Nivus NivuFlow 750 User manual

FLOW

Instrumentation for Water Industry

NIVUS GmbH • Im Taele 2 • D-75031 Eppingen • Internet: www.nivus.de

Phone:+49(0)72629191-0•Fax:+49(0)72629191-999•E-Mail:[email protected]

Flow Measurement Transmitter

NivuFlow 750

Instruction Manual

1. Edition

Firmware Revision: 1.14

Original Manual: German

NIVUS AG, Schweiz

Hauptstrasse 49

CH - 8750 Glarus

Tel.: +41 (0)55 6452066

Fax: +41 (0)55 6452014

E-Mail: [email protected]

Internet: www.nivus.de

NIVUS, Austria

Mühlbergstraße 33B

A-3382 Loosdorf

Tel.: +43 (2754) 567 63 21

Fax: +43 (2754) 567 63 20

E-Mail: [email protected]

Internet: www.nivus.de

NIVUS, France

14, rue de la Paix

F - 67770 Sessenheim

Tel.: +33 (0)3 88071696

Fax: +33 (0)3 88071697

E-Mail: [email protected]

Internet: www.nivus.fr

NIVUS Ltd., United Kingdom

Wedgewood Rugby Road

Weston under Wetherley

Royal Leamington Spa

CV33 9BW, Warwickshire

Tel.: +44 (0)1926 632470

E-Mail: [email protected]

Internet: www.nivus.com

NIVUS Service, United Kingdom

1 Arisaig Close

Eaglescliffe

Stockton on Tees

Cleveland, TS16 9EY

Tel.: +44 (0)1642 659294

E-Mail: [email protected]

Internet: www.nivus.com

NIVUS Sp. z o.o., Poland

ul. Hutnicza 3 / B-18

PL - 81-212 Gdynia

Tel.: +48 (0) 58 7602015

Fax: +48 (0) 58 7602014

E-Mail: [email protected]

Internet: www.nivus.pl

NIVUS Middle East (FZE)

Building Q 1-1 ap. 055

P.O. Box: 9217

Sharjah Airport International

Free Zone

Tel.: +971 6 55 78 224

Fax: +971 6 55 78 225

E-Mail: [email protected]

Internet: www.nivus.com

NIVUS Korea Co. Ltd.

#2502, M Dong, Technopark IT Center

32 Song-do-gwa-hak-ro

Yeon-su-gu

INCHEON, Korea 406-840

Tel. +82 32 209 8588

Fax. +82 32 209 8590

E-Mail: [email protected]

Internet: www.nivus.com

Branch offices

1st Edition - as from July, 21st 2015

page 3

Copyrights and property rights

This document and its contents are proprietary to NIVUS GmbH and are not to be reproduced or

copied without the express written permission of NIVUS GmbH.

Violations oblige to compensation.

Important Note

This instruction manual may exclusively - even in parts - be copied or translated in any

other way with the express written consent of NIVUS GmbH.

Translation

If the device is sold to a country in the European Economic Area (EEA) this

instruction handbook must be translated into the language of the country in

which the device is to be used.

Should the translated text be unclear, the original instruction handbook (Ger-

man) must be consulted or the manufacturer contacted for clarification.

Copyright

No part of this publication may be reproduced, transmitted, sold or disclosed

without prior permission. Damages will be claimed for violations.

All rights reserved.

Names

The use of general descriptive names, trade names, trade-marks and the

like in this handbook does not entitle the reader to assume they may be used

freely by everyone. They are often protected registered trademarks even if

not marked as such.

