Nippon RA-4300FG+ User manual

RA-4300FG+

Service Manual

Document

Number NIC-704-2033-01

Date of

Issue 2020/2/26

Control

Department

Technical Service

Group Page 1/48

RA-4300FG+

Service Manual

Nippon Instruments Corporation

Technical Service Group

Date Prepared Checked Approved

First

Edition

2020/2/26 Kinoshita - Noda

NIC-704-2023-01

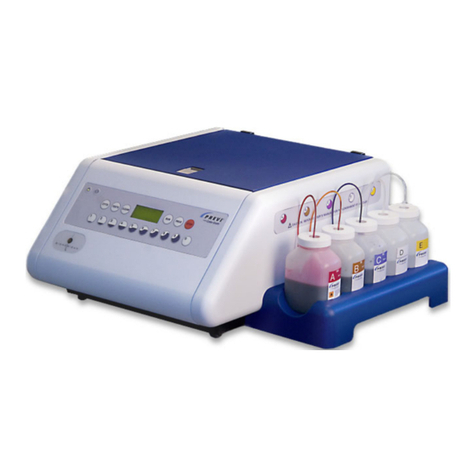

Reducing-Vaporization Mercury Analyzer

Mercury/RA-4300FG+ Service Manual

Table of Contents

INTRODUCTION ................................................................................................................ 1

SAFETY PRECAUTIONS ............................................................................................... 1

Meaning and explanation of symbols............................................................... 1

Precautions for work......................................................................................... 1

TARGET USERS.......................................................................................................... 1

UPDATING THE FIRMWARE ............................................................................................ 2

METHOD OF UPDATING THE FIRMWARE........................................................................ 2

Loading the file ................................................................................................. 3

Writing............................................................................................................... 4

Enabling the change......................................................................................... 5

IF THE FIRMWARE UPDATE FAILS.................................................................................. 6

REPLACING PARTS.......................................................................................................... 7

REPLACING THE MAIN BOARD...................................................................................... 7

REPLACING THE REAGENT PUMP................................................................................. 8

REPLACING THE MEASURING CAP AND BUBBLER .........................................................11

REPLACING THE REACTION TUBE .............................................................................. 13

REPLACING THE REAGENT TUBE ............................................................................... 16

REPLACING THE LAMP .............................................................................................. 19

REPLACING THE MERCURY COLLECTOR TUBE ............................................................ 23

REPLACING THE HEATER AND THERMOCOUPLE FOR COLLECTOR TUBE........................ 24

REPLACING THE ZERO-GAS FILTERS.......................................................................... 26

REPLACING THE NAFION TUBE.................................................................................. 27

REPLACING THE NEEDLE VALVE................................................................................. 27

REPLACING THE V1 VALVE........................................................................................ 28

REPLACING THE FLOW RATE SENSOR........................................................................ 29

REPLACING THE MASS FLOW CONTROLLER................................................................ 30

Table of Contents

NIC-704-2023-01

REPLACING THE DISPENSER ARM ASSEMBLY.............................................................. 31

REPLACING THE ACTIVE CARBON FILTER FOR THE COVER........................................... 36

ADJUSTMENTS............................................................................................................... 38

CLEANING THE CELL................................................................................................. 38

ADJUSTING THE OFFSET OF THE DISPENSER ARM AND TURNTABLE ............................. 40

ADJUSTING THE BELT OF THE TURNTABLE.................................................................. 41

MAINTENANCE ............................................................................................................... 43

DAILY INSPECTION............................................................................................................... 43

CORRECTIVE MEASURES............................................................................................. 44

ABNORMAL BLANK VALUE.......................................................................................... 44

WASHING METHOD................................................................................................... 45

Washing the reagent tube .............................................................................. 45

Washing the cap and bubbler......................................................................... 45

POOR SENSITIVITY ................................................................................................... 45

Recovering from poor sensitivity.................................................................... 46

Checking for and recovering from leakage .................................................... 46

OTHER TOPICS............................................................................................................... 47

PROVIDING THE PROTECTION FOR RELOCATION OR TRANSPORTATION........................ 47

PRECAUTIONS FOR DISPOSING OF THE ANALYZER...................................................... 47

CONTACT......................................................................................................................... 48

Introduction

1

NIC-704-2023-01

Introduction

Safety precautions

Meaning and explanation of symbols

Indicates that incorrect handling could result in the death or severe

injury to the operator.

Indicates that incorrect handling could result in

minor injury or

moderate injury to the operator or damage to property.

Precautions for work

• When removing the cover of the analyzer, be sure to cut off the power supply in

advance. Otherwise, an electric shock or machine damage may occur.

• Before updating the firmware, confirm that the version of the software on the PC is

compatible with the firmware.

• Remove any chemicals (e.g. in sample bottles and regent bottles) from the turntable

of the analyzer because they may accidentally spill during work.

Target users

Only qualified users, who have completed the service work training program in Nippon

Instruments Corporation, are allowed to conduct the work described in this work manual.

Observe the safety precautions to conduct work.

Warning

Caution

Warning

Caution

Service Manual

2

Updating the firmware

•Before updating the firmware, confirm that the version of the software on the PC is

compatible with the firmware.

