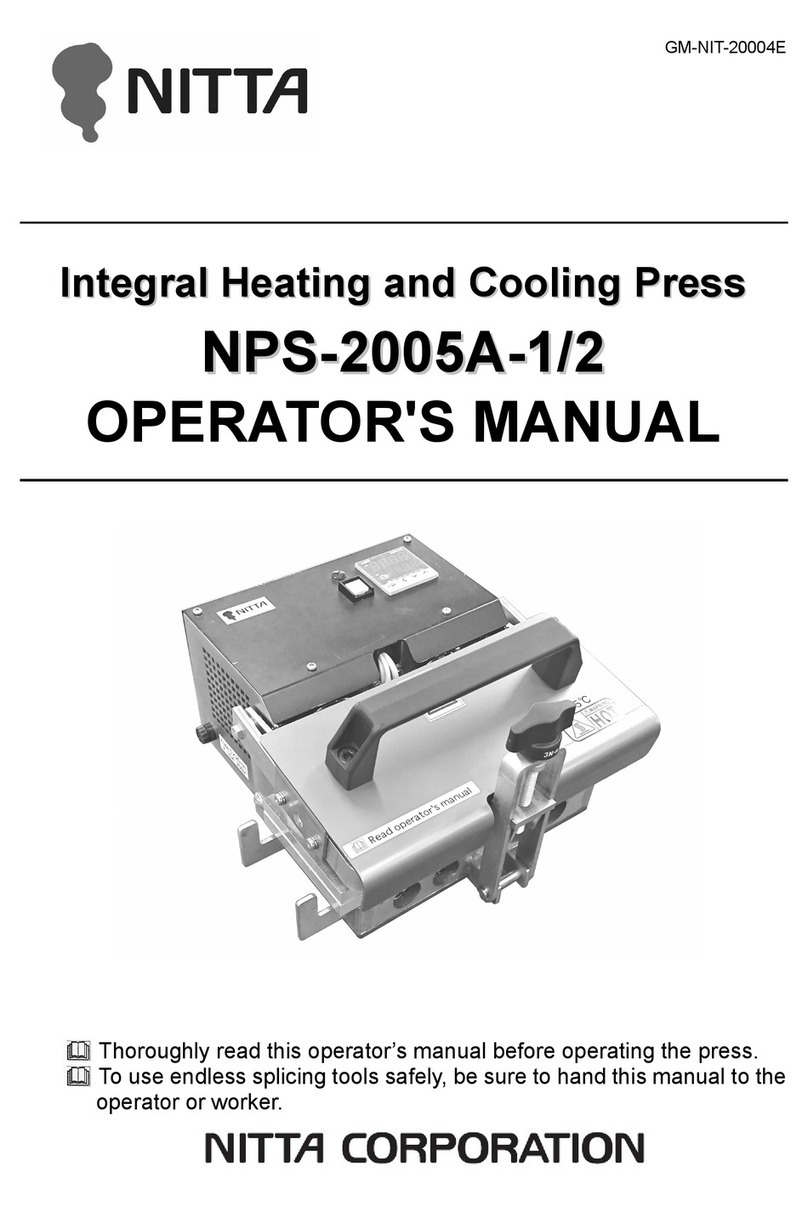

Nitta NittaBeltPoly PI-30 User manual

PM-NIT-15002E

Follow this manual when using NittaBeltPoly Heat Press.

Please pass this manual to NittaBeltPoly Heat Press users for a

safe andtrouble-free operation.

