Nippon Primex NP-K2092 User manual

Specs №D-F10087

Product Specifications

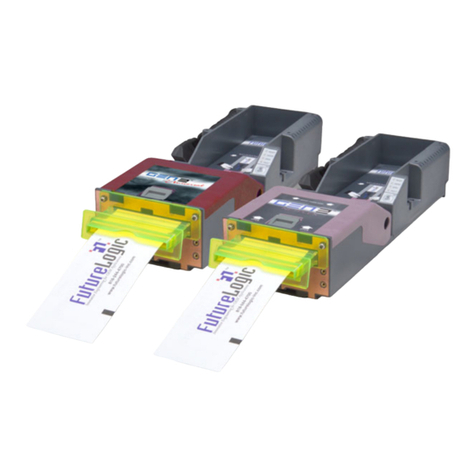

2 inch Compact KIOSK Face Mount Printer

N P – K 2 0 9 2

Revision 1.00 2011.10.24 1st edition

All specifications described are subject to change without prior notice.

Please contact us for double-checking if you find any descriptions unclear

or something which seems to be mistyped or mistranslated.

Nippon Primex Inc.

Head Office:

1-5-12 Unoki Ohta-ku Tokyo 146-8650 Japan

TEL :+81-3-3750-5817 FAX :+81-3-3750-4555

URL : http://www.primex.jp

D-F10087 NP-K2092 Product Specifications Rev.1.00

D-F10087 NP-K2092 Product Specifications Rev.1.00

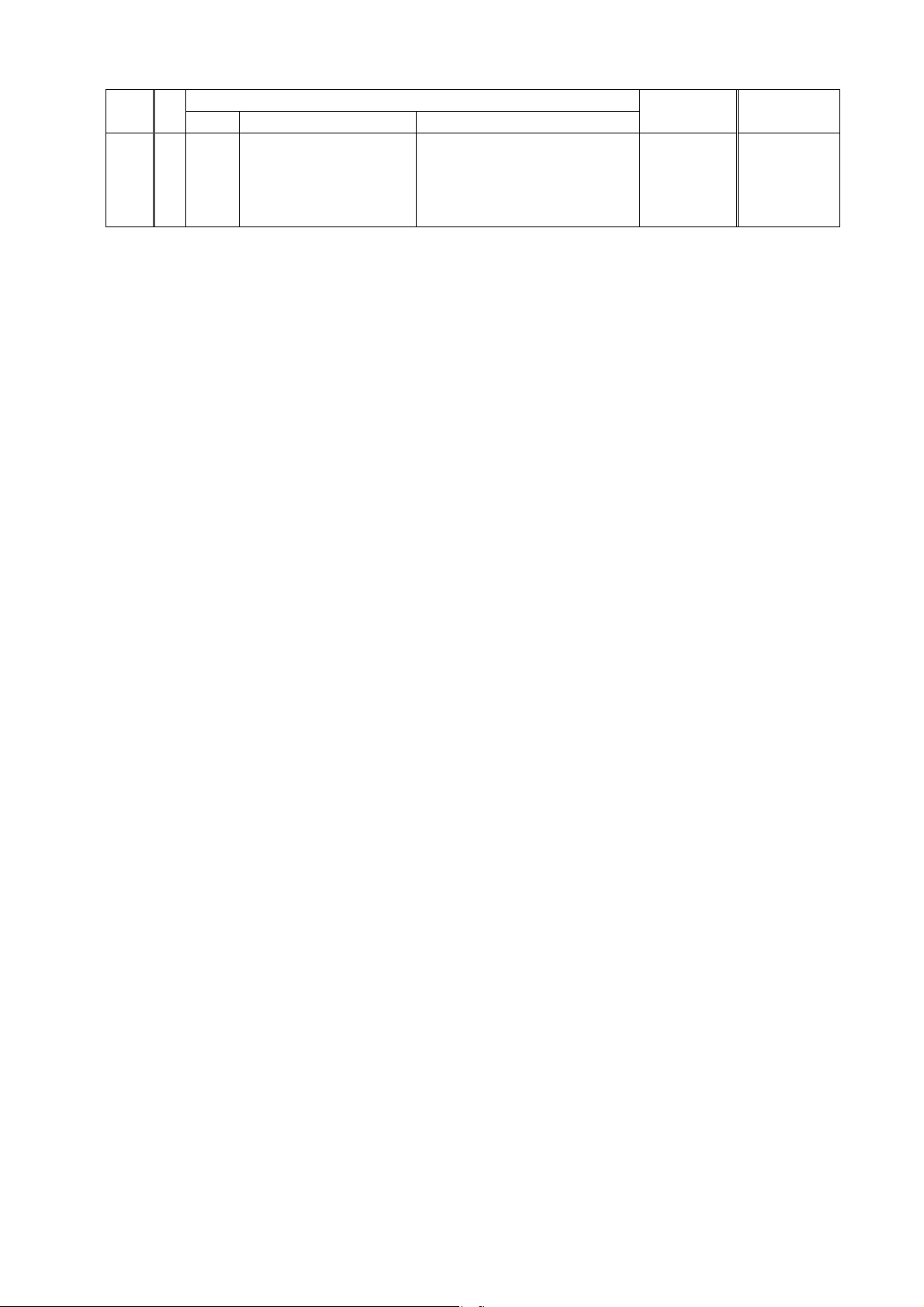

Record of Revision

Descriptions

Rev. V Page Item Change Approval PIC

1.00 1 New release Kobayashi Abe

2011.10.25 2011.10.24

D-F10087 NP-K2092 Product Specifications Rev.1.00

[ VCCI Class A ]

