NOVUS AUTOMATION 2/26

1SAFETY ALERTS...............................................................................................................................................................................................3

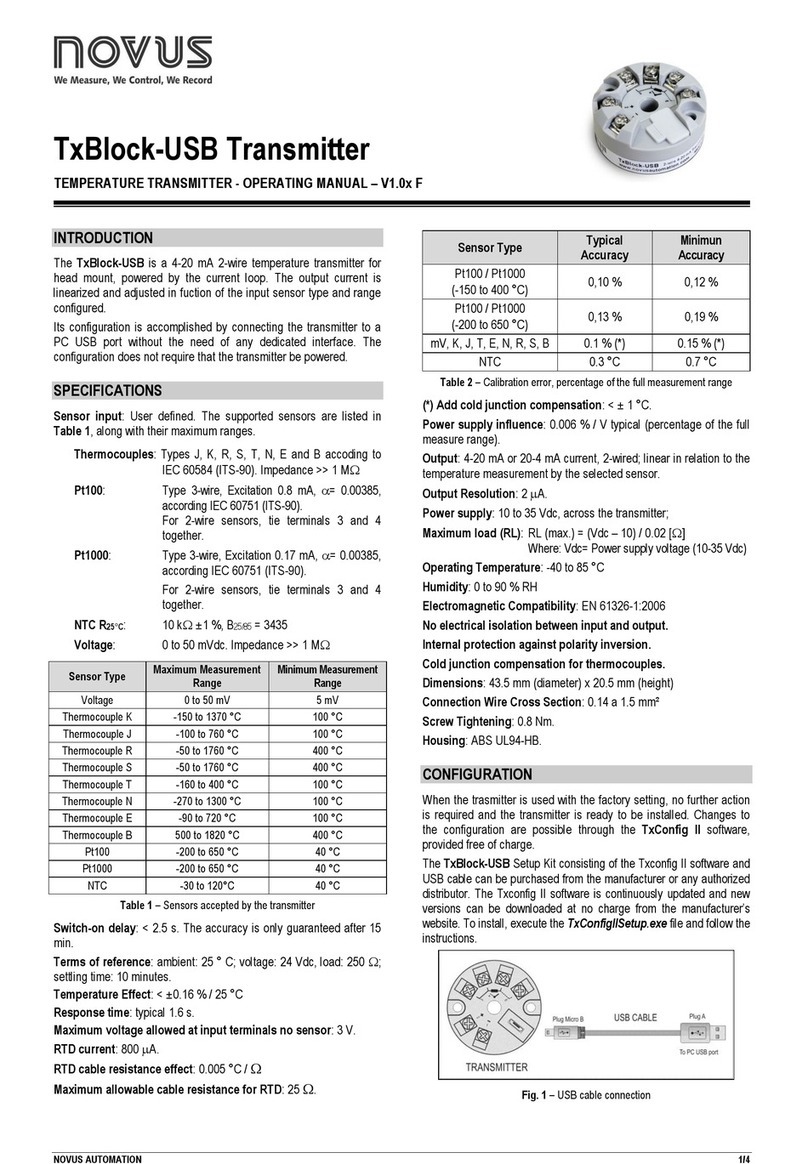

2PRESENTATION................................................................................................................................................................................................4

3IDENTIFICATION ...............................................................................................................................................................................................5

3.1 OVERVIEW .................................................................................................................................................................................................5

3.2 IDENTIFICATION ........................................................................................................................................................................................5

3.3 TL400-I ........................................................................................................................................................................................................5

4INSTALLATION ..................................................................................................................................................................................................6