Table of contents

1. General.........................................................................................................9

2. Safety Instructions....................................................................................10

2.1 Signs and symbols used .......................................................................10

2.2 Warning notices on the product ...........................................................11

2.3 Safeguards and precautions................................................................11

2.4 Liability Disclaimer.................................................................................12

2.5 User’s Responsibilities..........................................................................12

3. Productspecication ...............................................................................14

3.1 Product construction and overview .....................................................14

3.2 Connectable sensors.............................................................................15

3.3 Use in accordance with the requirements ...........................................16

3.4 Deviceidentication ..............................................................................17

3.5 Specications.........................................................................................18

3.6 Conguration..........................................................................................19

3.6.1 Device Types............................................................................................19

3.6.2 Delivery ....................................................................................................20

3.6.3 Transport ..................................................................................................20

3.6.4 Return.......................................................................................................20

3.6.5 Installation of spare parts and parts subject to wear and tear..................20

4. Functional Principle..................................................................................21

4.1 Level measurement using water ultrasound .......................................21

4.2 Level measurement using pressure ....................................................22

4.3 Level measurement using an external level sensor ...........................22

4.4 Flow velocity detection..........................................................................23

5. Installation and Connection.....................................................................26

5.1 Installation Instructions.........................................................................26

5.1.1 Hints on how to avoid electrostatic discharge (ESD) ...............................26

5.1.2 Choosing the installation place.................................................................26

5.2 Electric Installation ................................................................................27

5.2.1 Connection clamp for protective earth conductor and AC power supply..28

5.2.2 Power supply DC......................................................................................28

5.2.3 Power supply AC......................................................................................28

Table of contents

5.2.4 Relays ......................................................................................................28

5.3 Sensors ...................................................................................................29

5.3.1 Cable for sensor connection.....................................................................29

5.3.2 Sensor Connection...................................................................................30

5.4 Overvoltage Protection..........................................................................36

5.5 Connection to the Terminal Blocks ......................................................42

5.6 Transmitter Connection .........................................................................43

5.6.1 Types of Measurement Transmitter..........................................................43

5.6.2 Connection Diagrams...............................................................................43

5.6.3 Switching on voltage supply.....................................................................46

6. Putting into Operation ..............................................................................48

6.1 General....................................................................................................48

6.2 NivuFlow Control Elements...................................................................49

6.3 Display Overview....................................................................................49

6.4 Menus......................................................................................................50

6.5 Operation Basics....................................................................................51

7. Parameter setting......................................................................................52

7.1 Parameter Principles..............................................................................52

7.2 General Overview Main Menu ...............................................................52

7.3 Application..............................................................................................54

7.3.1 Measurement Place Settings ...................................................................54

7.3.1.1 Name of Measurement Place.................................................................54

7.3.1.2 ChannelProle.......................................................................................56

7.3.1.3 Low-owsuppression...............................................................................65

7.3.1.4 Sludge level..............................................................................................66

7.3.1.5 Damping...................................................................................................66

7.3.1.6 Stability.....................................................................................................66

7.3.2 h-sensors..................................................................................................67

7.3.2.1 h-sensor types..........................................................................................67

7.3.2.2 DeneMeasuringRanges........................................................................69

7.3.3 v-sensors..................................................................................................73

7.3.3.1 Number of Flow velocity sensors .............................................................73

Table of contents

7.3.3.2 Sensor types ............................................................................................74

7.3.3.3 Sensor mounting position.........................................................................75

7.3.3.4 v-Determination low levels .......................................................................80

7.3.3.5 Limitation of velocity evaluation................................................................82

7.3.4 Inputs/Outputs (analog)............................................................................83

7.3.4.1 Analog inputs............................................................................................84

7.3.4.2 Analog outputs .........................................................................................86

7.3.4.3 Digital inputs.............................................................................................89

7.3.4.4 Digital outputs...........................................................................................91

7.3.5 Q-Control..................................................................................................95

7.3.6 Diagnostics...............................................................................................96

7.3.6.1 h-Sensors.................................................................................................96

7.3.6.2 v-Sensors ...............................................................................................100