This device is Class A information technology equipment. Using this device

under home environment may cause interference. The user may be required to

take an adequate measure in that case. VCCI-A

[ FCC Class A ]

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that

may cause undesired operation.

D-F10087 NP-K2092 Product Specifications Rev.1.00

PRECAUTION

Handling the product in a wrong way may decline its performance and also damage the product. Please

read the notes below before handling the product. Since there are detailed precautions described other

than this section, please read this product specifications carefully before using the product. Also, please

sufficiently alert the user.

[FAILURE PRECAUTIONS]

Please comply with the following in order to use for many years to come and prevent troubles before

happens.

STATIC-ELECTRICITY;

• Static discharge prevention or body grounding must be made for installation and removal of the product

to prevent damage of heating element and IC etc. Connect it to the earth ground for ESD measures.

HANDLINGS;

• Do not apply excessive force to the input terminals.

• Use both hands when holding the product in order to prevent from dropping.

• Since it will cause damage of the heat elements, do not scrabble or give impact to thermal head with

sharp edge object or any hard materials.

INSTALLATION;

• This product is not protected against dust or dirt. If used in harsh environment like at dusty place, the

thermal head may get damaged or paper feed may not run properly.

• When cooling the product with a fan, keep the air exhaust slit away from the printer’s paper exit area so

that dust or dirt may not get in the thermal head. It will be a cause for premature failure.

• This product is equipped with an infra-red reflection sensor. The product must be installed where there is

no direct sun light/infra-red light coming in, as otherwise, the sensor would not function properly.

• This product should not be installed where it could be exposed to static electricity easily, strong vibration,

electromagnetic field, corrosive gas, rain, fog and direct sunlight.

MOVEMENT;

• Avoid printing with no paper loaded. It can damage thermal head and also shorten its life-time.

• Absolutely do not open the printer unit while printing or cutter movement. It may damage thermal head

or cutter.

• Do not pull paper with close status of the printer unit.

• Do not block the paper outlet while print movement. Also, do not grab the paper while print movement.

D-F10087 NP-K2092 Product Specifications Rev.1.00

[SAFETY PRECAUTIONS]

Please comply with the following in order to use for many years to come and prevent troubles before

happens.

• Make sure to turn OFF the power of the product when connecting or disconnecting the connector. Do

not disconnect by pulling out the cable.

• This product is not protected from water or dew drop. Do not put water to the product nor handle it with

wet hand because it may cause damage, heating, firing by short circuit.

• In order to prevent excessive current, please add element for protection and a fuse (Please refer to

power supply specifications for details).

• Please do not disassemble or modify the product.

• In case of disposal, please follow the regulations or rules of the local authorities.

• Use power supply in conformity with LPS standard.

• Turn OFF the power when not using for a long time.

• Regardless of during movement or stop of the cutter, do not touch the cutter blade.

[QUALITY PRECAUTIONS]

Please comply with following in order to use without imparing performance for many years to come and

prevent troubles before happens.

DATA;

• Movement when sending undefined control codes and commands to the product is not guaranteed.

• Since the print feed may jumble between for the first 1 – 4 dot lines with such a print program that the

print and paper feed gets interrupted temporarily in state of printer’s data queuing from the host device,

be cautious when graphics and the like are included in the print data.

PRINT MOVEMENT;

• The print may jumble in the first 1-2 dot right after cutter drive.

• Do not touch the heating element part of the thermal head with a finger or hand etc. It may degrade the

print quality due to soil.

• In case of using papers other than those specified in this document, print quality and lifetime of thermal

head may not reach the level guaranteed by the manufacturer.

• Do not pull out the paper while the printer is in motion of printing or paper feeding. When tearing partial

cut or perforated paper, tear off by pulling either to the right or left.

• Continuous motor running for a long time generates heat and may affect the printer performance. To

avoid this case, please limit the continuous motor running time to 6 minutes at maximum with the same

interval time for each operation.

• Motor may produce heat by continuously driving cutter motor for a long time and it may not perform

necessary functions. Make sure to follow cutter tolerable frequency. Use over the tolerable frequency

may break cutter at the worst case.

• Set the paper straightened with no slack.

• A part of this product is made from plated sheet steel. It does not affect the product’s quality and

performance at all even if the cut face of the steel get rusty after a long time period.

• This product may occur scrape etc, to the print surface because of its structure.