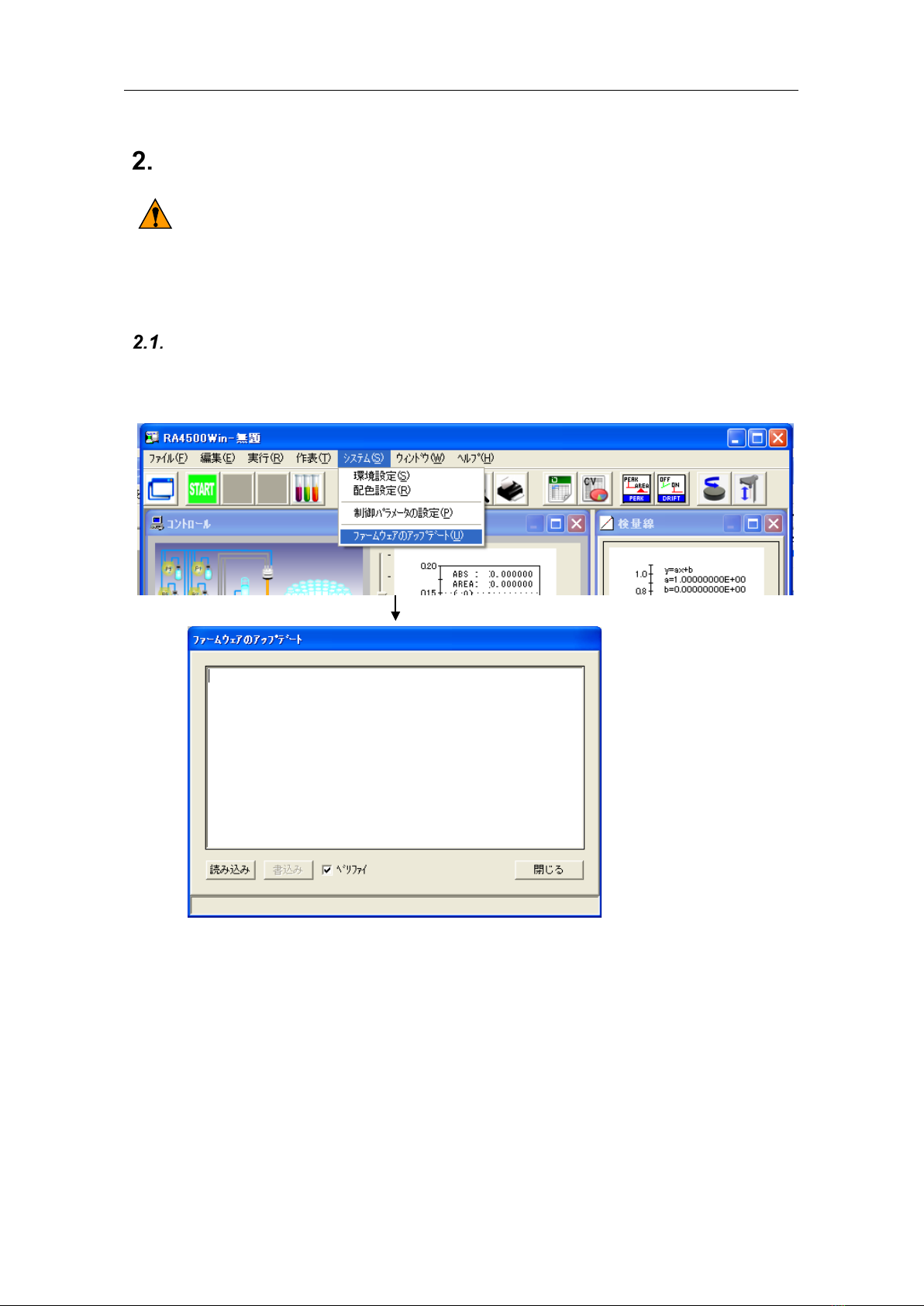

Method of updating the firmware

Because the firmware update function is built into both RA4Win and the firmware, you can

easily update the firmware. From the System menu bar of RA-4win, click [Update firmware].

The above window appears. You can update the firmware in this window.

The following is the flow of the updating procedure:

Load the firmware file into the PC.

Write the loaded data into the flash memory of the RA4’s main board.

Turn off the power of the main unit and then turn it on again to enable the change.