7.3.6.3 Analog inputs..........................................................................................103

7.3.6.4 Analog outputs .......................................................................................104

7.3.6.5 Digital inputs...........................................................................................107

7.3.6.6 Digital outputs.........................................................................................108

7.3.6.7 Q-Control................................................................................................ 111

7.3.6.8 Flowprole............................................................................................. 111

7.3.6.9 Simulation...............................................................................................112

7.4 Parameter Menu Data ..........................................................................115

7.4.1 Trend ......................................................................................................115

7.4.2 Day totals ..............................................................................................120

7.4.3 USB Stick ..............................................................................................122

7.4.4 Data storage (internal)............................................................................128

7.5 System...................................................................................................129

7.5.1 Information .............................................................................................129

7.5.2 Region Settings......................................................................................130

7.5.3 Time/Date ..............................................................................................135

7.5.4 Error Messages .....................................................................................135

7.5.5 Service ..................................................................................................137

7.6 Communication ...................................................................................139

Table of contents

7.7 Display...................................................................................................143

7.7.1 Connections ..........................................................................................145

8. Main Display ............................................................................................147

8.1 Flow screen...........................................................................................148

8.2 Display Level ........................................................................................151

8.3 Displayowvelocity............................................................................153

8.4 Temperature and sum screen .............................................................155

8.5 Display Trend/Hydrograph ..................................................................156

9. Maintenance and Cleaning.....................................................................157

9.1 Maintenance Interval............................................................................157

9.2 Transmitter Cleaning ...........................................................................157

9.3 Sensor Cleaning...................................................................................158

9.4 Customer Service Information............................................................158

9.5 Accessories ..........................................................................................158

9.6 Dismantling/Disposal...........................................................................158

11. CerticatesandApprovals.....................................................................159

12. Glossar.....................................................................................................160

page 9

1. General

Important Note

READ CAREFULLY BEFORE USE

KEEP IN A SAFE PLACE FOR LATER REFERENCE!

This Instruction manual for the flow measurement unit NivuFlow 750 is for the intended use of the

device. It is intended for exclusive use by appropriately trained and qualified personnel.

This manual must be read carefully and understood prior to Installation or connection.

This Instruction manual is part of the NivuFlow 750 delivery and shall be available to users at

any time. The safety instructions contained therein must be followed.

In case of selling the flow measurement unit this technical description must be provided to the

purchaser.

The description on the operation of the transmitter with the sensors can be found in the accom-

panying manuals .

• Technical Instructions for Correlation Sensors and external Electronic Box

• Installation Instruction for Correlation and Doppler sensors

• Technical Description for the Ex-Separation Interface iXT

• Technical Description for the Multiplexer MPX

Instruction manual

NivuFlow 750

page 10

2. Safety Instructions

2.1 Signs and symbols used

These safety instructions must be followed to ensure your safety and prevent property damage.

Hazard warnings

Indicates an immediate high risk which may result in death or severe personal injury if not

avoided.

Warning notice

Indicates a possible danger with moderate risk which may result in death or severe personal

injury if not avoided.

Danger of electrical shock

Indicates a possible danger by electrical power with moderate risk which may result in death

or severe personal injury if not avoided.

Notes for caution

Indicates a possible danger with moderate risk that may result in minor or moderate injury or

may result in property damage, if not avoided.

Important Note

Indicates situations that may result in damage to property and/or loss of data, if not avoided.

Contains information, that needs to be highlighted.

Note

Indicates situations that do not result in personal injury.

DANGER

WARNING

WARNING

CAUTION

Safety Instructions

page 11

2.2 Warning notices on the product

General warning label

This symbol is for operators to refer to this instruction manual. Observing the information con-

tained therein is required in order to maintain protection measures provided by the instrument

during installation procedures and operation.

Protective conductor

This symbol refers to the protective conductor of the unit.

Depending on the mode of installation the instrument shall be operated solely connected to

an appropriate protective conductor according to applicable laws and regulations.

2.3 Safeguards and precautions

Germ contamination

Please note that due to the operation in the waste water field the measurement system and

cables may be loaded with dangerous disease germs. Respective precautionary measures

must be taken to avoid damage to one’s health.

Wear protective clothing!

Regulations for health and safety at work have to be observed!

Before starting installation work, observing the work safety regulations need to be checked.

Failure to observe may cause personal injury.

Do not disable safety devices!

It is strictly prohibited to disable the safety devices or to change the way they work.

Failure to observe may cause personal injury as well as to system damage.

Disconnect from power supply

Disconnect the instrument from power supply before you begin to execute maintenance,

cleaning and/or repair works. Repair works shall be executed solely by expert personnel.

Disregarding may lead to electrical shocks.

Important Note

The system should be installed and put into operation only by qualified personnel.