NittaBeltPoly

H

He

ea

at

t

P

Pr

re

es

ss

s

P

PI

I-

-3

30

0

Operation Manual

- 1 -

Contents

1. Safety Precautions ・・・・・・・・・・・・・・・・ 2

2. Confirmation of Product ・・・・・・・・・・・・・・ 5

3. Specifications ・・・・・・・・・・・・・・・・・・ 6

4. Use Environment ・・・・・・・・・・・・・・・・・ 7

5. Storage Environment ・・・・・・・・・・・・・・・ 7

6. Name of Each Part ・・・・・・・・・・・・・・・・ 8

7. How to Operate NittaBeltPoly Heat Press ・・・・・・ 9

8. How to Make Belts Endless ・・・・・・・・・・・・ 10

9. Troubleshooting ・・・・・・・・・・・・・・ 12

10. Inspection ・・・・・・・・・・・・・・・・・・・ 13

11. Warranty and after-sales service ・・・・・・・・・・ 14

- 2 -

1. Safety Precautions

Please go over these safety precautions carefully to secure a correct and

safe operation of the NIttaBeltPoly Heat Press PI-30.

Disregarding instructions marked with this symbol

may lead to death or serious injury.

Disregarding instructions marked with this symbol

may lead to injury or property damage

WARNING

Do not use the Heat Press for any application other than the

intended purpose of making belts endless.

Use for any unintended purpose may cause an unexpected accident.

Failure to do this may cause fire, electric shock or injury.

This machine is not intended for the physical, sensory or

mental handicapped persons use.

They must have the supervision of a person responsible for

their safety, if they use this Heat Press.

Failure to do this may cause fire, electric shock or injury.

Do not allow the child to handle this Heat Press.

Keep this machine in the place where child's hand does not

reach.

Failure to do this may cause fire, electric shock or injury.

A person with experience and skills should always operate,

maintain and inspect the Heat Press.

Handling by an inexperienced person may cause fire, electric shock

or injury.

Do not dismantle or remodel the Heat Press in any event.

Dismantling or remodeling the Heat Press may cause fire,

electric shock or injury.

For repair or inspection, please contact your local distributor or agent

in your area.

In case of an emergency (such as smoke, fire, foul smell),

disconnect the main plug from the socket outlet and contact

Nitta or your local distributor or agent in your area for

inspection.

Failure to disconnect the main plug from the socket outlet may cause

fire or electric shock.

CAUTION

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

- 3 -

1 Safety Precautions- Continued-

Confirm that the power source used is within the designated

specifications of the Heat Press.

Use beyond the designated specifications may cause fire or electric

shock.

Specification Power Source Wattage Rating

For 100V 100V-110V 50/60Hz 70-80W

Connect the main plug correctly to the socket outlet.

The power cable of the press uses an earth connection plug.

Connect the main plug correctly into an earth connection outlet to

prevent electric shock.

Always use anti-heat gloves when handling the Heat Press to

prevent burns.

A label “Hot!” is on the top and bottom plates of the press to warn

against high temperature.

Disconnect the main plug from the socket outlet immediately after

use.

An operator should pay attention so that others do not touch the

press carelessly and get burned before the Heat Press has cooled

down.

It takes about one hours for a heated press (110°C) to cool down to

40°C in the room temperature of 25°C once it has been unplugged.

Do not use the Heat Press on a flammable material.

Use of any other product may cause fire.

Impressed voltage is distributed in the power cable.

To prevent fire, electric shock or damage, please consider the

following.

・ Disconnect the main plug from the socket outlet with your hand.

・ Do not remodel or replace the main plug.

・ Do not place any object on the power cable.

・ Do not fold the power cable.

・ Do not pull or stretch the power cable.

To prevent fire or electric shock, do not use the Heat Press under

the following conditions:

・ Under flammable gas or combustible gas environment

・ Under a corrosive gas environment

・ Under an ambient temperature of 5℃ or below

・ Under an ambient temperature of 30℃ or above

・ Under a high humidity environment. (Humidity surpassing 85%)

・ In places exposing the Heat Press to steam or water drops

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

- 4 -

1 Safety Precautions- Continued-

Use a three-pin earth line as an extension cord.

When an extension cord is required, use an earth-connection type

extension cord to prevent electric shock.

To prevent electric shock, do not operate the Heat Press with

moistened hands.

Do not pour water on the Heat Press and do not get it wet.

Use of a wet press may cause fire or electric shock.

Use a dry cloth for cleaning the Heat Press.

To prevent fire, do not use alcohol, benzine, thinner or

any other inflammable solvent.

