Sorvall MT-2B ULTRAMICROTOME User manual

s

Du

Pont

Company

I I

T·2

ULTRAMICROTOME

Clinical

and

Instrument

Systems

Division

SorvaJI®

Products

Wilmington, Delaware 19898

U.S.A.

Sorvall®

Microtomes

PN

16153-2

Issued

March

1984

ii

Sorvall®

Instruments

This

manual

is a guide for

the

use

of

the

SORVALL®

MT-2B

ULTRAMICROTOME

e

Data

herein

has

been

verified

and

validated

and is

believed

adequate

for

the

intended

use

of

the

instrument.

If

the

instrument

or

procedures

are

used

for

purposes

over

and

above

the

capabilities

specified

herein,

confirmation

of

their

validity

and

suitability

should

be

obtained;

otherwise,

DuPont

does

not

guarantee

results

and

assumes

no

obligation

or

liability.

This

publication

is

not

a

license

to

operate

under,

nor a

recommendation

to

infringe

upon, any

process

patents.

e

Publications

prior

to

the

Issue

Date

of

this

manual

may

contain

data

in

apparent

conflict

with

that

provided

herein.

Please

consider

all

data

in

this

manual

to

be

the

most

current.

NOTES, CAUTIONS,

and

WARNINGS

within

the

text

of

this

manual

are

used

to

emphasize

important

and

critical

instructions.

IWARNING I

!cAUTION~

NOTE

An

operating

procedure

which,

if

not

correctly

followed,

could

result

in

personal

injury,

affect

the

operator's

health,

or

contaminate

the

environment.

An

operating

procedure

which,

if

not

strictly

followed,

could

result

in

damage

of

equipment.

Highlights

essential

information.

Sorvall®Instruments

Table

of

Contents

Paragraph

1-l.

l-2.

l-3.

l-4.

2-l.

2-2.

2-3.

2-4.

2-5.

2-6.

4-l.

4-2.

4-3.

4-4.

4-5.

4-6.

4-7.

5-l.

5-2.

5-3.

5-4.

5-5.

5-6.

5-7.

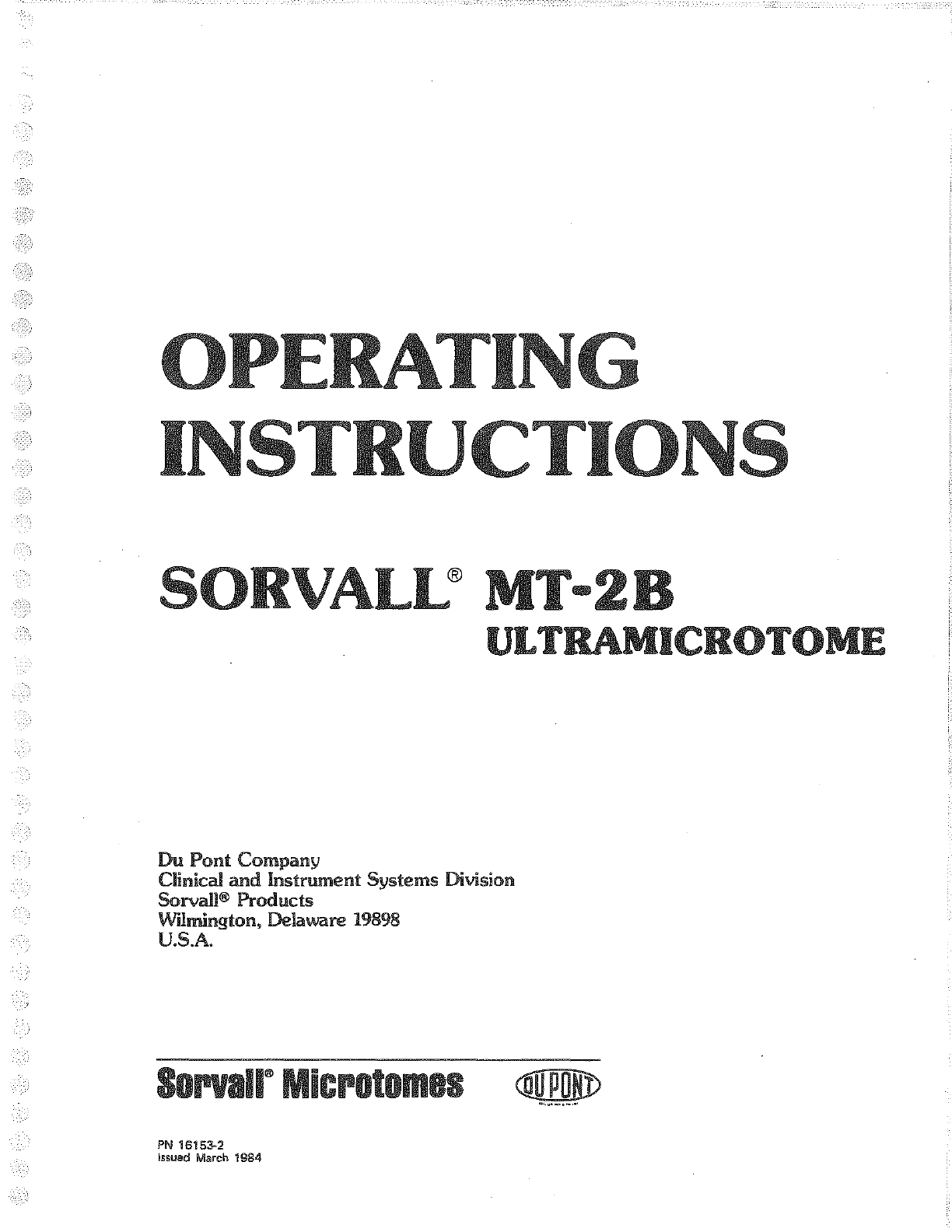

TABLE

OF

CONTENTS

WARRANTY.

Section

1.

DESCRIPTION

SCOPE

OF

THE

MANUAL . . .

DESCRIPTION

OF

THE MT-2B .

SPECIF!CA

TIONS • • • •

PARTS

AND

ACCESSORIES

.•

Section

2.

INSTALLATION

INSPECT!O

N • • . . . . • • •

LOCATION

• • . . • • • • • . • • • •

ASSEMBLY • . • • • • . • . • • • • .

ELECTRICAL

REQUIREMENTS

..•••.

MOVING THE MT-2B

ULTRAMICROTOME

•

CONTAMINATION

• • • • • • . • • • .

Section 3. MT-2B PARTS, CONTROLS & INDICATORS

Section

4.

OPERATION

SPECIMEN

PREPARATION

••..•••••••.•.••

SPECIMEN

AND

KNIFE POSITIONING • • • • • • • • . . •

SPECIMEN

AND

SPECIMEN

HOLDER

INSTALLATION

••••

KNIFE

INSTALLATION

AND

KNIFE

HOLDER

ADJUSTMENT

•

TRIMMING.

• • • • • • • • • • •

SECTIONING • • • • • • • • • • •

SERIAL

THIN

AND

THICK

SECTIONS

• • • • • •

Section

5.

