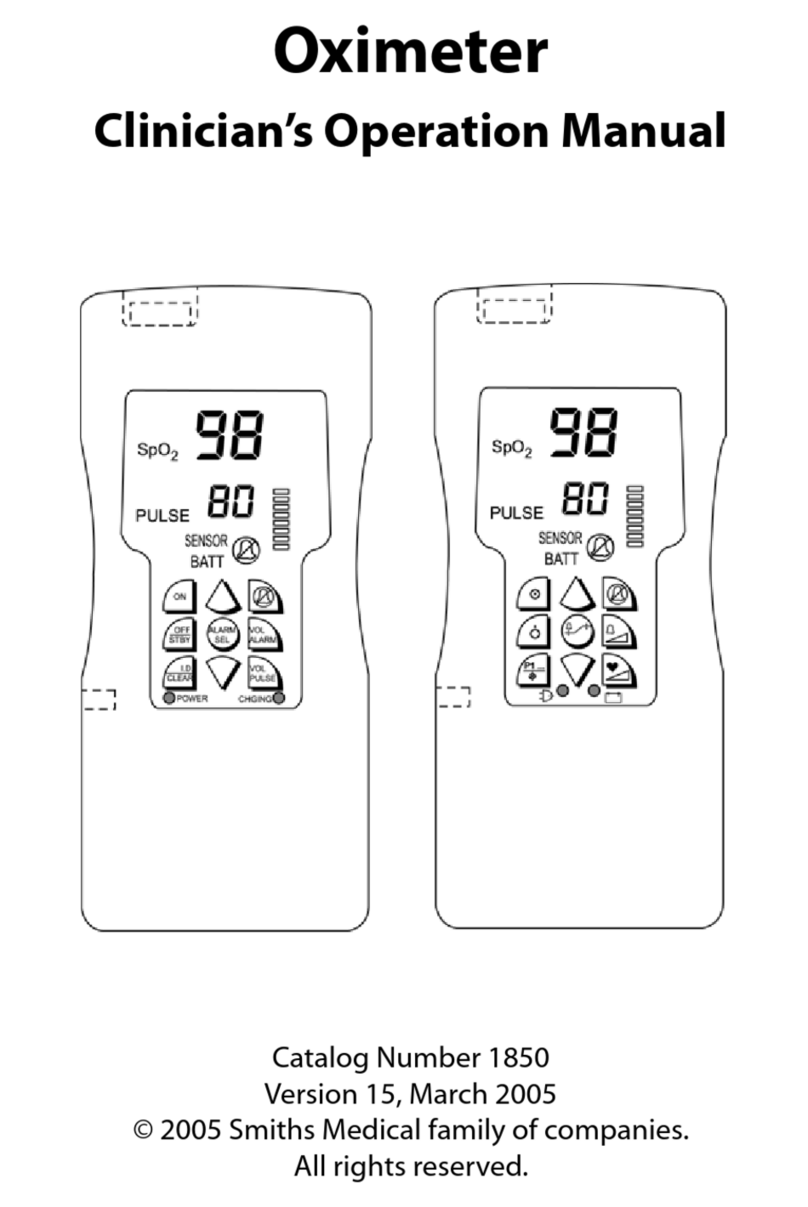

Nipro SURDIAL User manual

SERVICE MANUAL

SINGLE PATIENT DIALYSIS MACHINE

SURDIAL

Manufacturer NIPRO CORPORATION

3-9-3, Honjo-Nishi, Kita-Ku, OSAKA 531-8510, JAPAN

PHONE +81-6-6372-2331 / FAX +81-6-6371-7422

Version No.0R2135-1105

PREFACE-1

PREFACE

Thank you for purchasing NIPRO SINGLE PATIENT DIALYSIS MACHINE SURDIAL.

This Service Manual provides information for those who are engaged in inspection and repair of

SURDIAL. Only qualified service personnel and technicians must conduct works described in this

Manual. These service personnel and technicians must not only be competent to replace parts of

electronic equipment based on the microprocessor but also be knowledgeable about basics of

general dialysate circuit of the dialyzer. Before replacing parts of this equipment or maintaining the

equipment, service personnel and technicians must read this Manual and understand the contents

thoroughly.

