Nivus osm-f Technical manual

Instruction Manual

OCM F

OCM F -Rev. 04 as of 18.02.2014 Page 1

Instruction Manual for

OCM F Measurement Device

(Original Instruction Manual – German)

ab Software-Revisionsnummer 3.13

NIVUS GmbH

Im Taele 2

75031 Eppingen, Germany

Phone +49 (0) 72 62 / 91 91 - 0

Fax +49 (0) 72 62 / 91 91 - 999

E-mail: [email protected]

Internet: www.nivus.com

Branch offices

page 2

®

NIVUS AG

Hauptstrasse 49

CH - 8750 Glarus

Tel.: +41 (0)55 6452066

Fax: +41 (0)55 6452014

E-Mail: swiss@nivus.com

Internet: www.nivus.de

NIVUS Austria

Mühlbergstraße 33B

A-3382 Loosdorf

Tel.: +43 (0)2754 567 63 21

Fax: +43 (0)2754 567 63 20

E-Mail: [email protected]

Internet: www.nivus.de

NIVUS France

14, rue de la Paix

F - 67770 Sessenheim

Tel.: +33 (0)3 88071696

Fax: +33 (0)3 88071697

E-Mail: [email protected]

Internet: www.nivus.com

NIVUS U.K. Ltd

Wedgewood Rugby Road

Weston under Wetherley

Royal Leamington Spa

CV33 9BW, Warwickshire

Tel.: +44 (0)1926 632470

E-mail: [email protected]

Internet: www.nivus.com

NIVUS U.K.

1 Arisaig Close

Eaglescliffe

Stockton on Tees

Cleveland, TS16 9EY

Phone: +44 (0)1642 659294

E-mail: [email protected]

Internet: www.nivus.com

NIVUS Sp. z o.o.

ul. Hutnicza 3 / B-18

PL - 81-212 Gdynia

Tel.: +48 (0) 58 7602015

Fax: +48 (0) 58 7602014

E-Mail: [email protected]

Internet: www.nivus.pl

NIVUS Middle East (FZE)

Building Q 1-1 ap. 055

P.O. Box: 9217

Sharjah Airport International

Free Zone

Tel.: +971 6 55 78 224

Fax: +971 6 55 78 225

E-Mail: Middle-East@nivus.com

Internet: www.nivus.com

NIVUS Korea Co. Ltd.

#411 EZEN Techno Zone,

1L EB Yangchon Industrial Complex,

Gimpo-Si

Gyeonggi-Do 415-843,

Tel. +82 31 999 5920

Fax. +82 31 999 5923

E-Mail: [email protected]

Internet: www.nivus.com

Instruction Manual

OCM F

OCM F -Rev. 04 as of 18.02.2014 Page 3

Translation

If the device is sold to a country in the European Economic Area (EEA)

this instruction handbook must be translated into the language of the

country in which the device is to be used.

Should the translated text be unclear, the original instruction handbook

(German) must be consulted or the manufacturer contacted for clarifica-

tion.

Copyright

No part of this publication may be reproduced, transmitted, sold or dis-

closed without prior permission. Damages will be claimed for violations.

All rights reserved.

Names

The use of general descriptive names, trade names, trademarks and the

like in this handbook does not entitle the reader to assume they may be

used freely by everyone. They are often protected registered trademarks

even if not marked as such.

Instruction Manual

OCM F

Page 4 OCM F - Rev. 04 as of 18.02.2014

®

1 Contents

1.1 Table of Contents

1Contents...............................................................................4

1.1 Table of Contents .......................................................................... 4

2General.................................................................................6

3General Notes on Safety and Danger.................................7

3.1 General Danger Signs ................................................................... 7

3.2 Special Danger Notes ................................................................... 7

3.3 Turn-off procedure ......................................................................... 7

3.4 Device Identification ...................................................................... 8

4Overview and use in accordance with the requirements.9

4.1 Overview ....................................................................................... 9

4.2 Use in accordance with the requirements ..................................... 9

4.3 Specifications .............................................................................. 11

4.4 Installation of Spare Parts and Parts subject to Wear and Tear . 11

4.5 User’s Responsibility ................................................................... 12

5Function principle..............................................................13

