Nitta PolySprint NPS-1210A-1 User manual

PSM-NIT-20003E

PolySprint

I

In

nt

te

eg

gr

ra

al

l

H

He

ea

at

ti

in

ng

g

a

an

nd

d

C

Co

oo

ol

li

in

ng

g

P

Pr

re

es

ss

s

N

NP

PS

S-

-1

12

21

10

0A

A-

-1

1/

/2

2

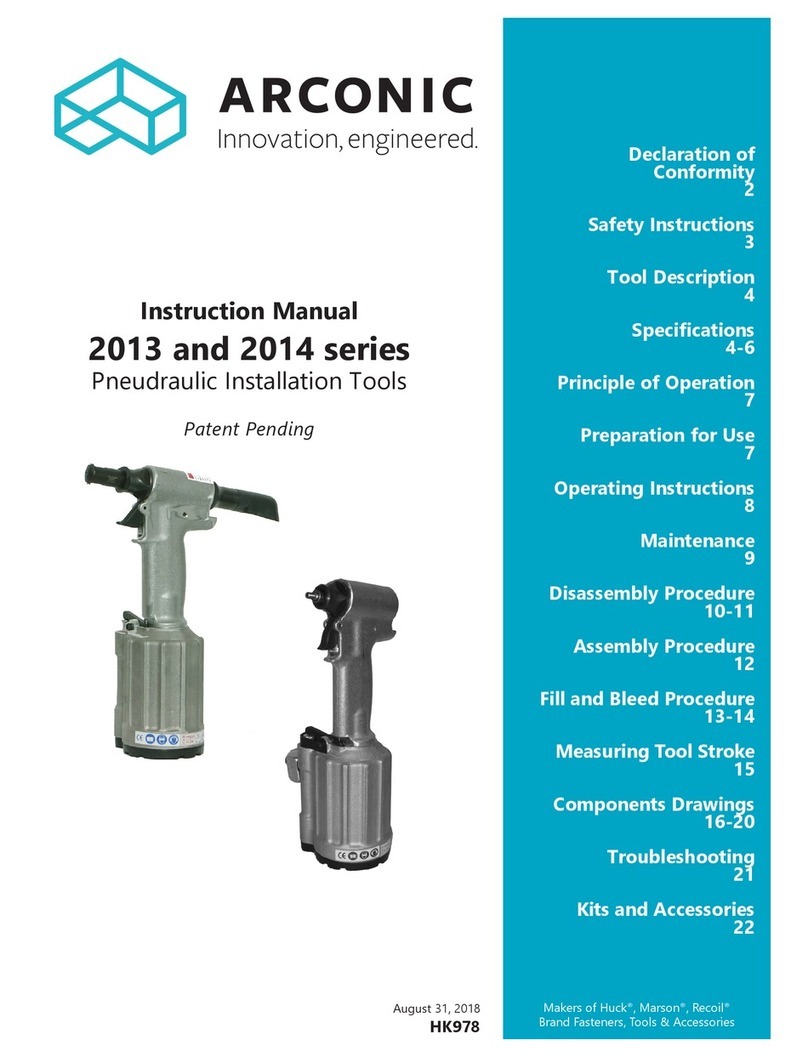

OPERATOR'S MANUAL

Thoroughly read this operator’s manual before operating the press.

To use endless splicing tools safely, be sure to hand this manual to the operator or

worker.

TM

- 1 -

Table of Contents

1. Precautions for the Safety ............ 2

2. Confirmation of Product ................ 6

3. Specification ................................... 7

4. Operation Environment ................. 8

5. Storage Environment ..................... 8

6. Name of each parts ........................ 9

7. Operation Procedure ................... 11

8. Endless Splicing Procedure ....... 13

9. Troubleshooting ........................... 17

10. Inspection ..................................... 18

11. Maintenance ................................. 19

12. Warranty and after-sales service . 20

- 2 -

1. Precautions for the Safety

We would like to thank you for having purchased our Integral Heating and Cooling Press

NPS-1210A-1/2.