WARNING

WARNING

WARNING

WARNING

Instruction manual

NivuFlow 750

page 12

2.4 Liability Disclaimer

The manufacturer reserves the right to change the contents of this document including this lia-

bility disclaimer without prior notice and cannot be held responsible in any way for possible

consequences resulting from such changes.

For connection, initial start-up and operation as well as maintenance of the unit the following

information and higher legal regulations of the respective country (e.g. VDE regulations in Ger-

many) such as applicable Ex regulations as well as safety requirements and regulations in order

to avoid accidents shall be observed.

All operations on the device which go beyond installation or connection measures in principle

shall be carried out by NIVUS staff or personnel authorised by NIVUS due to reasons of safety

and guarantee.

The manufacturer is not liable for failures resulting from improper or inappropriate use.

2.5 User’s Responsibilities

Important Note

In the EEA (European Economic Area) national implementation of the framework directive

89/391/EEC and corresponding individual directives, in particular the directive 89/655/EEC

concerning the minimum safety and health requirements for the use of work equipment by

workers at work, as amended, are to be observed and adhered to.

Make sure to have a local operating permit available and observe the associated conditions. In

addition to this you must observe environmental requirements and local laws the following points:

• Personnel safety (accident prevention regulations)

• Safety of work materials and tools (safety equipment and maintenance)

• Disposal of products (laws on wastes)

• Disposal of materials (laws on wastes)

• Cleaning (cleansing agents and disposal)

Connections:

Operators shall make sure prior to operating the instrument that during installation and initial

start-up the local regulations (such as regulations for electrical connection) are observed.

Personnel requirements

Installation, commissioning and maintenance shall be executed only by personnel meeting the

demands as follows:

• Expert personnel with relevant training an appropriate qualification

• Personnel authorised by the plant operator

Safety Instructions

page 13

Qualified personnel

within the context of this documentation or the safety notes on the product itself are per-

sons who are sufficiently familiar with installation, mounting, starting up and operation of the

product and who have the relevant qualifications for their work; for example

I. Training, instruction or authorisation to activate/deactivate, isolate, ground, and mark

electric circuits and devices/systems according to the safety engineering standards.

II. Education and instruction according to the standards of safety engineering regarding the

maintenance and use of adequate safety equipment.

III. First aid training

Additional instructions

For installation and operation of the complete system apart from this instruction manual the

following instruction manuals shall be used additionally:

• Technical Instructions for Correlation Sensors and external Electronic Box

• Installation Instruction for Correlation & Doppler Sensors

• Technical Instructions for Ex Separation Interface iXT (for the use in hazardous areas)

• Technical Instructions for Multiplexer MPX (for the use of several sensors)

Important Note

This instruction manual is part of the standard delivery and must be available to the user at

any time. Observe any notes on safety contained therein.