5.1 General ........................................................................................ 13

5.2 Level Measurement using Pressure ............................................ 14

5.3 Flow Velocity Detection ............................................................... 15

5.4 Unit Versions ............................................................................... 16

6Storing, Delivery and Transport.......................................17

6.1 Receipt ........................................................................................ 17

6.2 Delivery ....................................................................................... 17

6.3 Storing ......................................................................................... 17

6.4 Transport ..................................................................................... 18

6.5 Return .......................................................................................... 18

7Installation..........................................................................19

7.1 General ........................................................................................ 19

7.2 Enclosure Dimensions................................................................. 19

7.3 Transmitter Installation and Connection...................................... 20

7.3.1 General ........................................................................................ 20

7.3.2 Safety Instructions for the Cabling .............................................. 20

7.3.3 Hints for the avoidance of Electrostatic Discharge (ESD) ........... 21

7.4 Electrical Installation.................................................................... 21

7.4.1 Transmitter Connection ............................................................... 22

7.4.2 KDA Sensor Connection ............................................................. 25

7.5 OCM F Power Supply.................................................................. 28

7.6 Overvoltage Protection Precautions ............................................ 29

7.7 Regulator Mode ........................................................................... 32

7.7.1 General ........................................................................................ 32

7.7.2 Construction of Measurement Section and Control Section ....... 33

7.7.3 Connection for Controller Operation ........................................... 34

7.7.4 Control Algorithm ......................................................................... 35

8Initial start-up.....................................................................36

8.1 Notes to the User ........................................................................ 36

8.2 General Principles ....................................................................... 36

8.3 Keypad ........................................................................................ 37

8.4 Display ......................................................................................... 37

8.5 Operation Basics ......................................................................... 39

Instruction Manual

OCM F

OCM F -Rev. 04 as of 18.02.2014 Page 5

9Parameter Setting ..............................................................40

9.1 Basics .......................................................................................... 40

9.2 Operation Mode (RUN) ............................................................... 41

9.3 Display Menu (EXTRA) ............................................................... 44

9.4 Parameter Menu (PAR) ............................................................... 47

9.4.1 Parameter Menu „Measurement Place“ ...................................... 47

9.4.2 Parameter Menu “Level“ .............................................................51

9.4.3 Information on how to connect i-Series sensors. ........................ 54

9.4.4 Parameter Menu „Flow Velocity“ ................................................. 55

9.4.5 Parameter Menu „Digital Inputs“ ................................................. 55

9.4.6 Parameter Menu “Analog Outputs“ ............................................. 57

9.4.7 8.4.6 Parameter Menu "Relays“ .................................................. 60