This Service Manual is designed to be used together with the SURDIAL Instruction Manual. There

are only minimum contents which are overlapping between this Service Manual and the Instruction

Manual. In general, the Instruction Manual describes information required for operating SURDIAL

(although some chapters contain technical information) and this Service Manual describes

information about maintenance of the equipment, replacement of parts and setting of each item.

There are two types, Type I and Type II, of SURDIAL. When using this Service Manual, check the

type of installed SURDIAL first.

Copyright of this instruction manual is protected and owned by the manufacturer.

Copying, duplicating, translating a part or a compete service manual without the manufacturer’s

permission is prohibited.

PREFACE-2

SAFETY PRECAUTIONS-1

SAFETY PRECAUTIONS

Proper operation and regular maintenance are essential for safe operation.

Thoroughly read and understand the safety precautions listed in this instruction manual before use.

Operation and safety precautions listed in this manual are specific intended for the use of this unit. If

this unit is used for other purposes, which are not listed in this instruction manual, the user will be

responsible for the consequential safety issues.

(1) Degree of safety hazard, damage and displays (attention-attracting symbols and signaling terms)

Degree of safety hazard and damage that result from improper handling is classified into 3 levels.

Each level will be indicated by a specific attention-attracting symbol and signaling term.

DANGER

This indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING

This indicates a potentially hazardous which, if not avoided, could result in death or injury.

CAUTION

This indicates a potentially hazardous, if not avoided, may result in moderate injury or

damage in property.

(2) Annotation and its display

NOTE

Annotation is displayed. Use this as a reference when handling the unit.

Because of our ceaseless research and improvement, details of the design of the unit described in

this manual may be slightly different from those of the unit you purchased. If you have any question

about the unit you purchased or contents of this instruction manual, please contact the nearest

branch or agency.

SAFETY PRECAUTIONS-2

DANGER

Read this instruction manual before using the unit.

• When this machine is operated and maintained in a proper way, a safe and reliable treatment is

warranted.

• Before operating the unit, thoroughly read and understand this manual. Improper operation can

lead to injury or abnormal operation. This unit should be operated by professionals only.

Learn the methods to immediately stop the treatment.

• To avoid serious problems, know how to quickly stop the operation.

• Do not allow non-professionals to operate the unit without having proper instructions.

Know how to respond when the unit stops for any reason.

• Check the status of the unit and act in accordance with this manual.

During the maintenance, special caution should be exercised for the electronic boards, electric

wiring, and terminals.

• Do not touch non-isolated electric wiring and terminals.

• Do not touch the electronic boards with a wet hand.

• Before touching the terminal block, disconnect the power plug from the power supply.

During the connection/disconnection of a patient, special attention should be taken to avoid the

following risks that can harm the patient.

• Avoid air entrance into the patient.

• Do prime the blood circuit before connecting the patient.

• Do not connect the patient blood circuit during rinsing/disinfection.

• Prevent the contact of harmful viruses and chemicals with the patient.

Inappropriate connection of the blood circuit is dangerous for the patient. A bad connection can

cause extracorporeal leakages. Improper pressure can result in rupture of the circuit. Ensure

that the blood circuit is connected properly at all times.

Before connecting the patient, ensure that the alarm of the unit is not interrupted. Treatment

without using the alarm functions can cause great risks for the patient.

Mixing of chlorine and acid rinsing solutions generates chlorine gases. Inhalation of these toxic

gases is very dangerous. Ventilate the room, and be careful not to inhale the generated gases.

SAFETY PRECAUTIONS-3

WARNING

Electronic equipment producing radio waves should not be used in the same room or building as

where this unit is used.

• Avoid the use of electronic equipment that produces radio waves including cellular phones,

transceivers, and radio-controlled toys. Use of this equipment inside of a hospital building can

lead to malfunction of the machine.

• To prevent a possible accident, inform and instruct people not to carry or use radio-wave

producing equipment in the hospital building.

Do not change the setting values during treatment if there is no emergency.

• Change setting values, if any, before connection to the patient.

• Before selecting a function, ensure to understand the function thoroughly.

Provide a drain opening in the floor.

• The power cable should not touch the floor to prevent from electric shocks due to a technical

failure and liquid leakages.

• Provide a drain opening near to the unit.