Thoroughly read this manual, especially the chapter of Precautions for the Safety, to use this

machine safely.

This indicates a hazardous situation which, if improperly handled,

will result in death or serious injury.

This indicates a potentially hazardous situation which, if

improperly handled, will result in minor injury or property

damage.

WARNING

Do not use this machine for any use other than belt endless splicing.

Any use not intended for the prescribed purpose may invite an unexpected

accident.

Improper use may possibly spoil the safety protection function of the product.

This machine is not intended for the physical, sensory or mental

handicapped persons use. They must have the supervision of a person

responsible for their safety, if they use this machine.

Failure to do this may cause fire, electric shock or injury.

Do not allow the child to handle this machine. Keep this machine in the

place where child's hand does not reach.

Failure to do this may cause fire, electric shock or injury.

A person with technical knowledge and skills should always operate,

maintain and inspect this machine.

Handling by a person not having technical knowledge may cause fire, electric

shock or injury.

Strictly avoid disassembling or remodeling this machine.

Disassembling or remodeling this machine may cause fire or electric shock.

When repair or check is required, please contact your local distributor, agent in

your area or our company.

In the event of trouble (smoke, fire or nasty smell, etc.), please

immediately disconnect the power plug and contact your local distributor,

agent in you area or our company for inspection or repair.

Failure to do this may cause fire or electric shock.

When not using or carrying this machine, be sure to set the hook and

turn the rotary handle until it slips to securely clamp the heat plate.

Failure to do this may cause injury.

WARNING

CAUTION

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

- 3 -

Confirm that the power supply to be used is within the designated of

specification for this machine.

Failure to do this may cause fire or electric shock.

Avoid using the press in the following environment.

Failure to do this may cause fire or electric shock.

In the atmosphere of inflammable or ignitable gas

In the atmosphere of corrosive gas

In the ambient temperature of 5C or below

In the ambient temperature of 40C or above

In the atmosphere of high humidity (environment where humidity exceeds

85%)

In the environment subject to wetting by steam, water drop or dew

condensation, etc.

Be sure to wear heat-resistant gloves when operating this press.

Failure to do this may cause burn.

When operating this press, avoid touching the heat plate area even if

wearing heat-resistant gloves.

Press heat plates get heated to the preset temperature while being heated.

Failure to do this may cause burn, even if wearing heat-resistant gloves.

Avoid operating the press at the place close to combustible material.

Failure to do this may cause fire.

Always use the pre-setter of our product.

Failure to do this may cause fire or electric shock.

Use of the pre-setter made by other product may possibly spoil the safety

protection function of the product.

Use a dry cloth for cleaning this machine. Strictly avoid using alcohol,

benzene, thinner or other inflammable solvents.

Using inflammable solvents may cause fire.

Impressed voltage is directly applied to the power cable. Observe the

following precautions not to damage the cable.

Failure to do this may cause fire or electric shock.

Disconnect the power plug by hand.

Avoid pulling the cable to disconnect the power plug.

Avoid remodeling the power plug or replacing the plug with other

manufacturers.

Avoid placing a thing on the power cable.

Avoid bending the power cable.

Take care to prevent the power cable from touching the heat plate of the

press.

Connect the power plug to the socket correctly.

Failure to do this may cause electric shock.

The power cable of this machine uses an earth connection plug. Connect the

power plug correctly into an earth connection socket.

Model Power supply

NPS-1210A-1 100 - 120V 50 / 60Hz

NPS-1210A-2 200 - 240V 50 / 60Hz

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

- 4 -

Use a conversion plug when the plug shape does not match the socket.

Failure to do this may cause electric shock.

The plug shape of the attached power cable is as follows. The conversion

plug is not attached. When the conversion plug is necessary, the user must

prepare it yourself.

Never handle this machine or the plug, cable, etc. with your hands

wetting.

Failure to do this may cause electric shock.

Never use this machine if wetting.

Failure to do this may cause electric shock or fire.

