or electrolyte.

■ Immediately remove any oil or grease on the floor of the operator’s

compartment or on the handrail. It is very dangerous if someone slips while

on the machine.

■ Always use pure oil or grease and be sure to use clean containers.

■ Oil is a dangerous substance. Never handle oil, grease or oily clothes in

places where there is any fire or flame. As preparation for use of fire

extinguishers and other fire- fighting equipment.

■ Keep the battery away from fire hazards. The generated gases are

explosive.

■ Store all the oils in a specified place.

■ Keep the flammable things away from the machine. Do not smoke at the working

place.

■ Battery should always be disconnected during replacement of electrical

components.

■ Always use the grades of grease and oil recommended by NOBLELIFT choose

the viscosity specified for the ambient temperature.

■ Exhaust gas is dangerous provide ventilation when working in a closed space.

■ Avoid breathing dust that may be generated when handling components containing asbestos fibers. Wear a

gas mask if necessary.

■ When working on top of the machine, be careful not to lose your

balance and fall.

■ Hand a caution sign in the operator’s compartment (for example

“Do not start” of “Maintenance in progress”). This will prevent

anyone from starting or moving the machine by mistake.

■ When welding on the machine or working on the electrical system,

ALWAYS turn the key switch OFF and remove the battery plug

from the battery. Park the machine on firm, flat ground. Lower

the fork to the min. height and stop the motor.

■ Sulfuric acid in battery electrolyte is poisonous. It is strong enough

to

burn skin and eat holes in clothing. If you spill acid on your clothes or

skin, immediately flush with large quantities or water.

■ When working on the battery, wear goggles or safety glasses. If splashed

into the eyes, flush with water and get medical attention immediately.

■ Battery terminals touched by metal objects can cause short circuit and burn

you. Keep tools away from the terminals.

■ Keep sparks, lighted matches, and open flame away from the top of battery.

Battery (hydrogen) gas can explode.

■ When disassembling and assembling the battery, make sure that the battery

terminals (+, –) are correctly connected.

■ If water gets into the electrical system, abnormal operation or failure can

result. Do not use water or steam on sensors, connectors and

instruments in the cab.

■ Do not handle electrical equipment while wearing wet gloves, or in wet

places, as this can cause electric shock.

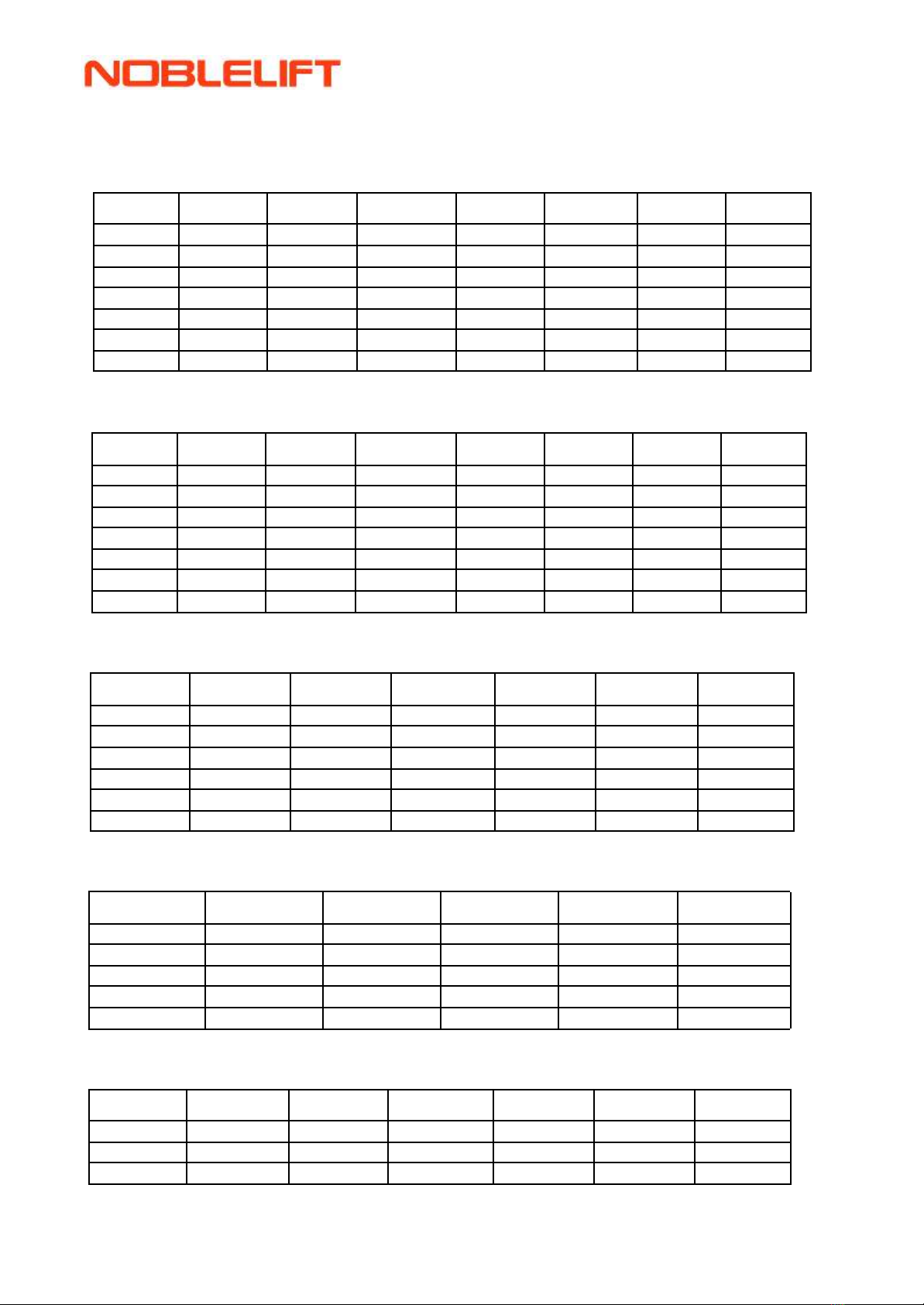

■ When working with other, choose a group leader and work according

to his instructions. Do not perform any maintenance beyond the

agreed work.

■ Unless you have special instructions to the contrary, maintenance should always be

carried out with the motor stopped. If maintenance is carried out with the motor

running, there must be two technicians present: One operating the stacker and the

other one performing the maintenance. In such a case, never touch any moving part.

■ Before making adjustment, lubricating or performing any other maintenance, shut off all power

controls.

■ When removing parts containing O-ring Gaskets or seal clean the mounting surface and replace

with new sealing parts.