Make sure to read this Manual before starting maintenance and inspection.

• Read and understand this Manual thoroughly before starting maintenance and inspection.

• Exactly follow the described procedures for maintenance and inspection.

• Maintenance and inspection out of a range described in this Manual must be entrusted to

specialists.

Do not choose unnecessarily functions during the treatment.

Do not incline the equipment by more than 5 degrees with something placed on the tank base or

hanger. Doing so may topple over the equipment.

Do not relocate the equipment with something placed on the tank base or hanger.

Do not tilt the unit more than 10 degrees. It can overturn.

Equipment, not permitted to be used together with this machine, may not be connected. The

total electric leakage current from the unit and other equipment together can exceed the

maximum allowable value.

The operation and maintenance not specified by the manufacturer and the application of

unspecified accessories may cause death or injury of the patient. The manufacturer is not

responsible for the patient safety when the unit is operated, maintained, or calibrated by

methods not specified by the manufacturer. Trained and authorized personnel must operate the

unit in accordance with the methods established by the manufacturer.

Check the dialysate parameters with external testing equipment before starting any treatment.

• Verify the actual dialysate concentration by an osmometer, conductivity meter, flame photometer,

etc.

• Check if the displayed concentration level is accurate.

Verify, at the end of the cleaning, that there is no residual chemical or acid present.

• Verify, at the end of the disinfection the presence of chemicals (sodium hypochlorite, citric acid,

peracetic acid, or other chemicals) using a test paper or reagent.

SAFETY PRECAUTIONS-4

CAUTION

Before installing the unit, thoroughly read and understand the installation section of this manual.

• Only trained professionals may install the unit.

• Install the unit in accordance with the installation instructions.

The connection of optional parts should be performed after reading and thoroughly

understanding the corresponding manuals.

• Only trained professionals are allowed to do the connections.

Do not give excessive force or impact to the display or operation panel.

• Do not give forcible force or impact to the display or operation panel during cleaning.

Disinfect and rinse the unit thoroughly before use.

• Disinfection and rinse are necessary when the machine has been out of use for a long term.

• Disinfection and rinse are necessary when the machine has been out of use for a long term to

flush the waste water.

Keep the machine always clean.

• Wipe off blood, dialysate, cleaning solutions carefully.

• Clean and disinfect regularly.

Some panel displays and processes do not accept switch operations. Do not use buttons when

inappropriate.

Use only dialysate concentrate containers with an appropriate label mentioning the composition

of the concentrate. Respect the color code during the connection of the concentrates (red for A

solution, blue for B solution).

Handle used disposables carefully to prevent infecting yourselves and other persons. Used

disposables might be contaminated with viruses (hepatitis, aids, HIV, MRSA, …)

To ensure the performance and safety of this unit, use water, dialysate concentrate, and fluid

replacement with appropriate quality.

With the blood pump of this equipment, a gap (where the blood rolling tube is crashed) between

the roller and the housing is adjustable within a specified range. Depending on the size of the

rolling tube, it may be necessary to ensure a designated amount of blood feed by adjusting this

gap.