Instruction manual

NivuFlow 750

page 14

3. Product specification

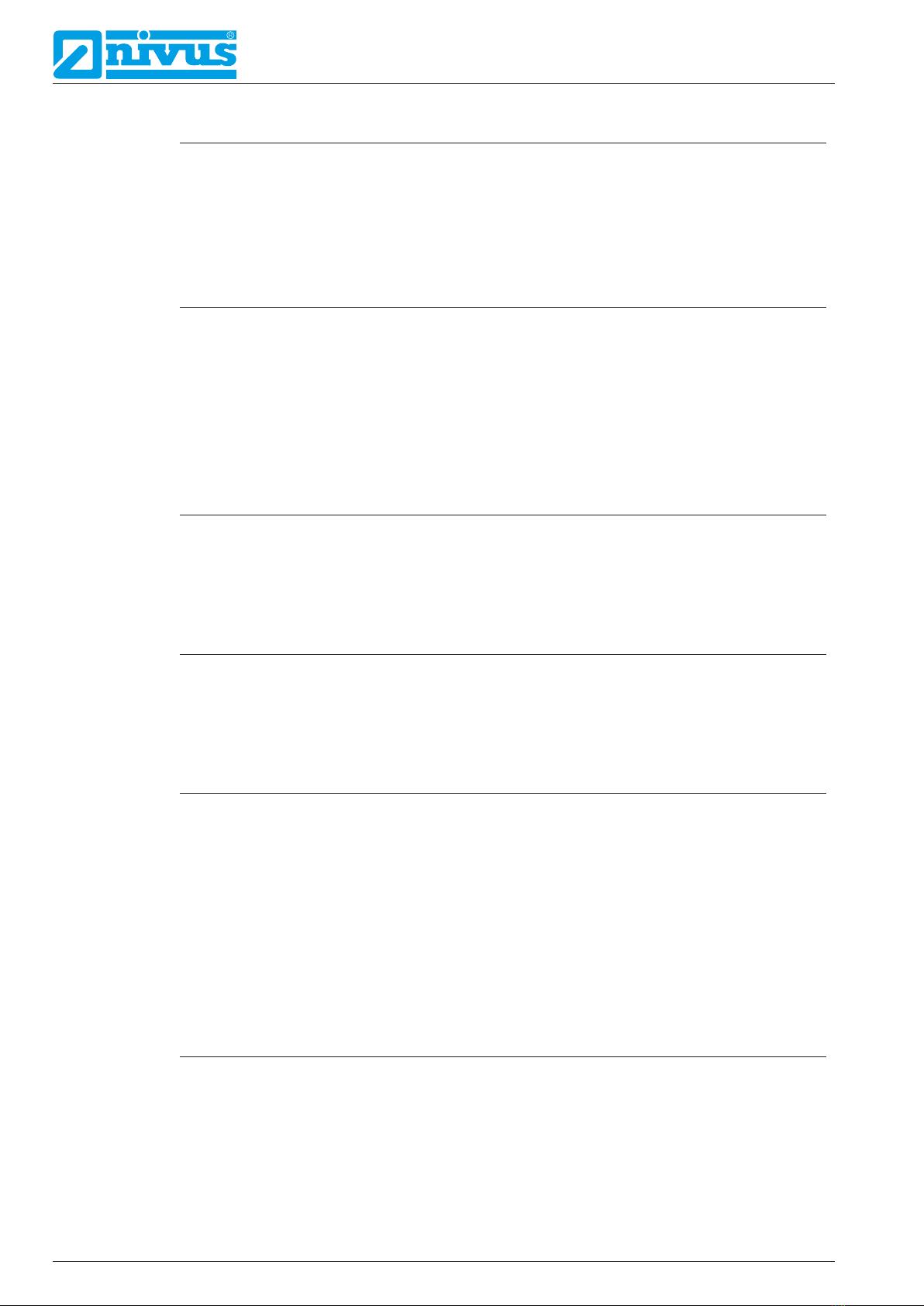

3.1 Product construction and overview

Fig. 3-1 G

2

3

4

5

6

X2X1 X3 X4 X5

LAN

1

7 8 9 10 11

12

13 14 15

1 16

1. Trims / cover strips

2. Network interface (LAN)

3. Bus interface

4. Connection air-ultrasonic sensor (RS485)

5. Power supply

6. Plugin X2 - v-sensor 1

7. Plugin X3 - Type S1, M3, M9 only

8. Plugin X4 - Type S1, M3, M9 only

9. Plugin X5 - spare plugin port (unused)

10. USB-A interface (data transfer)

11. USB-B interface (service)

12. Graphic display

13. Function key

14. Rotary pushbutton

15. Function key

16. DIN rail fastening

eneral view NivuFlow 750

Product specification

page 15

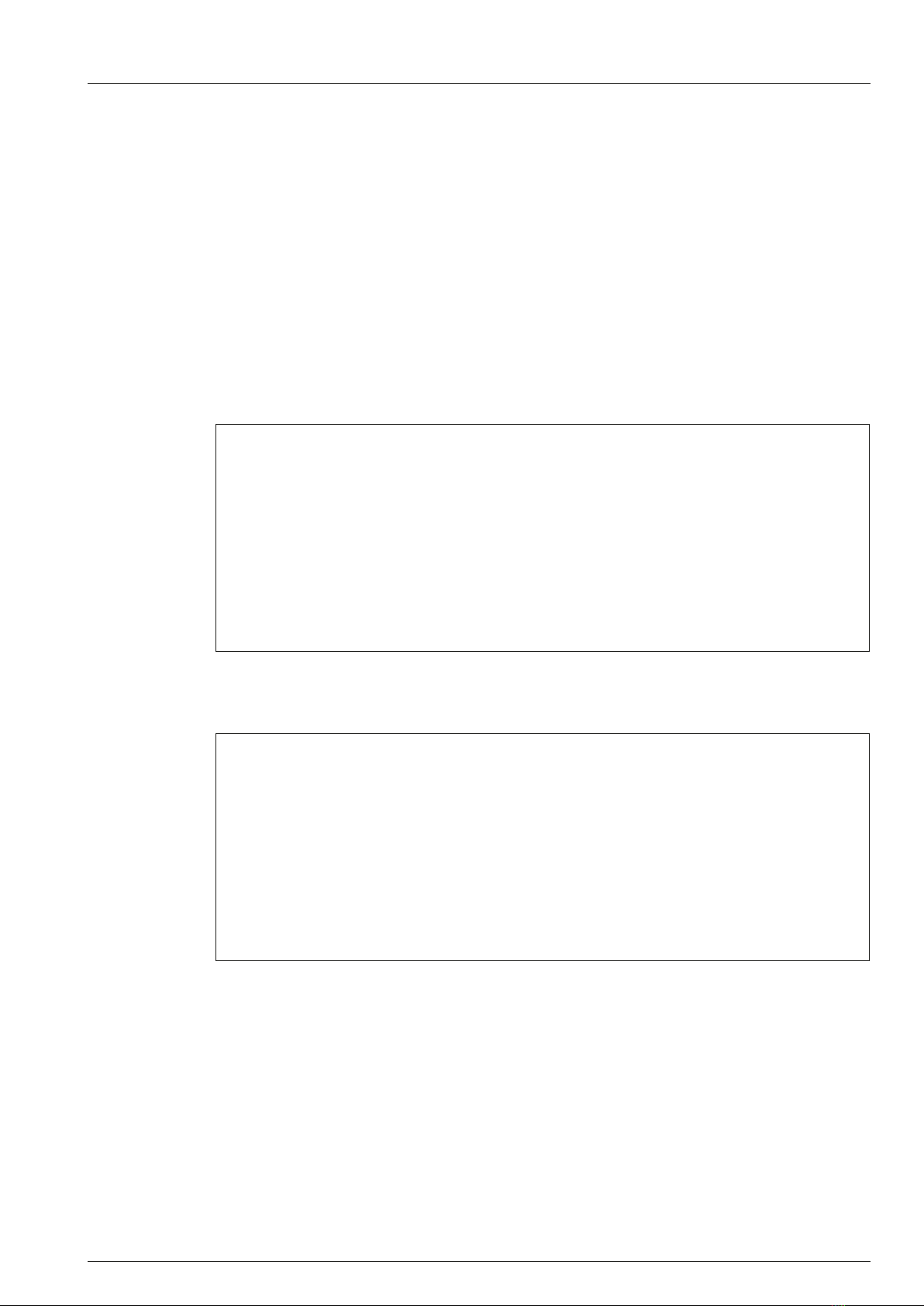

3.2 Connectable sensors

The image below provides an overview on the connectable sensors.

Fig. 3-2

1. Flow velocity wedge sensor, Type POA-V2H1/V2U1

2. Flow velocity wedge sensor, Type POA-V200/V2D0

3. Flow velocity wedge sensor, Type CS2

4. Pipe sensor, Type CS2, with sensor screw joint and retaining element

5. Pipe sensor, Type POA, with sensor screw joint and retaining element

6. Ultrasonic level sensor, Type OCL-L1

7. Mini flow velocity wedge sensor, Type CSM-V100

8. Mini flow velocity wedge sensor, Type CSM-V1D0

9. Ultrasonic level sensor, Type DSM

10. Electronic Box, Type EBM

Overview sensors and Electronic Box

Instruction manual

NivuFlow 750

page 16

3.3 Use in accordance with the requirements

Important note

The instrument is intended solely for the purpose described below.

Modifying or using the instruments for any other purposes without the manufacturer’s writ-

ten consent will not be considered as use in accordance with the requirements.