9.4.8 Parameter Menu “Control Unit“ ...................................................62

9.4.9 Parameter Menu „Setup Parameter“ ........................................... 65

9.5 Signal Input-/Output Menu (I/O) .................................................. 67

9.5.1 I/O Menu “Digital Inputs” ............................................................. 67

9.5.2 I/O Menu “Analog Outputs” ......................................................... 67

9.5.3 I/O Menu „Digital Outputs” .......................................................... 68

9.5.4 I/O Menu „Measurement Data” ................................................... 68

9.5.5 I/O Menu “Sensor-Info”................................................................ 69

9.5.6 I/O-Menu „v-Histogram”...............................................................69

9.5.7 I/O Menu “External Level“ ........................................................... 70

9.5.8 I/O Menu “Control Unit” ............................................................... 71

9.5.9 I/O Menu “Test control unit – manual mode” .............................. 71

9.6 Calibration and Calculation Menu (CAL) ..................................... 72

9.6.1 CAL Menu “Level“ ....................................................................... 72

9.6.2 CAL Menu “Flow Velocity“ ........................................................... 73

9.6.3 CAL Menu “Analog Outputs“ ....................................................... 77

9.6.4 Basic Hints on Simulation: ..........................................................77

9.6.5 CAL Menu „Digital outputs“ ......................................................... 79

9.6.6 CAL Menu „Simulation“ ............................................................... 79

9.7 Parameter storage ....................................................................... 80

10 Parameter tree....................................................................82

11 Troubleshooting ................................................................88

12 Verification of the Measurement System.........................91

12.1 General ........................................................................................ 91

12.2 Verification of Combi Sensor with Pressure Measurement Cell . 91

12.3 Verification of external Level Measurement ................................ 92

12.4 Verification and Simulation of Input and Output Signals ............. 93

12.5 Verification of Flow Velocity Measurement ................................. 93

13 Maintenance and Cleaning ...............................................94

13.1 General Maintenance .................................................................. 94

13.2 KDA-Sensor ................................................................................94

13.3 Accessories (optional) ................................................................. 95

14 Table „Manning - Strickler Coefficients“ .........................96

15 Emergency .........................................................................97

16 Dismantling/Disposal ........................................................97

17 Table of Pictures................................................................97

18 Index .................................................................................100

19 Certificates and Approvals .............................................101

Instruction Manual

OCM F

Page 6 OCM F - Rev. 04 as of 18.02.2014

®

2 General

Important

READ CAREFULLY BEFORE USE

KEEP IN A SAFE PLACE FOR LATER REFERENCE

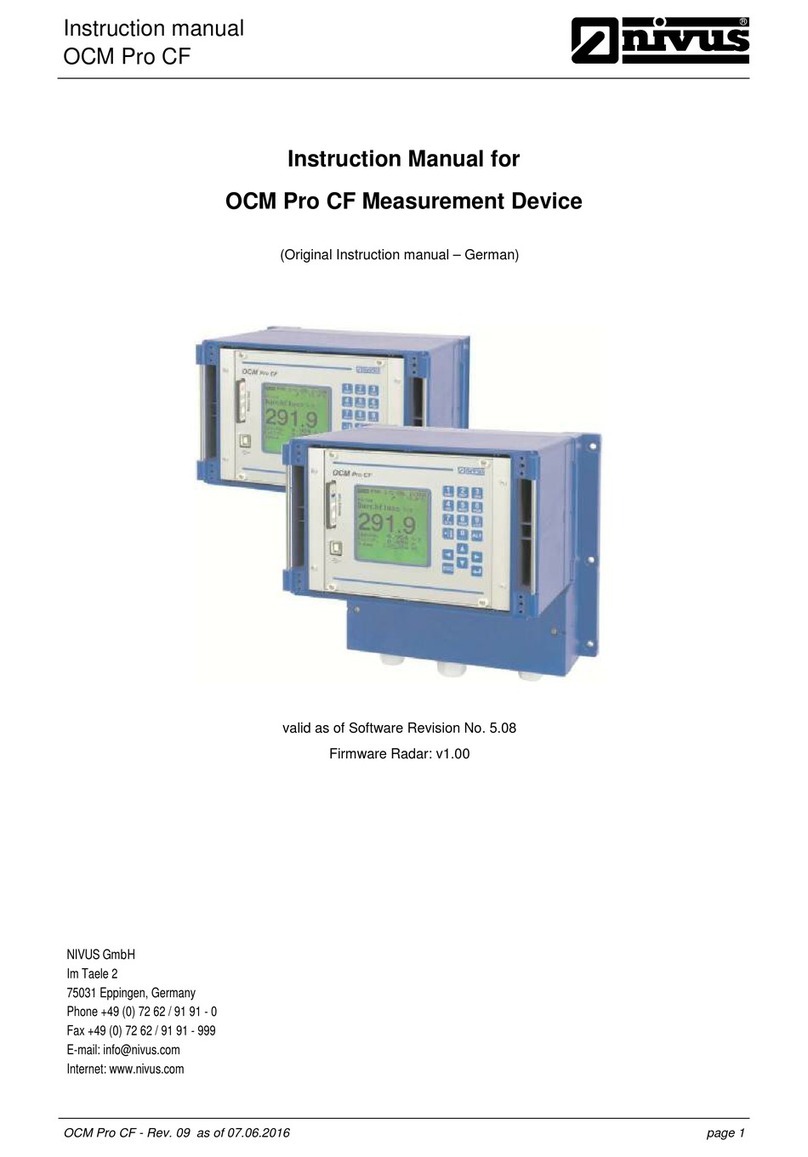

This Instruction manual for the measurement transmitter OCM F is intended for

the initial start-up of the unit depicted on the title page.