Model Plug type Plug illustration

NPS-1210A-1 A Type

NPS-1210A-2 CEE7 (S Type)

WARNING

WARNING

WARNING

- 5 -

CAUTION

Exercise care not to pinch your hands between the top cover and control

box or the upper and lower heat plates.

Failure to do this may cause injury.

Avoid inserting your hands into the opening (part with a wire net) on the

front face of the press.

Failure to do this may cause burn.

Avoid using this machine outdoors.

This product is not intended for the use outdoors.

Avoid dropping this machine or giving a strong shock.

Failure to do this may cause fire or electric shock.

Take a measure to prevent this machine from dropping or falling, or do

not install or operate the press at an unstable place.

Failure to do this may cause injury, fire or electric shock.

Carry out the inspection described on page 18 of this manual before

operating this machine.

Failure to do this may cause fire or electric shock.

Do not use this machine for the endless splicing of belt of other

manufacturers.

Endless splicing may become imperfect if this machine is used for the endless

splicing of belt of other manufacturers.

This may spoil the full functioning and performance of the belt.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

- 6 -

2. Confirmation of Product

Before operating the press, check that the product is exactly what you

have ordered. Using this product other than those specified in this

manual may cause fire, electric shock, injury or burn.

2-1) Confirmation of Product

On opening the package, confirm the following points.

1) Are descriptions on the nameplate the same as those of your order item?

Confirm the model and power supply specification.

2) Aren't there any breakage or lack?

The packages contain this manual, the press and power cable.

3) Has screw and nut loosened?

We make assurance doubly sure on the inspection and shipment of products. In the event of

any defect or failure, if any, please contact your local distributor, agent in your area or our

company.

2-2) Confirmation of the nameplate

MODEL: Press model

INPUT: Input power supply specification and power consumption

S/N: Serial number

2-3) Press model

Final numbers 1 and 2 of the model indicate the specification of input power supply.

Number 1 indicates the AC100 - 120V specification, and 2 the AC200 - 240V specification.

2-4) Notes for inquiry

When making inquiry, please contact us together with the press model and serial number.

CAUTION

- 7 -

3. Specification

3-1) Outline of the press

(1) This machine is the press intended for finger-endless splicing of the PolySprintTM belt of

our product, and composed of the press mechanism with the turning of rotary handle,

press body equipped with electric heaters and cooling fans, and control box to regulate

heater temperature and heating and cooling times.

(2) This machine is applicable with the following belt endless splicing specifications.

Joint specification : Finger shape: 120 mm long 10 mm pitch

70 mm long 10 mm pitch

Maximum belt width : 100 mm or less

Maximum belt thickness : 6 mm or less

(3) Finger-endless splicing requires the finger puncher and pre-setter* of another-sales.

* The pre-setter is required for each width belt that is to be made endless-spliced.

3-2) Main specifications of the Press

Model NPS-1210A-1 NPS-1210A-2

Input power supply

100 - 120V 200 - 240V

50 / 60Hz 50 / 60Hz

800 - 1200W 800 - 1200W

Fuse 5.2 20mm 10A, 250V*

Preset temperature

45 - 200C**

Outer dimension

With the press closed: 240 mm wide 332 mm long 180 mm

high

With the press opened: 240 mm wide 468 mm long 301 mm

high

Weight 9.2 kg

* When replacing the fuse, use the article of the specification shown above.

** Cannot set outside the range of the preset temperature (44C or lower, 201C or

higher).

This machine has been set to end cooling at 45C of temperature. Hence setting

the temperature to around 45C may cause this machine to go standby without

operating the cooling fan.

- 8 -

4. Operation Environment

Ambient temperature 5 – 40C (no dew condensation)

Ambient humidity 15 – 85%R.H.

Working place Indoor (place without dust and water)

Atmosphere No inflammable, combustible or corrosive gas and steam

Avoid using this machine in the following environment.

Failure to do this may cause fire or electric shock.

