Nittan EVA-DIP-SCI User manual

DW1401989 Rev.K2

Dec 18, 2019

1

Instruction Manual

EVA-DIP-SCI Dual Input Module

Before Installation

Please read these instructions carefully and keep for future reference.

The information in this document is subject to change without notice. For

updates please refer to our website.

Note :Follow the requirements for the installation of the product in

accordance with the Specifications. Otherwise it may cause malfunction.

Note :Do not install the product in any location where oil, dust, iron

powder, chemicals, or hydrogen sulphide may occur or affect the product. It

may cause malfunction.

This package contains the following items:

Main unit ……………………………………………………………………1

Outer cover EVA ……………………………………………………………1

Instruction Manual …………………………………………………………1

Tapping screw ………………………………………………………………2

Pan head screw ……………………………………………………………2

EOL register (RE-10k) ………………………………………………… 2

General Description

EVA-DIP-SCI Dual Input Module with Short Circuit Isolator is intended

for use in addressable two wire systems. The module monitors and

transmits the status (normal, open, short, or active) of devices equipped

with NC/NO dry contacts to a control panel. The initiating device circuit

(IDC) can be wired on Class A or Class B.

Note: Any conventional detector cannot be connected with the module.

General Operation

Normal standby condition: The module receives polling from the control

panel at the regular interval. Polling LED (green) flashes.

Active condition: When an external input is activated, Input LED (red)

illuminates, and the module communicates to the control panel the active

status.

Trouble condition: If an overcurrent occurs because SLC (Signaling Line

Circuit) is shorted, SCI LED (yellow) illuminates, and the module

communicates to the control panel the short status. The module also

communicates to the control panel the open/short status of IDC, depending

on the Subtype Setting described below.

SCI (Short Circuit Isolator) Function

The module has a built-in short circuit isolator. SCI circuit prevents entire

loop failure in the event of a short between L+ and L- on the loop. If a short

is detected between L+ and L-, the yellow LED indicator is illuminated.

The line between Lin- and Lout- is disconnected automatically to isolate

the short circuit, and short circuit status is communicated to the control

panel. Upon removal of the short condition, the module will automatically

connect between Lin- and Lout- to restore the entire loop to the normal

standby status.

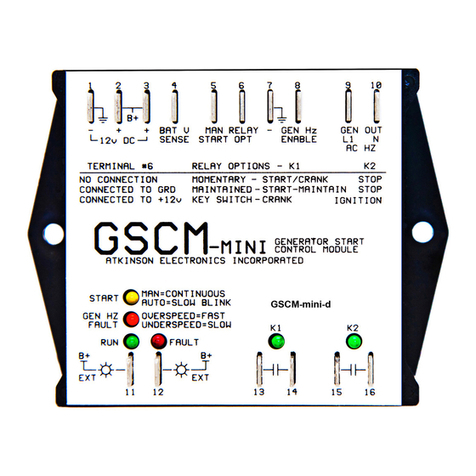

Figure 1

Figure 2

NITTAN COMPANY, LIMITED

1-54-5 SASAZUKA, SHIBUYA-KU, TOKYO 151-8535, JAPAN

http://www.nittan.com

Polling LED (GREEN)

Input LED (RED)

SCI LED (YELLOW)

Address Setting Port

mm(in)

Make sure to turn the power off before commencing any wiring work.

Otherwise it may cause electric shock or damage to equipment.

CAUTION

!

Do not use the products outside the rated power supply voltage range

specified in the Specifications. It may cause a fire or damage to

equipment.

CAUTION

!

Do not disassemble, repair, or modify the products. It may cause a fire

or electric shock.

CAUTION

!

DW1401989 Rev.K2

Dec 18, 2019

2

Compatibility Requirement

To ensure proper operation, the module shall be connected to UL listed

control panel NFU-7000 series.

Before Installing

Disconnect power to the control panel before installing the module. If the

module is installed in an existing operational system, inform the operators

and local authorities that the system will be temporarily out of service.