Warning

Service Manual

3

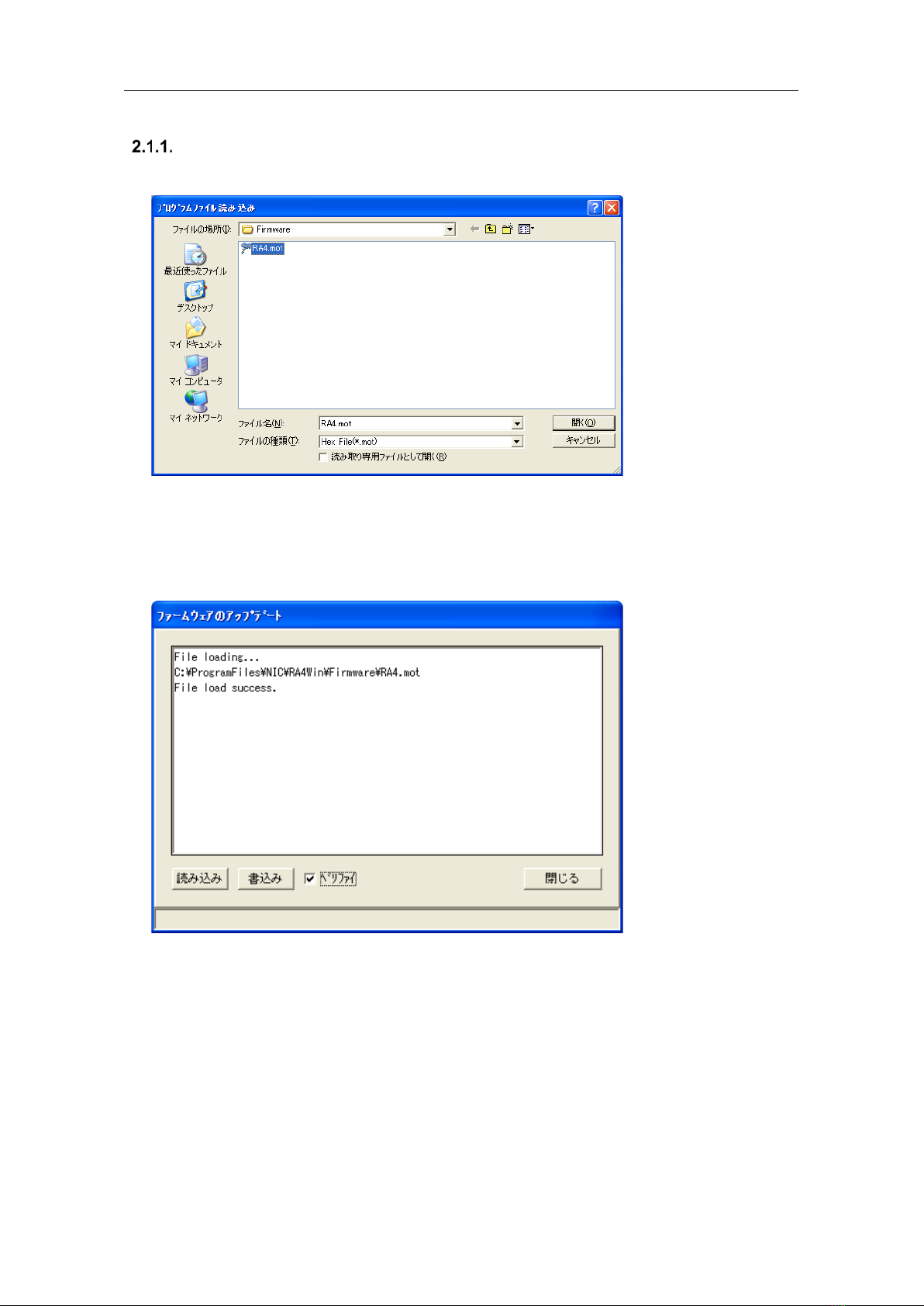

Loading the file

Click [Load] button to load the firmware file. The file name is normally “RA4.mot.”

When the loading is successfully completed, the message “File load success” appears as

shown below, and [Write] button becomes clickable. If there is something wrong with the

loaded file, the message “File loading fail” appears, and [Write] button stays grayed out.

Service Manual

4

Writing

Click [Write] button to write the loaded data into the flash memory of the RA4’s main unit.

The sequence of the writing process is erasing, programming (writing), and verifying.

* Do not turn off the power during the writing process, otherwise you will not be able

to rewrite the firmware.

You can skip the verification step by deselecting [Verify] checkbox even during the process.

[Writing window]

[Verifying window]

Service Manual

5

Enabling the change

When the writing is complete, the following window appears. Click [OK] to exit the program.

Turn off the power of the RA4’s main unit, and then turn it on again.

The update is enabled after rebooting.

Service Manual

6

If the firmware update fails

If you turn off the power during the update of the firmware, the program cannot be written

normally. In such a case, you cannot even start up the system by turning on the power

again. Because the system cannot start up, you cannot rewrite the program through the

normal method.

If you are in this situation, you need to write the firmware by starting up the system in boot

mode, a mode dedicated to updating the firmware.

Turn off the power, open the rear cover of the main unit, and set SW1 on the CPU board

to the positions of boot mode.

Confirm that the PC and the RA4’s main unit are connected via ethernet cables. Then

turn on the power.

Start RA4Win.

Write the firmware using the procedure in 2.1. Method of updating the firmware.

When the writing is complete, turn off the power, set SW1 on the CPU board back to

the positions of normal mode, and then turn it on again. The procedure is now

complete.

Boot mode

Boot mode

Normal mode

Normal mode

Service Manual

7

Replacing parts

• When removing the cover of the analyzer, be sure to cut off the power supply in

advance. Otherwise, an electric shock or machine damage may occur.

• Remove any chemicals (e.g. in sample bottles and regent bottles) from the turntable

of the analyzer because they may accidentally spill during work.