In the environment of inflammable or combustible gas

In the environment of corrosive gas

In the ambient temperature of 5C or below

In the ambient temperature of 40C or above

In the environment of high humidity (humidity exceeds 85%)

In the environment of wetting by steam, water drop or dew condensation,

etc.

5. Storage Environment

Ambient temperature 5 - 40C (no dew condensation)

Ambient humidity 15 - 85%R.H.

Working place Indoor (place without dust and water)

Atmosphere No inflammable, combustible or corrosive gas and steam

When not in use, store this machine under the above conditions.

Poor storage condition may cause mechanical disorder this machine and

may cause electric shock or fire.

When not using or carrying the machine, be sure to set the hook and turn

the rotary handle until it slips.

Insufficient clamping may cause injury.

Before operating the machine, be sure to conduct the prior-to-use

inspection and confirm the normal performance.

In the event any abnormality is found in the prior-to-use check, please

immediately contact your local distributor, agent in your area or our

company.

WARNING

WARNING

WARNING

WARNING

- 9 -

6. Name of each Part

6-1) Front view of the press

6-2) Rear view of the press

WARNING label

Power cable inlet

Nameplate

Temperature controller

Torque limiter ASSY

Fuse box

Upper heat plate

Lower heat plate

Start switch

Pilot lamp

Pre-setter guide

Hook

Fuse nameplate

Top cover

- 10 -

6-3) Temperature controller

Present temperature display

Preset temperature display

Setting buttons

Display change button

- 11 -

7. Operation Procedure

7-1) Power ON

Connect the power plug to the socket correctly.

The power is supplied to the temperature controller. The controller indicates the present

temperature (upper display) and preset temperature (lower display).

Be sure to connect an earth line.

7-2) Temperature setting (Temperature controller)

1) Check that the pilot lamp is off (no heating or cooling).

2) Push the para display change button three times to indicate “SP-1” on the present

temperature display. At this time, the preset temperature display indicates the preset

temperature.

* The preset temperature before shipping is 190C.

3) Push the (up) button to raise the preset temperature or push the (down) button to

lower. Push the button once and the flickering figure increase or decrease 1C each

time.

Pushing the (side) button shifts the figure of temperature.

4) The figure of the preset temperature display is flickering when the figure of the

temperature is adjusting.

The preset temperature will be fixed when no pushing is made for 2 sec or more.

5) Push the para display change button two times to return the present temperature

display to the original state.

7-3) Hold time setting (Temperature controller)

1) Check that the pilot lamp is off (no heating or cooling).

2) Push the para display change button four times to indicate “E1.on” on the present

temperature display. At this time, the preset temperature display indicates the hold time

(in sec).

* The hold time before shipping is 60 sec.

3) Push the (up) button to increase the time or push the (down) button to decrease.

Push the button once and the flickering figure increase or decrease 1 sec each time.

Pushing the (side) button shift the figure of hold time setting.

4) The figure of the hold time display is flickering when the figure of the hold time is

adjusting.

The hold time setting will be fixed when no pushing is made for 2 sec or more.

5) Push the para display change button once to return the present temperature display to

the original state.

The indicator of temperature returns to the preset temperature.

Although changing the preset temperature and hold time is possible also

during heating or cooling, heating or cooling may become incorrect.

Hence avoid changing the setting during heating or cooling since it may

cause incorrect endless splicing.

WARNING

CAUTION

- 12 -

7-4) Operation

1) To start operation, push the start switch for 0.5 sec or more.

2) On starting of operation, the pilot lamp lights and the heating of upper and lower heat

plates start.

3) The machine operates in the sequence of; heating to the preset temperature,

temperature holding (period previously set) and cooling. On completion of temperature

holding, the pilot lamp goes off, and the machine operate the cooling fan until present

temperature goes below 45C.

4) When present temperature goes below 45C, the cooling fan stops and the machine

become a standby.

Be sure to wear heat-resistant gloves when operating the press.

Failure to do this may cause burn.

An operator should not leave the machine in use. Take a measure to

prevent other people from touching this machine unexpectedly.

Failure to do this may cause burn on other people.