Caution

Do not use the Heat Press outdoors.

When using the Heat Press on any equipment, use a safety

catcher for the press so it doesn’t fall or collapse. This will help

prevent fire, electric shock or injury.

This may cause fire or electric shock or injury.

Do not take place on the Heat Press the application of the

adhesive.

This may cause fire or burns.

Before using the Heat Press be sure to inspect the press in

accordance with the procedure described on page 13 to help

prevent fire or electric shock.

Do not use this machine for the endless splicing of belt of other

manufacturers.

Endless splicing may become imperfect if this machine is used for the

endless splicing of belt of other manufacturers.

This may spoil the full functioning and performance of the belt.

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

- 5 -

2. Confirmation of Product

Thank you for choosing our Heat Press PI-30

Check that the product is exactly what you have ordered.

Use of the wrong product may cause fire, electric shock or injury.

2-1)Confirmation of Product

Confirm the following items upon accepting delivery of your order. Contact your

local sales office or distributor in your area if you find any deficiency or defect in

your item.

① Are descriptions on the face plate the same as those of your order item?

Please confirm the model type and the power source specifications.

② Has the product been damaged during transportation?

③ Has a nut or screw slackened?

2-2)How to Read Face Plate

2-3)Serial number

2-4)Accessories

Operation Manual, Cushion rubber, Release sheet, Hanging hook

2-5) Notes for inquiry

When making inquiries, please contact us with both the press model and serial

number.

② Specifications of power source

① Model type

CAUTION

- 6 -

3. Specifications

3-1)Outline of Heat Press

① Heat Press is exclusively designed for making endless NittaBeltPoly belts

② Heat Press is compatible with the following endless specifications:

Joint specifications: skiver endless (Right angle)

Maximum belt width: up to 30mm

Maximum belt thickness: up to 1.5mm

③ Tools required for making skiver endless belts: NITTA Poly Skiver

3-2)Major Specifications of Heat Press

Type PI-30

Specification of

power source 100V

Input power supply

100V~110V

50/60Hz

70-80W

Temperature 110℃ ※

Outer Dimension 88mm wide ×139mm long ×73mm high

Weight 0.7kg

- 7 -

4. Use Environment

Ambient Temperature 5-30 ℃(no condensation)

Ambient Humidity 15~85%RH

Place of Use Indoors (free from dust, water)

Environment No flammable, combustible or corrosive gas;

no steam

In order to prevent fire or electric shock, do not use the Heat

Press under the following conditions:

・ Under flammable gas or combustible gas environment

・ Under a corrosive gas environment

・ Under an ambient temperature of 5℃ or below

・ Under an ambient temperature of 30℃ or above

・ Under a high humidity environment (humidity surpassing 85%)

・ In places exposing the Heat Press to steam or water drops

5. Storage Environment

Ambient Temperature 0-40 ℃ (no condensation)

Ambient Humidity 15~85%RH

Place of Use Indoors (free from dust, water)

Environment No flammable, combustible or corrosive gas;

no steam

The Heat Press which is not in use should be stored subject to the

above conditions.

Wrong or poor storage may cause mechanical disorder to the

press and may cause fire or electric shock.

Before using the Heat Press, perform a prior-to-use inspection

and confirm that the press is working properly.

Any problem found in the prior-to-use inspection should

immediately be notified to your local sales office or distributor in

your area.

WARNING

WARNING

WARNING

- 8 -

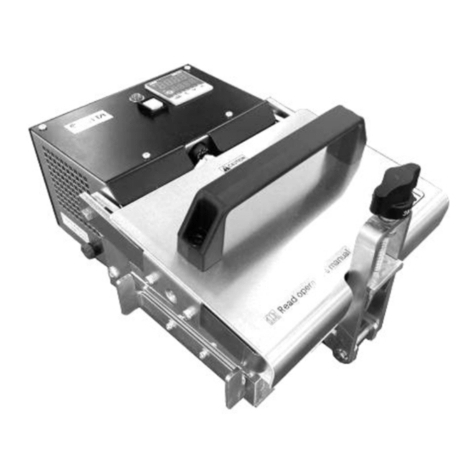

6. Name of Each Part

6-1)Main Press Body

Belt clamp

Heat plate

Surface plate

Handle

P

ower cable

Press

ing

roller

Belt clamp

C

over

F

ace plate

- 9 -

7. How to Operate NittaBeltPoly Heat Press

7-1) Required Tool

a. Heat Press(PI-30)

b. Release sheet(PI-30 contained)

c. Anti-heat Gloves (burn-preventive protection

kits)