CONTENTS-1

CONTENTS

PREFACE

SAFETY PRECAUTIONS

1. APPLICATION ································································································ 1-1

2. CONTRAINDICATION ···················································································· 2-1

3. PRECAUTIONS ······························································································ 3-1

4. SYMBOL FOR SAFETY·················································································· 4-1

5. FLOW CHART

5.1. Fluid and blood lines··············································································· 5-1

5.1.1. Flow chart······················································································· 5-1

5.1.2. List of input components ································································ 5-3

5.1.3. List of output components ······························································ 5-4

5.1.4. List of other components ································································ 5-5

6. DISASSEMBLING AND REPLACEMENT

6.1. Input components ··················································································· 6.1.1-1

6.1.1. Conductivity cell Assy (CD) ···························································· 6.1.1-1

6.1.1.1. A Type·················································································· 6.1.1-1

6.1.1.2. B Type·················································································· 6.1.1-2

6.1.1.3. C Type·················································································· 6.1.1-3

6.1.1.4. D Type·················································································· 6.1.1-4

6.1.1.5. Conductivity cell Assy and Temperature sensor Assy·········· 6.1.1-5

6.1.2. Dialysate pressure sensor Assy (PD)············································· 6.1.2-1

6.1.2.1. TYPE I·················································································· 6.1.2-1

6.1.2.2. TYPE II: A type····································································· 6.1.2-2

6.1.2.3. TYPE II: B type····································································· 6.1.2-3

6.1.3. Blood leak sensor Assy (BLD)························································ 6.1.3-1

6.1.3.1. TYPE I: RK-GR1 ·································································· 6.1.3-1

6.1.3.2. TYPE II: RK-GR2 ································································· 6.1.3-2

6.1.3.3. TYPE II: BLD-01··································································· 6.1.3-3

6.1.4. Pressure SW: AW-3200-63-A (PS) ················································ 6.1.4-1

6.1.5. Temperature sensor Assy (T)························································· 6.1.5-1

6.1.5.1. PT-HST-1000 ······································································· 6.1.5-1

6.1.5.2. PT100-HSTA-900································································· 6.1.5-2

6.1.6. Air bubble detector Assy (BD) ························································ 6.1.6-1

CONTENTS-2

6.2. Output components ················································································ 6.2.1-1

6.2.1. Two way electromagnetic valve: AV-3200-318-SC

(V2 / V3 / V12 / V13 / V14 (V17))··················································· 6.2.1-1

6.2.2. Two way electromagnetic valve (V4 / V11) ···································· 6.2.2-1

6.2.2.1. TYPE I: AV-3202-63-S ······················································· 6.2.2-1

6.2.2.2. TYPE II: SVB-2B ·································································· 6.2.2-2

6.2.2.3. TYPE II: SV2-322-S ····························································· 6.2.2-3

6.2.3. Two way electromagnetic valve (V10)············································ 6.2.3-1

6.2.3.1. A Type: AV-3202-63-SH······················································· 6.2.3-1

6.2.3.2. B Type: SAV-3202-33-SB ···················································· 6.2.3-2

6.2.3.3. C Type: SV2-322-S ······························································ 6.2.3-3

6.2.4. Three way electromagnetic valve:

AV-3302-63-S (V5 / V6 / V7 / V8 / v9) ··········································· 6.2.4-1

6.2.5. Bellowphragm pump: VCP-60 (Vpa / VPb)····································· 6.2.5-1

6.2.5.1. Sensor guide rod: Pin type 1 ················································ 6.2.5-1

6.2.5.2. Sensor guide rod: Plane type ··············································· 6.2.5-2

6.2.5.3. Sensor guide rod: Pin type 2 ················································ 6.2.5-3

6.2.5.4. Sensor guide rod: Pin type 3 ················································ 6.2.5-4

6.2.5.5. Reference for Bellowphragm Pump ····································· 6.2.5-5

6.2.6. Blood pump Assy (BP / BPC) ························································· 6.2.6-1

6.2.6.1. M3 type ················································································ 6.2.6-2

6.2.6.2. M4 type ················································································ 6.2.6-3

6.2.7. Gear pump Assy (P1/P2) ······························································· 6.2.7-1

6.2.7.1. TYPE I: Micro gear pump ····················································· 6.2.7-1

6.2.7.2. TYPE II: Magnet gear pump (Normal Type) ························· 6.2.7-3

6.2.7.3. TYPE II: Magnet gear pump (A Type) ·································· 6.2.7-5

6.2.7.4. Reference for Gear Pump ···················································· 6.2.7-7

6.2.8. Venous clamp Assy (CLV)······························································ 6.2.8-1

6.2.9. Syringe pump Assy (SP) ································································ 6.2.9-1

6.3. Other components ·················································································· 6.3.1-1

6.3.1. Deaeration tank Assy (AS1) ··························································· 6.3.1-1

6.3.1.1. A Type·················································································· 6.3.1-1

6.3.1.2. B Type·················································································· 6.3.1-2