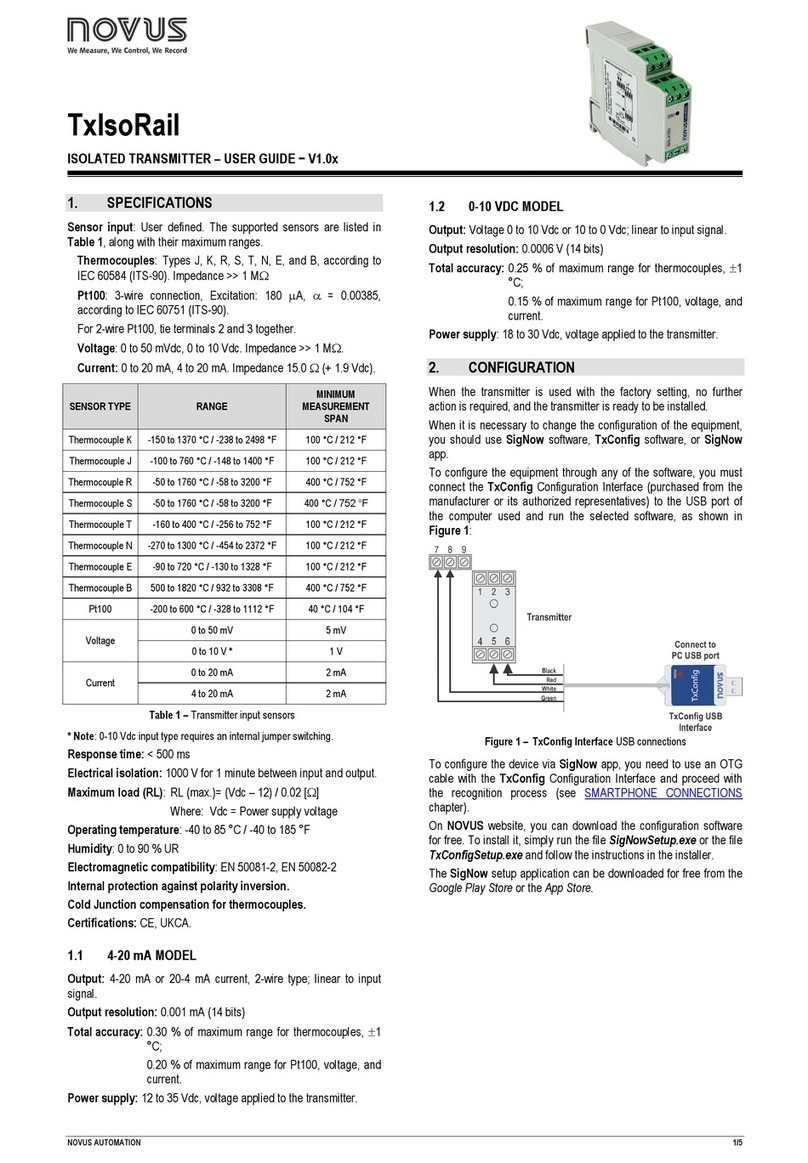

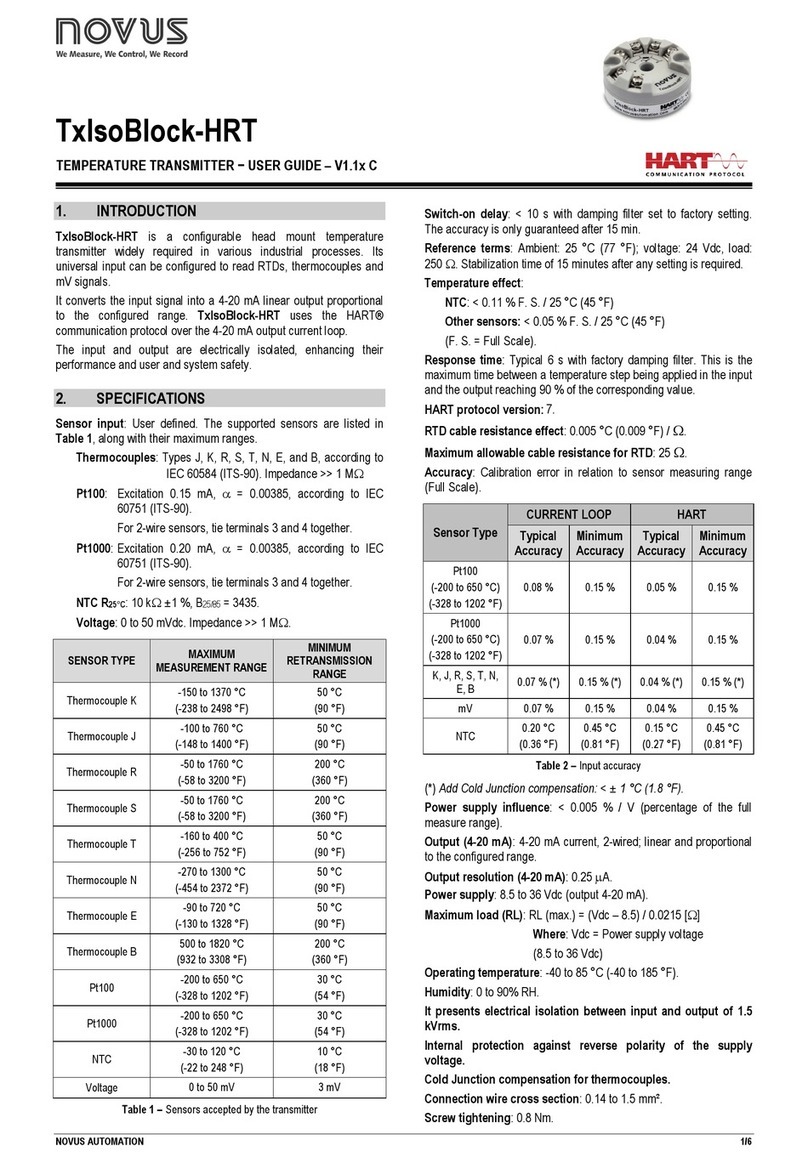

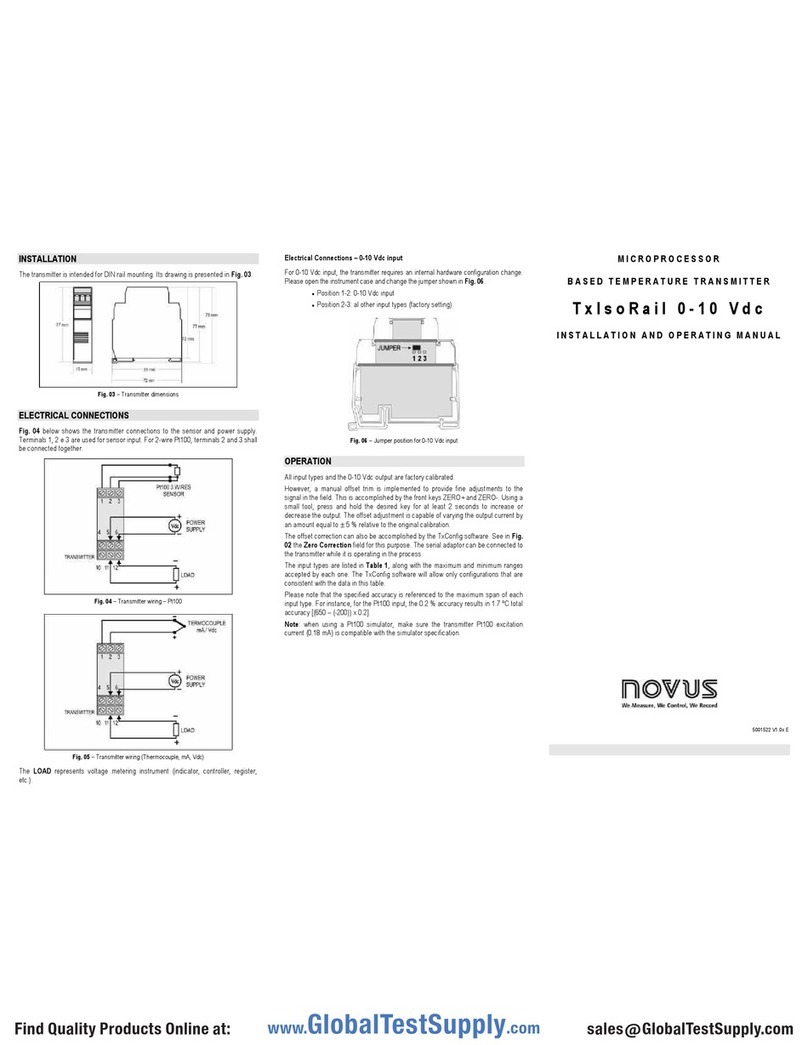

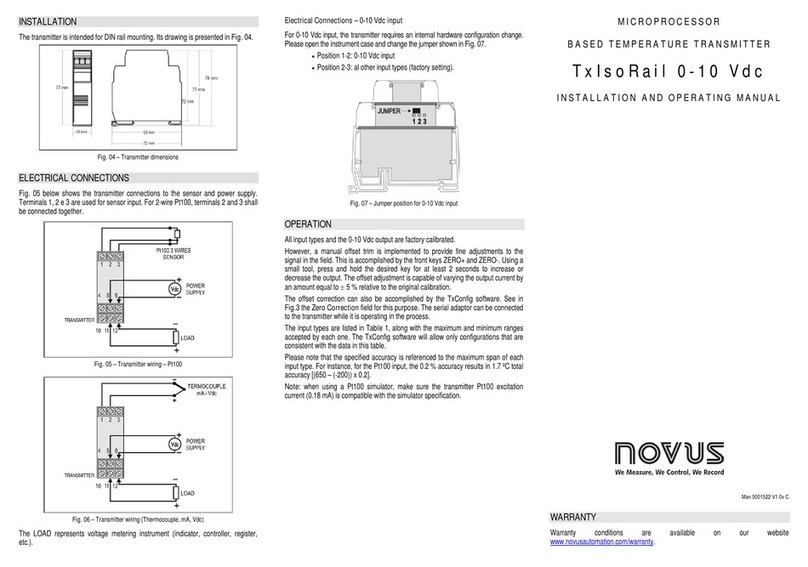

4.1 ELECTRICAL INSTALLATION....................................................................................................................................................................6

4.1.1 INSTALLATION RECOMMENDATIONS...........................................................................................................................................6

4.1.2 ELECTRICAL CONNECTIONS.........................................................................................................................................................6

4.1.3 DIMENSIONS ....................................................................................................................................................................................6

4.1.3.1 TL400-I ....................................................................................................................................................................................... 6

4.1.3.2 5-HOLE TO 4-HOLE ADAPTER ................................................................................................................................................ 7

4.2 MECHANICAL INSTALLATION ..................................................................................................................................................................7

4.2.1 TL400-I WITH AND WITHOUT ADAPTER........................................................................................................................................8

4.2.2 INSTALLATION EXAMPLES.............................................................................................................................................................8

5DEFINITIONS ...................................................................................................................................................................................................10

5.1 TECHNICAL TERMINOLOGY...................................................................................................................................................................10

5.2 SOME TYPES OF TANKS ........................................................................................................................................................................10

6SIGNOW APP...................................................................................................................................................................................................12

