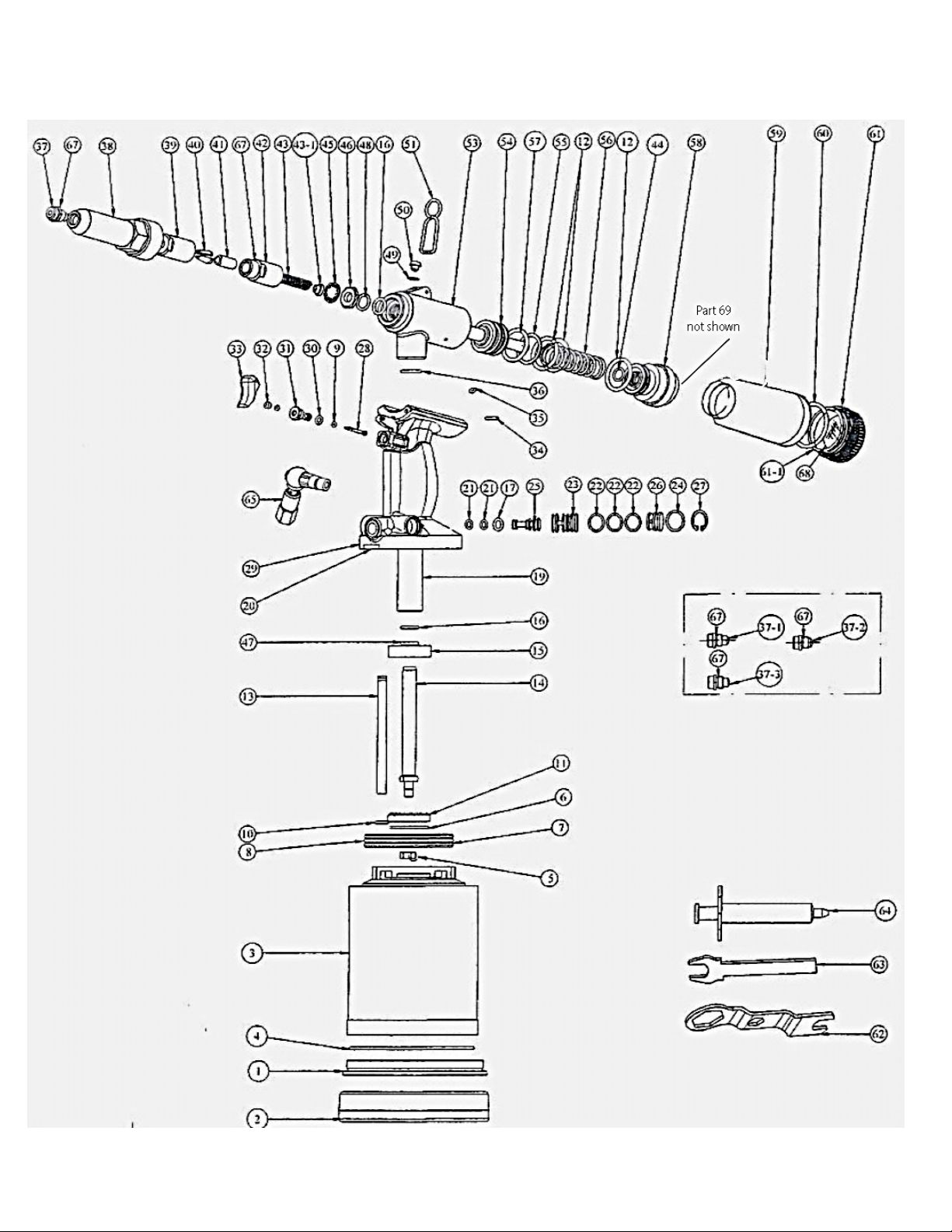

1. Remove the frame head (part #38, fig.1).

2. Using two wrenches, separate front jaw housing (part #39) from rear jaw housing (part #42, fig. 2).

3. Remove and replace part #40 (fig. 3 jaws) and re-assemble part #39 back onto tool (fig. 2).

4. Using spanner gauge (part #63), adjust position as shown in fig. 4 and tighten.

5. Reassemble frame head (part #38 fig.1) back onto tool and tighten together front jaw housing

(part #39) and rear jaw housing (part #42).

!

How'to'change'the'hydraulic'oil''

1. Remove the oil plug (#50) from the tool.

2. Hold tool upside down over a suitable container, apply air to the tool and squeeze the trigger 2-3

times to remove oil.

3. Release the air from the tool.

4. Fill the syringe that came in the tool kit with hydraulic oil. We recommend Mobil DTE 24 as our

preferred hydraulic oil.

If recommended hydraulic fluid is not available be sure to use a non-foaming hydraulic fluid.

5. Screw the syringe into the top of the tool and press the top of the syringe until all of the oil has

been inserted into the tool.

7. Repeat steps 5 & 6 until the tool no longer accepts oil. *

* Note – the oil capacity should not exceed 14ml.

8. Remove the syringe and reinstall the oil plug.

9. Re-install the frame head back onto the tool.

Returning'the'tool'to'the'factory'setting'

1. Loosen and remove the frame head (#38) from the tool.

2. Loosen the lock nut from the rear of the assembly.

3. Using the spanner gauge (see fig. 4 above), move the assembly until the distance of the front of

the collet case to the tool frame matches the distance on the spanner gauge.

4. Re-tighten the lock nut.

5. Re-install the frame head back onto tool.