Read the instructions carefully prior to use.

This Instruction manual is part of the OCM F delivery and shall be available to

users at any time. The safety instructions contained therein must be followed.

In case of selling the OCM F this technical description must be provided to the

purchaser.

The operation of the complete system is described in the separate manual

>Technical Instruction for Doppler Sensors< and >Installation Instructions for

Correlation and Doppler Sensors<.

Instructions on how to connect external level sensors are provided with the

standard delivery of the according sensors (e.g. NivuCompact, i-Series sen-

sors…).

Instruction Manual

OCM F

OCM F -Rev. 04 as of 18.02.2014 Page 7

3General Notes on Safety and Danger

3.1 General Danger Signs

Cautions

are framed and labelled with a warning triangle.

This indicates an immediate high risk threatening life and limb.

Danger by electric voltage

is framed and labelled with the Symbol on the left.

Warnings

are framed and labelled with a “STOP“-sign.

This indicates a possible risk to persons as well as possible damage to facili-

ties and material.

Notes

are framed and labelled with a “hand“

For connection, initial start-up and operation of the OCM F the following infor-

mation and higher legal regulations (e.g. in Germany VDE), such as Ex-

regulations as well as safety requirements and regulations in order to avoid ac-

cidents, must be kept.

All operations, which go beyond steps to install, to connect or to program the

device, must be carried out by NIVUS staff only due to reasons of safety and

guarantee.

3.2 Special Danger Notes

WARNING Germ contamination

Please note that due to the operation in the waste water field the measure-

ment system and cables may be loaded with dangerous disease germs. Re-

spective precautionary measures must be taken to avoid damage to one’s

health.

3.3 Turn-off procedure

For maintenance, cleaning and repairs (authorised staff personnel only!) the

device shall be disconnected from mains.

Instruction Manual

OCM F

Page 8 OCM F - Rev. 04 as of 18.02.2014

®

3.4 Device Identification

The instructions in this manual apply only for the type of device indicated on the

title page. The nameplate is fixed on the on the bottom of the device and con-

tains the following:

− Name and address of manufacturer

− CE label

− Type and serial number

− Year of manufacture

− Ex-label (on Ex-version devices only) as mentioned in chapter Special Dan-

ger Notes.

It is important for enquiries and replacement part orders to specify article num-

ber as well as serial number of the respective transmitter or sensor. This en-

sures correct and quick processing.

Fig. 3-1 Transmitter nameplate

This instruction manual is a part of the device and must be available for the

user at any time.

The safety instructions contained within must be followed.

In addition to this instruction manual please see the "Technical Instruction of

Doppler Sensors" as well as the "Installation Instruction for Correlation and

Doppler Sensors" to correctly install and to operate the complete system.

WARNING

Do not disable safety devices!

It is strictly prohibited to disable safety measures or to change the way

they work!

Instruction Manual

OCM F

OCM F -Rev. 04 as of 18.02.2014 Page 9

4 Overview and use in accordance with the requirements

4.1 Overview

1 Clear view door

2 Display

3 Keypad

4 Cable Glands

5 Terminal Clamp Housing

6 USB-B Interface

7 Pipe Sensor with retaining element

8 Wedge Sensor (Flow Velocity)

Fig. 4-1 Overview

4.2 Use in accordance with the requirements

WARNING Damage due to improper use

The device is exclusively intended to be used for purposes as described

above.