The Heat Press body reaches

a high temperature. Always

use anti-heat gloves to

prevent burns.

d. Stopwatch or timer

7-2)Preheating

the closed state of the heating plate of the

press.

Connect the main plug correctly to an

electrical outlet, it is done preheating.

Be sure to connect an earth

line to prevent electric

shock.

It is to a temperature suitable for endless

about 30 minutes.

Do connect or disconnect the power plug

ON / OFF of the press.

Always use anti-heat

gloves when handling the

Heat Press to prevent

burns.

This may cause burns.

An operator should pay

attention so that others do

not touch the Heat Press

carelessly.

This may cause bums or

injury.

WARNING

a

b

c

d

WARNING

WARNING

WARNING

- 10 -

8. How to Make Belts Endless

8-1) Work Procedures

Always use anti-heat

gloves when handling the

Heat Press to prevent

burns.

Apply the adhesive to the belt

※Check the splicing manual method of

applying adhesive.

Do not take place on the

Heat Press the application

of the adhesive.

Is fixed to the center of the heat plate with

upward skive surface of the belt.

Overlaid nylon core to match the belt the

other.

Make sure the joints are not bent at scale,

to be fixed in the belt clamp the belt.

※Overlaid nylon core to match the belt

the other.

※Belt Centering the heat plate.

Pressure is not applied uniformly belt

has not been set in the center of the heat

plate.

WARNING

CAUTION

Center

- 11 -

Overlaid in the order of the release sheet.

Close the top heat plate.

Pressurized horizontal to operate the

handle.

During the heating time, which is described

in splicing manual, hold the state in which

the heated and pressurized.

Releasing the handle and remove the belt.

The belt that was removed from the Heat

press, Use it after cooling for 1 hour or

more.

The Heat Press and belt

are hot, It may cause

burns.

The Heat Press after use,

Unplug the power plug

immediately and until cool

to a safe temperature,

please like other people

not to touch carelessly.

WARNING

WARNING

- 12 -

9. Troubleshooting

Problem Cause Solution

The Heat

Press does not

heat.

The power plug has been

disconnected. Connect the power plug.

Disconnection of the power cord.

Replacement of the

power cord.

※ Please contact us.

Heat press does not heat up.

(Fusing of thermal fuse,

Circuit disconnection)

Replacement of the Heat

Press.

※ Please contact us.

Temperature of the Heat Press

does not reach to 110 ℃.

(Bad thermostat)

Replacement of the Heat

Press.

※ Please contact us.

Heating of the Heat

Press is malfunction.

Temperature of the Heat Press

greatly exceeds 110 ℃.

(Bad thermostat)

Replacement of the Heat

Press.

※Please immediately

discontinue use

※ Please contact us.

Lack of pressure.

Wear of the pressing roller.

Rattling of the pressing roller.

Other parts wear.

Replacement of the Heat

Press.

※ Please contact us.

- 13 -

10. Inspection

Inspection items date/staff

date/staff

date/staff

date/staff

date/staff

The power cable is free of

damage or destruction.

Main plug is free of damage

or destruction.

The Heat Press is free of

damage or destruction.

All screws of the Heat Press

are tightened.

The heating plate is free of

foreign object.

That there is no malfunction

in the handle.

※Make a copy of this page and use it for a prior-to-use inspection

- 14 -

11. Warranty and after-sales service

1. Warranty period

The warranty period is for one full year after the delivery of the order at your

appointed place.

