Nippon Primex NP-2411 Installation instructions

D-F0472 NP-2411/3411 Product Specifications Ver.1.00

Revision 1.00 2008.05.09 1st edition

Nippon Primex Inc

●Head Office

1-5-12 Unoki, Ohta-Ku, Tokyo 146-8650 Japan

TEL: +81 3 3750 5817 FAX: +81 3 3750 4555

E-mail: [email protected]

URL: http://www.primex.jp

[Notice] *All features and specifications referred are subject to change without prior notices.

*Please contact us if there is any wrong description or missing in this specification.

Spec. №D-F0472

Product Specifications

for

2” / 3” Module Printer

NP-2411/3411

D-F0472 NP-2411/3411 Product Specifications Ver.1.00

Record of Revision 1

Description

Rev. No Page Item Contents of change

Approval Person in

charge

0.01

Prov.

New release Abe

(Provisional)

2008.02.08

0.02

Prov.

1 Characteristics

Modified duplicate numbers

Abe

1 Characteristics Deleted due to duplication 2008.02.22

4) paper path~ with content of 13)

15 Standard Added: *NOTE2

19 1)Power Supply Jack Modified CN1→CN2

2)Serial data input Modified CN2→CN4

connector

20 4)Near-end sensor * Added sentence

connector

Connector figure Modified CN number

1.00 1 Provisional deleted Asahina Abe

1 Control No. Added: In case of select~ 2008.05.12 2008.05.09

Added: Bezel, 7th digit

Changed: *Presenter can~

Added:When using bezel~

2 Characteristics 14) Changed: accessory →

separately available

3 Configuration Deleted from standard

3. Paper Support Added: Separately

available accessory table

3) Changed to “Separately

available accessory”

Added:*Starting from April~

6 Roll paper shape Changed to “Separately

[CAUTION] available accessory”

7 (3) Paper Holder Changed to “Separately

*NOTE1) available accessory”

14 Regulations UL60950-1: Acquired

TUV: Acquired

Deleted: **NOTE2

15 External Dimensions Deleted: Misdescription

(Roll paper, arrow)

Added: Reference diagram

16 External Dimensions Added: Reference diagram

24 Chinese Added: *NOTE1

27 (3)Setting paper by~ Added:Head close drawing

44

[Partition Drive Selection]

Modified:“n” range 03→05

D-F0472 NP-2411/3411 Product Specifications Ver.1.00

PRECAUTION

Read Carefully Before Using the Product

Handling the product in a wrong way may decline its performance and also damage the product. Read the notes below before handling the product.

[

Failures

]

1. Static discharge prevention or body grounding must be made for installation and removal of the product to prevent damage of sensor parts etc. Connect

it to the earth ground for ESD measures.

2. Avoid excessive force to the input terminals.

3. Avoid printing with no paper loaded. It can damage thermal head and also shorten its life-time.

4. DO NOT open the front cover while printing and/or cutter operation. It may damage thermal head and cutter.

5. DO NOT pull out the paper with the front cover closed.

6. DO NOT block the paper outlet while print operation. Also, DO NOT grab the paper while print operation.

7. DO NOT scrabble or give impact to thermal head with sharp edge object or any hard materials, which may damage the heat elements.

8. This product is NOT protected against dust or dirt. If used in harsh environment like at dusty place, the thermal head may get damaged or paper feed

may not run properly.

9. When cooling the product with a fan, keep the air exhaust slit away from the printer’s paper exit area so that dust or dirt may not get in the thermal head.

10. This product is equipped with an infra-red reflection sensor. The product must be installed where there is NO direct sun light/infra-red light coming in, as

otherwise, the sensor would not function properly. The sensor function may be affected also by the pre-printed paper if the pre-printed color appears on

the side of paper roll.

11. Use both hands when holding the product in order to prevent from dropping.

12. The product should NOT be installed where it could be exposed to static electricity easily, strong vibration, electromagnetic field, corrosive gas, rain, fog

and direct sunlight.