Modifying or using the devices for other purposes without the written consent

of the manufacturer will not be considered as use in accordance with the re-

quirements.

Damages resulting from this are left at user’s risk.

The device is designed for a lifetime of approx. 10 years. After that period an

inspection in addition with a general overhaul has to be made.

The measurement device type OCM F including the respective sensor technolo-

gy is intended to be used for continuous flow measurement and control tasks of

slight to heavy polluted media in part filled and permanent full pipes, channels or

similar.

Here the allowed maximum values, as specified in chapter 4.3 shall be strictly

kept. All cases which vary from these conditions and are not passed by NIVUS

GmbH in writing are left at owner’s risk.

Instruction Manual

OCM F

Page 10 OCM F -Rev. 04 as of 18.02.2014

®

Note:

For installation and initial start-up the conformity certificates and test certifi-

cates of the respective authorities as well as applicable national regulations

shall be followed.

Important Note

The transmitter and the sensors always have to be installed outside of Ex-

zones!

Ex Approval

The Ex-version of the transmitter is designed for use in areas featuring explosive

atmosphere according to Zone 1.

Transmitter Approval:

II(2)G [Ex ib] IIB

WARNING The approval is only valid in connection with the respective indication on the

transmitter or the sensor nameplate.

The OCM F Ex version is adjusted to the NIVUS Doppler sensors, type KDA

requirements regarding the intrinsically safe system review according to

EN 60079-25.

In case of using sensors from third party manufacturers the operator must

carry out a system review according to EN 60079-25!

The required specifications of the OCM F Ex version can be taken from the

EC-type examination certificate IBExU07ATEX1081.

Note:

The Ex approval of the active sensors is part of the "Technical Instructions for

Doppler Sensors”.

Instruction Manual

OCM F

OCM F -Rev. 04 as of 18.02.2014 Page 11

4.3 Specifications

Power supply

85 to 260 V AC, 47 to 63 Hz

or 24 V DC ±15 %, 5 % residual fluctuation

Power consumption

max. 18 VA (7 VA typical)

Enclosure

-

Material: Polycarbonate

- Weight: approx. 1200 g

- Protection: IP 65

- Mounting wall or DIN rail mount

Ex-Approval (optional)

II(2)G [Ex ib] IIB

Operating temperature

-20 °C to +60 °C (-4 °F to +140 °F)

Ex: -20 °C to +40 °C (-4 °F to +104 °F)

Storage temperature

-30 °C to +70 °C (-22 °F to +158 °F)

Max. humidity

90 %, non-condensing

Display

back-lit full graphic LC display, 128 x 64 pixel

Operation

6 keys, menu driven in German, English, French and Polish

Inputs

-

1 x 4 –20 mA for external level measurement (2-wire sensor)

- 2 x 0/4 – 20 mA, 122 bit resolution for external level measurement

and external set points

- 4 x digital input

- 1 compact Doppler active sensor, type KDA, connectable

Outputs

- 3 x 0/4 – 20 mA, load 500 Ohm, 12 bit resolution, accuracy better

than 0.1 % (after adjustment)

- 5 switchable relays, loadable up to 230 V AC / 2 A (cos. ϕ 0,9 )

Controller

three-step controller, quick close control, adjustable slide valve posi-

tion in error case, auto-flush function in case of blocked slide valve

4.4 Installation of Spare Parts and Parts subject to Wear and Tear

We herewith particularly emphasize that replacement parts or accessories,

which are not supplied by us, are not certified by us, too. Hence, the installation

and/or the use of such products may possibly be detrimental to the device’s abil-

ity to work.

Damages caused by using non-original parts and non-original accessories are

left at user’s risk. Appropriate accessories and spare parts can be found in chap-

ter 13.3.

Instruction Manual

OCM F

Page 12 OCM F - Rev. 04 as of 18.02.2014

®

4.5 User’s Responsibility

In the EEA (European Economic Area) national implementation of the frame-

work directive 89/391/EEC and corresponding individual directives, in particu-

lar the directive 89/655/EEC concerning the minimum safety and health re-

quirements for the use of work equipment by workers at work, as amended,

are to be observed and adhered to.