D-F10087 NP-K2092 Product Specifications Rev.1.00

[OTHER PRECAUTIONS]

• This product is designed to use with general electronic devices. (Computer, PC, OA etc.) This product is

not designed and guaranteed to use with devices that require extremely high quality and reliability, also

to use with devices that those failures may directly endanger human body and life. (Atomic power

control device, aerospace aircraft device, transportation device, traffic signal device, ignition control

device, medical device and various safety devices: hereafter called as “Specific application”.) Users

shall take full responsibility for using with such specific application.

• Do not conduct operation that is not suggested in this instruction. It may cause accident or failure.

• Data can not be long-term stored, permanently stored and saved since it is basically evanescent.

Nippon Primex Inc is not responsible for any damages of data deletion or lost income due to breakdown,

repair or inspection.

• When selecting RTS/CTS in serial flow control, make sure to connect RTS/CTS signal to the flow

control signal of the host side, otherwise flow control will not function and may cause garbled character

or printing disarray.

• The coverage of warranty is limited within the product itself, Nippon Primex Inc is not responsible for

anything induced by the defect of the product and do not pay for any compensation that may occur.

D-F10087 NP-K2092 Product Specifications Rev.1.00

Table of Contents

1. Overview ···················································································································································1

1.1 Overview ········································································································································· 1

1.2 Features ·········································································································································· 2

1.3 Configurations ································································································································· 3

2. Specifications ············································································································································4

2.1 Basic Specifications························································································································· 4

2.2 Paper Specifications························································································································ 6

2.3 Print Area ········································································································································ 8

2.4 Specifications of Cutter···················································································································· 9

2.5 Paper Sensor ································································································································10

2.6 Power Specifications ······················································································································11

2.7 Reliability Specifications ················································································································ 12

2.8 Environment Specifications ··········································································································· 13

2.9 Regulations ··································································································································· 13

2.10 External Dimension ····················································································································· 14

3. Configurations ·········································································································································15

3.1 Interface [USB(V2.0 FULL SPEED)] ····························································································· 15

3.2 Interface [SERIAL (RS-232C compliance)]···················································································· 16

3.3 Connector Signal Details··············································································································· 17

4. Functions·················································································································································18

4.1 Function Setting ···························································································································· 18

4.2 Error Handling ······························································································································· 22

4.3 Buffer Full Print······························································································································ 23

4.4 Drive Mode Selection ···················································································································· 23

4.5 Print Selection of Full size / Half size ···························································································· 23

4.6 Operation Panel ···························································································································· 24

4.7 How to set paper roll ····················································································································· 25

4.8 How to remove the remained and jammed paper·········································································· 26

4.9 Cleaning Method for thermal head and others ·············································································· 27

4.10 Frame Ground ····························································································································· 28

5. Printer Installation····································································································································29

5.1 Receipt print surface and paper roll position selection ·································································· 29

5.2 Position Change of Paper Holder ·································································································· 30

5.3 How to handle each cable ············································································································· 31

Separate reference document (Please refer to document below for command and code page)

• Command reference [NP-K2092] (D-F10087)

The following code pages are described besides command in the command reference.

Domestic Character Code Table, Overseas Character Code Table, Code Page 858, International

Character Code Table, Code Page 1250, Code Page 1251, Code Page 1252, Code Page 1254

• Kanji Code Table [JIS C 6226・1983] (D-F10068)

D-F10087 NP-K2092 Product Specifications Rev.1.00 1

1. Overview

1.1 Overview

Basic model of this printer is categorized as follows.

NP- K

2

0

9

2

D

(1) (2) (3) (4)

- M -

* *

(5) (6)

(1) Type (Fixed)

K:KIOSKtype

(2) Mechanism (Fixed)

2 : 2 inch model

(3) Cutter Type (Fixed)

2 : with autocutter

(4) Interface (Factory setting)

Standard

D : Dual Interface (SERIAL-RS232C and USB-V2.0 FULL SPEED) – select use

Conceivable specifications for production

U : USB (V2.0 FULL SPEED) only

R : SERIAL (RS232C) only

(5) Power Supply Voltage (Fixed)

Standard

M:DC12V(±5%)

(6) OEM (Factory setting)

No mark : Standard

D-F10087 NP-K2092 Product Specifications Rev.1.00 2

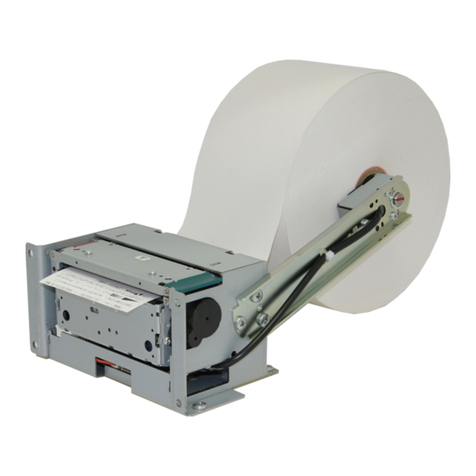

1.2 Features

This printer is a module printer equips with our own printer mechanism and it is a KIOSK printer

realized cost reduction by simplifying the structure.