[

Safety

]

1. Turn OFF the power before connecting or removing connectors. When disconnecting, handle with the connector body and DO NOT pull out by a cable.

2. The product is NOT protected from water or dew drop. DO NOT put water to the product nor handle it with wet hand because it may damage the

product due to short circuit or heat or fire.

3. In order to prevent excessive current, add an electrolytic capacitor and a fuse(refer to power supply specifications for details) to external 24V power line.

4. Plug off the printer when the product is not in use for a long time.

5. DO NOT disassemble or modify the product.

6. In case of disposal, follow the regulations or rules of the local authorities.

7. Use power supply in conformity with LPS standard.

D-F0472 NP-2411/3411 Product Specifications Ver.1.00

[

Quality

]

1. The product supports only control codes and commands authorized in this document.

2. With such print program that printing and paper feeding movements get interrupted temporarily due to data queuing etc, printing and paper feeding may

jumble on a very first few dots line.

3. The print may jumble at the first 1-2 dot right after the paper cut action.

4. DO NOT touch the heating element part of the thermal head, since it could degrade the print quality due to soil.

5. In case of using print papers other than those specified in this document, print quality and lifetime of thermal head may not reach the level guaranteed

by the manufacturer.

6. DO NOT pull out the paper while the printer is in motion of printing, paper feeding or cutting. When removing the partially cut paper, pull it to either right

or left direction without too much force.

7. Continuous motor running for a long time generates heat and may affect the printer performance. To avoid the case, it is necessary to limit the

continuous motor running time to 6 minutes at maximum with the same interval time for each operation.

8. Set the paper straightened with no slack.

9. A part of this product is made from coated steel plate. It does not affect the product’s quality and performance at all even if the cut face of the steel plate

get rusty after a long time period.

10. Since the print feed may jumble between the first 1 – 4 dot lines with such a print program that the print and paper feed gets interrupted temporarily in

state of printer’s data queuing from the host device, be cautious when graphics and the like are included in the print data.

[

Others

]

1. This product is designed to use with general electronic devices. (Computer, PC, OA etc.) This product is not designed and guaranteed to use with

devices that require extremely high quality and reliability, also to use with devices that those failures may directly endanger human body and life.

(Atomic power control device, aerospace aircraft device, transportation device, traffic signal device, ignition control device, medical device and various

safety devices: hereafter called as “Specific application”.) Users shall take full responsibility for using with such specific application.

2. DO NOT conduct operation that is not suggested in this instruction. It may cause accident or failure.

3. Data can not be long-term stored, permanently stored and saved since it is basically evanescent. Nippon Primex Inc is not responsible for any damages

of data deletion or lost income due to breakdown, repair or inspection.

4. When selecting RTS/CTS in serial flow control, make sure to connect RTS/CTS signal to the flow control signal of the host side, otherwise flow control

will not function and may cause garble character or printing disarray.

5. The coverage of warranty is limited within the product itself, Nippon Primex Inc is NOT responsible for anything induced by the defect of the product and

DO NOT pay for any compensation that may occur.

D-F0472 NP-2411/3411 Product Specifications Ver.1.00

Table of Contents

1. Overview ··································································································································1

1.1 Overview ·······························································································································1

1.2 Control No. (default setting)···································································································1

1.3 Characteristics·······················································································································2

1.4 Configuration (bundled items) ·······························································································3

2. Specifications ···························································································································4

2.1 Basic Specifications···············································································································4

2.2 Paper Specifications··············································································································6

2.3 Printing Area··························································································································9

2.4 Cutter Specifications············································································································10

2.5 Black Mark Position (common use with paper sensor) ························································11

2.6 Power Supply Specifications ·······························································································13

2.7 Reliability Specifications ······································································································14

2.8 Environmental Specifications·······························································································15

2.9 External Dimensions············································································································16

3. Configurations ························································································································18