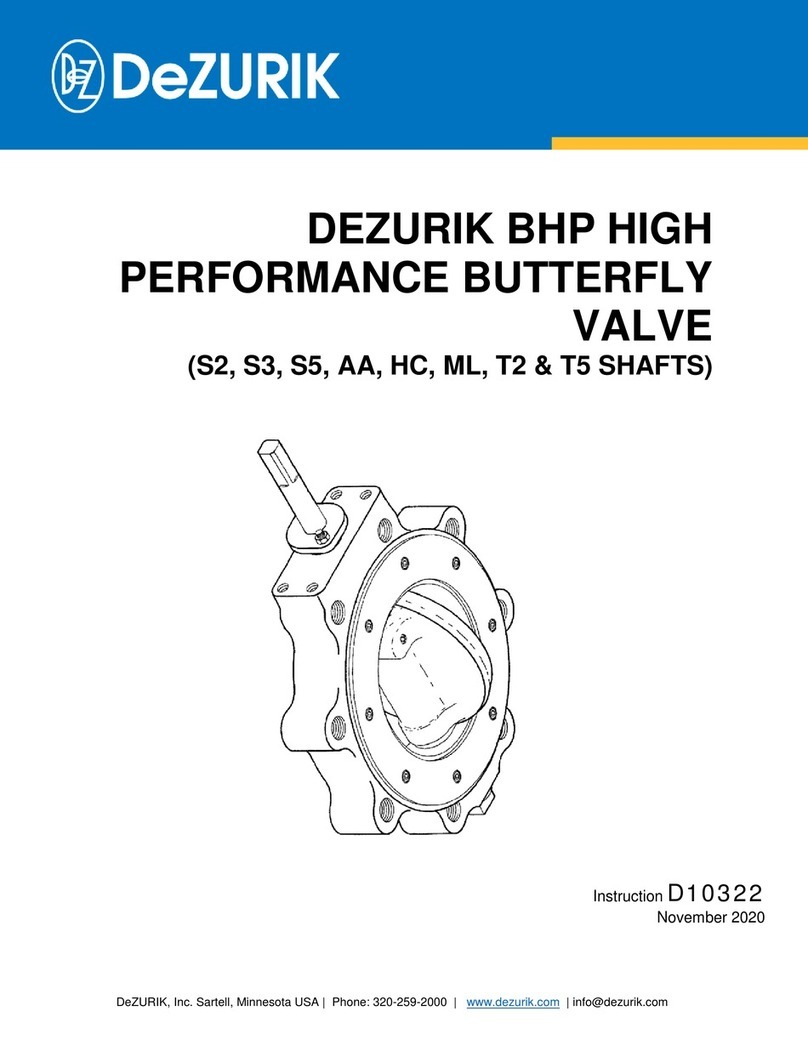

Mounting

Mount the module directly to 4’’ square electrical box (UL Listed).

Secure the module to the electrical box, as shown in Figure 3.

Main unit

Outer cover EVA

Electrical box

Tapping screw

Pan head screw

Figure 3

Setting

・Address Setting

Use EVA-AD2 Programmer for setting the address of the module prior to

installation. EVA-DIP-SCI has an address given at random from factory.

Connect the Programmer with the address setting port to change the

address to any of 1-254 (dec), with reference to the instruction manual of

EVA-AD2 Programmer. The address can be set regardless of whether

power supply from the control panel is turned on or off. During setting

address, the module does not respond to the control panel.

Set the address of module according to Job data.

・Subtype Setting

Set the subtype depending on the wiring configuration as below. The

subtype is to be set through the Configurator for the control panel.

Sub

Type

Input

Method

Open

-circuit

Detection

Short

-circuit

Detection

Class

Interrupt

1

Normally

Open

Yes

No

Class B

Disabled

2

Enabled

3

Class A

Disabled

4

Enabled

5

Normally

Close

No

Yes

Class B

Disabled

6

Enabled

7

Normally

Open

Yes

Yes

Class B

Disabled

8

Enabled

9

Class A

Disabled

10

Enabled

When interrupt is enabled, it allows a high priority communication to the

control panel. The consumption current increases with this setting.

Note : Applicable subtype setting differs depending on control panels.

Subtype 1 to 10 can be used with the control panel complying with UL864

9th edition.

Subtype 7 to 10 can be used with the control panel complying with UL864

10th edition.