7-5) Discontinue on the way

Disconnect the plug if it becomes necessary to discontinue the machine in operation.

* Even if the plug is disconnected in operation, preset data of preset temperature and

hold time are maintained.

The machine when discontinued on the way is kept at high temperature.

Be sure to wear heat-resistant gloves when handling the machine.

Failure to do this may cause burn.

The operator should take a measure to prevent other people from

touching this machine unexpectedly, until the machine temperature

lowers near to room temperature (about two hours).

Failure to do this may cause burn on other people.

When the machine is discontinued on the way in making belt endless

splicing, do not use the belt.

Endless splicing may become imperfect possibly spoiling the full functioning

and performance of the belt.

WARNING

WARNING

WARNING

WARNING

CAUTION

- 13 -

8. Endless Splicing Procedure

8-1) Required Tool

Figure/Photo Description

Fig. a Integral Heating and Cooling Press

[NPS-1210A-1/2]

Fig. b Heat resistant gloves (burn-preventive

protection kits)

This item is not contained in the product

package. The user must prepare

gloves yourself.

Fig. c Pre-setter

This item is not contained in the product

package.

The pre-setter is required for each width

belt.

This machine reaches a

high temperature. Be

sure to prepare

heat-resistant gloves

and wear it.

Failure to do this may

cause burn.

8-2) Belt setting

Figure/Photo Description

Fig. d

Fig. e

1) Set both ends of the belt punched into finger

shape beforehand on the lower pre-setter as

shown in Fig. d.

* Exercise care not to twisting on the way

of belt.

* Confirm the front side and the back side

of belt before setting. Refer to the

attached endless condition table.

Always use the

pre-setter of our

product.

Use of any other product

possibly results in an

improper endless joint

and my cause fire.

2) Set the belt by mating finger joints leaving

no gap so that the joint part is located within

marking lines on the pre-setter as shown in

Fig. e.

Fig. a Fig. b

Fig. c

WARNING

WARNING

- 14 -

Figure/Photo Description

Fig. f

Silicone sheet (Both sides can be used.)

Presetter upper half

Fig. g

3) Set the silicone sheet on the belt as shown

in Fig. f.

* Remove any dust or foreign object on the

silicon sheet before operation.

* Change the sheet if deteriorated,

scratched or torn.

4) Place the upper pre-setter over the silicone

sheet as shown in Fig. g.

* The upper pre-setter has also marking

lines. Place the upper pre-setter over

the lower one while mating the marking

lines.

8-3) Preparation of press

Figure/Photo Description

Temperature controller

Start switch (Do not touch now.)

Fig. h

1) Connect the power plug to the socket.

Be sure to connect an

earth line. Failure to do

this may cause electric

shock.

2) Set the preset temperature and hold time on

the temperature controller according to

sections 7-2) Temperature setting and 7-3)

Hold time setting on page 11.

* Preset temperature and hold time

differ by belt widths. Set them by

referring to the attached endless

condition table.

* Avoid touching the start switch before

setting the belt and then clamping the

hook.

WARNING

- 15 -

8-4) Endless splicing

Figure/Photo Description

Presetter guide

Fig. i

Start switch

Torque limiter

Fig. j

This machine reaches a

high temperature in

operation. Wear

heat-resistant gloves

when carrying out the

following works.

1) Place the pre-setter prepared as described

in section 8-2) Belt setting on page 12,

between pre-setter guides as shown in Fig.

i.

* Place the pre-setter at the center as

much as possible.

* When placing, be careful not to pull out

the belt from the pre-setter.

2) Gradually close the top cover so that the

upper plate is positioned in parallel with the

pre-setter.

* Quick closing the top cover may cause

the pre-setter to shift its position or the

belt to come off the pre-setter.

3) Set the hook and turn the rotary handle until

it slips as shown in Fig. j.

* Excessive turning will cause the handle

to slip in removing also, disturbing easy

removing.

4) Push the start switch to start endless

splicing.

