Nippon Vpro NS User manual

OSCNS209-EN

1/7

Instruction manual

Electric

Actuated

Needle

Valve

NS

N

H

N

P

SP-1401

Please read this manual before installation and use.

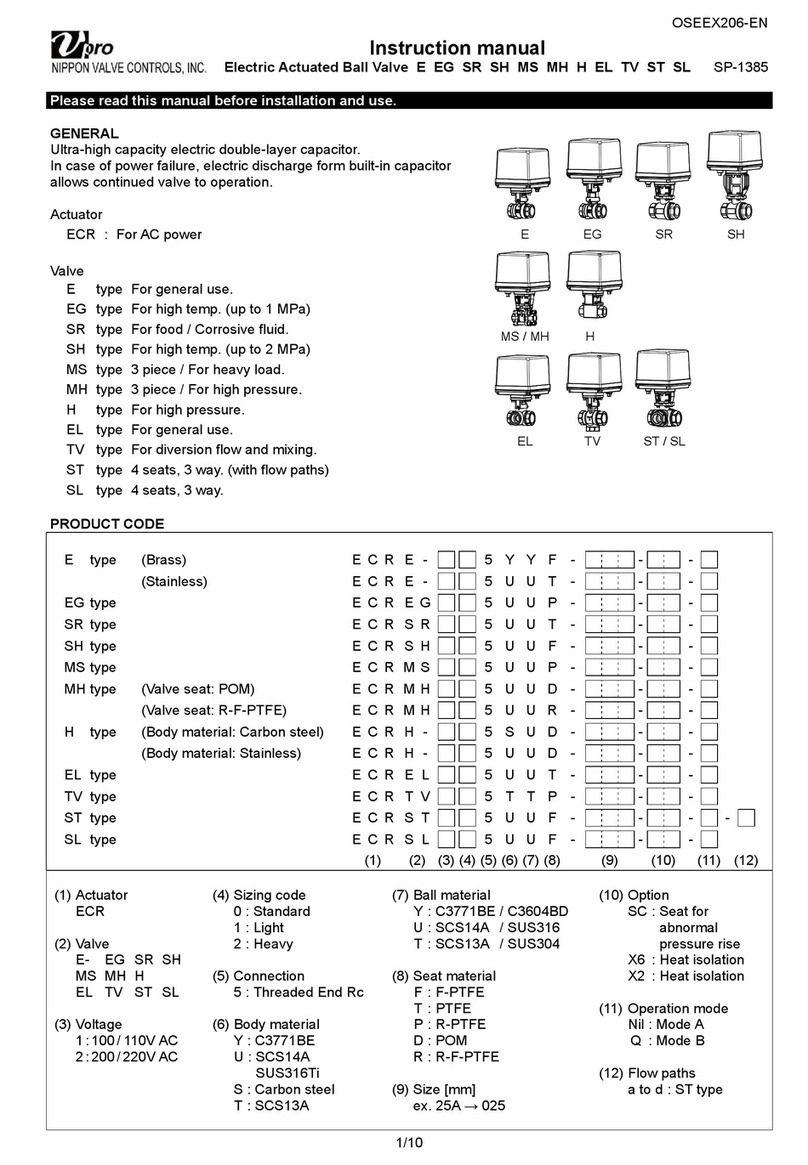

GENERAL

Compact and lightweight electric actuated needle valve. (linear)

LAX type actuator has a high quality positioner.

Valve

NS type For general use

NH type 3 piece / For high pressure and high temp.