3.1 Interface [USB (V2.0 FULL SPEED)] (Standard) ·································································18

3.2 Interface [Serial (RS-232C compliance)] (only for dual type)···············································18

3.3 Connector Signal Table ·······································································································19

4. Functions································································································································21

4.1 Function Setting ··················································································································21

4.2 Error Handling ·····················································································································24

4.3 Buffer Full Print····················································································································24

4.4 Driving Selection ·················································································································25

4.5 Print Selection of Full size / Half size···················································································25

4.6 Operation Panel ··················································································································26

4.7 How to set Roll Paper··········································································································27

4.8 How to remove the remaining paper, jammed paper. ··························································30

4.9 How to clean thermal head··································································································30

5. Commands ·····························································································································31

5.1 Command Table ··················································································································31

5.2 Printer Driver ·······················································································································33

5.3 Command Details················································································································33

D-F0472 NP-2411/3411 Product Specifications Ver.1.00

6. Character Code Table ············································································································57

6.1 Domestic Character Code Table (International character set: Japanese)····························57

6.2 Overseas Character Code (International set: USA)·····························································58

6.3 CODE PAGE 858 ················································································································59

6.4 International Character Code Table ·····················································································59

6.5 CODE PAGE 1250 ··············································································································60

6.6 CODE PAGE 1251 ··············································································································61

6.7 CODE PAGE 1252 ··············································································································62

6.8 CODE PAGE 1253 ··············································································································63

6.9 CODE PAGE 1254 ··············································································································64

Addendum Kanji Code Table, Chinese (GB18030-2000), KSX1001-1992

D-F0472 NP-2411/3411 Product Specifications Ver. 1.00 1

1. Overview

1.1 Overview

This printer is categorized as follows:

NP-3411U-*

(1) (2) (3)

(1) Paper size (default setting)

3: 3 inch (default setting: 80mm)

2: 2 inch (default setting: 58mm)

(2) Interface (default setting)

U: USB (V2.0 FULL SPEED) only (standard)

D: SERIAL (RS232C), and USB (V2.0 FULL SPEED)

(3) OEM number (TBD)

1.2 Control No. (default setting)

This product can set specifications except the above items of “standard” and its

specifications will be expressed by 10 digits of control number.

Control number will be determined as “default (ex-factory) setting”

There will be no control numbers for OEM production.

Since there are “Power Supply Jack”, “Auto cutter” and “Paper width” etc. for selectable

specification contents, please confirm to our company for more details.

* In case of ordering with bezel, it is separately packaged from a printer.

Paper

width

Auto

cutter Mark sensor Power

jack

Paper

holder Bezel

NIS No. Standard

model Control No. 1st,2nd

digit 3rd digit 4th digit 5th digit 6th digit 7th digit

70-00361 NP-2411U 58PL120000

70-00362 NP-2411D 58PL120000

58

:58mm

70-00357 NP-3411U 80PL120000

70-00358 NP-3411D 80PL120000

80

:80mm

P:

full cut,

partial cut

L:

left side from

insertion

1:

round

shape

2:

PH-10

0:

None

* Presenter can not be selected.

* Since the above chart is a standard specification, contact us for other specifications.

* When using bezel, beware paper length not to be below 55mm.

(If paper length is below 55mm, it will be difficult to take out paper from the bezel.)

D-F0472 NP-2411/3411 Product Specifications Ver. 1.00 2

1.3 Characteristics

This model mounts our printer mechanism also module printer that increases operability.

The only necessary built-in action to each device to activate is power supply (DC24V) and

data input also enables free retrofit of user-side.

1. Extreme small size and light weight offers free design for various embedded devices.

2. Wide range of Operating Environment

3. Low cost

4. Easy maintenance due to a complete openable mechanism of a paper path.

5. High Print Speed, High Print Quality

6. Interface corresponds to serial and USB.

7. Various 1D bar-codes are available.

8. Enables to apply to various kinds of applications

9. Corresponds to drivers of various OS

10. Windows 2000 / XP / Vista / CE5.0 Linux (sample)

11. Easy to write/rewrite F/W by adopted flash memory. Also, 3 patterns of NV bit image

can be saved and registered.