Feature that can freely change paper roll position enables most suitable built-in to various devices.

(1) Face mount printer that is directly mountable to the front surface panel.

(2) Receipt is selectable either to eject print surface showing down or up. (Select when mount)

(3) Easy paper load by cantilever shaft type paper holder.

(4) Paper roll set direction is selectable either to the right or left. (Select when mount)

(5) Paper roll position is selectable either to upper, middle or lower. (Select when mount)

(6) Max. 100mm/sec (M type) *NOTE1

(7) Autocutter

(8) Paper near end function

(9) High Quality Printing

(10)Interface : SERIAL and USB (selectable)

(11)Supports various types of 1D barcodes.

(12)Supports 2D QR code model 2.

(13)Adaptation to various applications.

(14)Driver (Windows XP(32bit) / Vista(32,64bit) / 7(32,64bit) / CE5.0 / CE6.0, Linux(sample)

(15)Easy to re-write firmware*NOTE2 due to Flash Memory and 3 patterns of registration available

with NV bit image.

(16)Easy paper load due to auto loading function.

*NOTE1: There are conditions to use with Max. 100mm/sec

Please refer to “5.1 Selection of receipt print surface and paper roll position”

*NOTE2: Notation of [F/W] in the sentence hereafter indicates [Firmware]

D-F10087 NP-K2092 Product Specifications Rev.1.00 3

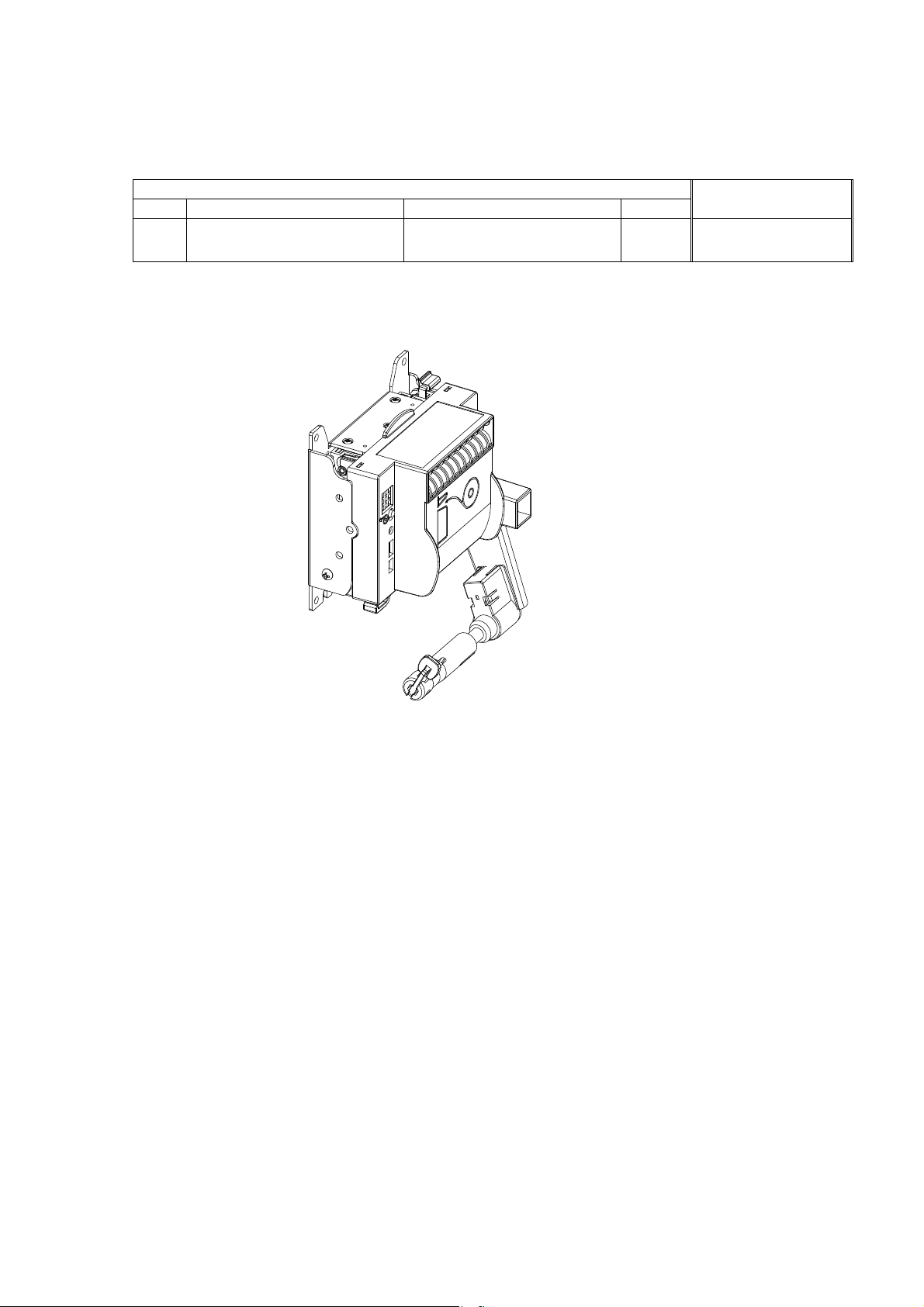

1.3 Configurations

1) NP-K2092D-M (standard)