MAINTENANCE

PARTS

REPLACEMENT

•.•

INSPECTION

AND

CLEANING

COVER

REMOVAL

••

LUBRICATION

.••••••

LAMP

REPLACEMENT

• • •

FUSE

REPLACEMENT

• • •

TROUBLESHOOTING

SECTIONING

DIFFICULTIES

Page

• v

1-l

1-l

1-1

l-2

. 2-1

• 2-1

•

2-l

•

2-2

•

2-2

• 2-2

• 4-1

.

4-l

•

4-2

•

4-3

•

4-5

•

4-9

• 4-10

.

5-l

.

5-l

.

5-l

•

5-3

.

5-3

•

5-4

•

5-4

iii

Table

of

Contents

iv

Figure

l-1.

3-1.

3-2.

3-3.

4-l.

4-2.

4-3.

4-4.

4-5.

5-l.

Table

l-l.

l-2.

3-1.

3-2.

3-3.

4-l.

5-l.

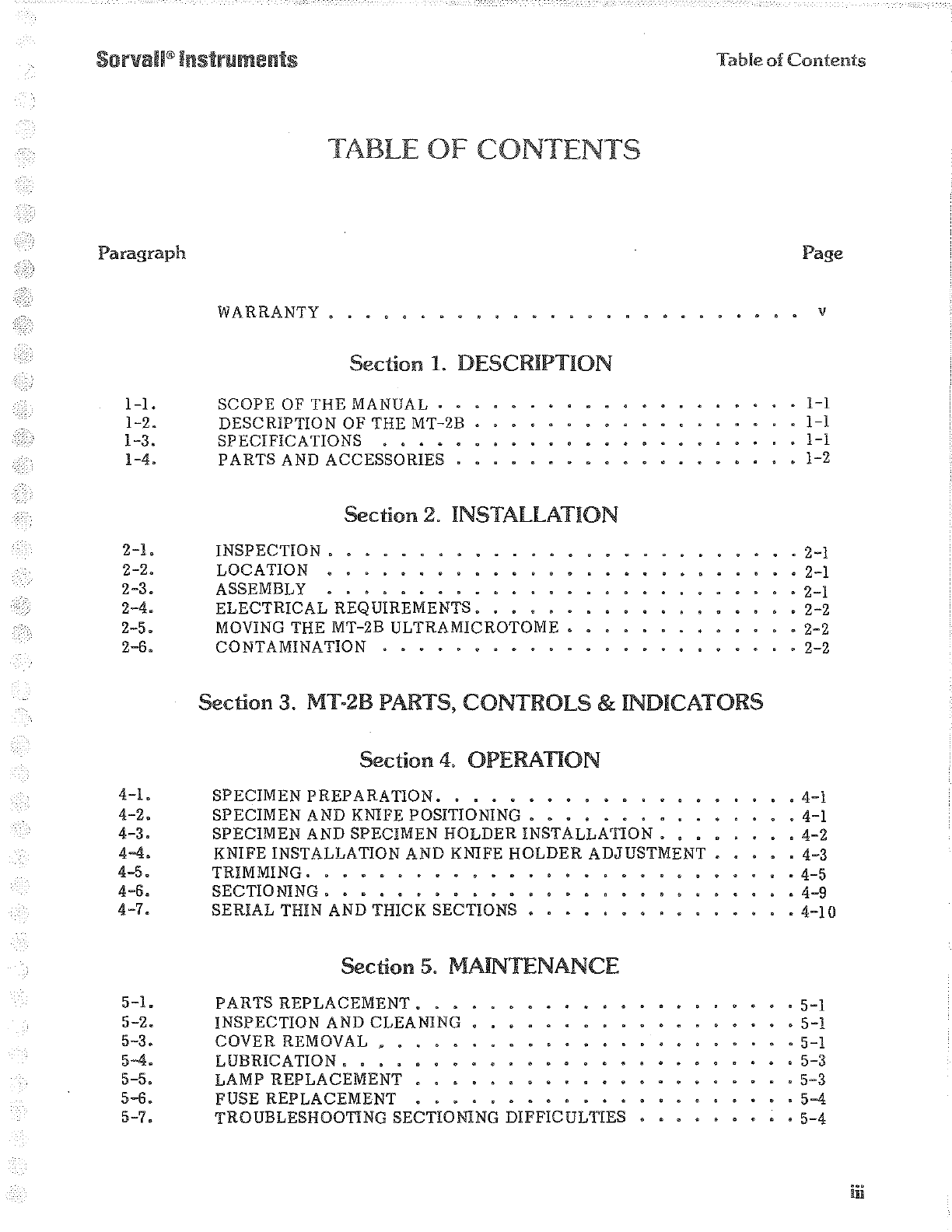

LIST

OF

ILLUSTRATIONS

Sorvall® MT-2B

tntramicrotome

MT-2B

Parts

Identification·

·

Knife

Stage

Parts

. . . . .

Controls

and

Indicators

. . .

Specimen

Holder

Installation

.

Glass

Knife

Dimensions

. . .

Adjusting

Glass

Knife

Height.

Ribbon

Formation

. . . . .

Diagram

of

Precision

Trimming

Sequence

Rear

View

of

MT-2B

(Rear

Cover

Removed)

LIST

OF

TABLES

Parts

and

Accessories

Supplied

. • • . •

Additional

Parts

and

Accessories

• • • .

MT-2B

Parts

Identification

and

Function

•

Function

of

the

Knife

Stage

Parts

. . . •

Controls

and

Indica

tors

• . . . • • • .

Summary

of

Precision

Trimming

Sequence

Troubleshooting

Chart

-Sectioning

Difficulties

Sorvall®Instruments

Page

vi

3-2

3-4

3-6

4-2

4-3

4-4

4-6

4-7

5-2

Page

l-2

l-3

3-l

3-3

3-5

4-8

5-4

Warranty

WARRANTY

The

Sorvall® MT-2B

Ultramicrotome

is

warranted

to

be

free

from

defects

in

materials

and

workmanship

for a

period

of

one

year

from

the

date

of

delivery.

DuPont

will

repair

or

replace

and

return

free

of

charge

any

part

which is

returned

to

its

factory

within

said

period,

transportation

prepaid

by

user,

and

which is found upon

inspection

to

have

been

defective

in

materials

or

workmanship. This

warranty

does

not

include

normal

wear

from

use,

it

does

not

apply

to

any

instrument

or

part

which

has

been

altered

by

anyone

other

than

an

employee

of

DuPont,

nor

to

any

instrument

which

has

been

damaged

through

accident,

negligence,

failure

to

follow

operating

instructions,

the

use

of

electric

currents

or

circuits

other

than

those

specified

on

the

plate

affixed

to

the

instrument,

use

beyond

the

specified

capacity

of

the

instrument,

misuse

or

abuse.

DuPont

reserves

the

right

to

change,

alter,

modify or

improve

any

of

its

instruments

without

any

ol;>ligation

whatever

to

make

corresponding

changes

to

any

instrument

previously

sold

or

shipped.