12. Multi language (Japanese, Korea, Chinese, Greek, Polish, Russian,

Scandinavian, Turkish)

13. Simple and easy paper loading by “Auto Paper Loading” function.

14. Mounting newly developed clamping type paper holder “PH-10”(see *NOTE1 below)

I. Roll paper holder with one-touch easy loading and certain near end detection.

II. Besides ID12mm of roll paper, it enables to use roll paper of ID25.4mm by

attaching separately available attachment.

III. Besides ex-factory setting of near end detection is OD22mm, it enables to

change to 24mm dia. by adjusting sensor position.

*NOTE1) Please see “2.2 Paper Specifications” for details.

D-F0472 NP-2411/3411 Product Specifications Ver. 1.00 3

1.4 Configuration (bundled items)

Name Specification P/N Qty NP-2411U NP-2411D

NP-2411U Only USB 70-00361 1 ○

1 NP-2411D USB and Serial (dual) 70-00362 1 ○

2 Thermal

roll paper W58xOD30(ID12)mm 24-00017 1 ○○

Name Specification P/N Qty NP-3411U NP-3411D

NP-3411U Only USB 70-00357 1 ○

1 NP-3411D USB and Serial (dual) 70-00358 1 ○

2 Thermal

roll paper W80xOD30(ID12)mm 24-00018 1 ○○

*Separately available accessory

Name Specification P/N Qty

3 Paper support For core ID25.4mm 35-00168 2

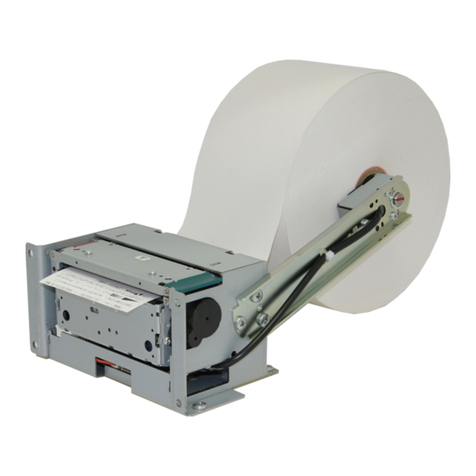

(1) Printer Main Body (NP-3411 or NP-2411) ………… 1 unit

(2) Accessories

* Thermal roll paper (sample) …………… 1 roll

(3) Separately available accessory

* Attachment for inner core diameter of 25.4mm ….2 pieces

* Starting from April2008, it was changed from standard accessory to separately

available accessory.

D-F0472 NP-2411/3411 Product Specifications Ver. 1.00 4

2. Specifications

2.1 Basic Specifications

No. Specifications NP-2411 NP-3411

1 Head 1: Print method Thermal line dot

2: Total dots/line 432 dots 576 dots

3: Dot density 8dot/mm

4: Printing width 54 mm 72 mm

2 Printing 1: Printing speed (max)*NOTE1 max.150mm / sec

Conditions Head temp. at over 35ºC, buffering method,

optimized driving print ratio 50% or less.

*except communication time

2: Max. print digit

Font A (12 × 24) 36 digits 48 digits

Font B (9 ×17) 48 digits 64 digits

Kanji (24 × 24) 18 digits 24 digits

3: Line feed pitch 0.125mm

3 Characters 1: Character size

Font A (12 × 24) 1.50 × 3.00mm

Font B (9 × 17) 1.13 × 2.13mm

Kanji (24 × 24) 3.00 × 3.00mm

2: Character types

Japanese JIS C 6226 1983 (Full size)

Katakana character (Half size)

Extended Graphic character set (Half size)

Code Page 858 (Half size)

International character set (Half size)