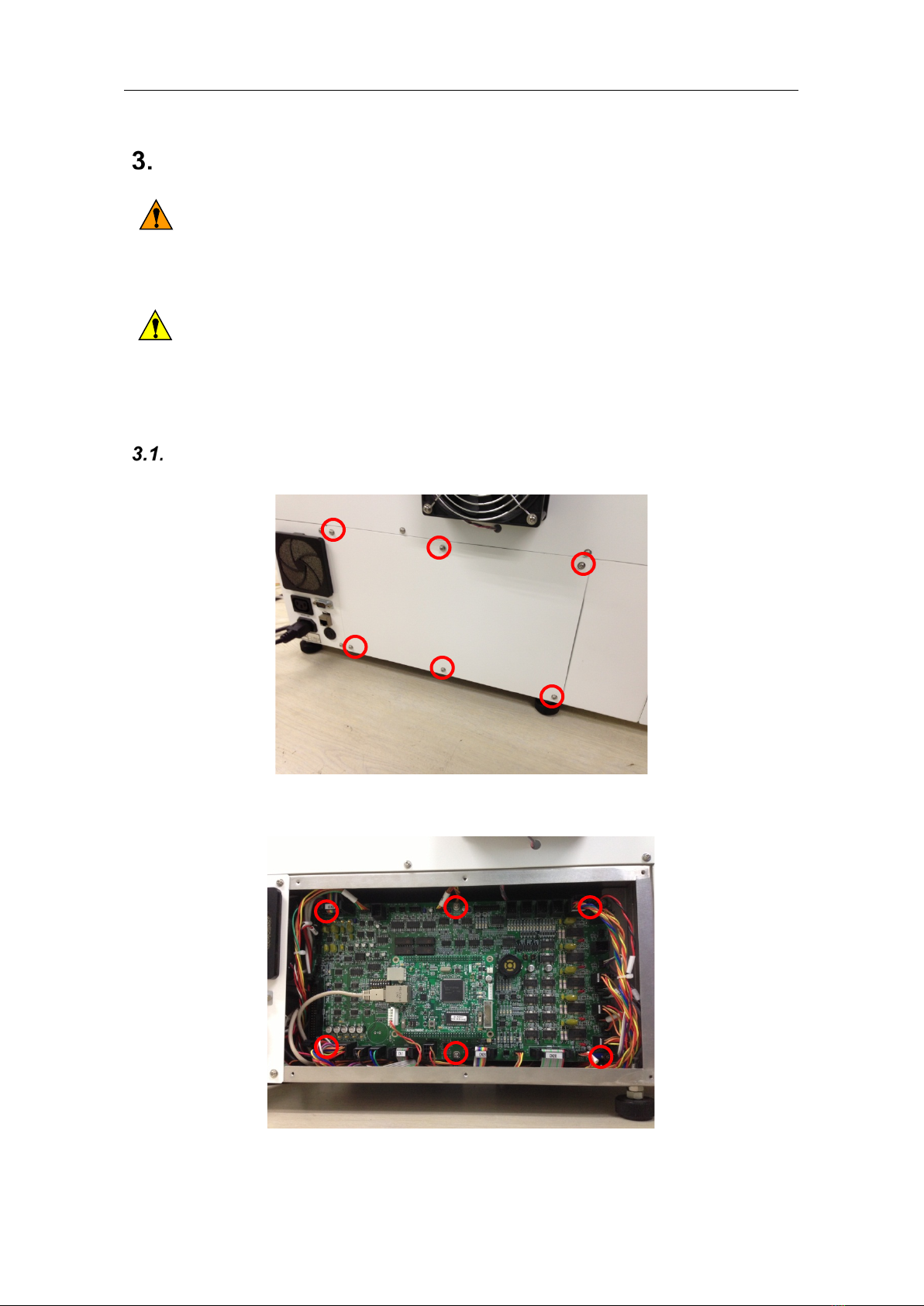

Replacing the main board

Remove the six screws from the rear side of the analyzer.

Disconnect the connectors from the main board, and remove the six screws.

Install a new main board by reversing the disassembling procedure.

