NLI DHR-6 User manual

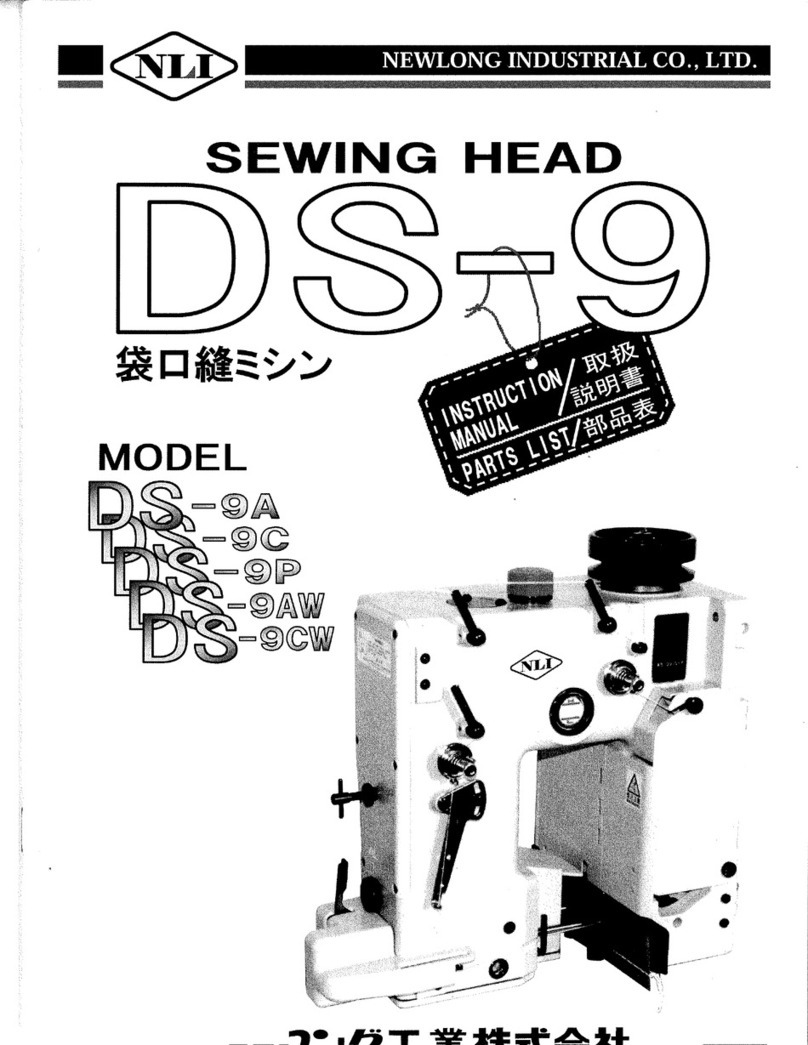

NEWLONG INDUSTRIAL CO., LTD.

BAG

SEWING

MACHINE

I

No.1

For Operator Safety

Thank you for purc h a s ing t he N LI

Model DHR-6 Bag Sewing Machine Head.

• This

manual

contains the instructions

and

precautions

for

using

the

Model

DHR-6 Bag Sewing

Machine

Head. Be

sure to read and understand this

manual

before use and

use

the

machine

correctly.

• Keep this manual near

the

sewing machine for easy

reference.

Be

sure to attach this

manual

to the

machine

when

lending

or

transferring

it

to

another person

or

company.

• Please orderthis

manual

from

the nearest NU

office

ifit is

lost.

• The contents

of

this manual are subject

to

change

without

prior notice

for

improvement

and safety purpose.

&Hazard

of

Being

Caught

in the

Machine

• Be careful, when

YoU

insert a bag to

be

closed into

the

sewing

machine, or your fingers

ma:y

be caught

in

the

machine between

the

presser foot and feed

dog.

•A·

Hazardous·

mark

is attached to the

machine.

When

sewing, be sure not

to

touch on

the

machine.

~

Hazard

of

Being Caught in

the

Machine

• A

Needle

Bar and

Needle

Thread Take-Up are

moving

at high speed.

A•

Hazardous"

mark

is attached

to

the

machine. When the

machine

is operation, keep fingers

and yourself

away

from

the

Needle

Bar and

Needle

Thread Take-Up.