Korean KS X 1001:1992 (Full size)

Katakana character set (Half size)**NOTE2

Extended Graphic character set (Half size)**NOTE2

Code Page 858 (Half size)

Chinese GB18030-2000 (Half / Full size)

Greek Code Page 1253 (Full size)

Polish Code Page 1250 (Half size)

Russian Code Page 1251 (Half size)

Scandinavian Code Page 1252 (Half size)

Turkish Code Page 1254 (Half size)

3: Character decoration Double width

Double height

Quadruple (double width and height)

Enhanced print

Double strike

Inverted

90°clockwise rotation

Underline

4: Line spacing (default) 4.25mm (1/6 inch)

*NOTE 1) Printing speed depending on condition.

**NOTE 2) KS X 1001:1992 built-in font.

D-F0472 NP-2411/3411 Product Specifications Ver. 1.00 5

No. Specifications NP-2411 NP-3411

4 Print mode 1: Line mode ANK mode

Barcode mode

Bit image mode

Buffering mode

5 Barcode 1: 1-D barcode UPC-A

UPC-E

JAN-13 (EAN-13)

JAN-8 (EAN-8)

CODE39

ITF

CODABAR

CODE128

6 Interface 1: Serial (dual type) RS232C compliance

2: USB(dual type, U type) V2.0 FULL SPEED compliance

7 Auto cutter 1: Cutting mode Full / Partial cut

*selectable by command

8 Buffer receipt Approx. 15K bytes

9 Alarm display ALARM LED

10 Operation switch FEED switch

RESET switch

11 Appearance 1: Outer dimensions 103.6 (W) × 123.5 (D) 124.6 (W) × 123.5 (D)

(w/o connector, paper) × 77.3 (H) mm × 77.3 (H) mm

2: Weight Approx. 500g Approx. 560g

(w/o paper)

3:Mounting***NOTE3 Horizontal

***NOTE 3) Mounting shall be placed horizontally. Please contact us for different mounting.

D-F0472 NP-2411/3411 Product Specifications Ver. 1.00 6

2.2 Paper Specifications

(1) Paper width / thickness

2 inch 3 inch

Paper width 58/60-1 mm 76/80-1 mm

Paper thickness 65~150µm

[CAUTION]

* Do NOT change paper width from narrow to wide during operation. (There is possibility

of thermal head damage when scraping against platen directly.)

*Please consult with us when using paper width of 60 and 76mm. (All of the paper

widths are set as default setting.)

(2) Roll paper shape

Paper size (max.) Thickness Inner core Outer core

83mm dia. 65~85µm 12.0mm dia. 18.0mm dia.

83mm dia. 100~145µm 25.4mm dia. 33.4mm dia.

[CAUTION]

*Use standard paper holder PH-10.

(Please consult with us when using paper width of over 84mm dia.)

*Axis core width should be same as the paper width.

*Use separately available attachment when using paper of inner core DIA25.4mm. (see below fig.)

[Conditions for using roll paper]

Make sure to follow the following conditions.

*No glue, no tape at the end of roll paper.

*No deformed core of roll paper.

*Core width should be same size as the paper width.

*Do NOT keep roll paper under environment of high temperature and humidity.

*Roll paper is not loosened. Unable to detect normally when roll paper is loosen.

Since it detects roll paper O.D. by using reflection photo sensor, near end detection will

not be available when using axis core excessing detecting value.

*Printing surface shall be outer surface. Involute paper is not applicable.

DIA25.4mm attachment

DIA12mm

D-F0472 NP-2411/3411 Product Specifications Ver. 1.00 7

(3) Paper Holder (Standard: PH-10)

Name Paper width Max. OD Axis core OD to NE sensor

ID12.0mm

OD18.0mm DIA22.0±2.5mm

PH-10 - DIA83mm ID25.4mm*NOTE1

OD33.4mm DIA37.0±2.5mm **NOTE2

*NOTE1) Use separately available attachment for roll paper of axis inner core

DIA25.4mm.