6.3.2. Deaeration tank Assy (AS2) ··························································· 6.3.2-1

6.3.3. Buffer tank W Assy (BTW)······························································ 6.3.3-1

6.3.4. Buffer tank D Assy (BTD1 / BTD2)················································· 6.3.4-1

6.3.5. Check valve (C1/C2) ······································································ 6.3.5-1

6.3.5.1. Dialysate check valve (C1)··················································· 6.3.5-1

6.3.5.2. Bellowphragm check valve (C2)··········································· 6.3.5-2

6.3.6. Filter ······························································································· 6.3.6-1

6.3.6.1. Supply water filter (F) ··························································· 6.3.6-1

6.3.6.2. Coupler line filter (F7)··························································· 6.3.6-2

6.3.7. Flow meter Assy (FM / FS)····························································· 6.3.7-1

CONTENTS-3

6.3.7.1. A Type·················································································· 6.3.7-1

6.3.7.2. B Type·················································································· 6.3.7-2

6.3.7.3. C Type·················································································· 6.3.7-3

6.3.8. Reducing valve Assy (PR)······························································ 6.3.8-1

6.3.8.1. ER0883ZSS8/RW83 ···························································· 6.3.8-1

6.3.8.2. ER0884ZBS8 ······································································· 6.3.8-2

6.3.9. Relief valve (RV1/RV2/RV3/RV4)··················································· 6.3.9-1

6.3.9.1. Relief valve 1 / Relief valve 2 ··············································· 6.3.9-1

6.3.9.2. Relief valve 3········································································ 6.3.9-2

6.3.9.1. Relief valve 4········································································ 6.3.9-3

6.3.10. Sampling port Assy (SL)······························································· 6.3.10-1

6.3.11. Chamber Assy (VCa / VCb)·························································· 6.3.11-1

6.3.11.1. Chamber Assy (Overall) ····················································· 6.3.11-1

6.3.11.2. Chamber Assy (Viscous chamber)····································· 6.3.11-3

6.3.12. Concentrate tank connectors························································ 6.3.12-1

6.3.12.1. A and B concentrates ························································· 6.3.12-1

6.3.12.2. Disinfectant concentrate····················································· 6.3.12-4

6.3.13. Rinse port ··················································································· 6.3.13-1

6.3.13.1. Rinse port No.1 (for A and B concentrates)························ 6.3.13-1

6.3.13.2. Rinse port No.2 (for A and B concentrates)························ 6.3.13-2

6.3.13.3. Rinse port No.3 (for A and B concentrates)························ 6.3.13-3

6.3.13.4. Rinse port (for disinfectant concentrate)····························· 6.3.13-4

6.3.14. Coupler Assy ·············································································· 6.3.14-1

6.3.14.1. A Type················································································ 6.3.14-1

6.3.14.2. B Type················································································ 6.3.14-2

6.3.15. Needle valve (NV1 / NV2) ···························································· 6.3.15-1

6.3.15.1. AM-1200-55A ····································································· 6.3.15-1

6.3.15.2. SAS-08001········································································· 6.3.15-2

6.3.16. Piping parts ················································································· 6.3.16-1

7. CONSTRUCTION OF ELECTRICAL PART

7.1. Components of electrical part ································································· 7.1-1

7.1.1. Components at upper part of electrical part···································· 7.1-1

7.1.2. Component at lower part of electrical part······································ 7.1-1

7.1.3. Placement of electrical part at machine·········································· 7.1-2

7.1.3.1. TYPE I·················································································· 7.1-2

7.1.3.2. TYPE II················································································· 7.1-3

7.1.4. Components at left side in electrical POWER BOX························ 7.1-4

7.1.5. Components at right side in electrical POWER BOX······················ 7.1-5

8. CONNECTION, REPLACEMENT AND ADJUSTMENT

8.1. Operation panel sheet ············································································ 8.1-1

8.2. Operation panel board ············································································ 8.2-1

8.3. LCD module···························································································· 8.3-1

CONTENTS-4

8.4. Bubble sensor board··············································································· 8.4-1

8.4.1. SBY0160 board ·············································································· 8.4-1

8.4.2. SBY0205 board ·············································································· 8.4-2

8.5. Dialysate pressure sensor board ···························································· 8.5-1

8.5.1. TYPE I···························································································· 8.5-1

8.5.2. TYPE II: A Type·············································································· 8.5-3

8.5.3. TYPE II: B Type·············································································· 8.5-4

8.6. Main board······························································································ 8.6-1

8.7. Venous and arterial pressure sensor boards ·········································· 8.7-1

8.8. DSUB board ··························································································· 8.8-1