In Germany the Industrial Safety Ordinance must be observed.

The customer must (where necessary) obtain any local operating permits re-

quired and observe the provisions contained therein. In addition to this, he must

observe local laws and regulations on

- personnel safety (accident prevention regulations)

- safety of work materials and tools (safety equipment and maintenance)

- disposal of products (laws on wastes)

- disposal of materials (laws on wastes)

- cleaning (cleansing agents and disposal)

- environmental protection.

Connections

Before operating the device the user has to ensure, that the local regulations

(e.g. for operation in channels) on installation and initial start-up are taken into

account, if this is both carried out by the user.

This instruction manual is a part of the device and must be available for the

user at any time.

The safety instructions contained within must be followed.

In addition to this instruction manual please see the "Technical Instruction of

Doppler Sensors" as well as the "Installation Instruction for Correlation and

Doppler Sensors" to correctly install and to operate the complete system.

It is strictly prohibited to disable the safety devices or to change the way they

work!

Instruction Manual

OCM F

OCM F -Rev. 04 as of 18.02.2014 Page 13

5Function principle

5.1 General

The OCM F is a permanent measurement system for flow measurement and

flow control. The device is designed to be used primarily in slight to heavy pol-

luted media with various compositions. It can be operated in partial and perma-

nent filled channels and pipes with various shapes and dimensions.

The measurement method is based on the ultrasound Doppler principle.

Hence, it is indispensable for the system’s capability to work that the water

contains particles which are able to reflect the ultrasonic signal sent by the

sensor (dirt particles, gas bubbles or similar).

The OCM F utilises an active compact Doppler sensor Type KDA (after this

named >KDA sensor<). This KDA sensor is available as flow velocity and combi

sensor. The combi sensor Type “KDA“ can be combined with a sensor-

integrated pressure measurement cell for hydrostatic level measurement.

1 Ground plate

2 Acoustic coupling layer with sonic converter behind

3 Temperature sensor

4 Electronics

5Pressure measurement cell (option)

6 Duct to pressure measurement (option)

7 Cable gland

8 Sensor cable

Fig. 5-1 Construction of combi sensor Type “KDA“ with additional

pressure measurement cell

Instruction Manual

OCM F

Page 14 OCM F -Rev. 04 as of 18.02.2014

®

1 Sensor head

2 Sensor enclosure

3Double nipple

4 Spigot nut

5 Cable gland

6 Sensor cable

7 Adjustment aid (screw M4)

8 Retaining element

Fig. 5-2 Construction pipe sensor, type KDA

5.2 Level Measurement using Pressure

The combi sensor type “KDA“ additionally contains a hydrostatic level measure-

ment via integrated pressure measurement cell.

The piezo-resistive pressure sensor operates according to the relative pressure

principle, i.e. the pressure of the standing water column above the sensor is di-

rect proportional to the flow level.

During initial start-up procedure, the pressure sensor is going to be adjusted by

entering a manually investigated reference value.

Instruction Manual

OCM F

OCM F -Rev. 04 as of 18.02.2014 Page 15

5.3 Flow Velocity Detection

The flow velocity sensor, type “KDA“ operates according to the continuous Dop-

pler principle (CW-Doppler) using 2 built-in piezo crystals with a slope of 45°.

The crystal surfaces are arranged parallel to the slope of the flow velocity sen-

sor. One of the crystals continuously operates as ultrasonic transmitter, the other

one as receiver detecting the reflected ultrasonic signal.

The sensor enclosure enables acoustic coupling of the high-frequency ultrasonic

signal between piezo crystal/enclosure and enclosure/medium. Due to that rea-

son an ultrasonic signal with an angle of 45° is sent permanently against the flow

direction of the medium to be measured. As soon as the signal hits dirt particles,

gas bubbles or similar a portion of the sonic energy is reflected, being converted

into an electric signal by the receiving crystal subsequently.