THE

FOREGOING

OBLIGATIONS

ARE

IN

LIEU

OF

ALL

OTHER

OBLIGATIONS

AND

LIABILITIES INCLUDING

NEGLIGENCE

AND

ALL

WARRANTIES

OF

MERCHANTABILITY

OR

OTHERWISE,

EXPRESSED

OR

IMPLIED

IN

FACT

OR

BY

LAW,

AND

STATE

OUR

ENTIRE

AND

EXCLUSIVE LIABILITY

AND

BUYER'S

EXCLUSIVE

REMEDY

FOR

ANY CLAIM

OR

DAMAGES IN

CONNECTION

WITH

THE

SALE

OR

FURNISHING

OF

GOODS

OR

PARTS,

THEIR

DESIGN, SUITABILITY

FOR

USE,

INSTALLATION

OR

OPERATION.

DUPONT

WILL

IN

NO EVENT BE LIABLE

FOR

ANY

SPECIAL

OR

CONSEQUENTIAL

DAMAGES WHATSOEVER,

AND

OUR

LIABILITY

UNDER

NO

CIRCUMSTANCES

WILL

EXCEED

THE

CONTRACT

PRICE

FOR

THE

GOODS

FOR

WHICH LIABILITY IS

CLAIMED.

v

Sorvall®Instruments

Figure

1-1.

Sorva/1®

MT-28

Ultramicrotome

vi

Sorvall®

Instruments

Description

Section

1.

DESCRIPTION

1-1.

SCOPE

OF

THE MANUAL

This manual provides you with

the

information

you will

need

to

install,

operate

and

maintain

your MT-2B

Ultramicrotome.

If

you

encounter

any problem

concerning

either

operation

or

maintenance

that

is

not

covered

in

this

manual,

please

contact

the

nearest

district

office

or

local

representative

of

DuPont's

Clinical

and

Instrument

Systems

Division, Sorvall®Products,

listed

on

the

back

of this

manual.

1-2. DESCRIPTION

OF

THE MT-2B

The Sorvall MT-2B

Ultramicrotome

is used

to

produce

ultrathin

sections

of

specimens

for

light

or

electron

microscopy. The

microtome

is

capable

of

cutting

sections

in

the

range

of

10

nm

to

4)lm.

Specimen and Knife Positioning

The MT-2B

cantilever

arm

advances

the

specimen

a maximum

of

85

)1m

at

a 50 nm

setting.

Total

advance

can

be

as much

as

!50

]1m

at

the

4

]1m

setting.

The

specimen

holder

that

is supplied with

the

microtome

permits

specimen

orientation

in

different

planes

around

the

knife edge by allowing

360°

rotation

of

the

specimen

holder

as

well

as

a

20°

arc

above and below

the

central

axis.

The

microtome

knife

stage

assembly

rotates

about

the

vertical

axis

that

passes through

the

specimen/knife

contact

point. The

knife

stage

assembly

rotates

30°

to

the

left

and

right

and can

be

locked

into

any position in

this

60°

range.

The knife

stage

assembly

also

provides

coarse

and fine

front

to

back

adjustment.

Specimen Viewing

The MT-2B is equipped with a

variable

stereozoom

microscope which

can

be

moved

forward

and

back.

A

built-in

fluorescent

lamp

provides wide

angle

illumination.

Cutting

The MT-2B

can

either

be

used manually or

automatically

by using

the

motor

drive.

The

duration

control

determines

the

length

of

the

stroke

at

the

preset

cutting

speed.

1-3. SPECIFICATIONS

,.

Depth.

'"

Width .

e Height

e Mass (Weight)

e

Electrical

Requirements*

56 em (22 in)

27

em

(10-3/4

in)

47 em

(!8-l/2

in)

to

top of

stereomicroscope

54.5

kg (120 lbs)

ll5V,

60

Hz

.,_

For

220V,

50 Hz operation, Cat. No.

04264

step--down

transformer

is

required.

1-1

Description

Sorvall®Instruments

1-2

o

Control

Specifications

Manual

Mechanical

Stage

Advance:

Coarse

advance

. .

Fine

advance

. . .

Automatic

Advance:

Variable

. . . •

Limit

of

advance

Cutting

Speed:

20

mm

100 flm

l 0 nm

to

4

flm

85

fJm

at

50

nm

per

section

150

flm

at

4

flm

per

section

Variable

between

0.09

mm/s

to

3.2

mm/s

in

motor

driven

mode;

manual

mode

speed

variable

by

handwheel

revolutions.

Sectioning

Rate:

Duration

Control

• . . .

Range

(at

2 mm

duration

setting)

• . . . . • . .

Knife

Adjustment:

Longitudinal

. .

Lateral

• . . •

Specimen

Orientation:

Around

central

axis .

Vertical

from

central

axis

Knife

stage

rotation.

. .

2 mm

to

10

mm

4

sections/min

at

speed

0.1

mm/s

to

15

sections/min

at

speed

3.0 m

m/s

20 mm

12

mm

1-4.

PARTS

AND

ACCESSORIES

The

parts

and

accessories

supplied

with

the

basic

MT-2B

Ultramicrotome,

(Cat.

No.

16188)

are

listed

in

Table

l-1.

Catalog

Number

16190

16193

16189

16913

16916

16815

16915

61055

16800

16841

16153

Table 1-1.

Parts

and

Accessories

Supplied

Description

Microscope

Arm

Assembly

Variable

Stereomicroscope

Accessory

Pack

containing:

Base

Plate

Assembly

Microscope

Stand

Assembly

Plastic

Shield

Microscope

Holder

Assembly

Cap

Screws

(3

ea)

Dust

Cover

Accessory

Box

containing:

(Fluorescent

Bulb,

Starter,

Vials,

Fuses,

Bearing

Oil,

Screwdriver,

Knife

Height

Adjusting

Wrench,

Lubricating

Grease,

Vise-Type

Holder)