Component parts of this product are as follows;

Component parts

№Name Specifications Q’ty

NP-K2092D-M

1 NP-K2092D-M USB, SERIAL common use 1 ○

*There is no attached accessories. (Neither sample paper roll)

D-F10087 NP-K2092 Product Specifications Rev.1.00 4

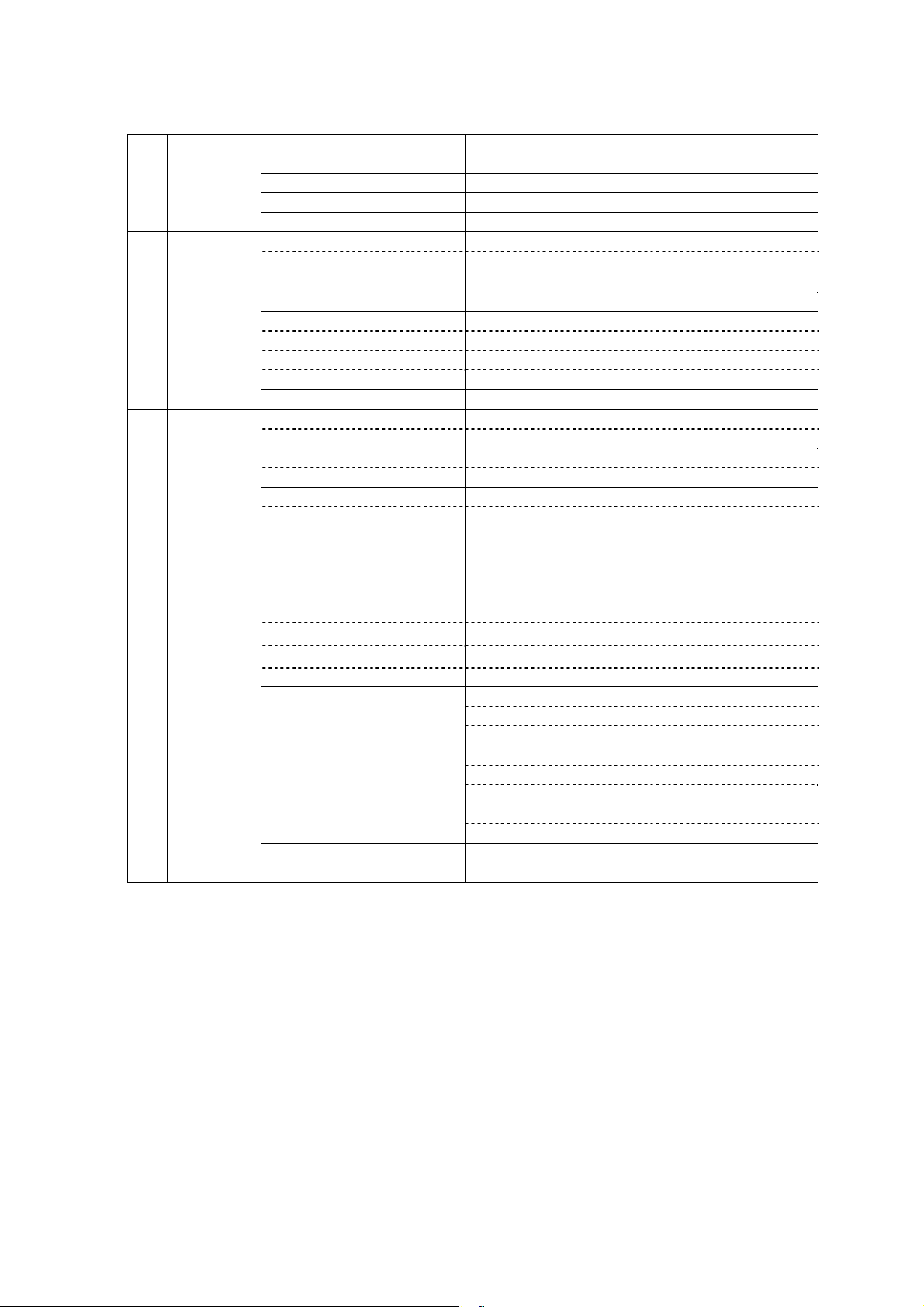

2. Specifications

2.1 Basic Specifications

№Specifications NP-K2092

1 Print Head 1: Print Method Line thermal dot

2: Total dots 384 dots

3: Dot density 8dot/mm

4: Print width (MAX) 48mm

2 Printing 1:Print speed (MAX) *Note1 MAX.100mm/sec

Conditions Head temperature at 35ºC or more,

Below 64dots, optimized drive.