Caused by the movement of the reflecting particles in relation to the acoustic

source the frequency of the ultrasonic signal is shifted. The resulting frequency

shift is directly proportional to the particles’ movement within the medium and

hence represents the flow velocity.

The sensor processes the received reflection signal, converting it to be sent to

the transmitter.

Due to varying velocities within the flow profile, vorticity, rotation of single reflect-

ing particles, surface waves etc. a frequency mixture is emerging. This mixture is

evaluated directly within the KDA sensor regarding statistic considerations relat-

ed to average flow velocity. The frequency mixture is indicated on the transmitter

display in >I/O / v-Histogram< (see chapter 9.5.6).

It is recommended to verify the measurement if conditions are disadvantageous

from a hydraulic standpoint. Verification should not be based on the CW-Doppler

method since in this case it is not possible to spatially allocate recorded flow ve-

locities.

In this case the VDI/VDE Directive 2640 is very helpful and important.

NIVUS recommends the portable meter Type >PVM/PD< or >PCM Pro< as cali-

bration measurement or the NIVUS initial start-up service.

Instruction Manual

OCM F

Page 16 OCM F - Rev. 04 as of 18.02.2014

®

5.4 Unit Versions

The OCM F transmitter is available in different versions. The tables below give a

brief overview on the various possibilities.

The transmitters primarily vary in terms of power supply and Ex-protection. The

current type of device is indicated by the article number, which can be found on

a weatherproof label on the bottom of the enclosure.

From this article key the type of device can be specified.

Fig. 5-3 Type key for OCM F measurement transmitter

OCF- Type

00

Enclosure

W0 w all mount IP 65

Power Supply

AC 85 - 265 V AC, 47-63 Hz

DC 20 - 28 V DC

Approvals

0non

EIntrinsically safe sensor supply in Ex zone 1

OCF- 00 W0

Standard version for various pipe and channel shapes. 5 relays, 3 mA

outputs (galv. isolated), 1 mA input (galv. isolated w ith 2-w ire sensor

supply) or for external level measurement , integrated 3-step controller

Instruction Manual

OCM F

OCM F -Rev. 04 as of 18.02.2014 Page 17

6Storing, Delivery and Transport

6.1 Receipt

Please check your delivery if it is complete and in working order according to

the delivery note immediately after receipt. Any damage resulting from transport

or transit shall be reported to the carrier instantly. An immediate, written report

must be sent to NIVUS GmbH Eppingen as well.

Please report any shortcoming due to delivery to your representative or directly

to NIVUS Eppingen within two weeks in writing.

Mistakes cannot be rectified later!

6.2 Delivery

The standard delivery of the OCM F measurement transmitter contains:

− the instruction manual with the certificate of conformity. All required steps to

correctly install and to operate the measurement system are listed herein.

− a OCM F transmitter

− a screwdriver with a 2.5 mm (0.098 in) blade for connecting the sensor inside

the terminal clamp housing

Additional accessories such as sensors, pressure compensation element (in

case of using sensors, type “KDA” with integrated pressure measurement cell

combi sensor), overvoltage protection, separate level measurements etc. de-

pending on order. Please check by using the delivery note.

6.3 Storing

The following storing conditions must be strictly adhered to:

Transmitter:

min. temperature: - 30 °C (-22 °F)

max. temperature: + 70 °C (158 °F)

max. humidity: 80 %, non-condensing

KDA-Sensor:

min. temperature: - 30 °C (-22 °F)

max. temperature: + 70 °C (158 °F)

max. humidity: 100 %

The devices must be protected from corrosive or organic solvent vapours, radio-

active radiation as well as strong electromagnetic radiation.

Instruction Manual

OCM F

Page 18 OCM F - Rev. 04 as of 18.02.2014

®

6.4 Transport

Sensor and Transmitter are conceived for harsh industrial conditions. Despite

this do not expose them to heavy shocks or vibrations.

Transportation must be carried out in the original packaging.