**NOTE2) Change position of near end sensor with using roll paper of inner core

DIA25.4mm. (see figure below)

1) Change of NE (near end) setting

Replace or loosen M2 screw and move near end sensor.

a) Axis inner core diameter 12.0mm

A position: Remaining OD22.0±2.5mm (default)

B position: Remaining OD24.0±2.5mm

b) Axis inner core diameter 25.4mm

C position: Remaining OD34.0±2.5mm

D position: Remaining OD37.0±2.5mm

(Recommended position for OD33.4mm)

[CAUTION]

*Remaining setting for axis inner core diameter of 25.4mm, unscrew the M2 screw

and re-screw to another screw hole.

(Loosen the screw and slide from “C” to “D” for adjustment.)

A B

NE sensor unit

C D

M2 screw

D-F0472 NP-2411/3411 Product Specifications Ver. 1.00 8

(4) Recommended Thermal Paper

P/N thickness Maker

PD160R 0.075mm OJI seishi

PD450-145 0.145mm OJI seishi

PD150R 0.075mm OJI seishi

PDC600-145 0.145mm OJI seishi

[CAUTION]

*Since printing quality will degrade effecting by circumstances of temperature and

humidity etc., confirm printing quality before setting printing density. Printing density

can be set by switching memory switch MS2-8 or using command of [Print Density

Setting] «GS ~ n»

*Printing at high print ratio under low temperature or high humidity environment

cause printed paper to be tainted or dew drop due to vapor occurred from the roll

paper. Beware water not to drop to the thermal head part. This may lead thermal

head’s electrolytic corrosion.

In case of dew drop, turn OFF and wait until the dew disappears.

*Select thermal paper which has a low level of Na+ ion, K+ ion and CI- ion when

using non-recommended thermal paper and should be well evaluated in reliability.

D-F0472 NP-2411/3411 Product Specifications Ver. 1.00 9

2.3 Printing Area

(1) Code name

Code Name

A Print dot No.

B Left margin

C Print area

D Right margin

E Paper width

(2) Paper width and print area

A (dot) B (±1mm) C (±0.2mm) D (±1mm) E (-1mm) Default

416 3 52 3 58 ○

432 3 54 1 58

*NOTE1

2 inch

432 3 54 3 60 -

560 4 69 3 76 -

3 inch 576 4 72 4 80 ○

*NOTE1: It is possible to set by turning on memory switch MS2-7 (refer to 4.1.2 Memory

switch MS2), however the right margin (D) will be 1mm, so that printing may be out

of range due to paper bias.

1dot 2dot Adot

0.125mm

B CD

E

FEED direction

Print Surface

D-F0472 NP-2411/3411 Product Specifications Ver. 1.00 10

2.4 Cutter Specifications

Code Description Size

A Tab width (in partial cut) 1.0~2.5mm

B Cut ~print head position 9.5±1mm

C Back feed limit 6.5mm

D Paper edge(from 1st dot) to

partial cut distance

About 30mm (NP-2411)

About 40mm (NP-3411)

(1) Cutting method : Slide type

(2) Cutting mode : Full cut / Partial cut A / Partial cut B

*Selectablebycommand

*PartialcutA:narrowmargin

*PartialcutB:widemargin

(3) Allowable cut frequency : 30 cuts / minute

(4) Paper thickness : 65 ~ 150µm

* If partial cut is activated with paper thickness of 75µm or more, the paper located at

mechanism side may be haled when cutting off the printed paper.

[CAUTION]

* When platen is given under heavy load such as pulling out printed paper strongly after

partial cut etc. note that next line head may garble.

To battle with, pull the paper towards either to right or left side or take

countermeasures like feeding paper for approx. 1mm before print starts.

* Since there is automatic paper feed of approx. 2mm for a paper jam protection after

paper cut, the above cutting margin will be 11.5±1mm.