*except communication time

2:Max. print digit

Font A (12×24) 32 digit

Font B (9×17) 42 digit

Kanji (24×24) 16 digit

3: Paper feed pitch 0.125mm

3 Character 1:Character size

Spec. Font A (12×24) 1.50×3.00mm

Font B (9×17) 1.13×2.13mm

Kanji (24×24) 3.00×3.00mm

2:Characters

Japanese JIS C 6226・1983 (Full size)

Katakana character set (Half size)

Extended graphic character set (Half size)

Code Page 858 (Half size)

International character set (Half size)

Polish Code Page 1250 (Half size)

Russian Code Page 1251 (Half size)

Scandinavian Code Page 1252 (Half size)

Turkish Code Page 1254 (Half size)

3:Character Double width

Modifications Double Height

Quadruple

Bold print

Double strike

Inverted

90°clock-wise rotation

Underline

4:Line feed Amount 4.25mm (1/6 inch)

(Default)

*NOTE1: Printing speed varies on conditions.

There are conditions to use with Max. 100mm/sec

Please refer to “5.1 Selection of receipt print surface and paper roll position”

D-F10087 NP-K2092 Product Specifications Rev.1.00 5

№Specifications NP-K2092

4 Print mode Line mode

5 Barcode 1:1D Symbology UPC-A

Specs. UPC-E

JAN-13(EAN-13)

JAN-8(EAN-8)

CODE39

ITF

CODABAR

CODE128

2:2D Symbology QR code model 2

6 Interface 1:SERIAL (D or R type) RS232C compliance

2:USB (D or U type) V2.0 FULL SPEED compliance

7 Autocutter 1:Cut Mode Partial cut / Full cut

*Selectable by command

8 Receive Approx. 10K Byte

buffer

9 Alarm display ALARM LED

10 Operation FEED Switch

switch RESET Switch

11 External *shipping form Approx. 98.8(W) × 67.7(D) × 132.4(H)mm

Dimensions *w/o stopper, paper roll

12 Weight *without paper roll Approx. 450g

13 Mounting Please refer to “5. Printer Installation”

14 Package 1:Individual carton size Approx. 206(W) × 152 (D) × 146(H)mm

2:Individual carton weight Approx. 600g

3:Master carton size Approx. 479(W) × 432 (D) × 324(H)mm

4:Master carton weight Approx. 8.4kg

(includes 12 pcs)

D-F10087 NP-K2092 Product Specifications Rev.1.00 6

2.2 Paper Specifications

1) Paper width and thickness

NP-K2092

Paper width 580-1mm

Paper thickness 59 ~ 75μm

• Please make sure to use axis core width same as the paper width.

2) Paper Shape

• Paper should be roll shape.

OD (Max.) Axis Core ID Axis Core OD

OD80mm ID12.0mm OD18.0mm

[Precautions for paper roll]

• Please use thermal paper.

• Please do not stick end of paper with glue and scotch tape.

• The core of paper roll should not be deformed.

• The core should not be stuck out over the side of the paper roll.

• Please do not use paper that was stored under condition of high temp and humidity.

• Paper roll is not loosened.

• Printing surface shall be outer surface. Involute paper is not applicable.

•Sufficiently confirm when using preprinted paper. Especially, beware of the print side surface

because there is a paper sensor and near end sensor to the side surface equipped.

•Please do not use long-term stored paper roll because it may not perform satisfactory print

quality.

•Please make sure to use paper roll with axis core.

3) Recommended Thermal Paper

Base Paper №Paper

Thickness Manufacturer

TF50KS-E2D*NOTE1 59μm NIHON Paper Co.

PD160R 75μm OJI Paper Co.

*NOTE1: There are conditions to use with Max. 100mm/sec.

Please refer to “5.1 Receipt print surface and paper roll position selection”.

[ CAUTION ]

– Since print quality may decrease depending on temperature and humidity, determine print

density setting upon confirmation of print quality under use environment.

Enables to set by [Print Density Setting] « GS ~ n » command.

– Printing at high print ratio under low temperature or high humidity environment causes the

paper to be tainted or makes dew drops due to vapor occurred from the roll paper. Beware

water not to drop to the thermal head. It may cause galvanic corrosion of thermal head. In case

of dew drop, turn OFF and wait until the condensation disappears.

– Select thermal paper which has a low level of Na+ ion, K+ ion, CI- ion.

When using non-recommend type of paper, it should be well evaluated in reliability.

D-F10087 NP-K2092 Product Specifications Rev.1.00 7

4) Paper Near End Setting

Howtoset;

Position of paper near end sensor is fixed and can not be removed.

Following settings are available by “Memory Switch Setting”. Make sure to confirm axis core

outer diameter of use paper roll.

Axis Core OD Memory Switch Setting NE Detection Value Factory Setting

OD18mm OFF OD22±2.5mm ○

OD22mm MS2-6 ON OD28±2.5mm

[CAUTION]

– Refer to “4.1 Function Setting” for Memory Switch setting method.