NP type For Corrosive fluid

NS NH

NP

PRODUCT CODE

NS type (Linear) L A X N S 0 5 U U F 0 - -

(EQ%) L A X N S 0 5 U U F X E 1 5 - -

NH type L A X N H 0 5 U U T 0 - -

NP type L A X N P 0 1 K K T 0 1 5 - -

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) (12) (13)

(1) Actuator

LAX

(2)

Valve

NS

NH

NP

(3)

Voltage

1 : 100 / 110 V AC

2 : 200 / 220 V AC

(4) Sizing code

0 : Standard

1 : Light

2 : Heavy

(5) Connection

5 : Threaded End Rc

1 : JIS 10K

(6) Body material

U : SCS14A / SUS316

K : PEEK

(7) Trim material

U : SUS316

K : PEEK

(8) Stem packing material

F : F-PTFE

T : PTFE

(9) Cv value

S : 0.05

M : 0.13

L : 0.34

H : 0.8 (NP: 1.4)

X : 2 (NP: 0.8)

(10) Flow characteristics

0 : Linear

E : EQ%

(11) Size [mm]

ex. 15 A 15

(12) Option

(13) Operation mode

Nil : Mode A

J : Mode B

OSCNS209-EN

2/7

VALVES SPECIFICATIONS

Water Oil Air, Gas Steam Chemicals Sea water Slurry Negative pressure

NS NH NP type

Valve type NS NH NP

Design 2-way 2-way 2-way, Wafer

Connection Threaded End Rc Threaded End Rc JIS10K Flanged-end

Fluid

Max pressure 4 MPa 14 MPa 1 MPa

Size [mm] 10 to 15 10 to 15 15

Material Body SCS14A SUS316 PEEK

Trim SUS316 SUS316 + HCr PLTD PEEK

Seat F-PTFE SUS316 None

Stem seal Packing F-PTFE PTFE PTFE

Allowable Leak Rate Bubble-tight

Class VI (ANSI B16.104)

Less than 0.01 % of rated Cv.

(ANSI Class IV)

Less than 0.01 % of rated Cv.

(ANSI Class IV)

PRESSURE & TEMPERATURE RATING

NS NH NP

INHERENT FLOW CHARACTERISTIC

Linear EQ%

Cv value (%)

Valve opening (%)

Cv value (%)

Valve opening (%)

Range ability 30:1 Range ability 30:1

OSCNS209-EN

3/7

ELECTRIC ACTUATOR SPECIFICATIONS

LAX type

Actuator type ( :Voltage code) LAX-030- LAX-070-

Voltage 100 / 110 V AC ±10 % 50/60 Hz (Code: 1)

200 / 220 V AC ±10 % 50/60 Hz (Code: 2)

Thrust [N] 300 700

Operation time [mm/s] 0.39 / 0.47 (50/60 Hz) 0.46 / 0.55 (50/60 Hz)

Stroke [mm] 7.5 7 to 11.5

Adjustment range Fixed Adjust by OPEN / SHUT trimmers

Power consumption [VA] 4.5 11

Motor Synchronous motor (Triac control)

Overload protection Timer

Method of operation Proportional control (linear motion)

Input signal 4 to 20 mA (Input resistance: 220 ) 4 to 20 mA (Input resistance: 250 )

Operation [Mode A] SHUT by decreased signal OPEN by increased signal (Standard)

[Mode B] SHUT by increased signal OPEN by decreased signal (Option: J)

Impossible to change the mode. Please appoint it at the time of the order.

Indication signal 0 mA : SHUT 1 mA : OPEN (External load resistance: less than 3 k)

Common in mode A / B

Resolution Less than 0.2 %

Duty cycle 100 / 200 V AC : 100 %

110 / 220 V AC : 50 % 30 min.

Ambient temperature -10 to 50 ºC

Space heater Built in to the control board

Manual operation Manual shaft

Enclosure Equivalent to IP65 (IEC 60529)

Housing material Aluminum alloy diecast (acrylic resin baking finish)

Terminal block For bare wire 0.2 to 1.5 mm² (AWG 26 to 16) Ground terminal: M3

Conduct port G3/8 Cable gland (for 5 to 10.5 mm cable)

WIRING

Note) • Input signal circuit is non-isolated. Do not connect DC (-) wire to other DC (-) common.

• Do not adjust operating angle of a valve (OPEN/SHUT trimmer).

Please contact us if you need to adjust operating angle.