6.5 Return

The units must be returned at customer cost to NIVUS Eppingen in the

original packaging.

Otherwise the return cannot be accepted!

Instruction Manual

OCM F

OCM F -Rev. 04 as of 18.02.2014 Page 19

7Installation

7.1 General

For electric installation the local regulations in the respective countries

(e.g. VDE 0100 in Germany) must be referred to.

The OCM F power supply must be separately protected by a 6 A slow-blow

fuse and has to be isolated from other facility parts (separate turn-off, e.g. by

using an automatic cut-out with >B< characteristics).

Before feeding the rated voltage the transmitter and sensor installation must be

correctly completed. The installation should be carried out by qualified personnel

only. Further statutory standards, regulations and technical rulings have to be

taken into account.

All outer circuits, wires and lines connected to the device must have a minimum

isolation resistance of 250 V. If the voltage exceeds 42 V DC an isolation re-

sistance with 500 kOhm min. will be required.

The cross-sectional dimension of the power supply wires must be 0.75 mm2

(0.03 in2) and must be in accordance to IEC 227 or IEC 245. The device protec-

tion rating is IP 65.

The maximum allowed switching voltage on the relay contacts must not exceed

250 V. According to Ex protection it must be checked if the devices power sup-

plies must be integrated into the facility’s emergency shutdown conception.

7.2 Enclosure Dimensions

Fig. 7-1 Wall mount enclosure

Instruction Manual

OCM F

Page 20 OCM F - Rev. 04 as of 18.02.2014

®

7.3 Transmitter Installation and Connection

Important Note:

- Ensure the installation is completed properly!

- Comply with the existing legal and/or operational directives!

- Improper handling can cause injuries and/or damage to the devices!

7.3.1 General

The transmitters mounting place has to be selected according to certain criteria.

Please strictly avoid:

- direct sunlight (use weatherproof cover if necessary)

- heat emitting objects (max. ambient temperature: +40 °C (104 °F))

- objects with strong electromagnetic fields (e.g. frequency converters, electric

motors with high power consumption or similar)

- corrosive chemicals or gas

- mechanical shocks

- installation close to footpaths or travel ways

- vibrations

- radioactive radiation

The clear view door of the measurement transmitter is provided with a protection

foil for protection during transport and from scratches during assembly. This pro-

tection foil has to be removed immediately after the assembly.

Clear view door

The clear view door as well as the display of the measurement transmitter is

provided with a protection foil for protection during transport and from scratches

during assembly. This protection foil has to be removed immediately after the

assembly.

If the view door or the display protection foil has been exposed to direct solar

radiation for a long period, it cannot be removed easily.

In this case view door or display can be cleaned using spirit or if necessary with

car polish. If this is not successful, door or display must be replaced by NIVUS.

This service is subject to charge.

7.3.2 Safety Instructions for the Cabling

If connections are placed to the OCM F, the following warnings and information

must be observed, in addition to the warnings and information found in the indi-

vidual chapters for installation.

Table of contents

Other Nivus Measuring Instrument manuals

Nivus

Nivus NivuCompact User manual

Nivus

Nivus NivuLink Compact NLC0CLOG User manual

Nivus

Nivus NFP User manual

Nivus

Nivus NFP User manual

Nivus

Nivus NivuCont Plus User manual

Nivus

Nivus OCM PRO CF User manual

Nivus

Nivus NivuFlow Mobile 600 User manual

Nivus

Nivus NivuFlow Stick User manual

Nivus

Nivus OCM PRO CF User manual

Nivus

Nivus NivuSonic Clamp On User manual

Popular Measuring Instrument manuals by other brands

Applent Instruments

Applent Instruments AT5220 user guide

WiMo

WiMo 6CP10 Operation and configuration instructions

Extech Instruments

Extech Instruments EX613 user guide

AquaLabo

AquaLabo NEON pH-RedOx Operation manual

DENGENSHA

DENGENSHA WS-100 instruction manual

iZ Technology

iZ Technology RADAR I Upgrade manual