:=..::i.-rz:Y!>'°.I•(t*)

DHR-6~

~

1/:Y~;td

_R1,,J:l1"'~tt~11~J1,

:::-~1,"~T,,

•

;:Q)Jtk•tt~•f:t

DHR-6

~ffl~v~Q)Jlk~fl1,

'7i~

~fscffl

J:Q)ttt:•lJltilte.8~.tL-n,

'*To

~fscfflKiH::;:Q)JlkflUM•~~,-ftdWf~<t.::~1,,0

P9~

~+~t,

-CJE.t,<

::'M

<te~v

'o

•

;:Q)

11kffi~

IJJHIJ'1~v~Q),t

J'f

l:::,

1,

,--::i-c1,~1Jffl

1,

,tt.te

lt-o.t;,

{*/fl,

-c<r.:~1,,0

DHR-6

~,u~Jfl~v~Mfl,l:ijl,,

*1tt.J:llill11J!l1tt.J:

;:,Q)

11kffiit~-~,hl;:~L,

"(

<t.::~1,

,,,

e;:Q)Jtk•U~-~~~~tLtt.•1tt.J:=.::i.-o~,I~

cm½1111t•m·i!llfm1:::.::-ttx<te~1,

,,,

•

:.11J

llilffili~

i!Fl'1M~

!Pl

J:

* ft.

1-x~½Q)ft.afJ,

7fit.t

t,

1.:RJ!To:.ttit~t.>*T,,

&-~~-

•

~v~l.:a~t1JA-tot$f±tt:tL-t~11,l:tt~tfll.x~

l::tt)t,S~$l6*Mifctl,t,S~tJ*-t,,

• ~v~•~•'1~l6tt......

-!l~Jli!i-:>-Cll

'*i°"

a

m.o~~v~l;:a•~v~t.,!1,

,.t%:.tt•t-

-c

<~~1,

'-·

.~

~]6~-

• tt-f*~..l:*~fft.J:itH!k~IIJ1,

,-c1,

'*T.,

~vYl;:•';J:~JAtttl...,.-~~Jl~-:>

"Clt

'°*To

~v~t,11JJ1,

,-c1,

,;s2::~1'1tH$~..l:*~ff

l=ti~i*~

i!r--:Sltf~l,

'~<~~1,

,,,

• The instruction manual and parts

list

is subject

to

change

without prior notice.

•

~O)JDl

••

lJ.I.

/I {-•:JIJ

At-lctatBtai

..t

O)f.:NJ~i!t(i:L.1::JIJ!"t

-1,~ciJ(it)

':J;l;"t

0

From the Library of Superior Sewing Machine & Supply LLC

WARNING

PERSONAL

INJURY

MAY

RESULT

IF

THE

FOLLOWING

SAFETY

PRECAUTIONS

ARE

NOT

OBSERVED.

1.

BE

SURE

THE

AREA

SURROUNDING

MACHINE

IS

FREE

OF

ALL

HAZARDS

SUCH

AS

FIRE,

WATER,

OIL,

RUBBISH

OR

ANYTHING

THAT

CAN

CAUSE

INJURY.

2.

DO

NOT

OPERATE

MACHINE

IN

AN

EXPLOSIVE

AREA

OR

UNDER

WET

CONDITIONS.

THE

MACHINE

IS

NOT

AN

EXPLOSION-PROOF

TYPE

NOR

WATER-PROOF

TYPE.

3.

DO

NOT

OPERATE

MACHINE

BEFORE

READING

INSTRUCTION

MANUAL.

4.

DO

NOT

OPERATE

MACHINE

ON

VOLTAGES

OTHER

THAN

SPECIFIED

FOR

THE

MACHINE.

5.

BE

SURE

MACHINE

IS

CONNECTED

TO

BUILDING

ELECTRICAL

SAFETY

GROUND

(EARTH).

6.

BE

SURE

POWER

(AND

A

IR

SUPPLY)

IS

OFF

BEFORE

PERFORMING

MACHINE

MAINTENANCE,

PARTS

REPLACEMENT,

ADJUSTMENTS

OR

CLEANING.

7.

DO

NOT

OPERATE

MACHINE

WITH

GUARDS

AND

COVERS

REMOVED.

8.

DO

NOT

TOUCH

KNIFE,

NEEDLE,

PULLEY,

BELT

AND

MOVING

PARTS

WHEN

MACH

I

NE

IS

IN

OPERATION.

9.