LAX-070only

Voltage

100/110V AC

200/220V AC

Input signal

4 to 20mA

Indication signal

0 to 1mA

Ground terminal(M3)

Trimmers

Operation

range

Potentiometer

Indication

signal

Dead band

OSCNS209-EN

4/7

ELECTRIC ACTUATOR SPECIFICATIONS

DIMENSION

LAX-030 LAX-070

Parts name

1 Body 4 Control board 7 Drive shaft

2 Motor cover 5 Terminal block 8 Manual shaft

3 Motor 6 Potentiometer 9 Rubber packing

ADJUSTMENT

LAX-030

Adjust ZERO / SPAN trimmer

The trimmer is already setting when the shipped.

Adjust SHUT trimmer

Please contact us if you need to adjust trimmer.

Terminal board : Mode A

LAX-070

Adjustment of dead band

Adjustment of dead band is useful to prevent hunting of the

actuator. Turning D.B. trimmer clockwise increases the dead

band range.

Adjust ZERO / SPAN trimmer

The trimmer is already setting when the shipped.

Adjust OPEN / SHUT trimmer

The trimmer is already setting when the shipped.

Terminal board : Mode A

8

9

7

8

9

7

SHUT O-

ZERO

SPAN

:

O+

I+

I-

T2

T1

Terminal board

Connector

LAX-030

:

SHUT OPEN

D.B. O-

ZERO SPAN

A B

O+

I+

I-

T2

T1

Terminal board

Connector

LAX-070

OSCNS209-EN

5/7

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

HANDLING & STORAGE

HANDLING

Proper care in handling the valve should be taken to

prevent damage. Do not drop or throw it.

STORAGE

Store the valve in the protected area from dust,

moisture, and direct sunlight. If possible, valve should

be kept in the original packaging.

CHECKING

• Check the product code, power supply, and voltage

before installation.

• Make sure that the bolts are not loose.

INSTALLATION

PRECAUTIONS

Flush the pipeline carefully before installing the valve.

Foreign particles, such as sand or pieces of welding

electrode, will damage the trim and seats.

INSTALLATION NOTES

• This type valve has a flow direction. Install the valve

accordingly.

• NS / NH / NP type has a flow direction. Install the

valve accordingly.

• When the Cv value is small, the foreign object

contained in the fluid causes blockage. The filter is

used in front of the valve.

Threaded End Rc (NS / NH type)

• If seal tape or sealant protrudes into the valve,

malfunction may result.

Pay attention to tape treatment and coating amount.

Flanged-end (NP type)

• Use only rubber gasket for plastic flange.

• Use spring washer to prevent from decreasing

surface pressure gasket when the temperature

change happens frequently.

• Tighten all bolts using crossover method to load the

joint evenly.

• Wafer type needle valve is put between two seats of

flanged-end and tightened with long bolts.

SUPPORT

Use proper support to prevent distortion of the valve.

ENVIRONMENT

• Do not install in place where corrosive gas is present

or where vibration is heavy (0.5 G or more).

• When radiant heat causes the surface temperature of

the control unit to exceed 50 °C, provide an

appropriate shielding plate.

• If there is a possibility that the fluid and drive part

freeze, please take measures to prevent freezing.

POSITIONING

• Should be positioned through 90° upward from

horizontal. Provide space around the product to allow

manual operation, inspection and replacement work.

• Maintenance space more than 90 mm upward from

the actuator is required.

OTHER NOTES

Until the wiring is completed there must be no

condensation or flooding in the interior of the actuator,

after piping. Protective caps on the cable gland are

not waterproof.

WIRING

• Do not wiring outdoors on a rainy day.

• Check the power supply and voltage.

Connect the signal as shown in the wiring diagram.

Do not connect unnecessarily terminal.

• Use suitable flexible cable (5 to 10.5 mm).

Lock and seal the cable completely to prevent

condensation inside the actuator.

• Built-in terminal block can clamp up to 1.5 mm in

diameter without using solderless terminal.

• Allow proper cable slack for maintenance.

• Actuator should be electrically grounded.

Use the terminal marked ( ) inside the actuator.

PREVENT DEW CONDENSATION

• When installing the cover after wiring, perform the bolt

by the temporary tightening procedure and the

permanent tightening procedure to tightly and

securely tighten the rubber packing so that water does

not enter from the outside.