Instruction

Manual

Son·all®

Instruments

Description

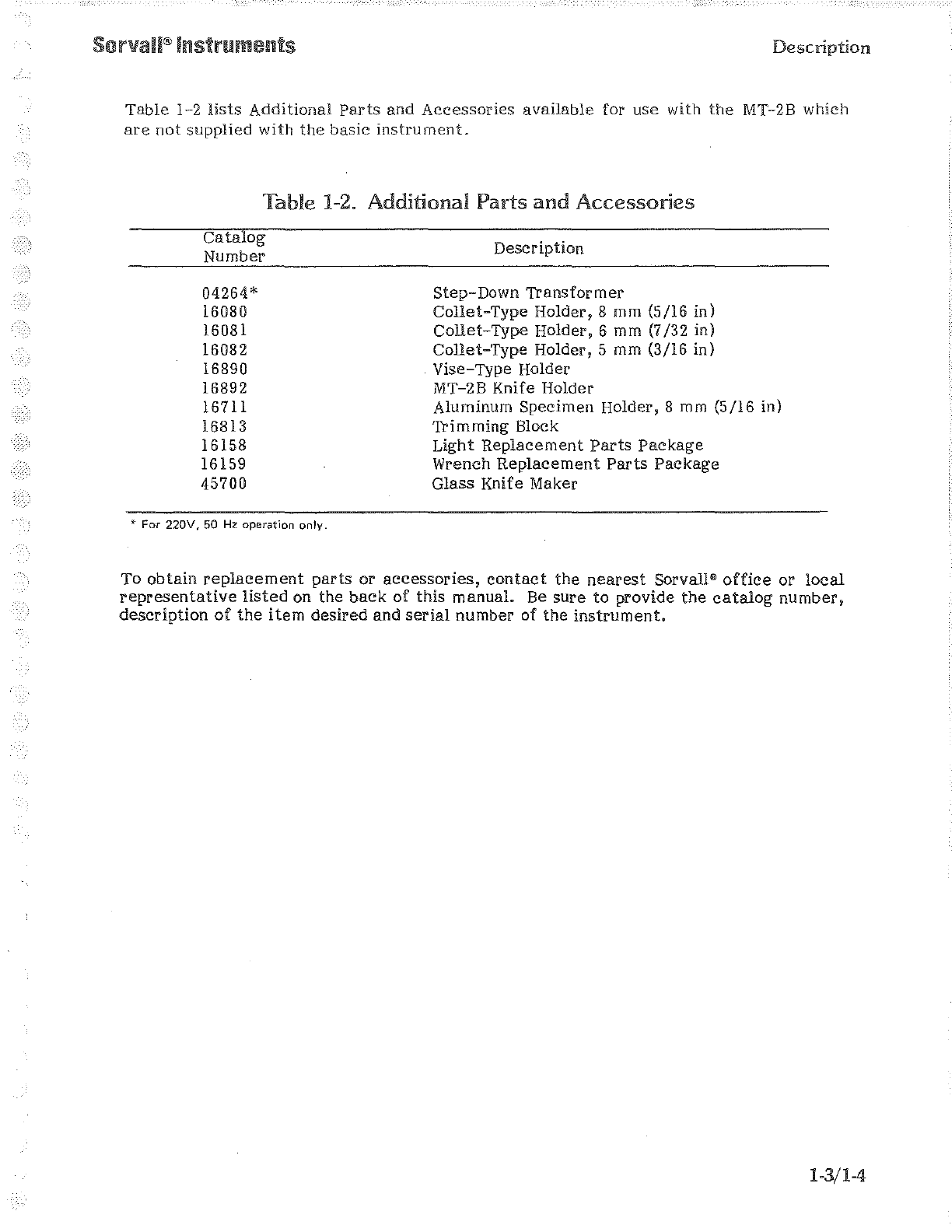

Table

l-2

lists

Additional

Parts

and

Accessories

available

for

use

with

the

MT-28

which

are

not

supplied

with

the

basic

instrument.

Table

1-2.

Additional

Parts

and

Accessories

Catalog

Number

04264*

16080

16081

16082

16890

16892

16711

16813

16158

16159

45700

• For

220V,

50 Hz operation only.

Description

Step-Down

Transformer

Collet-Type

Holder,

8

mm

(5/16

in)

Collet-Type

Holder,

6 mm (7/32 in)

Collet-Type

Holder,

5 mm (3/16 in)

Vise-Type

Holder

MT-28

Knife

Holder

Aluminum

Specimen

Holder,

8 mm

(5/16

in)

Trimming

Block

Light

Replacement

Parts

Package

Wrench

Replacement

Parts

Package

Glass

Knife Maker

To

obtain

replacement

parts

or

accessories,

contact

the

nearest

Sorvall®

office

or

local

representative

listed

on

the

back

of

this

manual.

Be

sure

to

provide

the

catalog

number,

description

of

the

item

desired

and

serial

number

of

the

instrument.

l-3/l-4

Installation

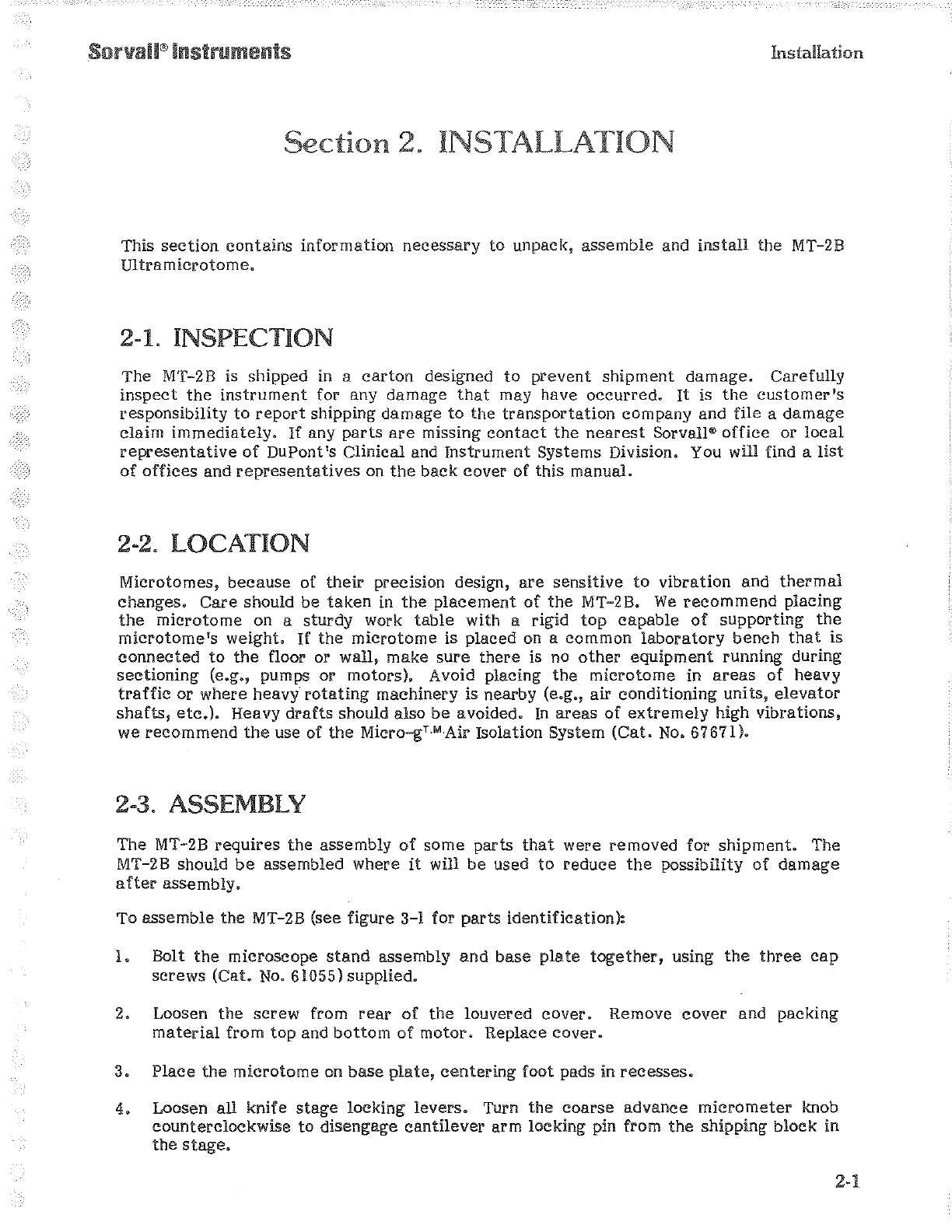

Section

2. INSTALLATION

This

section

contains

information

necessary

to

unpack,

assemble

and

install

the MT-2B

mtramicrotome.