BE

SURE

MACHINE

IS

PLACED

ON

A

SMOOTH

(LEVEL)

SURFACE

WHEN

PERFORMING

MAINTENANCE,

PARTS

REPLACEMENT,

ADJUSTMENTS,

CLEANING

OR

STORAGE.

10.

BE

SURE

THE

MATERIAL

TO

BE

SEWN

OR

CLOSED

COMPLIES

WITH

THE

MACHINE

SPECIFICATIONS.

11.

DO

NOT

USE

SPARE

PARTS

OTHER

THAN

"

NL!"

GENUINE

PARTS.

••

~~©~~~§~~~L~~?~~~

l:::l~t:-Ml:©ffli~

c.

t.;.

")

a::"t©~~~

L

L <

t::

~

I,

\0

1.

•

~

0)

)!] ill

I=

$

i!it

~

~

.:.

"t"

mt

~

c.

t.;

7a>

!k

~..

JJ<..

im..

i:iJ:I!~

t.;

ct.it~

1.

,t.i,.fitt.i,cY)

t

(f;:~l,\o

2.

-~O)ffi;l!iO)

if>

7a>•:tl

• ll<m!it.iti~Ji.~I=

f.1,f.1,7a>.±Jl--c:l;t-ftffl

L,tJl,\""(:

<t::~

(,\0

.:.0)-~l;t

..

Rn-~.

Rnm!i~--C:l;tN.,

")

'tit

lvo

3.

Jljif&mBJ.lif~~"(McA,--c:f.l,

1:,--~jifii

L

t ( f;:~

l,\o

4. -~O)}~JE'.fflff

J~H'l-

--c:l;tjifii

Lt.;

I.'

--c:

<

t::

~l,\o

5.

7-7..~t.it~*.,'c~ht1.,7a>$~.fit~

Lt<

f;:~l,\o

6.

•~O)~iiffi

• !B~3'.cm.

ru11~

• ~11:m~O)

AAl=~"fffl;Ji

C.&ttI7-;Ji)

~~-:it<

f;:~l,\o

7.

ii~1JJ{-t.i<~nt=~~--c:l;t·~~jifii

L

fJl,\""(:( f;:~l,\o

8.

..O)jifji

cp

l;j:

7.J

'~

5(

-

,.

$t

._

-;/-

1)

-

._

~Ji.,

"-t

O)·fttt1.11.,

t

1.

,7a,

~rffl=

11-¥

~Mn

fJl,\""(:( f;:~l,\o

9.

•~O)•iiffi·!B~3'.cm-~•-:m~~~~O)

~1=11:qr

i;

t.;:t1rffl=i'fi1.

't

<

t::

~

1.

,0

10.

ifl;Js-3

c.

"t"

7a>~*1t.it-~O)f±~l=-€.--:i t

(,\

7a,

f.1,-fitf.1,cY)

t <

t::

~

I,

\0

11.

"=-.:i.-Cl/~I~(*l)"

til!iE!B~~~l;t

ilffl

Lt.;

I.'

1: <

t::

~

I.

'o

From the Library of Superior Sewing Machine & Supply LLC

Identifying and Ordering Parts

Cautions When Using the Machine

Maintenance

Where the construction permits, each part

is

stamped with

its part number. On

all

orders, please include part number,

part name

and

model name

of

machine.

Safety Rules

To prevent personal injury:

•

All

power sources to the machine must be turned

off

before threading, oiling, adjusting or replacing parts.

•

All

cover and guards must be

in

position before operating

machine.

•

Do

not tamper with safety cover, guards, etc.,

while

machine

is

in

operation.

Safety Precautions

1)

Always

turn power off before threading, oiling, and

adjusting the machine or replacing parts.

2)

Wear safety glasses.

3)

Make

sure, before starting the machine, that

all

covers

and shields are

in

place and closed.

4)

Do

not touch on the machine when it

is

run.

5)

Turn power

off

and make sure the cutter does not operate

before you put your fingers under the cutter blades and

the needles to adjust.

6)

Do

not touch on the machine when it

is

run.

• Please keep

in

mind

to handle the machine carefully and to

maintain the machine

in

good condition.

• Thread fuzz or dust must be cleaned

with

air or brush on

throat plate,

in

the groove of feed dog or around looper

after the day's work.

• Wipe the area easy to rust with

oil

cloth.

• Check the machine for loose screws and tighten them, if

any, once a month.