6.1 BLUETOOTH INTERFACE .......................................................................................................................................................................12

6.2 PAIRING TL400-I WITH YOUR SMARTPHONE ......................................................................................................................................12

6.3 CONFIGURING YOUR TL400-I ................................................................................................................................................................13

6.3.1 INFORMATION................................................................................................................................................................................13

6.3.2 BASIC CONFIGURATION...............................................................................................................................................................14

6.3.3 ADVANCED CONFIGURATION .....................................................................................................................................................14

6.3.3.1 INPUT....................................................................................................................................................................................... 15

6.3.3.2 OUTPUT................................................................................................................................................................................... 16

6.3.3.3 ADVANCED FILTER................................................................................................................................................................ 17

6.3.3.4 SECURITY ...............................................................................................................................................................................18

6.4 DIAGNOSTIC ............................................................................................................................................................................................18

6.5 FIRMWARE UPDATE................................................................................................................................................................................20

7ADVANCED FILTER ........................................................................................................................................................................................21

7.1 WHEN USE THE ADVANCED FILTER.....................................................................................................................................................21

7.2 A MORE DETAILED EXPLANATION OF THE ADVANCED FILTER PARAMETERS.............................................................................21

7.2.1 "SIZE OF THE MAIN VECTOR" PARAMETER ..............................................................................................................................21

7.2.2 "SIZE OF THE DISTANCE VECTOR" PARAMETER .....................................................................................................................21

7.2.3 "MEDIAN INDEX" PARAMETER.....................................................................................................................................................21

7.2.4 "ENABLE BLOCKING FILTER" PARAMETER ...............................................................................................................................22

7.2.5 "ACCEPTANCE PERCENTAGE" PARAMETER ............................................................................................................................22

7.2.6 "PERCENTAGE INCREASE" PARAMETER ..................................................................................................................................22

7.2.7 "ACCEPTANCE COUNTS" PARAMETER......................................................................................................................................22

7.2.8 "ACCEPTANCE RATIO" PARAMETER..........................................................................................................................................22

8USAGE EXAMPLES.........................................................................................................................................................................................23

8.1 EXAMPLE 1: 3-METER HIGH AND 2-METER WIDE WATER TANK ......................................................................................................23

8.2 EXAMPLE 2: 80 CM OIL TANK.................................................................................................................................................................23

9TECHNICAL SPECIFICATIONS ......................................................................................................................................................................25

9.1 CERTIFICATIONS.....................................................................................................................................................................................25

10 WARRANTY .....................................................................................................................................................................................................26