2-1. INSPECTION

The MT-2B is shipped in a

carton

designed

to

prevent

shipment

damage.

Carefully

inspect

the

instrument

for any

damage

that

may have

occurred.

It

is

the

customer's

responsibility

to

report

shipping damage

to

the

transportation

company and file a

damage

claim

immediately.

If

any

parts

are

missing

contact

the

nearest

Sorvall"'

office

or

local

representative

of

DuPont's Clinical and

Instrument

Systems Division. You will find a

list

of

offices

and

representatives

on

the

back

cover

of

this

manual.

2-2. LOCATION

Microtomes,

because

of

their

preciSIOn design,

are

sensitive

to

vibration

and

thermal

changes.

Care

should be

taken

in

the

placement

of

the

MT-2B.

We

recommend

placing

the

microtome

on a

sturdy

work

table

with a rigid

top

capable

of

supporting

the

microtome's

weight.

If

the

microtome

is placed on a

common

laboratory

bench

that

is

connected

to

the

floor or wall, make

sure

there

is no

other

equipment

running during

sectioning

(e.g., pumps or motors). Avoid placing

the

microtome

in

areas

of

heavy

traffic

or

where

heavy

rotating

machinery is nearby (e.g.,

air

conditioning

units,

elevator

shafts,

etc.).

Heavy

drafts

should also

be

avoided.

In

areas

of

extremely

high

vibrations,

we

recommend

the

use of

the

Micro-gT.MAir Isolation System

(Cat.

No.

67671).

2-3. ASSEMBLY

The MT-2B

requires

the

assembly

of

some

parts

that

were

removed

for

shipment.

The

MT-2B should

be

assembled where

it

will

be

used

to

reduce

the

possibility

of

damage

after

assembly.

To

assemble

the

MT-2B (see figure 3-1 for

parts

identification):

l.

Bolt

the

microscope

stand

assembly

and

base

plate

together,

using

the

three

cap

screws

(Cat.

No.

61055) supplied.

2. Loosen

the

screw

from

rear

of

the

louvered

cover.

Remove

cover

and packing

material

from

top

and

bottom

of

motor.

Replace

cover.

3.

Place

the

microtome

on

base

plate,

centering

foot pads in

recesses.

4.

Loosen all knife

stage

locking

levers.

Turn

the

coarse

advance

micrometer

knob

counterclockwise

to

disengage

cantilever

arm locking pin from

the

shipping

block

in

the

stage.

Installation

2-2

5.

To

release

locking pin, loosen

the

collet

holder,

turning

counterclockwise.

To

release

block,

loosen knife

clamping

thumbscrew.

(Note: pin and

block

should

be

retained

for

future

use in

the

event

the

microtome

is moved.)

6.

Place

handwheel

on

shaft

and

tighten

mounting

screw.

7.

Loosen

each

of

the

Phillips

screws

(about

one-quarter

turn)

at

lower

left

and

right

corners

of

front

panel

and on

the

top

of

the

cover

behind

the

upper

thickness

control

knob.

8.

Turn upper

thickness

control

knob

clockwise

to

zero,

then

turn

counterclockwise

to

position

10.

9.

Insert

microscope

arm

in

microscope

stand

assembly

and

tighten

locking

clamp

screw.

10.

Insert

microscope

holder

into

the

microscope

arm

and

tighten;

insert

the

microscope

into

holder

and

lock

in

place

with

side

levers.

11.

Plug

the

power

cord

into

power supply.

The MT-2B should

be

placed

8

em

to

13

em

(3

to

5 in) from

the

edge

of

the

work

surface.

2-4. ELECTRICAL REQUIREMENTS

The

motor

and

cold

light

source

require

a

power

supply

of

115

V,

60 Hz.

The

cord

is

fitted

with

a NEMA Type

5-15P

3-prong

molded

cap

with

ground

pin

and

parallel

blades.

For

power

supplies

200 V and 240

V,

50

and

60 Hz,

Cat.

No. 04264

Step-Down

Transformer

is

required.

2-5. MOVING THE MT-28 ULTRAMICROTOME

The MT-2B is a

delicate

instrument

and

must

be

moved

carefully.

If

there

is

a

possibility

the

MT-2B will

be

moved

to

another

building,

it

is

recommended

that

the

original

shipping

carton

and

unpacking

instructions

be

saved

for

repacking.

To move

the

MT-2B

to

a new

location,

reverse

the

assembly

procedure

outlined

in

paragraph

2-3,

then

place

the

microtome

in

its

shipping

container

reversing

the

order

of

the

unpacking

instructions.

2-6. CONTAMINATION

.----------1

WARNING

1---------,

Because

of

the

nature

of

samples

likely

to

be

processed

in

the

laboratory,

the

chance

of

contamination,

either

biological

or

radioactive,

is

possible.

Always

be

aware

of

this

possibility

and

take

normal

precautions.

Use

the

appropriate

decontamination

procedures

should

exposure

occur.

Installation

Should an

instrument

that

has

been

used

with

radioactive

or

pathogenic

material

require

servicing

by

DuPont

personnel,

either

at

the

customer's

laboratory

or

at

a DuPont

facility,

comply

with

the

following

procedure

to

ensure

the

safety

of

all

personnel:

®

Clean

the

instrument

to

be

serviced

of

all

encrusted

material

and

decontaminate

it

prior

to

servicing

by

the

DuPont

representative.

There

must

be

no

radioactivity

detectable

by

survey

equipment.

..

Complete

and

attach

Decontamination

Information

Certificate

(Sorval!®

Instruments

Form No. !PDP-59)

to

the

instrument.

If

an

instrument

to

be

serviced

does

not

have

a

Decontamination

Information

Certificate

attached

and,

in

DuPont's

opinion,

presents

a

potential

radioactive

or

biological

hazard,

the

DuPont

representative

will

not

service

the

equipment

until

proper

decontamination

and

certification

is

complete.

If

DuPont

receives

an

instrument

at

its

Service

facilities

which,

in

its

opinion, is a

radioactive

or

biological

hazard,

the

sender

will

be

contacted

for

instructions

as

to

disposition

of

the

equipment.

Disposition

costs

will

be

borne

by

the

sender.

Decontamination

Information

Certificates

are

included with

these

instructions.