* It takes about 60 min to finish one cycle

of operation (heating, temperature

holding and cooling) with the presetting

before shipping at 23C of environmental

temperature.

* The required time changes according to

ambient environmental temperature or

the setting of preset temperature or hold

time of the press.

5) On completion of temperature holding, the

pilot lamp goes off and operate the cooling

fan. Check that the cooling fan has

stopped after cooling completion before

opening the top cover.

6) Take out the pre-setter and remove the

upper one, silicone sheet and belt in order.

* Use the belt after it has cooled down to

room temperature.

WARNING

- 16 -

Figure/Photo Description

Torque limiter

Hook

Fig. k

7) To continue endless splicing, prepare the

pre-setter by following the procedure of

section 8-2) Belt setting and then repeat the

procedure of section 8-4) Endless splicing.

Be sure to wear

heat-resistant gloves

when operating the

press.

8) To end operation, check that cooling is

completed. Then set the hook and turn the

rotary handle to lock before disconnecting

the power plug as shown in Fig. k.

Securely clamp the hook

and rotary handle.

Insufficient clamping

may cause injury.

WARNING

WARNING

- 17 -

9. Troubleshooting

Abnormal

phenomenon Cause Solution

No display on the

temperature controller

The power plug has been

disconnected. Connect the power plug.

The fuse has blown out. Replace the fuse.

The power is supplied to

the socket.

Yes

Failure of the temperature controller or

disconnection of power cable or internal

wiring is suspected.

* Please contact your local distributor,

agent in your area or our company.

No

Supply the power to the socket.

The temperature

controller gives a

display starting with

AL.

(AL01 - AL99)

Defective data of temperature

controller

Disconnect the power plug once and connect

it again.

* If the alarm display does not disappear,

failure on the temperature controller is

suspected.

* Please contact your local distributor,

agent in your area or our company.

Temperature and hold

time cannot be set.

Setting change is not possible

for 6 sec right after power ON.

Wait 6 sec or more to make a setting.

The para and other buttons

is pushed right after the preset

value was changed.

To fix the preset value, avoid push the button

for 2 sec or more.

Other than the above.

Failure of the temperature

controller

If setting is not possible even by the above

controlling, failure on the temperature

controller is suspected.

* Please contact your local distributor,

agent in your area or our company.

Can not be heated to

the set temperature.

The power supply is not

same as the specification.

Yes

Impress the suitable power supply.

No

Failure of the temperature controller or

disconnection of internal wiring is suspected.

* Please contact your local distributor,

agent in your area or our company.

The cooling fan does

not operate.

Preset temperature has

been set to around 45 C.

Yes

This machine has been set to end cooling at

45 C of temperature. Setting the

temperature to around 45 C may cause the

cooling fan to operate incorrectly.

Set the preset temperature higher.

No

Failure of the cooling fan or disconnection of

internal wiring is suspected.

* Please contact your local distributor,

agent in your area or our company.

The torque limiter

slips and cannot be

loosened.

The torque limiter was turned

excessively.

Lightly hit the handle from the rear to the

front with the plastic hammer while taking

care not to give a strong shock.

* Throttling force is sufficient when the

rotary handle begins to slip.

- 18 -

10. Inspection

Check item Date/check

Date/check

Date/check

Date/check

Date/check

The power cable have no

flaw.

The temperature controller

is not damaged.

There is no screw or part

missing.

The machine body is not

damaged.

Heat plates have no resin

or foreign matter adhered.

The pre-setter have no

flaw.

The pre-setter have no

resin or foreign matter

adhered.

The hook or torque limiter

have no distortion.

* Please make copies of this page and use them for daily check before use.

- 19 -

11. Maintenance

Applying grease to the pressure parts

Lightly apply the grease periodically to the point shown below ① through ④.

This will deliver a correct pressure. However please do not apply excessively.

① screw

② boss of the screw

③ boss of torque limiter

④ sliding part of metal plate

④

①

②

③

This manual suits for next models

1

Table of contents

Other Nitta Power Tools manuals