• Good

maintenance

will

prolong

the

machine life.

ii

•

:=.=1-

-o:.,,~-I~

(~)

~OO~~ffl·~~ml;:.f';:!:DHR-6

(J)

itililE

ti%fb

:a:-~-Om

L,

--c

:Jo~

~To

•

:::·r±.x(J)~i-;:1:,

/"-o/!J?-J--(1)/"-o/*%,1:~~--c:-:::·mjf-

<tt~i.

\0

•*fflL~~OO~~&O*ffl~(J)~-~~-~~-~

(J){i:!!l!f-0mftc1::--C:-/g¥~

f;:.

<v,~_.g.l'i,

:Jo

J'l

v

'LITv

'tctc~

~L,tc:=.=1--01/~-I~(~)~OO~~Pfr·~mm1;:.~~m

<tt~v

'o

j\!;j~(J)~.

~fl~,

~~:ffi:%, ~1/1/.lm®~,

~

1/1/:ffi:%:a:-:::·mjf-<tc~v

'~T

J:5:Jol»lv

'v

'fcL,~"t"o

1>

~~~~

•*mn(J),l:~(J)*ifilL,, *(1)3'.t~.

*1'i71:!l.

w.Bl!f.

®&3'.t~.

f*"'f,¢.e~f'F~(J)irrr1;:.~,--rt7JJ:a:-m-::i--c<tt~

v'o

2)

W!Bl!ffp~(J),l:~l'i'ti:V:JJ

*(J)*ffl

:a:-:Jo"t"T~

L,~"t"

o

4)

.iJ

/'{-ftc1::;vt1¥J~-::i

--Cv

,Q;:_,1::a:-~~

L,

--c;v,G~~L,

--c

<

tc~v\o

5)*(J)-fl;:.-¥:a:-AnQ,1:~1'i,

~,--rt7JJ:a:-m-::i--c<tt~i.

'o

f~~W!ffl!f

(J)

,1:~1'i,

~,

--rt7JJ:a:-m

~~1/:.,,;vtllJ;v,ftv

,;:_,1:

:a:-~~L,

--c;v,Gf'F~:a:-rr-::i--c<tc~v'o

• ~1/1/llli'tf~l'i~!Wft1J,~ft$

Jl1=1;v>G/±:l*L;vt-::i--Cv

'~To

r±.~~<

I&Wl5

,1:,1:t

1;:.

~

1;:.l!f-Om

1;:.,tA1Ht--c

<

tt~v

'o

• -

f::l

(J)fp~;vt~TL,~L,tcG,

*fi(J)L,

~!J~(J)r#(J)

~-

1v-/"-(J)~:b~1;:.~~-::itdi::.~~l'i~hv'l;:.I&~

~v'--C<tc~v\o

• -¥Ah(!).&L,~U'i~~(J)~~f;:.J&9L,~T(J)--c:':::·r±.~

<tc~v\o

From the Library of Superior Sewing Machine & Supply LLC

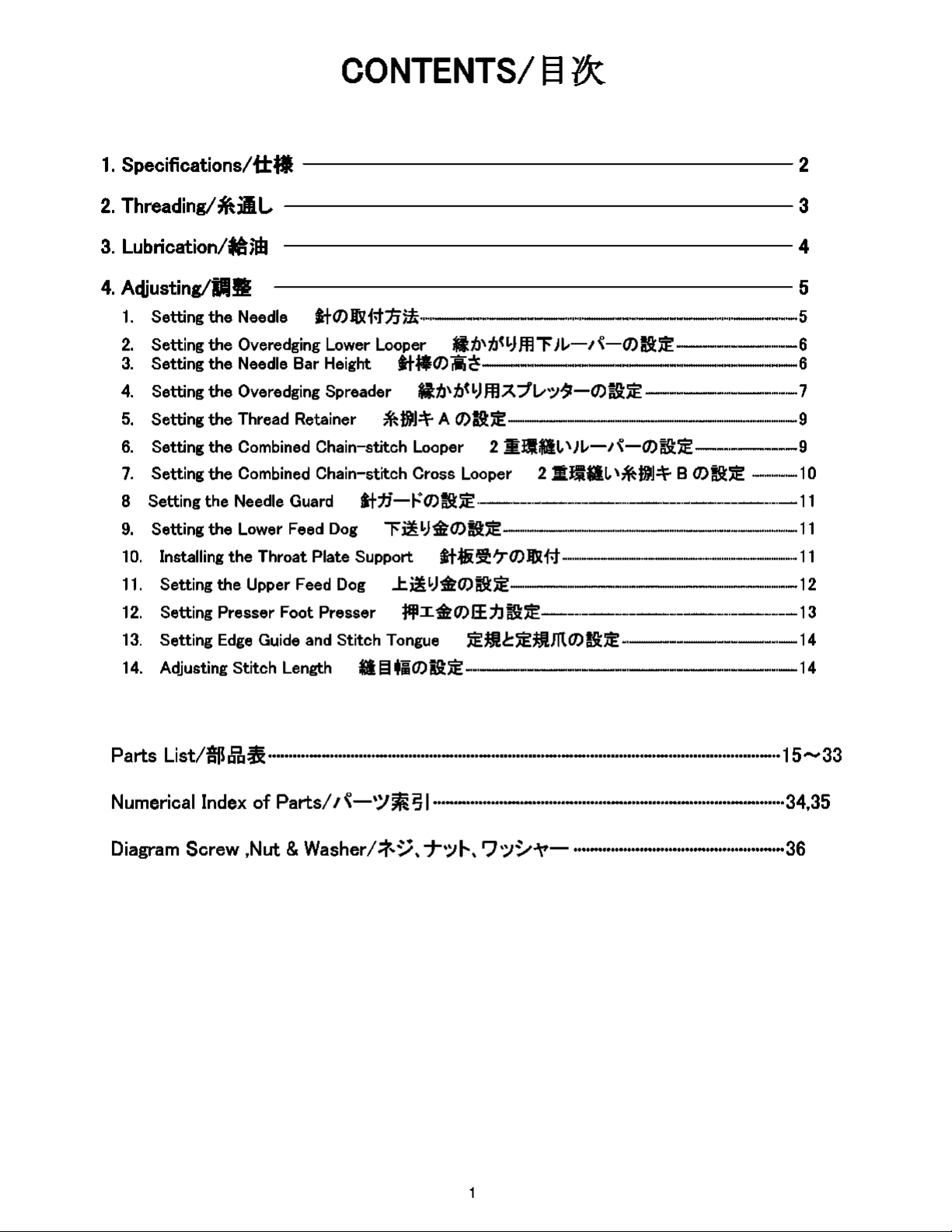

CONTENTS/

~

{X

1.

Specifications/fr~

--------------------

2

2.

Threading/*ill,

3

3.

Lubrication/~nb 4

4.

A<tjusting/iffljg