Additional

certificates

are

available

from

the

local

Technical

or

Service

Representative.

ln

the

event

these

certificates

are

not

available,

a

written

statement

certifying

that

the

unit

has

been

properly

decontaminated

and

outlining

the

procedures

used

will

be

acceptable.

NOTE

The

Service

Representative

will

note

on a Field

Service

Repair

Report

if

decontamination

was

required,

and

if

so,

what

the

contaminant

was

and

what

procedure

was

used.

If

no

decontamination

was

required,

it

will

be

so

stated.

2-3/2-4

MT-2B

Parts,

Controls

and

Indicators

Section

3.

PARTS,

CONTROLS

&

INDICATORS

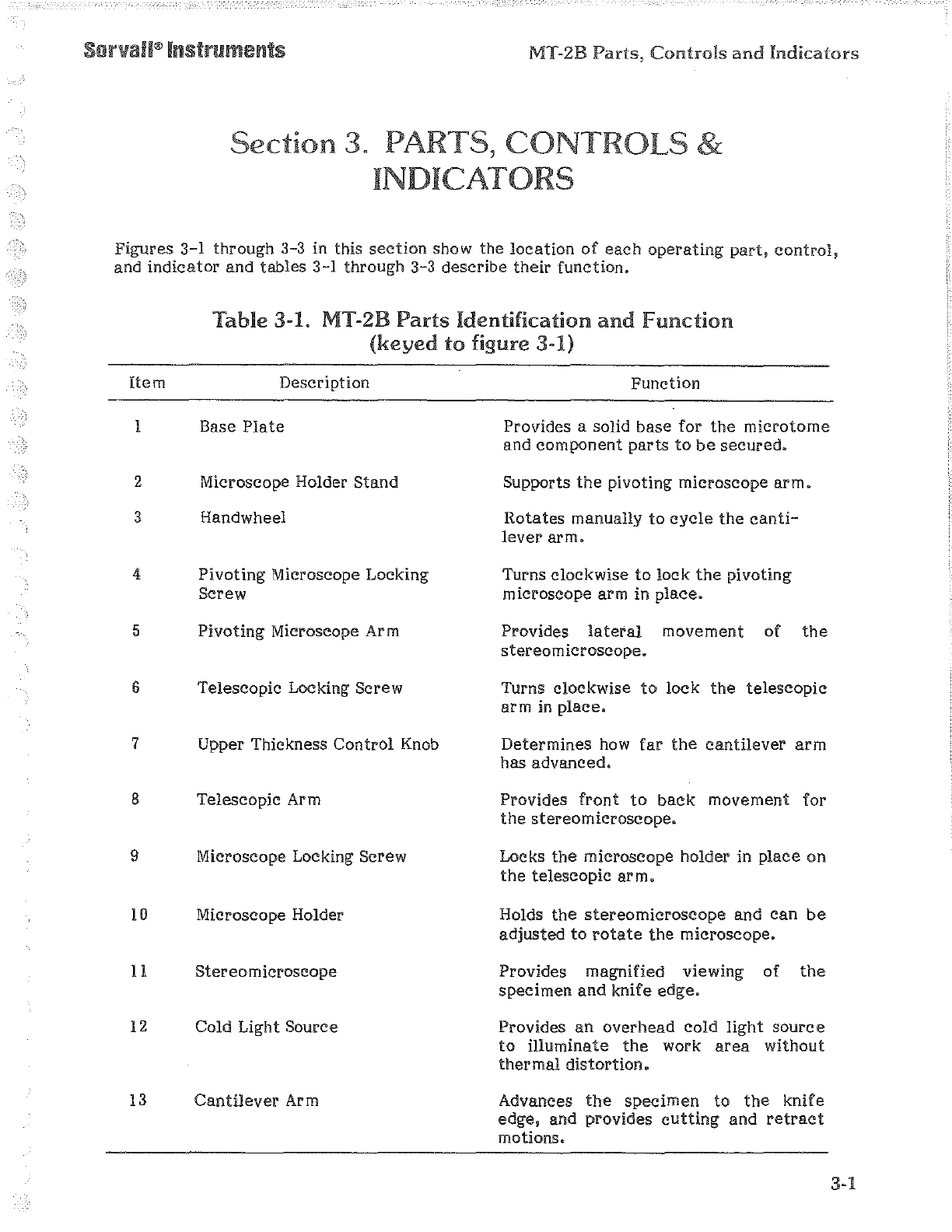

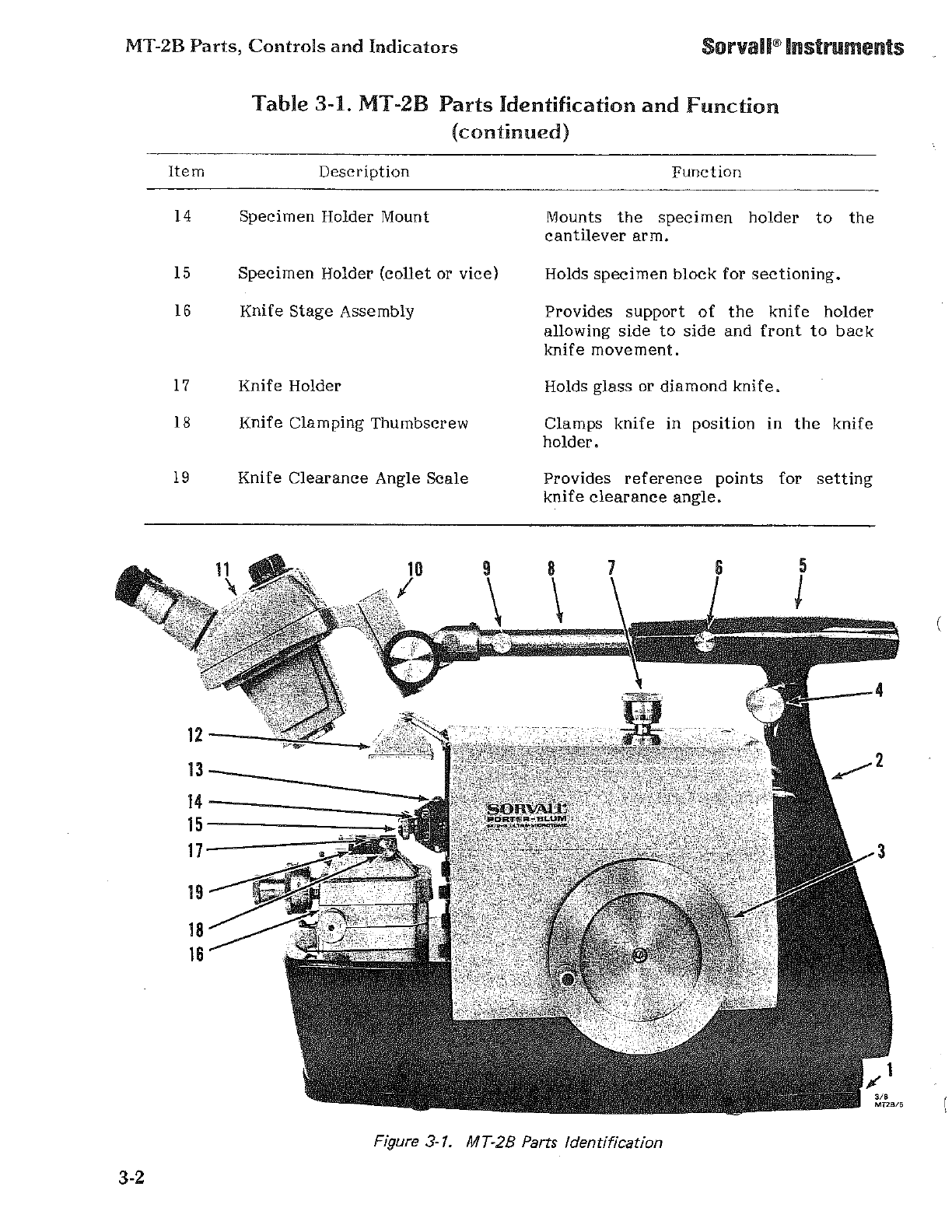

Figures

3-l

through 3-3 in this

section

show the

location

of

each

operating

part,

control,

and

indicator

and

tables

3-l

through 3-3 describe

their

function.

Item

l

2

3

4

5

6

7

8

9

10

!1

12

13

Table

3-1. MT-2B

Parts

Identification

and

function

(keyed

to

figure 3-1)

Description

Base

Plate

Microscope Holder

Stand

Handwheel

Pivoting

Microscope Locking

Screw

Pivoting

Microscope Arm

Telescopic Locking Screw

Upper Thickness

Control

Knob

Telescopic Arm

Microscope Locking Screw

Microscope Holder

Stereo

microscope

Cold Light Source

Cantilever

Arm

Function

Provides a solid base

for

the

microtome

and

component

parts

to

be

secured.

Supports

the

pivoting microscope

arm.

Rotates

manually

to

cycle

the

canti-

lever

arm.

Turns clockwise

to

lock

the

pivoting

microscope arm in

place.

Provides

lateral