8.9. Buzzer board: SBY0162 board / SBY0267 board ··································· 8.9-1

8.10. Sub-board····························································································· 8.10-1

8.10.1. SBY0157 board / SBY0163 board················································ 8.10-1

8.10.2. SBY0270 board ············································································ 8.10-5

8.11. DC+5V, ±12V Power supply ································································· 8.11-1

8.11.1. Switching regulator: SWT30-522 / SWT30-522kai ······················· 8.11-1

8.11.2. Switching regulator: LDC30F-1-G / LDC30F-1-Gkai ···················· 8.11-3

8.11.3. DC+5V, ±12V converter board: SBY0254 ···································· 8.11-5

8.12. DC+24V switching regulator ································································· 8.12-1

8.12.1. PLEY24HSZ-C ············································································· 8.12-1

8.12.2. ZWS150PAF-24/J ········································································ 8.12-4

8.12.3. CME150-24 ·················································································· 8.12-6

8.13. Operation panel board, main board, sub-board ···································· 8.13-1

8.14. VR board: SBY0268 board ··································································· 8.14-1

8.15. FUSE ···································································································· 8.15-1

9. MAINTENANCE MODES

9.1. Display···································································································· 9.1-1

9.2. Maintenance modes ··············································································· 9.2-1

9.2.1. ROM before Ver.2.40 ····································································· 9.2-1

9.2.2. ROM after Ver.3.00 ········································································ 9.2-3

9.3. Maintenance mode menu screen···························································· 9.3-1

9.4. Maintenance mode 1 screen ·································································· 9.4-1

9.4.1. ROM before Ver.2.40 ····································································· 9.4-1

9.4.2. ROM after Ver.3.00 ········································································ 9.4-2

9.5. Maintenance mode 2 screen ·································································· 9.5-1

9.6. Maintenance mode 3 screen ·································································· 9.6-1

9.7. Maintenance mode 4 screen ·································································· 9.7-1

9.8. Maintenance mode 5 screen ·································································· 9.8-1

9.8.1. When dialysis mode BC1 or BC2 is set·········································· 9.8-1

9.8.2. When dialysis mode AC is set ························································ 9.8-2

9.9. Maintenance mode 6 screen ·································································· 9.9-1

9.9.1. ROM before Ver.3.70 ····································································· 9.9-2

9.9.2. ROM after Ver.3.84 ········································································ 9.9-4

CONTENTS-5

9.10. Maintenance mode 7 screen ································································ 9.10-1

9.10.1. ROM before Ver.2.40 ··································································· 9.10-2

9.10.2. ROM after Ver.3.00 ······································································ 9.10-3

9.11. Maintenance mode 8 screen ································································ 9.11-1

9.11.1. ROM before Ver.2.40 ··································································· 9.11-2

9.11.2. ROM after Ver.3.00 ······································································ 9.11-3

9.11.2.1. Monitor screen ······································································· 9.11-3

9.11.2.2. Input screen ··········································································· 9.11-3

9.11.2.3. Zero cleared screen······························································· 9.11-3

9.12. Maintenance mode 9 screen ································································ 9.12-1

9.13. Maintenance mode 10 screen ······························································ 9.13-1

10. ADJUSTMENT

10.1. Measurement of chamber capacity

and adjustment of silicone volume······································ 10.1-1

10.1.1. Measurement of chamber capacity ·············································· 10.1-1

10.1.2. Adjustment of silicone oil volume ················································· 10.1-3

10.2. Adjustment of venous and arterial pressure sensors ···························· 10.2-1

10.2.1. Adjustment of venous pressure sensor ········································ 10.2-1

10.2.2. Adjustment of arterial pressure sensor········································· 10.2-2

10.3. Adjustment dialysate pressure sensor ·················································· 10.3-1

10.3.1. TYPE I·························································································· 10.3-1

10.3.2. TYPE II························································································· 10.3-3

10.3.2.1. Adjustment dialysate pressure sensor ··································· 10.3-3

10.3.2.2. Adjustment of PD offset ························································· 10.3-5

10.4. Adjustment of temperature sensor························································ 10.4-1

10.5. Adjustment of pressure SW ·································································· 10.5-1

10.6. Adjustment of blood leak sensor··························································· 10.6-1

10.6.1. TYPE I: RK-GR1 ·········································································· 10.6-1

10.6.2. TYPE II: RK-GR2 ········································································· 10.6-3

10.6.2.1. Zero revision of blood leak detector······································· 10.6-3