*When selecting “Full cut” in control no. do NOT use any other cut modes except full cut.

FEED direction

C

Cutting position

Print head position

A

Print Surface

B

Back FEED limit

D

D-F0472 NP-2411/3411 Product Specifications Ver. 1.00 11

2.5 Black Mark Position (common use with paper sensor)

(1) Code name

Code Description

A Print head ~ sensor position

B Sensor 1 position (standard)

C Sensor 2 position (option)

D Paper width

(2) Sensor Position

A (±1mm) B (±0.5mm) C (±0.5mm) D (-1mm)

58

2 inch 8.0 52 60

76

3 inch

11.5

7.5 72.5 80

*Take off or wipe out and clean the sensor periodically.

FEED direction

Print Surface

B

C

A

Sensor 1

Print head position

Sensor 2

D

D-F0472 NP-2411/3411 Product Specifications Ver. 1.00 12

(3) Black Mark Printing Specification

Mark print position Center position of the set sensor as a mark sensor is standard position.

Mark width (min.) 5.0mm for both left and right from standard position(total width: 10mm)*NOTE1

Mark height (min.) 5.0mm

Print surface Non printing surface

PCS value 0.9

Reflectance ratio The ratio of 900nm (infrared ray) is less than 7%.

Preprint limit area Preprint with dark color is prohibited in mark width area.

Confirm with extra care when using preprinted paper.

*NOTE1: It is not applicable when selecting “sensor 2” with paper width of 76mm.

Please contact us for any supports.

D-F0472 NP-2411/3411 Product Specifications Ver. 1.00 13

2.6 Power Supply Specifications

(1) Power Supply Jack

1) Round shape connector (standard)

Dedicated A/C adaptor will be connected. (Power supplied externally.)

Printer side connector: TCS7960 - 5320177 Hoshiden or equivalent.

Adaptor side connector: TCP8927 - 631178 Hoshiden or equivalent.

2) 2 pin connector (selectable by control no.)

Connector below will be connected to this connector. (Power supplied externally.)

Printer side connector: S2P-VH (LF) (SN) JST or equivalent.

Adaptor side connector: VHR-2N JST or equivalent.

(2) Power Supply Voltage: DC24V ± 5%

(3) Current Consumption (Estimation)

2 inch model 3 inch model

Power Supply Voltage +24V±5% +24V±5%

Standby approx. 80mA (typ) approx. 80mA (typ)

Print average 25% Max.approx. 3A Max.approx. 3A

Print average 100% Max.approx. 10A Max.approx. 10A

Condition: Printer initial condition. (Dual partition print, print density 100%)

[CAUTION]

* There may be a large peak current depending on printing contents. Use enough power

supply capacity in order to secure print quality.

* There may be a case of unstable movement, when power supply cable is too long.

To solve with, shorten power supply cable as short as possible.

Should it is not conductable, connect cables near by the printer and place an electrolysis

condenser of approx. 2200u between PS and GND. Voltage resistance should be higher

than 35V.

* Use power supply complied with LPS.

No. function

1 +24V

2 GND

3 N.C

shell FG

No function

1 +24V

2 GND

Connector Fig.

3

1

2

12

Connector Fig.

D-F0472 NP-2411/3411 Product Specifications Ver. 1.00 14

2.7 Reliability Specifications

(1) Life duration

1) Thermal head

Pulse resistance: 100 million pulse

Anti-abrasion: 100km

2) Cutter: 1 million cut

3) Definition of life duration

i) Entering point at period of abrasion failure.

ii) Conditions to satisfy the life duration.

Average Print ratio: 12.5%

Paper medium: Recommended thermal papers

Print Density: 100%

* Life duration will differ when using the non-recommended papers because of its

quality, width and thickness. Have the user confirm itself with paper that user

intends to use actually.

Other manuals for NP-2411

1

This manual suits for next models

1

Table of contents

Other Nippon Primex Printer manuals