movement

of

the

stereo

microscope.

Turns clockwise

to

lock

the

telescopic

arm

in

place.

Determines

how

far

the

cantilever

arm

has

advanced.

Provides

front

to

back

movement

for

the

stereomicroscope.

Locks

the

microscope holder in

place

on

the

telescopic

arm.

Holds

the

stereomicroscope

and

can

be

adjusted

to

rotate

the

microscope.

Provides magnified viewing

of

the

specimen

and

knife

edge.

Provides

an

overhead

cold

light

source

to

illuminate

the

work

area

without

thermal

distortion.

Advances

the

specimen

to

the

knife

edge, and provides

cutting

and

retract

motions.

3-1

MT-2B

Parts,

Controls

and

Indicators

Sorvall®Instruments

3-2

Table

3-1. MT-2B

Parts

Identification

and

Function

(continued)

Item

Description

14

Specimen

Holder

Mount

15

Specimen

Holder

(collet

or

vice)

16

Knife

Stage

Assembly

17

Knife

Holder

18

Knife

Clamping

Thumbscrew

19

Knife

Clearance

Angle

Scale

12--Z

13

_____

_

14-----_:

15------

....

;

17---~--:';

Function

Mounts

the

specimen

holder

to

the

cantilever

arm.

Holds

specimen

block

for

sectioning.

Provides

support

of

the

knife

holder

allowing

side

to

side

and

front

to

back

knife

movement.

Holds

glass

or

diamond

knife.

Clamps

knife

in

position

in

the

knife

holder.

Provides

reference

points

for

setting

knife

clearance

angle.

Figure 3-1. MT-28 Parts Identification

"'

MT2B/6

Sorvall®Instruments MT-2B

Parts,

Controls

and

Indicators

Item

1

2

3

4

5

6

7

8

9

10

ll

12

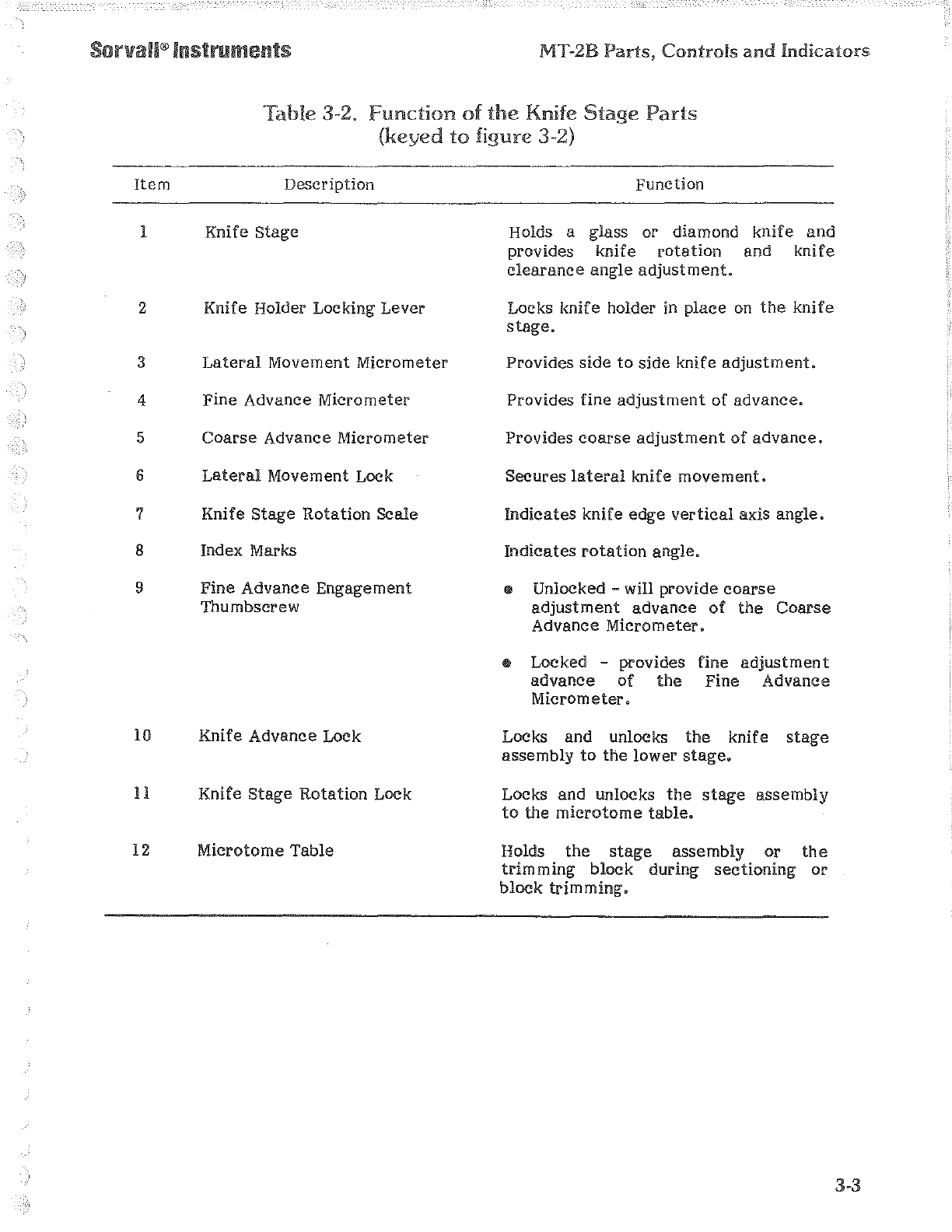

Table

3-2.