The manufacturer cannot be held responsible for any damage resulting from improper use.

The user alone bears any risk.

The permanent flow meter Type NivuFlow 750 including the accompanying sensors is designed

for continuous flow measurement of slight to heavily polluted media in part filled and full chan-

nels, pipes and similar. The maximum permissible limit values as specified in chapter 3.5 shall be

necessarily observed. Any case varying from these conditions which is not approved by NIVUS

GmbH in written form is left at the owner’s risk.

Ex protection

Important note

Install the transmitter out of Ex zones!

The Ex approval of the sensors is part of the „Technical Description for Correlation Sen-

sors“. The Ex approval of the Ex Separation Interface is part of the „Technical Description

for iXT Ex Separation Interface”.

To use flow velocity sensors in Ex areas an iXT Ex Separation Interface shall be necessar-

ily installed between transmitter and sensors.

The wiring diagrams can be found in the according instruction manual.

Note

For installation and commissioning the conformity certificates as well as the test certificates

issued by the respective authorities shall be followed.

The combination of NivuFlow and the iXT Ex Separation Interface is adjusted solely to

NIVUS correlation sensors regarding the intrinsically safe system review according to EN

60079-25.

In the event of using sensors by third-party manufacturers the operator shall carry out a

system review according to EN 60079-25!

The required specifications of the iXT Ex Separation Interface can be found in the accor-

ding EC type examination certificate.

Product specification

page 17

3.4 Device identification

The instructions contained within this manual are valid only for the type of device specified on

the title page.

The name plate is fixed on the side of the enclosure and contains the following:

• Name and address of the manufacturer

• CE label

• Information on type and series, serial no. if available

• Power supply

In case of enquiries and ordering replacement parts it is important to specify article number as

well as the serial number of the respective transmitter or sensor. This ensures correct and quick

processing.

Fig. 3-3 Nameplate AC version

Fig. 3-4 Nameplate DC version

Instruction manual

NivuFlow 750

page 18

3.5 Specifications

Power supply 100 to 240 V AC, -15 % / +10 %, 47 to 63 Hz

or 10 to 35 V DC

Supply connection Plug with spring-cage terminal clamps

Max. power consumption AC: 30 VA / DC: 20 W

Typ. power consumption 1x POA-V2U1 + 1x i-Sensor + 1 relay energised,

230 V AC: (rounded) 14 W

Enclosure - Material: aluminium and plastic

- Weight: approx. 1150 g

Protection IP20, shock resistance IK08

Operating conditions - Protection class I

- Overvoltage category II

- Pollution degree II

- AC unit for use in altitudes up to 3000 m above MSL. At relay

voltages > 150 V the use is restricted to an altitude of max.

2000 m (AC and DC units)

Operating temperature DC: -20 °C to +70 °C

AC: -20 °C to +65 °C

Storage temperature -30 °C to +80 °C

Max. ambient temp. for

installation and operation

+50 °C

Max. humidity 80 %, non-condensing

Display TFT full graphic colour daylight display,

240 x 360 pixel, 65536 colours

Programming Dialog mode using rotary pushbutton and 2 function keys, in

German, English and French

Connection Plug with spring-cage terminal clamps

Inputs - 1 x 4-20 mA for external level (2-wire probe)

- 1 x RxTx-Bus for NIVUS air-ultrasonic sensor Type OCL

- 1 x (Type S1) or 7 x (Type M3) 0/4-20 mA with 12 Bit reso-

lution for external level, external controller setpoint and data

storage of external units, accuracy ±0.4 % of measuring

range final value (20 mA), load 91 Ohm

- 2 x (Type S1) or 10 x (Type M3) digital input

- 1 (Type S1) or 1 - 3 (Type M3) velocity sensors (POA, CS2 or

EBM Electronic Box + CSM) connectable

Outputs - 2 x (Type S1) or 4 x (Type M3) 0/4-20 mA, load 500 Ohm,

- 12 Bit resolution, accuracy higher than ±0.1% at 20 °C (higher

than ±0.4 % at -20 °C … +70 °C)