Warning

Caution

Service Manual

8

Replacing the reagent pump

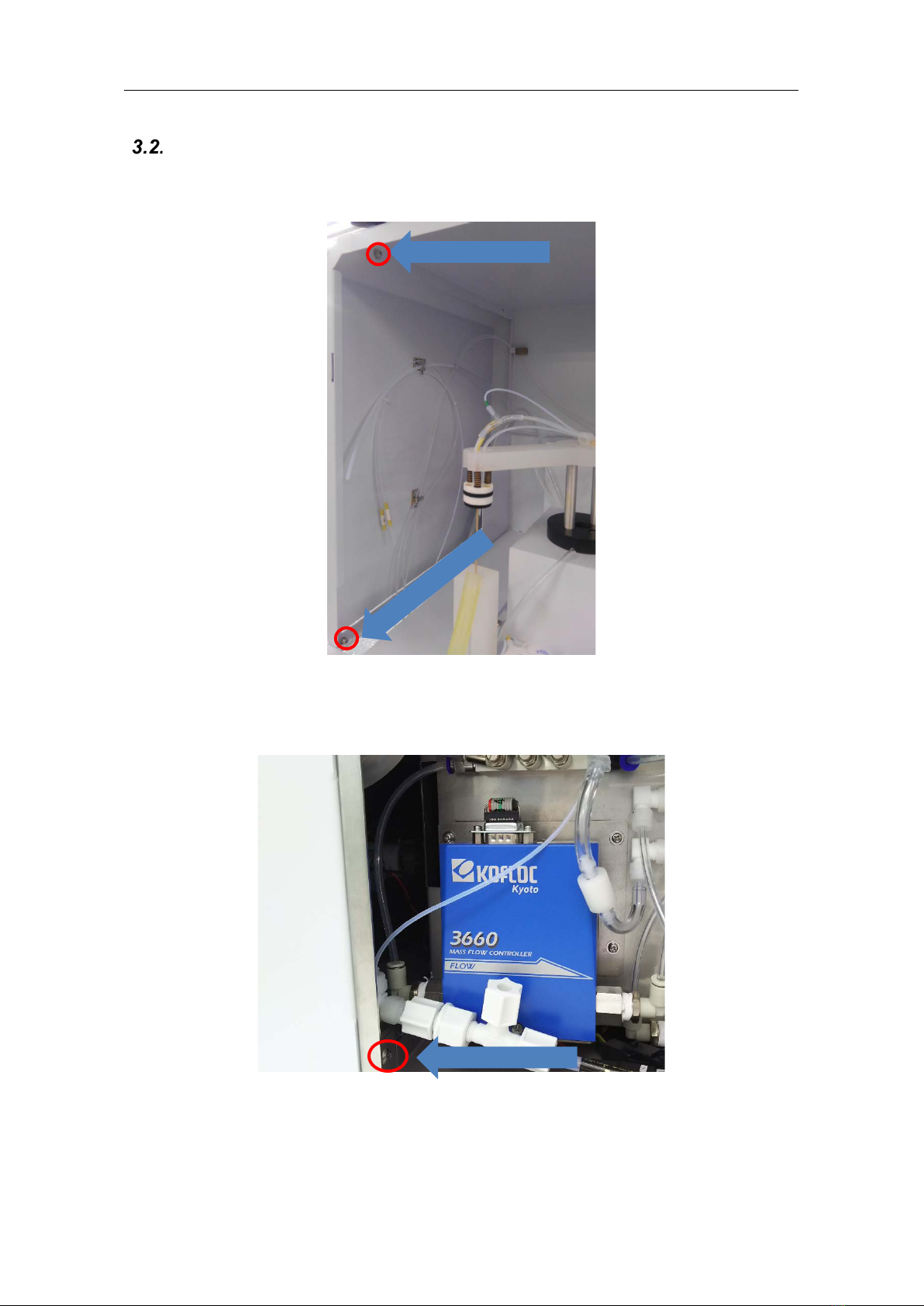

Remove the two screws from the side plate so that you can remove the pump mounting

base.

Remove the screw from the pump mounting base.

Service Manual

9

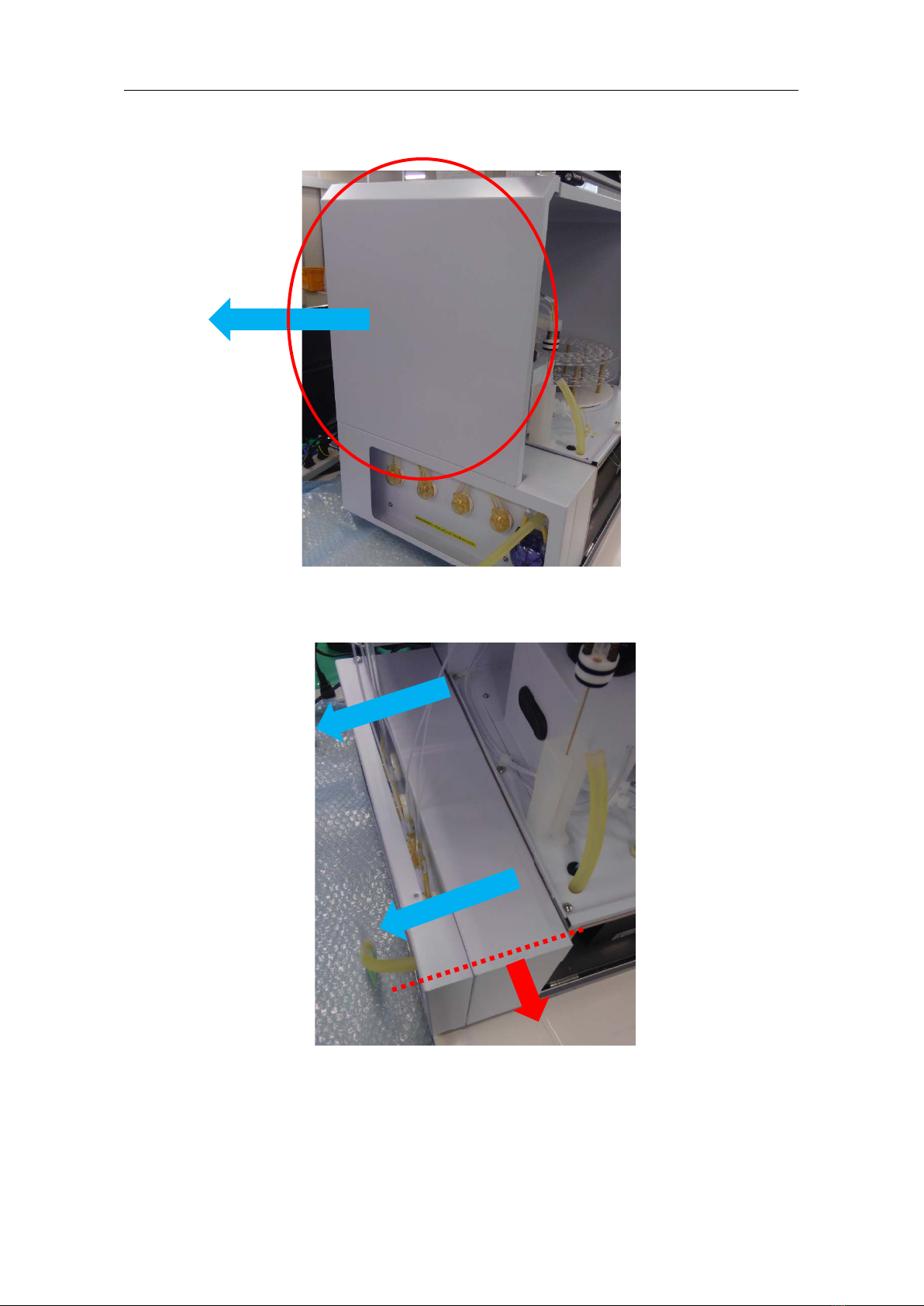

Slide the left-side plate toward the back and remove the plate.