Function

of

the

Knife

Stage

Parts

(keyed

to

figure

3-2)

Description

Knife

Stage

Knife Holder Locking Lever

Lateral

Movement Micrometer

Fine Advance Micrometer

Coarse

Advance Micrometer

Lateral

Movement Lock

Knife

Stage

Rotation

Scale

Index Marks

Fine

Advance Engagement

Thumbscrew

Knife Advance Lock

Knife

Stage

Rotation

Lock

Microtome

Table

Function

Holds a glass or diamond

knife

and

provides knife

rotation

and

knife

clearance

angle

adjustment.

Locks knife holder in place

on

the

knife

stage.

Provides

side

to

side

knife

adjustment.

Provides fine

adjustment

of

advance.

Provides

coarse

adjustment

of

advance.

Secures

lateral

knife

movement.

Indicates

knife edge

vertical

axis

angle.

Indicates

rotation

angle.

• Unlocked

-will

provide

coarse

adjustment

advance

of

the

Coarse

Advance

Micrometer.

Locked -provides

advance

of

the

Micrometer.

fine

adjustment

Fine Advance

Locks and unlocks

the

knife

stage

assembly

to

the

lower

stage.

Locks and unlocks

the

stage

assembly

to

the

microtome

table.

Holds

the

stage

assembly or

the

trimming

block

during

sectioning

or

block

trimming.

3-3

MT-2B

Parts,

Controls

and

Indicators

Figure

3-2.

Knife Stage

Parts

3-4

2

4

5

6

7

Sorvall®Instruments MT-2B

Parts,

Controls

ami

Indicators

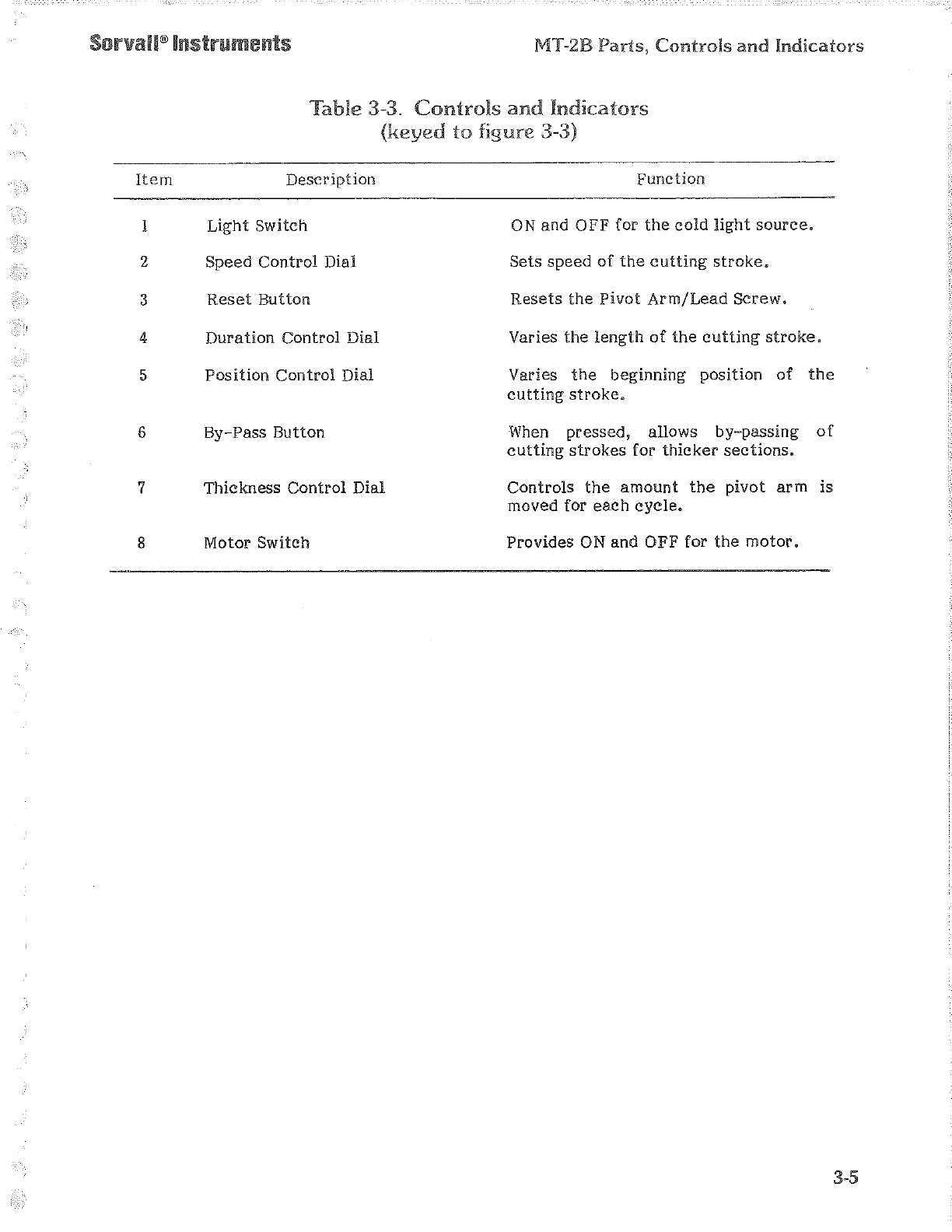

Item

l

2

3

4

5

6

7

8

Table

3-3.

Controls

and

Indicators

(keyed

to

figure

3-3)

Description

Light

Switch

Speed

Control

Dial

Reset

Button

Duration

Control

Dial

Position

Control

Dial

By-Pass

Button

Thickness

Control

Dial

Motor Switch

Function

ON

and

OFF

for

the

cold

light

source.

Sets

speed

of

the

cutting

stroke.

Resets

the

Pivot

Arm/Lead

Screw.

Varies

the

length

of

the

cutting

stroke.

Varies

the

beginning

position

of

the

cutting

stroke.

When

pressed,

allows

by-passing

of

cutting

strokes

for

thicker

sections.

Controls

the

amount

the

pivot

arm

is

moved for

each

cycle.

Provides

ON

and

OFF for

the

motor.

3-5

MT-2B

Parts,

Controls

and

Indicators

Figure

3-3. Controls and Indicators

3-6

Sorvall®Instruments

2

3

4

5

3/8

MT2B/14

Table of contents

Other Sorvall Laboratory Equipment manuals