10.6.2.2. Check of accuracy of blood leak sensor using pseudo filter ·· 10.6-4

10.6.3. TYPE II: BLD-01··········································································· 10.6-5

10.6.3.1. Zero offset of blood leak sensor············································· 10.6-5

10.6.3.2. Checking through pseudo blood leak filter ····························· 10.6-6

10.6.3.3. Adjustment of blood leak sensor············································ 10.6-7

10.7. Adjustment of reducing valve································································ 10.7-1

10.8. Adjustment of priming end pressure ····················································· 10.8-1

10.9. Adjustment of closed circuit pressure ··················································· 10.9-1

10.10. Adjustment of priming flow rate··························································· 10.10-1

10.10.1. Adjustment by Flow meter·························································· 10.10-1

10.10.2. Adjustment by Discharge Flow Time ·········································· 10.10-2

10.11. Adjustment of bypass flow rate··························································· 10.11-1

10.12. Adjustment of gaps between housing

CONTENTS-6

and rotor rollers of blood pump······································ 10.12-1

10.12.1. Adjustment by water head pressure ··········································· 10.12-1

10.12.2. Adjustment using syringe and manometer ································· 10.12-2

10.13. Adjustment of blood pump flow rate···················································· 10.13-1

10.13.1. In case of you use Standard Rolling Tube (φ8×φ12mm)············ 10.13-1

10.13.2. In case of you use Small Rolling Tube (φ6.35×φ9.75mm) ········· 10.13-2

10.14. Leak test and gap adjustment of clamp ·············································· 10.14-1

10.14.1. Leak test of clamp ······································································ 10.14-1

10.14.2. Gap adjustment of clamp···························································· 10.14-2

10.15. Adjustment of bubble sensor ······························································ 10.15-1

10.15.1. SBY0160 board ········································································ 10.15-1

10.15.2. SBY0205 board ·········································································· 10.15-2

10.16. Adjustment of conductivity and concentration····································· 10.16-1

10.16.1. Selection of dialysis mode to be adjusted··································· 10.16-2

10.16.2. Input of concentration data ························································· 10.16-3

10.16.3. Adjustment of dilution ratio ························································· 10.16-5

10.16.4. Calibration of indicated conductivity and concentration·············· 10.16-8

10.17. Adjustment of contrast ········································································ 10.17-1

10.18. Adjustment of gas purge pressure ······················································ 10.18-1

10.19. Adjustment of flashing volume in concentrate line······························ 10.19-1

10.19.1. Confirmation of flushing volume ················································· 10.19-1

10.19.2. Adjustment of flushing volume···················································· 10.19-2

10.20. Adjustment of priming volume in concentrate line······························· 10.20-1

10.20.1. Confirmation of priming volume·················································· 10.20-1

10.20.2. Adjustment of priming volume ···················································· 10.20-2

10.21. Adjustment of syringe pump infusion flow··········································· 10.21-1

10.22. Adjustment of overload detection on Syringe pump Assy,

when other than Nipro syringe used ··················································· 10.22-1

10.23. Adjustment of conductivity sensor ······················································ 10.23-1

11. DIP SWITCHES

11.1 Operation of dip SW’s············································································ 11.1-1

11.2. Functions of dip SW’s ··········································································· 11.2-1

11.2.1. ROM before Ver.2.40 ··································································· 11.2-1

11.2.2. ROM after Ver.3.00 ······································································ 11.2-2

11.2.3. ROM after Ver.3.93 ······································································ 11.2-3

11.2.4. ROM after Ver.4.41 ······································································ 11.2-4

12. VARIOUS DATA

12.1. Loaded CPU and ROM········································································· 12.1-1

12.2. Wiring in POWER box ·········································································· 12.2-1

12.2.1. Electrical power box ····································································· 12.2-1

12.2.2. A Type·························································································· 12.2-3

12.2.3. B Type·························································································· 12.2-4

CONTENTS-7

12.2.4. C Type·························································································· 12.2-5

12.2.5. D Type·························································································· 12.2-6

12.3. Record sheet of setting value ······························································· 12.3-1

12.3.1. ROM before Ver.2.40 ··································································· 12.3-2

12.3.2. ROM after Ver.3.00 ······································································ 12.3-4

12.3.3. ROM after Ver.3.30 ······································································ 12.3-6

12.3.4. ROM after Ver.3.84 ······································································ 12.3-8

12.3.5. ROM after Ver.4.41 ······································································ 12.3-10

CONTENTS-8

1-1

1. APPLICATION

(a) Single patient dialysis machine, SURDIAL is applied to treatment of patients with acute or