– Since NE detection outer diameter value changes depending on paper type and thickness

etc., handle as reference value.

– If you select 22mm outer diameter of Near End detection (MS2-6:OFF) and activate under

any of the following conditions, it alerts Near End at 3-4mm larger diameter than 22mm

prefixed value.

(1) If a smaller roll diameter than approx.28mm is newly loaded.

(2)If power turned off and returned as remaining roll diameter is lower than approx. 28mm.

D-F10087 NP-K2092 Product Specifications Rev.1.00 8

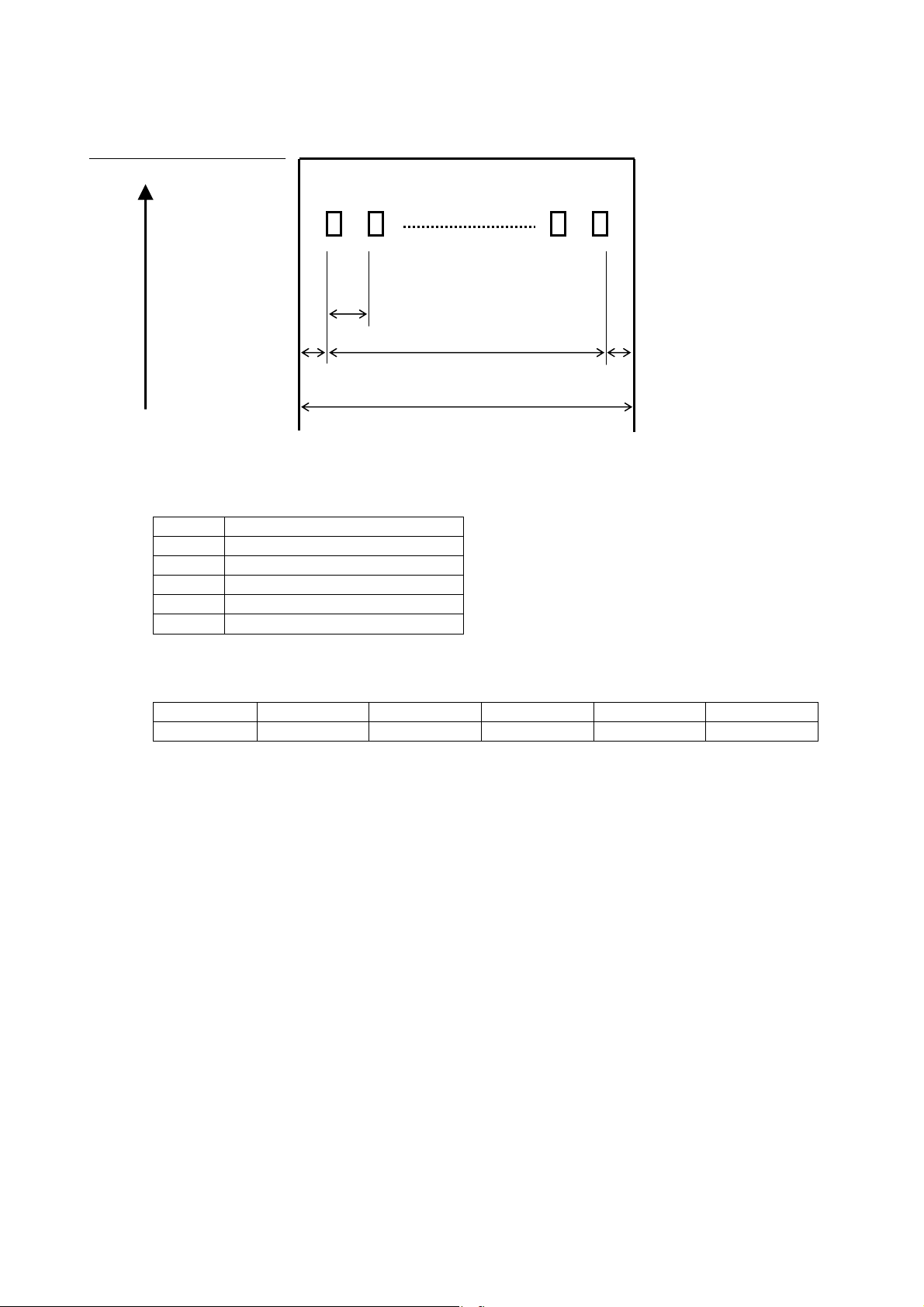

2.3 Print Area

(1) Name of Symbols

Symbol Name

A The number of dots for printing

B Left Margin

C Area of Printing

D Right Margin

E Paper Width

(2) Relations between Paper Width and Printing Area

A(dot) B(±1mm) C(±0.2mm) D(±1mm) E(-1+0mm)

NP-K2092 384 5 48 5 58

Feed direction

View from print face

Adot

1dot 2dot

0.125mm

D

C

B

E

D-F10087 NP-K2092 Product Specifications Rev.1.00 9

2.4 Specifications of Cutter

Cutting Position

Symbol Descriptions Measure

A Tab size on Partial Cutting 1.6±1.0mm

B Position of printer head from cut position 7.5±1mm

C Limit of Backfeed 4.5mm

D Distance from paper edge to center tab on partial cut. 29mm

(1) Cutting Method : Slide System

(2) Cutting Mode : Full Cut / Partial Cut

*Selectable by command.