Slide the pump mounting base toward you, and then move it to the left and detach the

base.

Service Manual

10

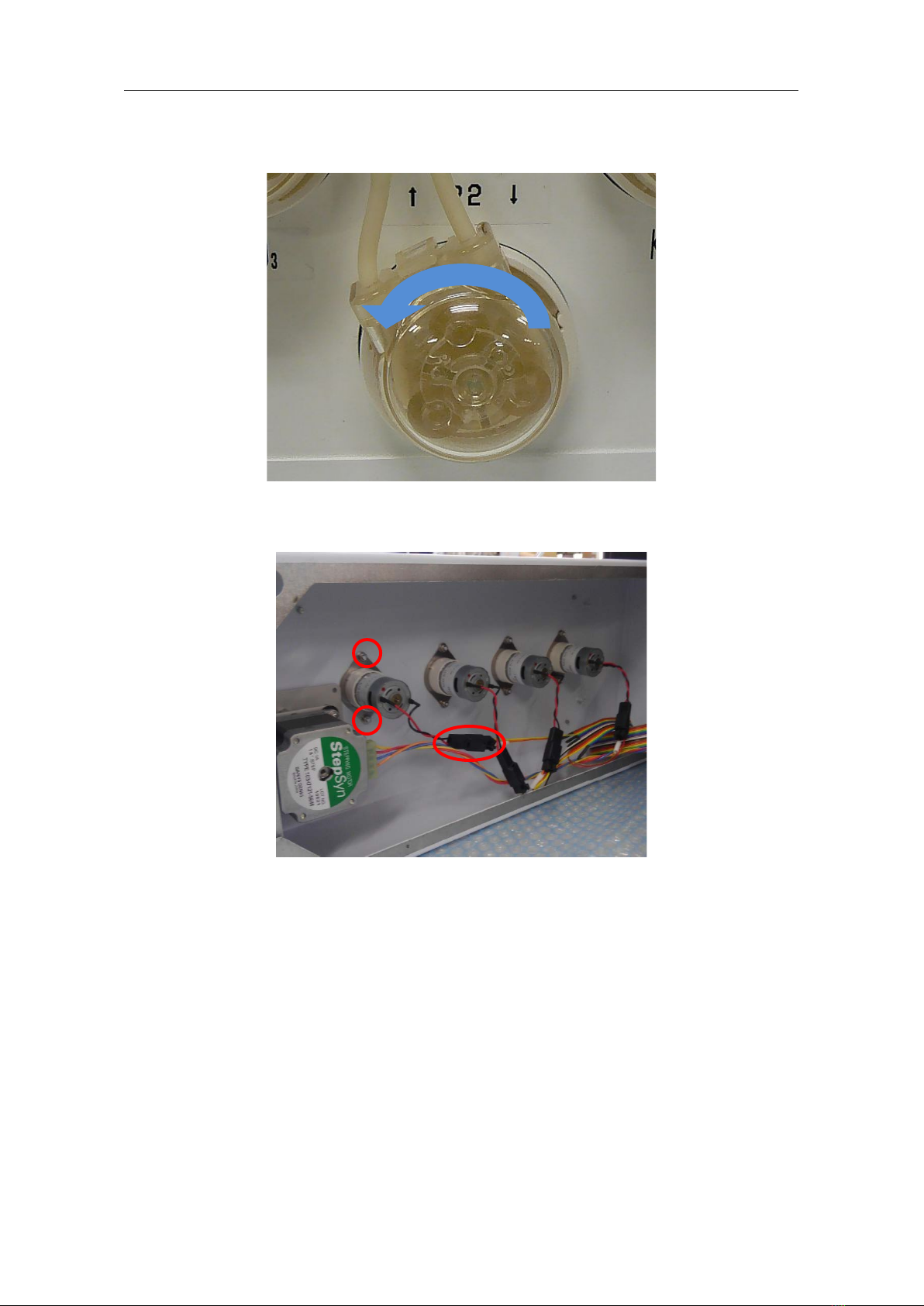

Turn thehead of the reagent pump to be replaced counterclockwise,and detach the head.

From the inside of the pump mounting base, remove the nuts holding the pump, and

disconnect its connector. Then replace the pump.

After installing a new reagent pump, reassemble the parts using the reverse procedure.

Service Manual

11

Replacing the measuring cap and bubbler

OntheMaintenancescreenofthemeasuringsoftware,movethemeasuringcapposition,

and then turn off the power of the analyzer. * Set the ARM to [2: B STAGE], and then set

the LIFT to [6: MEASURE].

Unscrew the three screws holding the cap, and then remove the cap.

Detach the reagent tube, reaction tube, and bubbler from the removed cap.

Assemble the cap.

* Pass the bubbler through the cap rubber in advance.

* Do not tighten the screws too much. If the rubber is crushed, the insertion of a tube will

become difficult.

