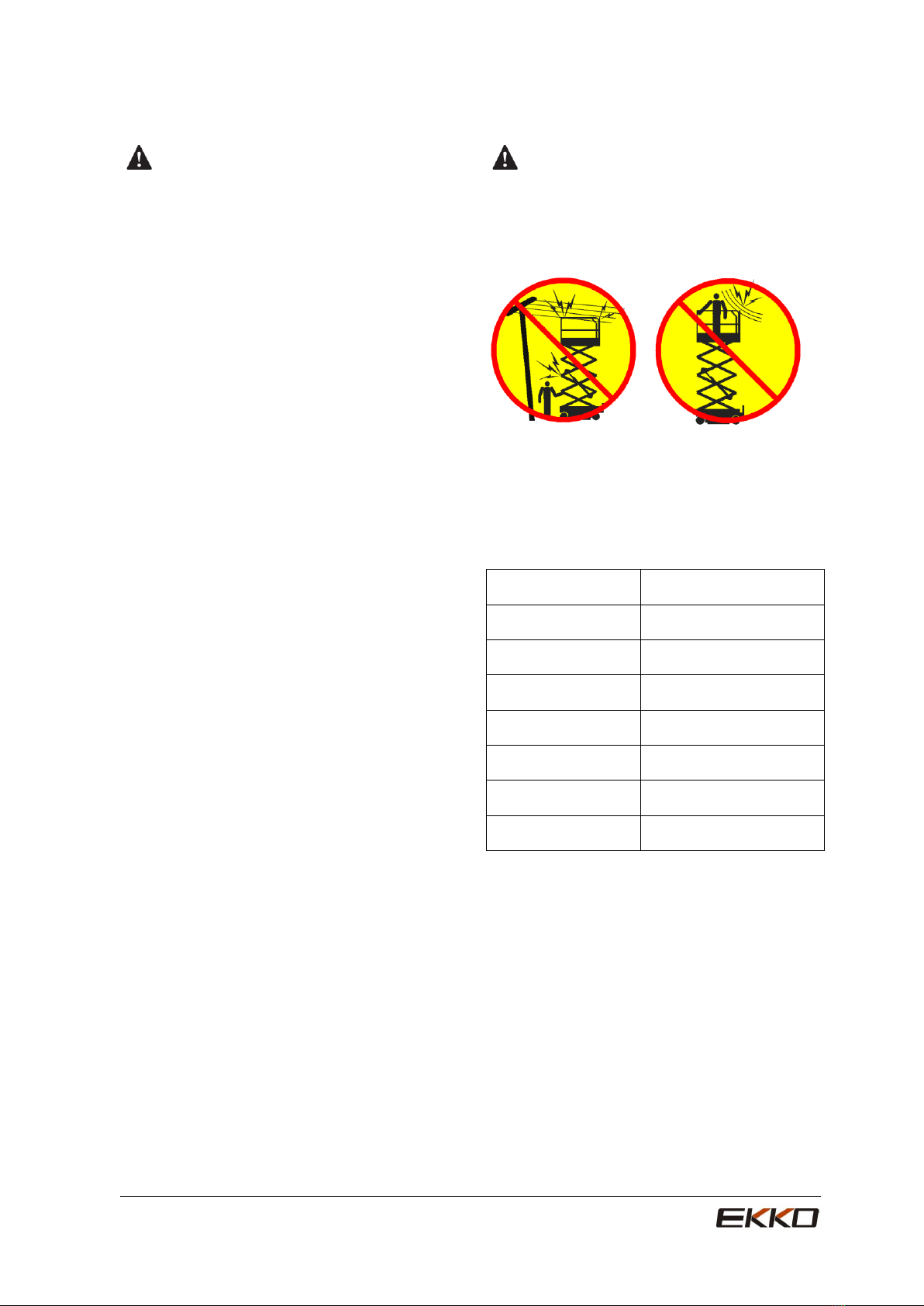

Attention

You should read, understand and follow these

safety rules and operating instructions before

operating this machine. Only trained or allowed

by authorized person can operate the machine.

This manual should be remained with the

machine at all time and considered a

permanent part of your machine. If you have

any questions please contact us

OwnersUsers and Operators:

Thank you for choosing our company and use

our machines. Our number one priority is user

safety, which is best achieved by our joint

efforts. We think that as a user and operator, if

you can comply with the following requirements,

will be very helpful for safe use of the

equipment:

1.Comply with the user rules, workplace rules

and government rules.

2.Read, understand and comply with the

manual and other instructions in manuals.

3.Routinel perform good safety work practices.

4.Only trained/certified operator or under the

guidance of a supervisors who has the

certificate can run the machine.

If there are any ambiguous in the manual or

you think we should add some contents, please

contact.

Contents

SafetyRules.................................................................1

Decals............................................................................2

PersonalSafety............................................................6

WorkAreaSafety.........................................................7

Legend........................................................................12

Controls.......................................................................14

Pre-operationInspection...........................................17

FunctionTest..............................................................19

WorkplaceInspection................................................22

OperatingInstructions...............................................23

TransportingAndLiftingInstructions........................28

Specifications..............................................................31

Maintenance...............................................................35

ElectricalSchematicDiagram..................................52

HydraulicSchematicDiagram..................................53

MaintenanceRecord.................................................56