- 1 x bistable relay SPDT (Typ S1), maximum load

230 V AC / 2 A (cos. 0.9), min. switching current 100 mA

- 1 x (Type S1) or 6x (Type M3) relay(s) SPDT, maximum load

230 V AC / 2 A (cos. 0.9), min. switching current 10 mA

Controller 3-step controller, quick close function, adjustable slide position

in case of error

Data memory Internal 1.0 GB, for programming and readings memory

Storage cycle 30 seconds to 5 minutes

Communication - Modbus TCP via networks (LAN/WAN, Internet)

- Modbus RTU via RS485 or RS232

- Internet via Ethernet (in preparation)

Product specification

page 19

Sensors

Observe the specifications of the according sensors as described in the respective instruction

manuals or technical descriptions.

Storing

The following storing conditions shall be strictly adhered to:

• max. temperature: +80 °C

• min. temperature: - 30 °C

• max. humidity: 80 %, non-condensing

• The NivuFlow shall be protected from corrosive or organic solvent vapours, radioactive

radiation as well as strong electromagnetic radiation. Always store the instrument in its

original packaging.

3.6 Configuration

3.6.1 Device Types

The NivuFlow is available in different versions which mainly vary in terms of the number of con-

nectable sensors. The article number can be found on the nameplate which is fixed on the side

of the enclosure.

NF7- Type

5For part filled and full applications

Typ

S1 1 x v-sensor, 1 x air-ultrasound OCL, 2x DE, 2x DA, 2x AE, 2x AA

SR 1 x v-sensor, 1 x air-ultrasound OCL, 7 x DE, 5 x DA, 5 x AE, 4 x AA

built-in 3-step controller

M3 3 x v-sensor, 1 x air-ultrasound OCL, 10 x DE, 6 x DA, 8 x AE,

4 x AA, built-in 3-step controller

Enclosure and construction

E0 DIN rail mounting/installation in switching cabinet

W0 Field enclosure

W2 Type S with built-in iXT Ex Separation Interface in field enclos.

W4 Type M3 with built-in iXT 420 Ex in field enclosure

Power

A0 100 - 240 V AC

D0 9-36 V DC

Firmware extensions

0none

AAnalytics (connection via RS 485)

Number of measurement places

11 measurement place

22 measurement places

33 measurement places

Instruction manual

NivuFlow 750

page 20

3.6.2 Delivery

Note

Check if your delivery is complete. Check the packaging for visible damage immediately

after receipt. Any possible damage in transit shall be instantly reported to the carrier.

Furthermore a written report shall be sent to NIVUS GmbH in Eppingen.

Incomplete deliveries shall be reported in writing either to your local representative or direc-

tly to the NIVUS head office in Eppingen within 2 weeks.

The standard delivery of the NivuFlow contains:

• The instruction manual including the certificate of conformity and approvals. It contains

any relevant information on how to operate the NivuFlow.

• a transmitter type NivuFlow 750

Check extra accessories depending on your order and by using the delivery note.

3.6.3 Transport

Do not expose the system to heavy shocks or vibrations. Use the original packaging for transport.

3.6.4 Return

The units shall be returned at customer cost to NIVUS Eppingen using the original packaging.

Insufficiently franked shipments will not be accepted!

3.6.5 Installation of spare parts and parts subject to wear and tear

We herewith particularly emphasise that replacement parts or accessories not supplied by

NIVUS moreover are not certified and approved by NIVUS too. Installation and/or the use of

such products hence may negatively influence predetermined constructional characteristics of

the measurement system or even lead to instrument failures.

NIVUS cannot be held responsible for any damage resulting due to the use of non-original parts

and non-original accessories.

You can find original manufacturer spare parts or accessories in chapter 9.5.

Other manuals for NivuFlow 750

1

Table of contents

Other Nivus Transmitter manuals

Popular Transmitter manuals by other brands

ATI Technologies

ATI Technologies F12/D O & M Manual

K-TEK

K-TEK AccuTrak AT100 Installation & operation manual

Lectronics

Lectronics Digital Hybrid Wireless HHa-941 instruction manual

August

August CR150 user manual

Endress+Hauser

Endress+Hauser Memograph CVM40 Brief operating instructions

Novus

Novus TL400-I user guide