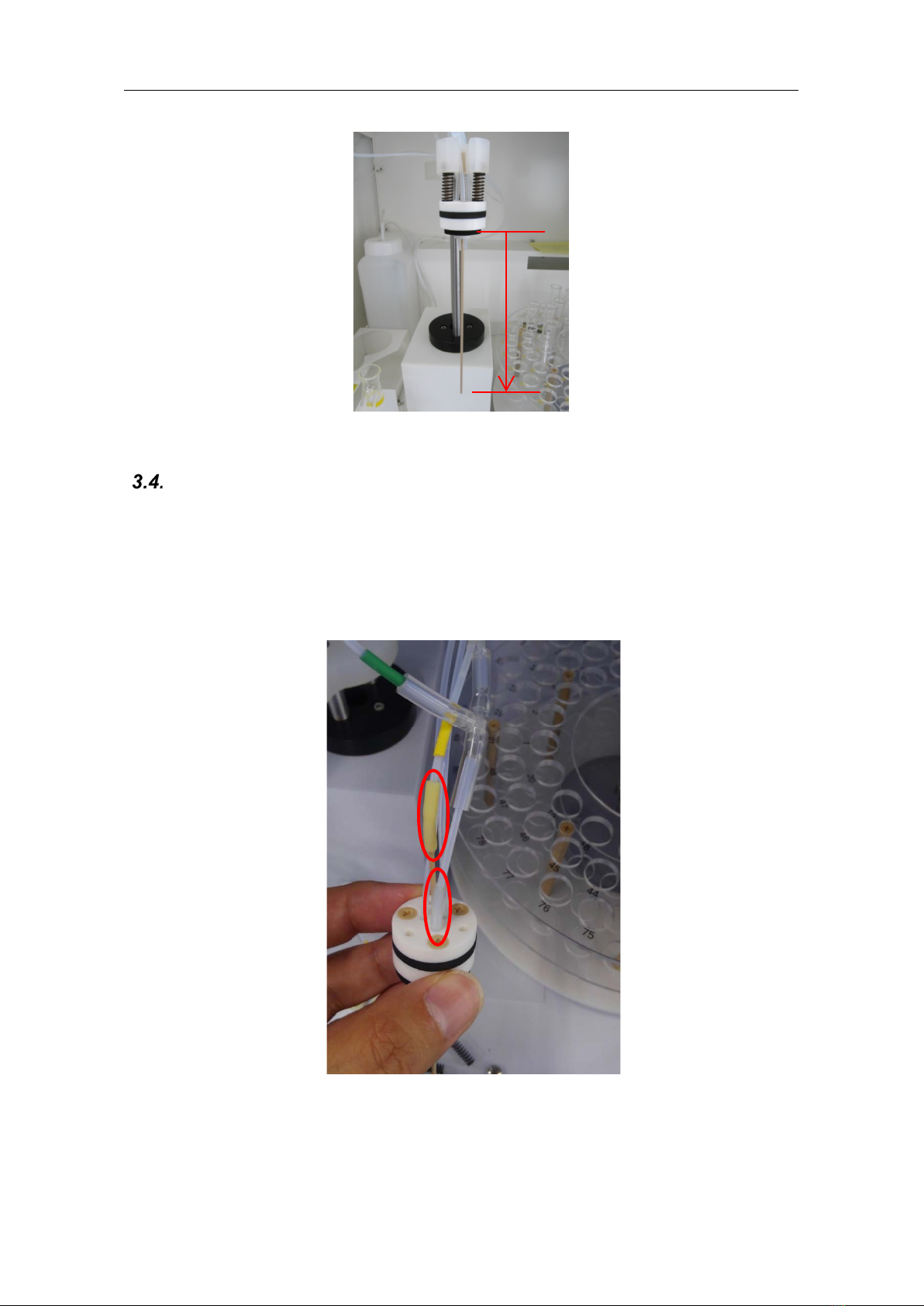

* Adjust the protrusion of the bubbler to 114 mm from the top of the cap gasket.

Service Manual

12

Reassemble the parts using the reverse procedure. Slide the spring over each resin

screw, and tighten the screws with a screwdriver until the screws do not turn anymore.

* If you tighten the screws too much, you may damage them.

* If the bubbler is leaning, you can correct it by loosening the screws.

Confirm that the protrusion of the bubbler is 114 mm from the top of the cap gasket.

* Excessively tightening the countersunk head screw of the cap makes it difficult to adjust

the protrusion of the bubbler.

114 mm

Service Manual

13

Replacing the reaction tube

Referring to [3.3. Replacing the measuring cap and bubbler], unscrew the three screws

holding the cap, and then remove the cap.

Pull the old reaction tubes out of the cap.