2. Warranty coverage

1) Should the product malfunction due to causes for which our company is

responsible during the abovementioned warranty period, our company will

provide a replacement product or repair the product free of charge. However,

even within the warranty period the following cases shall not be covered by the

warranty. Please note that even if our company provides a replacement product

or repairs the product, the warranty period will be calculated from the initial date

on which the product was delivered.

① Malfunction arising from any inappropriate conditions, environment, handling

and usage which are not described in the Operation Manual and the Endless

Splicing Procedure.

② Malfunction due to a cause arising from something other than the product,

such as your own device.

③ Malfunction arising from any remodeling or repairing by other than our own

company.

④ Malfunction arising from any reasons unpredictable due to our level of

chemistry and technology before shipment.

⑤ Malfunction arising from fire, earthquake, flood, other disasters, voltage error,

or other external factors for which our company bears no responsibility.

2) The warranty coverage is limited to what is stated in 1) above, and the warranty

does not cover secondary damages (equipment damage, opportunity loss, profit

loss) and any other damage incurred by the user as a result of a malfunction of

the product.

3) After the warranty period, if after examination the product is repairable, our

company will repair it upon request.

- 15 -

Oct,2020 Rev9 PI-30-E

Table of contents

Other Nitta Power Tools manuals

Nitta

Nitta PP103 User manual

Nitta

Nitta FP-120G-60 User manual

Nitta

Nitta PolySprint NPS-3050C User manual

Nitta

Nitta PolySprint NPS-0310H1 User manual

Nitta

Nitta NPS-2005A-1 User manual

Nitta

Nitta PolySprint NPS-1205H1 User manual

Nitta

Nitta PP1535-1 User manual

Nitta

Nitta PolySprint NPS-1210A-1 User manual

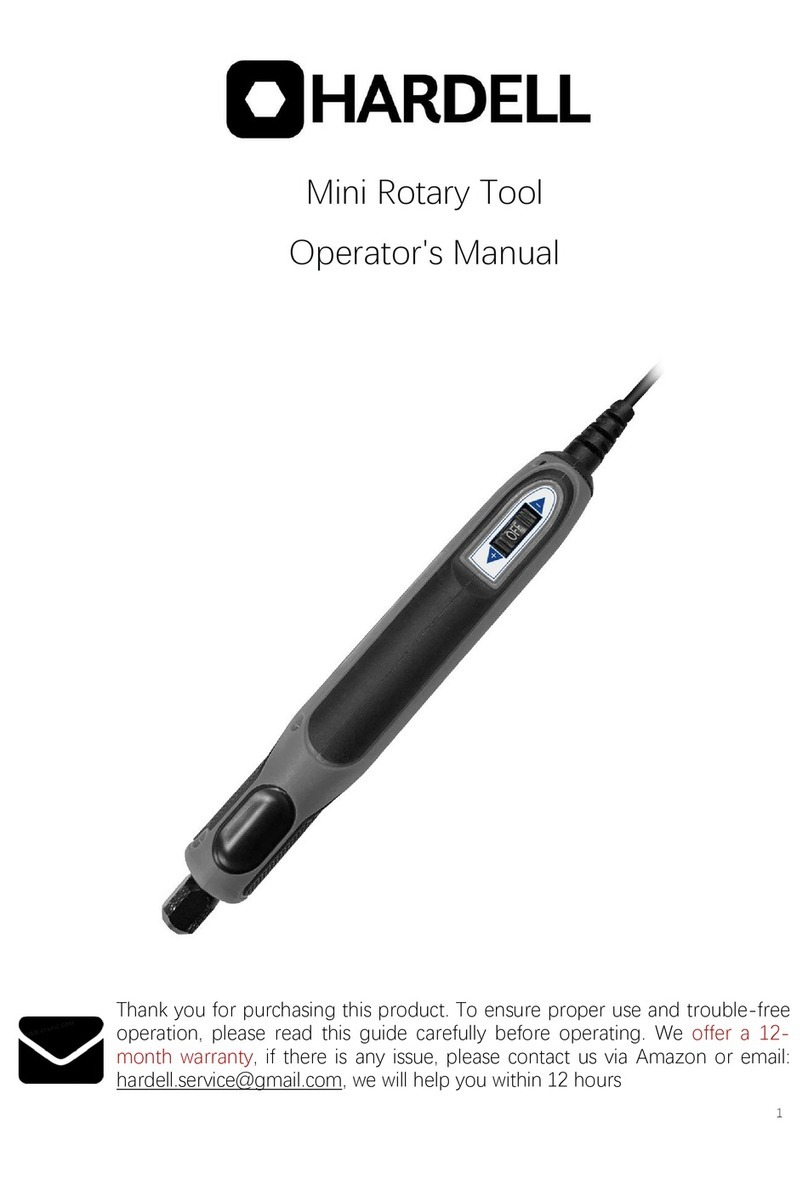

Popular Power Tools manuals by other brands

HARDELL

HARDELL HDRT1810 Operator's manual

Rockler

Rockler 36407 quick start guide

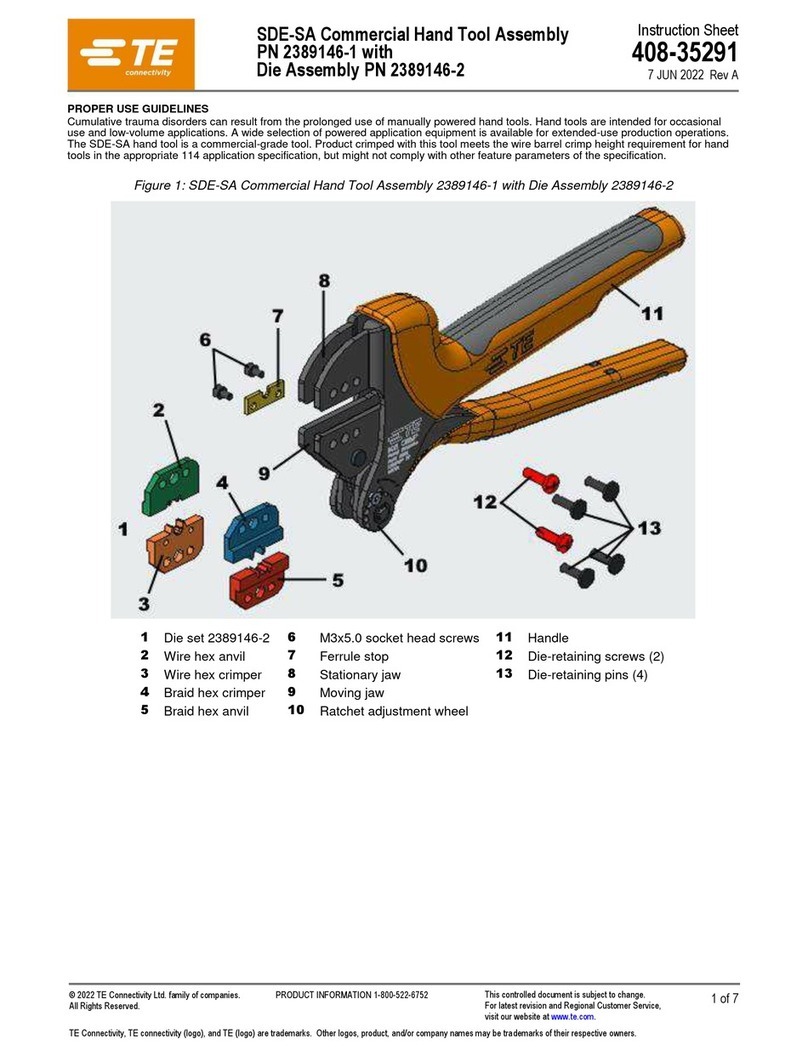

TE Connectivity

TE Connectivity SDE-SA instruction sheet

Hitachi Koki

Hitachi Koki CE 16 Handling instructions

Powermatic

Powermatic PM2500 Series Operating instructions and parts manual

FUXTEC

FUXTEC FX-KSF700 Original user manual