Please contact Nittan customer service for any required details.

Wiring

All wiring must conform to applicable local codes, ordinances, and

regulations.

Install module wiring in accordance with the appropriate wiring diagrams.

Use cable AWG12-22 for wiring. Do not connect different gauge cables

at one terminal in order to prevent loosening. Use a fork terminal for

crimping two cables.

CAUTION

!

Do not connect cables in reverse polarity. Failure to connect the polarity

correctly could result in damage to the module and/or other equipment.

CAUTION

!

Note: All wiring is power-limited and supervised.

DW1401989 Rev.K2

Dec 18, 2019

3

Class B (Short circuit detection is not available)

EOL (10k ohm) is connected between A+ (B+ )and A- (B-)in

EVA-DIP-SCI.

Dry contact switches(input switches)are OFF.

Figure 4

Class A (Short circuit detection is not available)

It is a status that dry contact switches connected between A+(B+)and A-

(B-)in EVA-DIP-SCI are OFF.

Figure 5

Class B (Short circuit detection is available)

EOL (10k ohm) is connected between A+ (B+ )and A- (B-)in

EVA-DIP-SCI.

Dry contact switches are OFF.

*Two external inputs can be connected to one input line.

*Resistor of 2.2k ohms(RE-2.2k)is an option and not included in this

product.

B-

B+

A+

A-

Lin+

Lin-

Lout+

Lout-

EOL

10kΩ

Typical wiring for N/O contacts only

2.2kΩ2.2kΩ

2.2kΩ2.2kΩ

EOL

10kΩ

Loop

- +

TO NEXT

DEVICE

- +

Loop

FROM PANEL OR

PREVIOUS DEVICE

Figure 6

Class A (Short circuit detection is available)

It is a status that dry contact switches connected between A+(B+)and A-

(B-)in EVA-DIP-SCI are OFF.

*Two external inputs can be connected to the input line.

*Resistor of 2.2k ohms(RE-2.2k)is an option and not included in this

product.

B-

B+

A+

A-

Lin+

Lin-

Lout+

Lout-

Typical wiring for N/O contacts only

2.2kΩ2.2kΩ

Loop

- +

TO NEXT

DEVICE

- +

Loop

FROM PANEL OR

PREVIOUS DEVICE

Figure 7

Normally Close Class B

A dry contact switch and EOL (10k ohm) are connected in series between

A+(B+)and A-(B-)in EVA-DIP-SCI.

Dry contact switches are ON.

*Only one external input can be connected to one input line.

B-

B+

A+

A-

Lin+

Lin-

Lout+

Lout-

Typical wiring for N/C contacts only

EOL

10kΩ

EOL

10kΩ

Loop

- +

TO NEXT

DEVICE

- +

Loop

FROM PANEL OR

PREVIOUS DEVICE

Figure 8

EOL

10kΩ

Typical wiring for N/O contacts only

EOL

10kΩ

B-

B+

A+

A-

Lin+

Lin-

Lout+

Lout-

Loop

- +

TO NEXT

DEVICE

- +

Loop

FROM PANEL OR

PREVIOUS DEVICE

B-

B+

A+

A-

Lin+

Lin-

Lout+

Lout-

Typical wiring for N/O contacts only

Loop

- +

TO NEXT

DEVICE

- +

Loop

FROM PANEL OR

PREVIOUS DEVICE

DW1401989 Rev.K2

Dec 18, 2019

4

Maintenance

Routine inspection: Ensure the module is secure and undamaged.

Operation Test

The purpose of the Operational Test is to confirm the product’s correct

operation.

1) When carrying out site testing of the product, the control panel shall

be set to “one-man-walk test mode” prior to the test.

2) Take any necessary precautions to limit the sounding of the alarm

sounders/bells and any fire service summoning device.

3) Turn on the external inputs connected to the module, and confirm

that the module is in active condition and the input LED (red)

illuminates. Confirm that an active signal is transmitted to the

control panel.

Note: If the test cannot be carried out through the external inputs, test the

area between terminal A+ and A-(or B+ and B-)to check the module. (In

accordance with the subtype setting, set the status either 0Ωshort (for

subtype 1-4), 2.2kΩshort (for subtype 7-9), or open (for subtype 5-6).)