• Tighten the cable gland nut so that there is no leakage

from the wire entrance.

OSCNS209-EN

6/7

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

CONTROL

• Set to stabilize the MV value the PID constant of the

adjustment meter.

• The life of the actuator and the valve becomes short if

the movement of MV value is used on unstable

condition.

• Use shielded wire for signal wiring where high level

noise is generated or when the wiring distance is long.

• When wiring, if wiring of a signal is mistaken, it will not

operate correctly. Contact us when you use two valve

or more by one controller or indicator.

• Input signal circuit is non-isolated.

Do not connect DC (-) wire to other DC (-) common.

• The input signal and operation mode are set as

follows. (Factory shipped)

Input signal 4 to 20 mA

Operation mode Mode A

Operation SHUT by decreased signal

OPEN by increased signal

OPERATION

TESTING

• Make sure that power supply voltage is correct. Also

check operating position, wiring, speed and signals.

• During trial operation, check that valve movement and

output signal are correct.

ATTENTION

• Keep power supplied for built-in space heater to

prevent condensation inside actuator.

• Do not touch the moving parts of actuator in

operation.

• Never put anything on the actuator or make it into a

foothold.

ADJUSTABLE RANGE OF STROKE

LAX-030

• SHUT by an input signal 4 mA and shipped.

• It is not necessary to adjust the stroke.

LAX-070

• SHUT by an input signal 4 mA and shipped.

• Can be adjusted in the range of 7 to 11.5 mm.

(default stroke: 11.5 mm)

MANUAL OPERATION

PRECAUTIONS

• Manual operation should be a temporary operation.

• Be sure to turn off the power before manual operation.

NOTE

• See indicator during operation and check OPEN /

CLOSE position to prevent overturn.

• For manual operation, do not give more than the rated

torque and make at a slow rate. Actuator might be

damaged if excessive force is added.

Manual operation is to put a wrench

(width: 13 mm)

,

turn manual shaft slowly.

MAINTENANCE

• To prevent electric shock, be sure to turn off the power

when removing the actuator cover.

• Perform the first time in the state of the first stage

included in real operation.

• Do the routine maintenance at least once in half a

year.

Inspection items

• Confirm operation of opening and closing.

• Confirm that an actuator is not hot excessively.

• Confirm existence of abnormal noise and

vibration during operation.

• Confirm whether screws are loose or not.

• Confirm that water or condensation no remains

in the actuator.

• Confirm that operate the hunting or move

continuously at high frequency.

OPEN

CLOSE

OSCNS209-EN

Document is subject to change without notice.

NIPPON VALVE CONTROLS, INC.

1-21-19 Meieki minami, Nakamura-ku, Nagoya 450-0003 JAPAN

TEL: 81-52-582-6435 FAX: 81-52-582-6439

7/7

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

TROUBLE SHOOTING

Problem Cause Solution

Actuator

does not

move.

Faulty wiring. Correct the wiring.

Voltage and

input signal are

not coming.

Check the voltage and

input signal.

Incorrect

voltage.

When it's burned out by

excess voltage, replace

the actuator.

Connection or

wiring is not

correct.

Correct the miswiring

and misconnection.

Be careful not to

mistake the plus and

minus of wiring.

Short the circuit,

contact failure.

Review wires and

connection.

Motor is too old. Replace the actuator.

Operation

is unstable.

Excess surge or

voltage was

applied.

Replace the actuator.

Rainwater

entered the

actuator.

Added high

harmonics noise

from an inverter.

Attachment a filter for

each inverter maker

option.

Effect of high

level noise.

Use the shielded wire

and ground the wiring.

Separate signal wire

from power line.

Problem Cause Solution

Stop in the

mid position.

• Biting of

valve seat.

• The scale

has adhered

to the valve

trim.

Remove a foreign

object.

Clean or replace valve

parts.

(NH)

Overload

protector runs

because of

over-torque.

Motor protection circuit

returns by the signal of

operation of an

opposite direction. Turn

on the power again.

Leakage

from

valve body

• Valve cap

get loose.

• Valve body is

damaged.

Replace the valve.