-------------------

5

1.

Setting

the

Needle

~fO)Joli.tn)!-----------------5

2.

Setting

the

Overedging Lower Looper fitJ,tJ<LJffl""FJL,-1{-0)~;E'. 6

3.

Setting

the

Needle Bar Height

~t,$0)

~

~

6

4.

Setting

the

Overedging Spreader

fiti,tJ<LJffiA:1v•;,1t-O)~JE'.-------7

5.

Setting

the

Thread Retainer

~H.!JI]=\=-

A

O)~JE'.-------------9

6.

Setting

the

Combined Chain-stitch Looper 2

m:J1a1,,Jt.,-1~-0)~JE'.-----9

7.

Setting

the

Combined Chain-stitch Cross Looper 2 mJ1a1,

'~H.IJI]=\=-

B

O)~;E'.

................

10

8 Setting

the

Needle Guard

~t:fl-~'O)~;E'.--------------11

9.

Setting

the

Lower Feed

Dog

""F~LJ~O)~JE'.-------------11

10.

Installing

the

Throat Plate Support

~HJ.i~70)1fXi-t-----------11

11.

Setting

the

Upper Feed

Dog

..t~

LJ~O)~;E'.

12

12.

Setting

Presser

Foot

Presser

:j:l:jl.I

~O)

ff.jJ

~;E

13

13.

Setting Edge Guide and Stitch Tongue

JE'.:ml=JE'.:mffiO)~;E'.

14

14.

Adjusting Stitch Length a

El

~;O)~;E'.

14

Parts

List/$~~····························································································································15,.,.,,,.,33

Numerical

Index

of

Parts/

I

~-'-Y~

S1

·····················································································34,35

Diagram

Screw ,Nut &

Washer/*~

..

T'.:11--

..

r'J':J~-'t'-

···················································36

From the Library of Superior Sewing Machine & Supply LLC

Table of contents

Other NLI Sewing Machine manuals