chronic renal failure by dialysis when the application is instructed by doctor.

(b) SURDIAL can be used at both hospital and home.

1-2

2-1

2. CONTRAINDICATION

Any application other than dialysis using SURDIAL is contraindicated.

2-2

Other manuals for SURDIAL

1

Table of contents

Other Nipro Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Handicare

Handicare SystemRoMedic Series Care Instructions

College Park

College Park Guardian Technical instructions

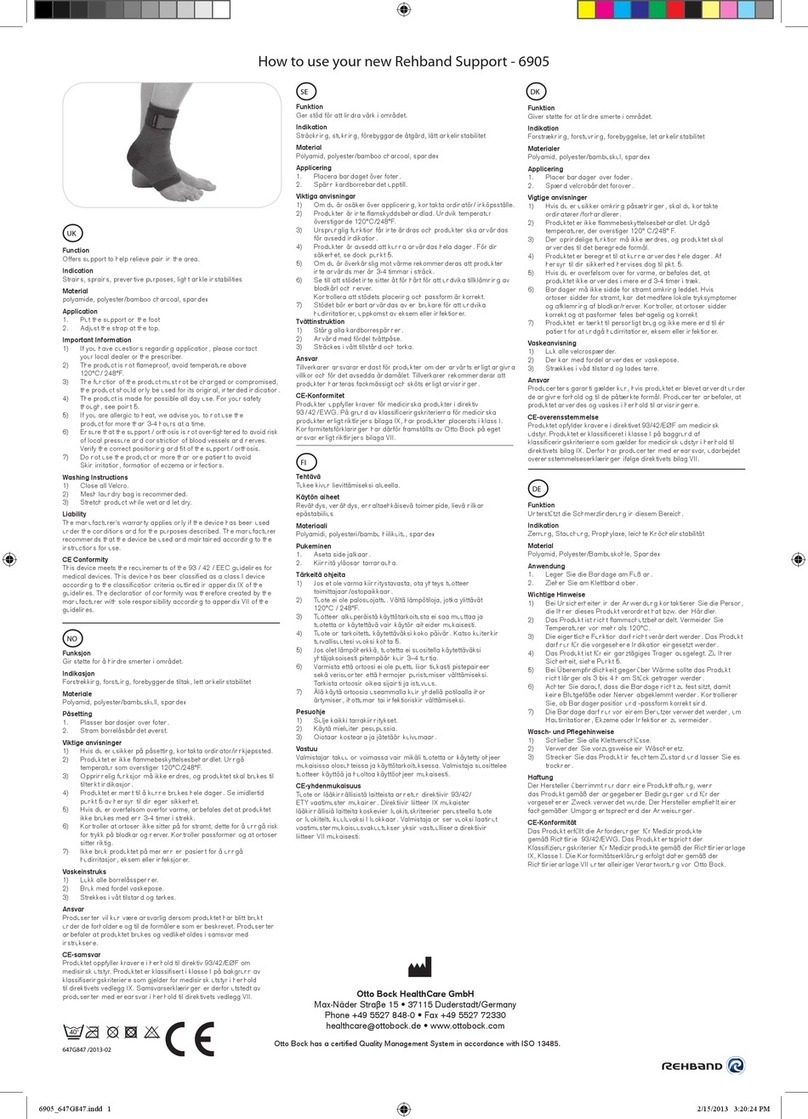

Rehband

Rehband 6905 How to use

GE

GE Lullaby Warmer Maintenance and service manual

Stealth Mobllity

Stealth Mobllity LIGHTNING PUSHCHAIR User & workshop manual

Coxo

Coxo C-SMART-1 Pro user manual