4) After the external inputs have brought the module into the active

condition, reset the external inputs. Confirm that the module goes

back to the initial status after the external inputs are reset.

5) If subtype is set as 1-4, or 7-10, open between terminal A+ and A-(or

B+ and B-)and confirm that the control panel detects the open

circuit. If subtype is set as 5-10, short between terminal A+ and A-(or

B+ and B-)and confirm that the control panel detects the short

circuit.

6) Short between terminal Lin+ (Lout+) and Lin- (Lout-), and the SCI

LED (yellow) illuminates. The short circuit isolator isolates the

devices connected after the short-circuited area, which makes these

devices have no response. Upon removal of the short condition, the

area is automatically connected to go back to the normal standby

status, and the SCI LED (yellow) turns off.

FOR WARRANTY SERVICE, RETURN TO:

OVERSEAS BUSINESS DIVISION, NITTAN COMPANY, LIMITED

1-54-5 SASAZUKA, SHIBUYA-KU, TOKYO 151-8535, JAPAN

http://www.nittan.com

Specifications

SLC Applied Voltage

Rated range 20 to 38VDC

SLC Current Consumption

Standby 3.0mA

Activated 16.9mA(max)

SLC Line Impedance

Up to 50 ohms

Number of IDC Circuits

1 x Class A or 2 x Class B

IDC Circuit Rating

15VDC, 2.2k ohms, 6.8mA (max)

IDC Line Impedance

Up to 50 ohms

EOL Device

RE-10k (10k ohms, 1/4W), Class B

only

2.2k ohms EOL required for each dry

contact switch in subtype setting

7,8,9,and 10

SCI on Resistance

0.2 ohms (max)

SCI Fault Detection Threshold

10V (min)

SCI Isolation Current

22mA (max)

Visual Indicator (Status LED)

Polling LED (GREEN)

Input LED (RED)

SCI LED (YELLOW)

Ambient Installation

Temperature

0℃to 49℃(32°F to 120°F)

Storage Temperature

-20℃to 60℃(-4°F to 140°F)

Max Relative Humidity

Up to 93%RH, non-condensing

Environment

Indoor dry use only

Max. number of units per loop

127 units

Terminal

Screw AWG12 to 22

Address Setting

EVA-AD2 Address Programmer

Dimensions

124mm H x 124mm W x 34.5mm D

(4.882’’ H x 4.882’’ W x 1.358’’ D)

(Mount to a 4’’ square by 2⅛’’ deep

box)

Weight

Approximately 153g (5.4oz)

Conformity

UL864

DW1401989 Rev.K2

Dec 18, 2019

5

Warranties

1.1 Nittan warrants to the customers that:

(a) all products supplied hereunder will be of merchantable quality and

will comply with any specification agreed between Nittan and

customer.

(b) it is not aware of any rights of any third party in the market which

would or might render the sale of the products, or the use of any of the

trade marks on or in products, or the use of any of the trade marks on

or in relation to the products, unlawful.

1.2 In the event of any breach of the Nittan's warranty in Clause 1.1(a)

whether by reason of defective materials, production faults or

otherwise, Nittan's liability shall be limited to:

(a) replacement of the products in question; or

(b) at the Nittan’s option, repayment of the price where this had been paid.

And the warranty period is three (3) years from the shipment from

Nittan’s factory.

1.3 Notwithstanding anything to the contrary in this warranty terms,

Nittan shall not be liable to the customer by reason of any

representation or implied warranty, condition or other term or any

duty at common law, or under the express terms of this warranty

terms, for any consequential loss or damage whether for loss of profit

or otherwise and whether occasioned by the negligence of Nittan or its

employees or agents or otherwise, arising out of or in connection with

any act or omission of Nittan relating to Nittan or supply of the

products, their use by any customer.

1.4 Customer shall indemnify Nittan against all loss, damages, liabilities,

costs and expenses which Nittan may suffer or incur as a result of or in

connection with any breach by customer of this warranties terms or

any laws or regulations of any jurisdiction or any rules of any

governing authorities.

Other Nittan Control Unit manuals