(3) Allowance of Cutting Frequency : 20 cuts per minute

(4) Paper Thickness : Please refer to “2.2 Paper Specifications”

(5) Minimum cut length : 30mm

[NOTE]

*When platen become overloaded with pulling paper hardly after partial cut etc, beware the

possibility of character crash of the next print line head.

*Feed paper for more than approx. 1mm (8 dot line) when printing after cutting operation.

*Make sure to tear off paper after the partial cut by pinching either right or left side of the printed

paper and pull to the hand held side.

*Since there is automatic paper feed of approx. 2mm for paper jam protection after paper cut, the

above B cutting margin will be 9.5±1mm.

*Please do not conduct operation that paper strip by cut will occur. It causes paper jam.

*We recommend to use partial cut for this product. When full cut, depending on use environment,

cut paper may stick because of static electricity etc., or may jam to ejection outlet etc., please use

upon sufficient confirmation.

A

D

View from print face

C

Backfeed Limit B

Feed Direction

Position of Printing Head

D-F10087 NP-K2092 Product Specifications Rev.1.00 10

2.5 Paper Sensor

Feed Direction

B

A

Sensor

Print Head Position

1) Name of Symbols

Symbol Description

A Distance from printer head to sensor position

B Sensor position

2) Sensor Position

A(±1mm) B(±0.5mm)

NP-K2092 7.5mm 3.0mm

*In order to prevent malfunction of the paper sensor, please do not pre-print to paper feed

direction of sensor position ±5mm width.

D-F10087 NP-K2092 Product Specifications Rev.1.00 11

2.6 Power Specifications

1) Power input connector

2-pin connector CN1

Printer side : S2P-VH (JST) or equivalent.

Host side : VHR-2N (JST) or equivalent.

PIN №Function

1 DC+12V

2 GND

Connector view from interdigitation side

2

1

2) Power Supply Voltage: DC12V±5%

3) Consumption Current

Condition Consumption Current (reference)

Standby Approx. 80mA (typ)

When printing (64 dot) MAX.approx.3.6A

[NOTE]

*Since the printer may reach to degradation and breakage at once when power voltage exceeds

absolute maximum rating even for a moment, do not exceed absolute maximum rating under

anytime of conditions.

* The current may be big at the peak time, depending on the power voltage and printing contents,

power supply with enough capacity is required to secure a good print quality.

Also, make sure to connect all of the wiring for power supply relations. Please pay an enough

attention to allowable current of wiring material.

*Although current capacity of thermal head itself is [4.0A], current capacity of connector cable is

not included to this, determine number of dots when current applying at the same time not to

exceed the current capacity.

*If power supply cable is excessively long, the operation may become unstable. Cable should be

made as short as possible. If not possible, connect cables near the printer and place an

electrolytic capacitor of rated voltage 25v, electrostatic capacity of 2200μF between power

supply and GND.

*Please set element for excessive current protection and appropriate fuse to the power line.

*We recommend to use power supply complied with LPS standard.

D-F10087 NP-K2092 Product Specifications Rev.1.00 12

2.7 Reliability Specifications

1)Lifetime

(1) Thermal Head

Anti-pulse Characteristics : 100 million pulse

Anti-abrasion characteristic : 50km

(2) Cutter Life : 0.5 million cut

(3)LifeDefinition

• Entering point of abrasion failure period.

• Condition to satisfy life is as follows;

Average Print Ratio : 12.5%

Medium (paper) : Refer to “2.2 Paper Specifications”

Print Density : 100%

PartialDrive :Optimization

[NOTE]

*In case of using paper other than recommended paper, since life time will differ depending

on paper quality, width and thickness, confirm with paper in actual use at the user’s side.

D-F10087 NP-K2092 Product Specifications Rev.1.00 13

2.8 Environment Specifications

1) Operating Environment

Temperature: 0~ 50 ºC (print warranty is 5 ~ 40 ºC)

Humidity : 35~85%RH

Except, 85%RH assumes 35ºC for no condensation

*Warrant scope of Print Quality (P/Q) & Print Operable (P/O) range

35°C 85%RH

60

2) Storage Environment (except for papers)

Temperature: - 20 ~ 70ºC

Humidity : 10 ~ 90%RH

Except, no condensation.

High temp and humidity: 40ºC90%RH (no condensation) shall be the worst value.

2.9 Regulations

VCCI : Class A (Acquired)

FCC : Class A (Acquired)

CE marking: Acquired

P/Q temp. & humidity range

40

P/O temp. & humidity range

30

40°C 65%RH

0 50°C

20

5°C 85%RH

90%RH

80

85

50

70

65

40

35

-10 5 10 30 35

Table of contents

Other Nippon Primex Printer manuals