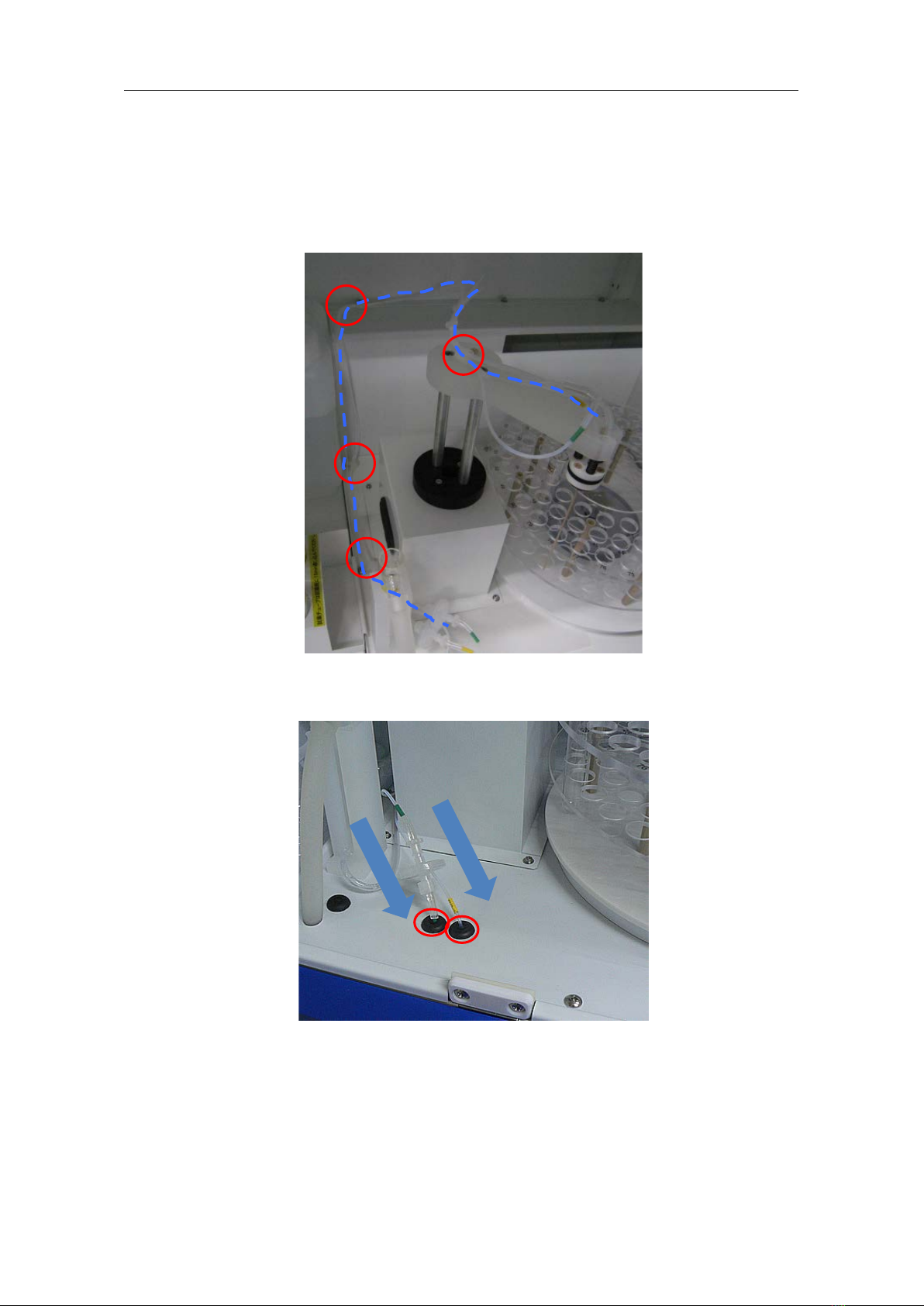

Connect the yellow-marked tube to the bubbler.

In addition, insert the transparent tube into the cap hole closer to you.

114 mm

Service Manual

14

Referring to [3.3. Replacing the measuring cap and bubbler - Step ], fix the cap in

place using the reverse procedure.

Run the tube along the route as shown in the picture below.

Hook the tube onto the clamps circled in the picture below.

Insert the yellow-marked tube into the grommet on the right side, and insert the green-

marked tube into the grommet on the left side.

Service Manual

15

Connect the yellow-marked tube to the check valve, and connect the green-marked tube

to the Teflon joint.

After the completion of assembling, conduct the procedure for checking the verticality of

the bubbler on the Maintenance screen. Place a sample bottle in No.1 holder, and then

set the [Bubbler Side] to “1” on the Maintenance screen. The measuring cap will move to

No.1 holder.

Check the verticality of the bubbler. If the bubbler is leaning, adjust it by loosening the

screws so that the cap becomes horizontal. However, to prevent the cap from coming off,

tighten at least one screw until it does not turn anymore.

Service Manual

16

Replacing the reagent tube

Referring to [3.3. Replacing the measuring cap and bubbler], remove the cap.

* Before starting this work, discharge any reagent from the tube by executing [Reagent

Discharge].

Unscrew the screws from the measuring cap. Then pull the old reagent tubes (P1, P2,

and P4) out of the cap.

Connect new reagent tubes (P1, P2, and P4) to the measuring cap.

Insert the reagent tubes into the two holes on the far side of the cap. In addition, slide the

heat-shrinkable tube over the bubbler and reagent tubes.

46 mm

10 mm

Heat-shrinkable

tube

Service Manual

17

Run the tube along the dashed line as shown in the picture below.

Pass the tube through the guides at the three spots.

Connect the reagent tube to the pump tube.

Insert the tube firmly so that the tube will not come off. (15 mm as a guide)

* If it is difficult to insert the tube, apply some alcohol to the tube to make it easier.

* To make the connection work easier, insert the tube before locking the pump head to

the motor unit rather than insert the tube after locking the pump head to the motor unit.

Table of contents

Other Nippon Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Mecmesin

Mecmesin Vortex-dV operating manual

Agilent Technologies

Agilent Technologies Labware MiniHub quick guide

Sorvall

Sorvall MT-2B ULTRAMICROTOME operating instructions

ANDO Technik

ANDO Technik DOSATRON D8R owner's manual

FINO

FINO FINODOSIL User information

Waters

Waters Xevo TQD IVD Overview and maintenance guide