4

TABLE OF CONTENTS

1. CORRECT APPLICATION.......................................................................................6

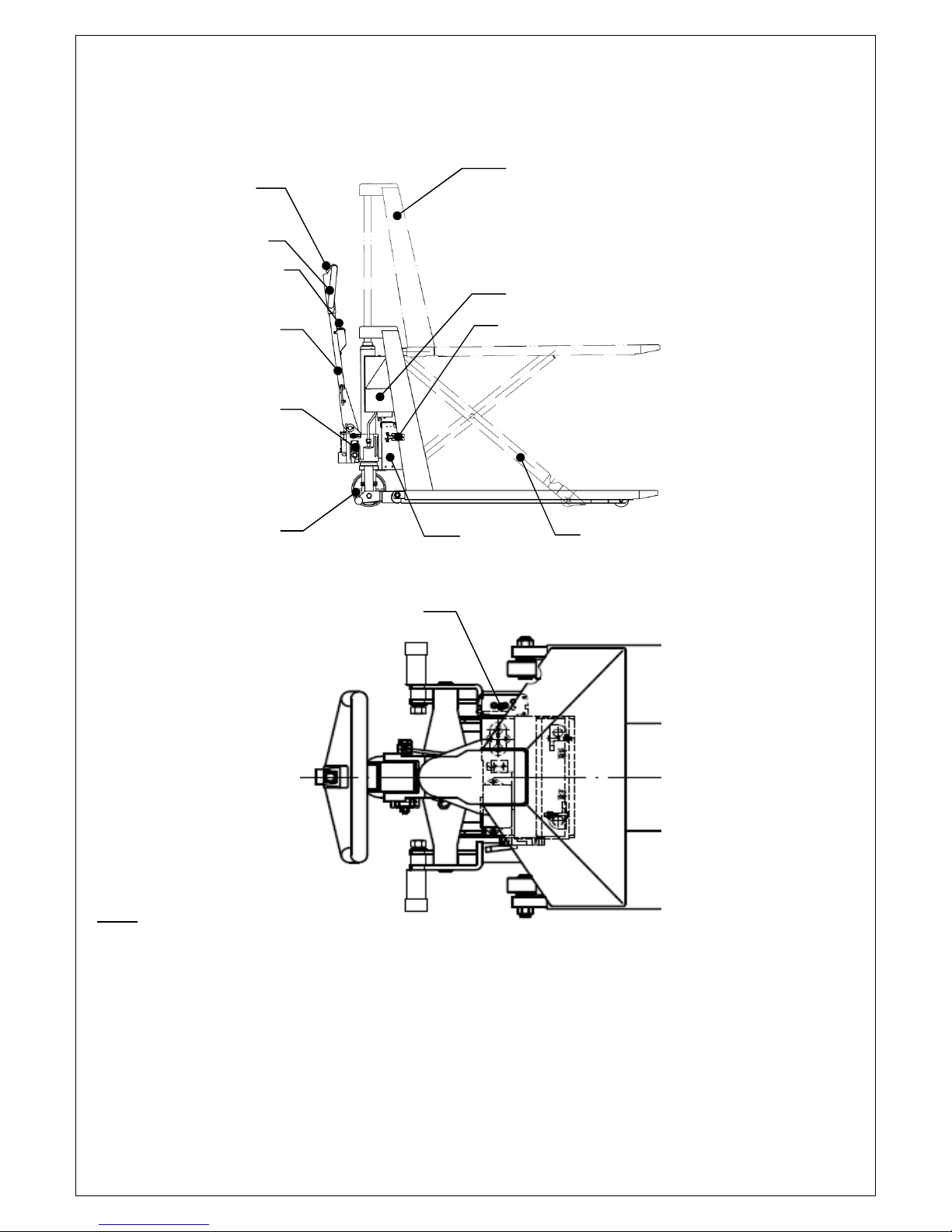

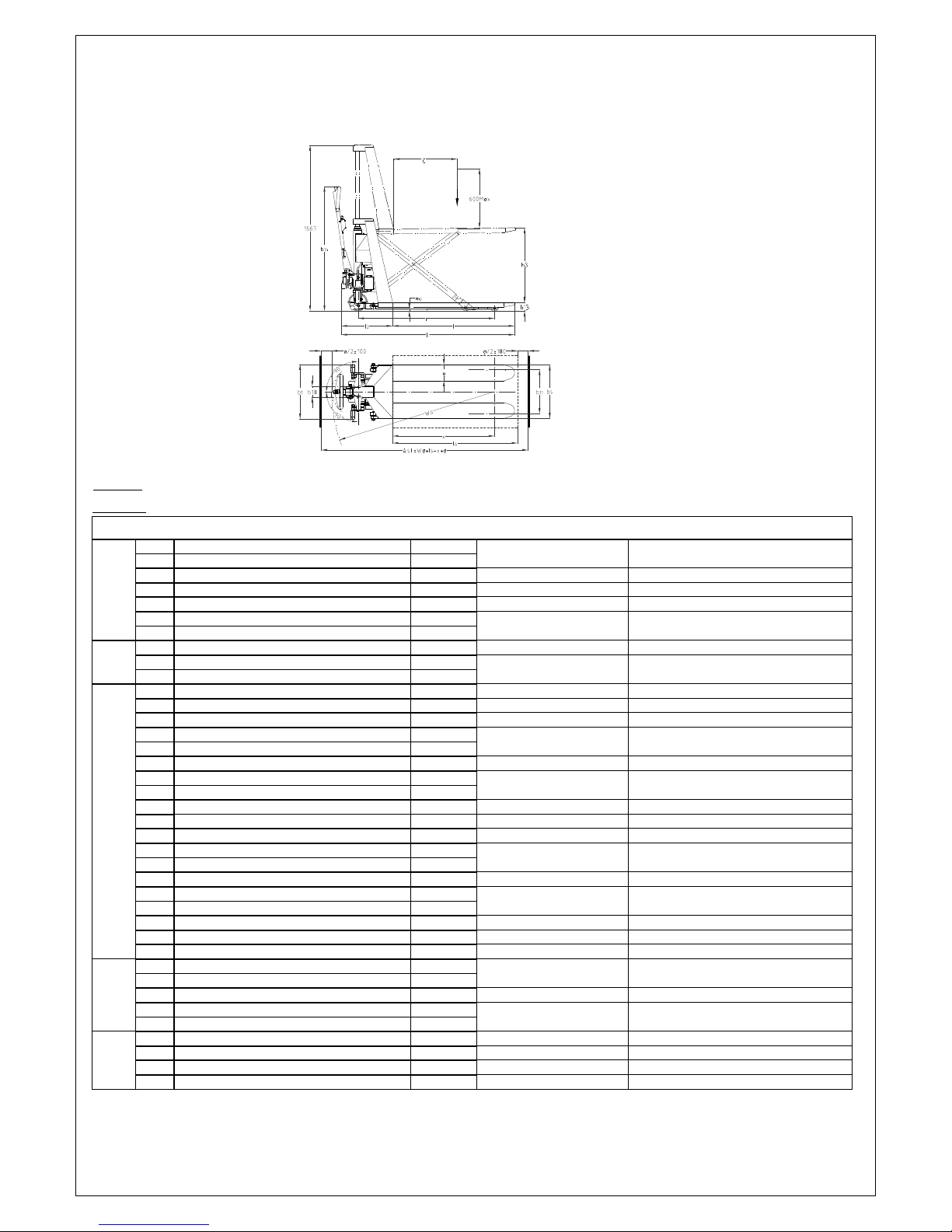

2. DESCRIPTION OF THE SCISSOR LIFT PALLET TRUCK......................................7

a. Main components ............................................................................................7

b. Main technical data..........................................................................................8

