8 9

Intended use

///

Use

›

The IKA G-L centrifuge is suitable for separating of substances and mixtures of substances of

various densities�

›

Intended use: Tabletop device

///

Area of use (only indoors)

› Laboratories

› Pharmacies

› Universities

› Schools

The device is suitable for all areas (EMC class A and B)�

The safety of the user cannot be guaranteed:

› if the device is operated with accessories that are not supplied or recommended by the

manufacturer�

›

if the device is operated improperly or contrary to the manufacture’s specifications�

› if the device or the printed circuit board are modified by third parties�

/// Disposal instructions

› The device, accessories and packaging must be disposed of in accordance with local and

national regulations�

/// Maintenance

› The device must only be opened by trained specialists, even during repair� The device must

be unplugged from the power supply before opening� Live parts inside the device may still

be live for some time after unplugging from the power supply�

/// Accessories

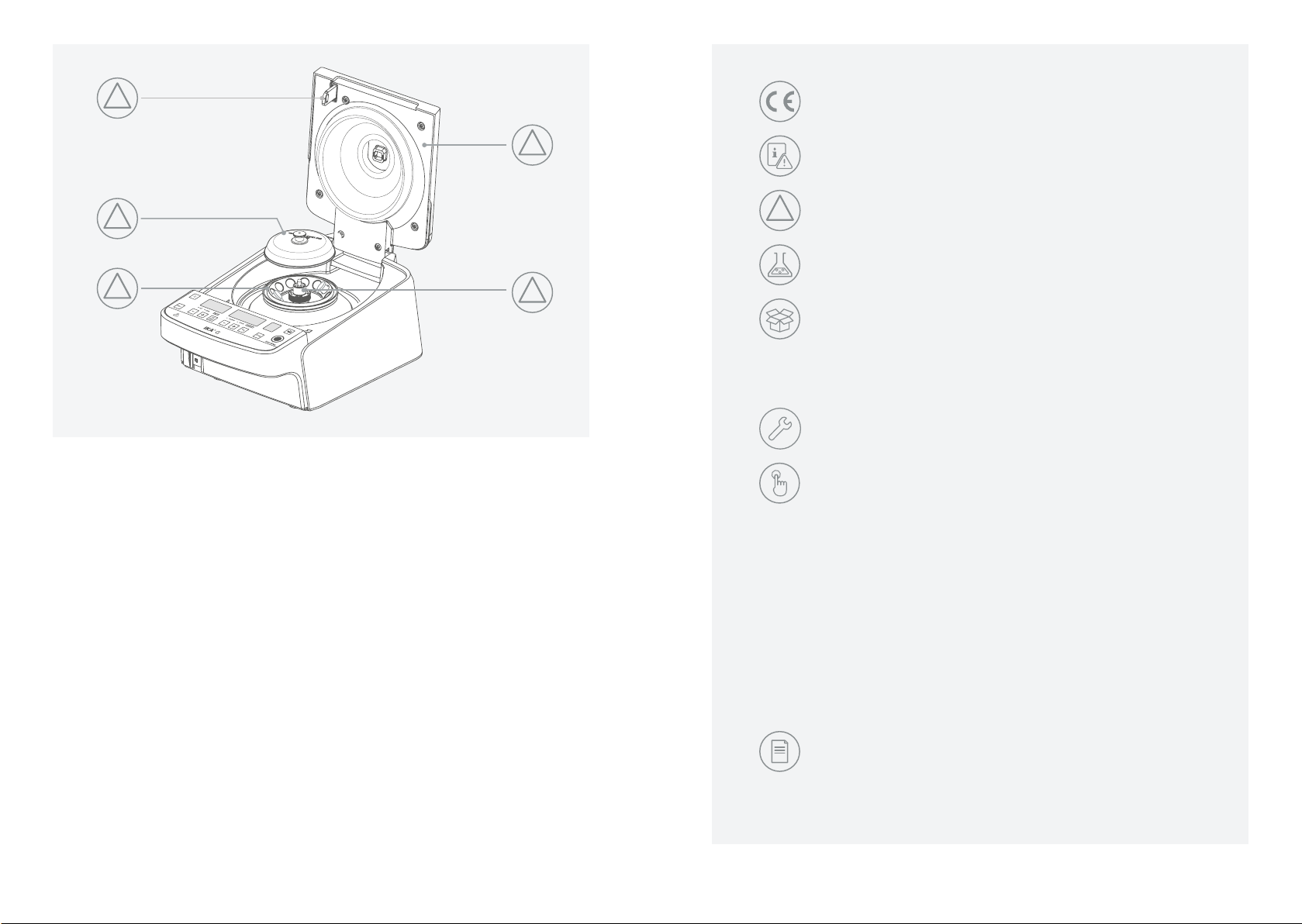

› Protect the device and accessories from bumping and impacting�

› Check the device and accessories beforehand for damage each time when you use them� Do

not use damaged components�

› Safe operation is only guaranteed with the accessories described in the ”Accessories” section�

› Disconnect the power plug before attaching or changing any accessories�

/// Power supply / switching off the device

› The voltage stated on the type plate must correspond to the power voltage�

› The device can only be disconnected from the power supply by pulling out the power plug

or the connector plug�

› The device must only be operated with the original power cord set�

› The socket for the power cord must be easily accessible�

› The device does not start up again automatically following a cut in the power supply�

Warning!

› When centrifuging hazardous substances or mixtures of substances which are toxic or are

contaminated with pathogenic micro-organisms, the user should take appropriate precau-

tions� In such cases, centrifuging vessels with special screw seals for hazardous substances

must always be used�

›For materials in risk groups 3 and 4, in addition to sealed centrifuging vessels a bio-safety

system must be used (see the “Laboratory Biosafety Manual” issued by the World Heath

Organisation)� No biosafety systems are available for this centrifuge�

!Notice!

› Before starting the device for the first use, make sure that the rotor nut is securely fastened�

Fail to do it, can result in permanent damage to the device and accessories�

› The rotor is subjected to extreme forces� Serious internal material damage can occur as a

result of even slight scratches and cracks� Do not use the device if the rotor is damaged�

› Do not operate the centrifuge if there is evidence of damage to the centrifuge chamber�

› Do not process materials that are radioactive, flammable or explosive, or materials that react

chemically with each other releasing large amounts of energy�

› If unusual noises occur when the centrifuge is started, the rotor is not secured correctly� In

this case, immediately stop the centrifuge�

› Covers or parts that can be removed from the device without tools must later be refitted to

ensure safe operation� This will prevent the infiltration of foreign objects, liquids and other

contaminants�

› Prior to centrifugation, the tubes should be visually inspected for any physical damage�

Broken tubes can damage centrifuge and accessories�

› If you are using aggressive chemicals, protect the device from being damaged by these

chemicals�

› Only process media that will not react dangerously to the extra energy produced through

processing� This also applies to any extra energy produced in other ways, e�g� through light

irradiation�

› Always use rotor cover along with the rotor�

› Inspect the rotor and rotor cover regularly�

› Do not run the motor without rotor�

› The device must be supervised when it is running�

› While the centrifuge is running, do not move it or strike it�

› The feet of the device must be clean and undamaged