(NS NP)

Leakage

from

valve seat

Seat is worn

or damaged.

Replace the valve.

Replace the actuator.

Loose

seal-spring,

damage.

Replace seal-spring.

Leakage

from

valve trim

Packing is

worn or

distorted.

Replace the valve.

Tighten the gland nut.

(NH)

For more information contact

NIPPON VALVE CONTROLS, INC. for consultation.

This manual suits for next models

2

Table of contents

Other Nippon Control Unit manuals

Popular Control Unit manuals by other brands

Telit Wireless Solutions

Telit Wireless Solutions M.2 N930 Series Hardware user's guide

Texas Instruments

Texas Instruments TPS92410EVM-001 user guide

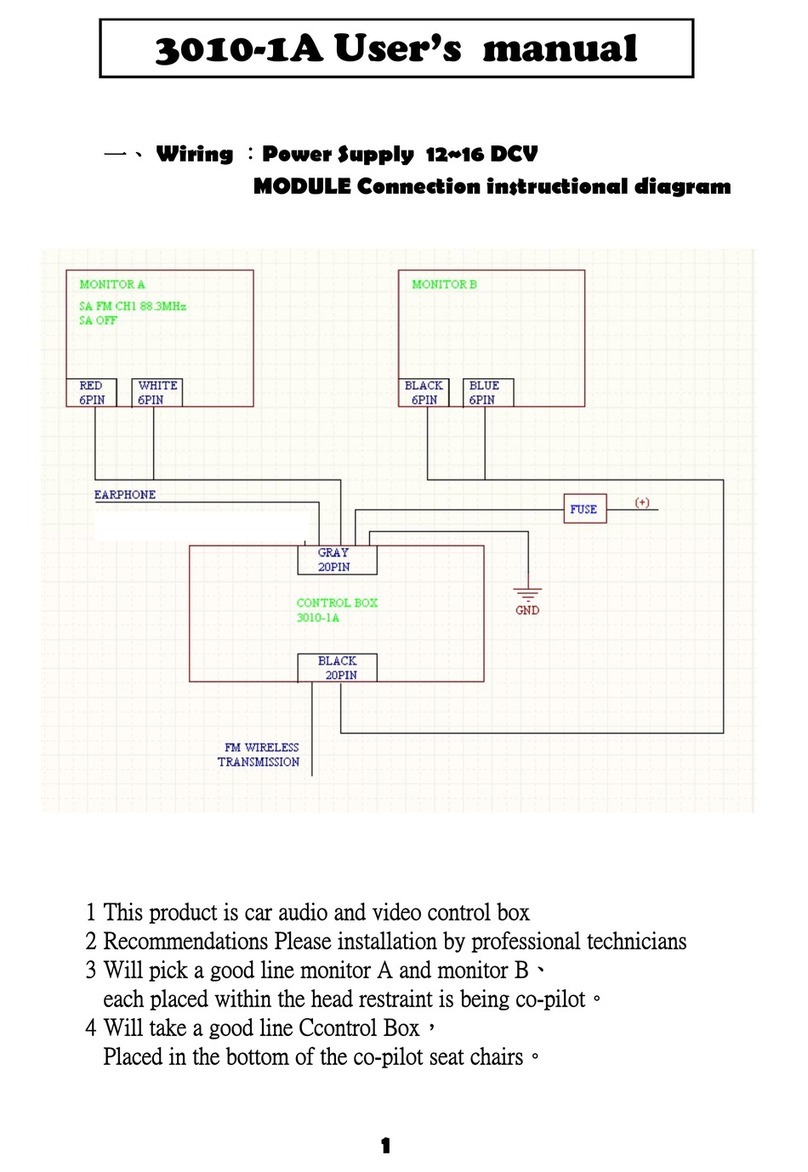

Giant Alarm System

Giant Alarm System 3010-1A user manual

Siemens

Siemens SIMOTION D4x5-2 Commissioning and hardware installation manual

Lenze

Lenze EPM-H315 operating instructions

Amphenol

Amphenol SGX SNSORTECH PS1-O3-5-MOD Data Sheet / Manual