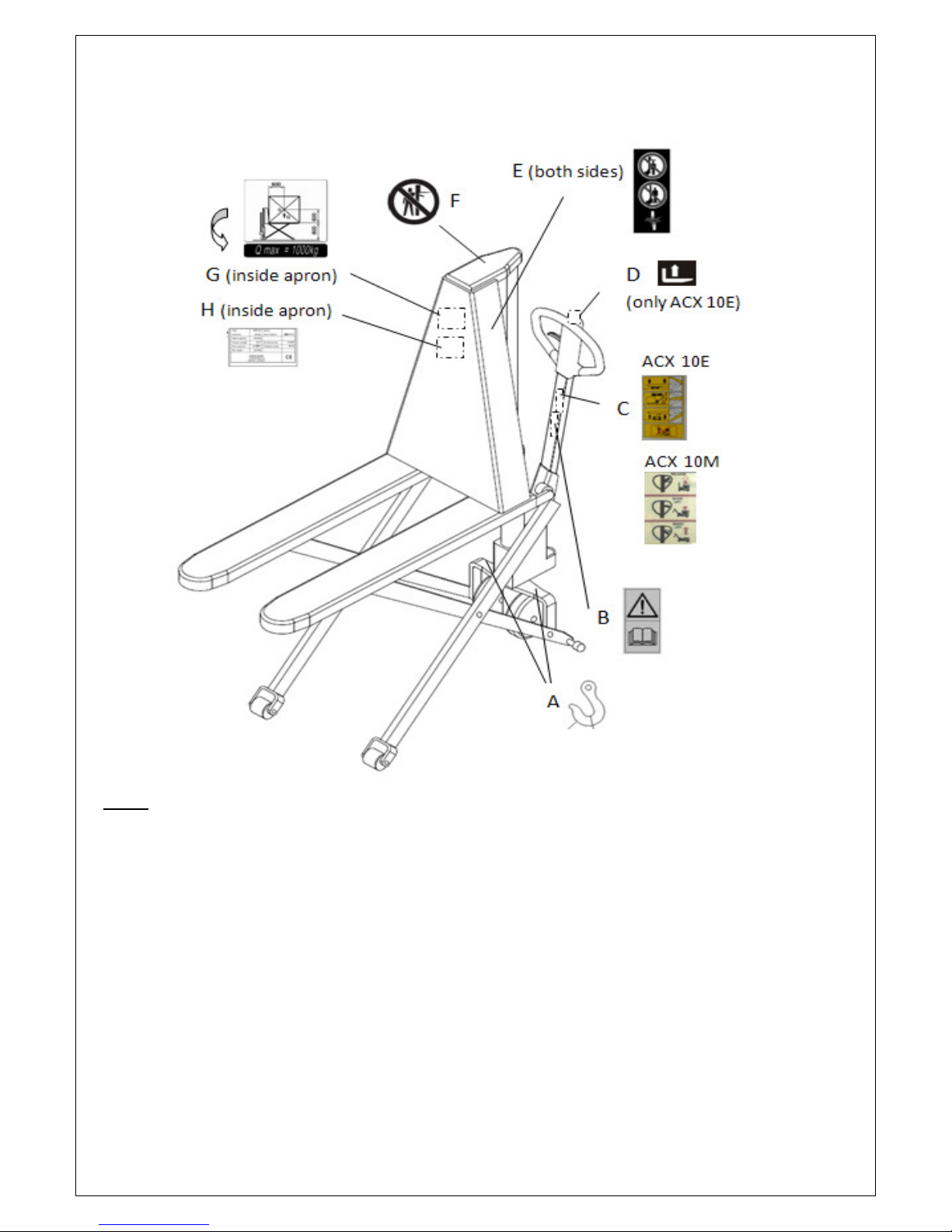

c. Description of the safety devices and warning labels ......................................9

d. Identification plate..........................................................................................10

3. WARNINGS AND SAFETY INSTRUCTIONS ........................................................10

4. COMMISSIONING, TRANSPORTING, STORAGE/ REASSEMBLING..................11

a. Commissioning – Tiller assembling ...............................................................11

b. Hydraulic valve adjustment............................................................................12

c. Lifting/transporting .........................................................................................13

d. Storage/ Reassembling .................................................................................13

5. DAILY INSPECTION..............................................................................................13

6. OPERATING INSTRUCTIONS..............................................................................14

a. Parking..........................................................................................................14

b. Lifting.............................................................................................................14

c. Lowering .......................................................................................................14

d. Moving...........................................................................................................14

e. Quick Lift (ACX 10M) ......................................................................................15

f. Malfunctions....................................................................................................15

7. BATTERY CHARGING AND REPLACEMENT (ACX 10E) ....................................15

a. Replacement .................................................................................................15

b. Battery indicator.............................................................................................16

d. Charging with Onboard charger (only ACX 10E, optional).............................16

e. Charging with external charger (only ACX 10E, optional)..............................17

8. REGULAR MAINTENANCE ..................................................................................17

9. TROUBLE SHOOTING..........................................................................................19

10. HYDRAULIC FLOW DIAGRAM AND CIRCUIT DIAGRAM..................................21

a. Hydraulic flow diagram ..................................................................................21

b. Circuit diagram (ACX 10E) ............................................................................21

11. SPECIALIZED STIPULATIONS FOR THE US- AMERICAN MARKET................22

a. Foreword/ Compliance..................................................................................22

b. Description warning labels (only US-market).................................................23

12. DECLARATION OF CONFORMITY (valid, if sold within the EU) ........................26