Nord Drivesystems B 1000 Specification sheet

B 1000 –en

Gear units

Manual with installation instructions

Gear units – Manual with installation instructions

2 B 1000 en-3921

Read this manual with installation instructions

Read this manual with installation instructions carefully prior to performing any work on or putting the

gear unit into operation. Always observe the instructions in this document.

Keep this document in the vicinity of the unit motor so that it is available if required.

Please also note the following documents:

• Gear unit catalogues,

• Documentation for the electric motor,

• Documentation for equipment which is attached or provided.

Please contact Getriebebau NORD GmbH & Co. KG if you require further information.

Documentation

B 1000 en-3921 3

Documentation

Designation:

B 1000

Part No.:

6052802

Series: Gear units and geared motors

Type series:

Gear unit

types: Parallel gear units

NORDBLOC helical gear units

Standard helical gear units

Parallel shaft gear units

Bevel gear units

Helical worm gear units

MINIBLOC worm gear units

UNIVERSAL worm gear units

Version list

Title,

Date

Order number /

Version Remarks

Internal code

B 1000,

February

2013

6052802 / 0713

-

B 1000,

September

2014

6052802 / 3814

• General corrections

B 1000

,

April 2015

6052802

/ 1915 • New gear unit types SK 10382.1 + SK 11382.1

B 1000,

March 2016

6052802 / 0916

• General corrections

• New bevel gear units SK 920072.1 + SK 930072.1

B 1000,

September

2016

6052802 / 3816

• General corrections

• New helical gear units SK 071.1, SK 171.1, SK 371.1, SK 571.1,

SK 771.1;

B 1000,

June 2018

6052802 / 2518

• General corrections

• New parallel shaft gear units SK 0182.1, SK 0282.1, SK 1282.1,

SK 1382,1

• New worm gear unit SK 02040.1

B 1000,

December

2018

6052802 / 5018

• General corrections

• Revision of safety and warning information

• New parallel shaft gear units NORDBLOC SK 871.1, SK 971.1, SK

1071.1

Gear units – Manual with installation instructions

4 B 1000 en-3921

Title,

Date

Order number /

Version Remarks

Internal code

B 1000,

October

2019

6052802 / 4419

• General corrections

• Addition of GRIPMAXX™ (Option M)

B 1000,

September

2021

6052802 / 3921

• Editorial revision

• General corrections and amendments

32551

Table 1: Version list B 1000

Copyright notice

B 1000 en-3921 5

Copyright notice

As an integral component of the device described here, this document must be provided to all

users in a suitable form.

Any editing or amendment or other utilisation of the document is prohibited.

Publisher

Getriebebau NORD GmbH & Co. KG

Getriebebau-Nord-Straße 1 •22941 Bargteheide, Germany •http://www.nord.com

Fon +49 (0) 45 32 / 289-0 •Fax +49 (0) 45 32 / 289-2253

Member of the NORD DRIVESYSTEMS Group

Gear units – Manual with installation instructions

6 B 1000 en-3921

Table of Contents

B 1000 en-3921 7

Table of Contents

1Safety information.....................................................................................................................................11

1.1 Intended use ....................................................................................................................................11

1.2 Do not make any modifications........................................................................................................11

1.3 Performing inspection and maintenance work .................................................................................11

1.4 Personnel qualification.....................................................................................................................11

1.5 Safety for particular activities ...........................................................................................................12

1.5.1 Check for transport damage...............................................................................................12

1.5.2 Safety information for installation and maintenance...........................................................12

1.6 Hazards............................................................................................................................................12

1.6.1 Hazards when lifting ...........................................................................................................12

1.6.2 Hazards due to rotating parts .............................................................................................12

1.6.3 Hazards due to high or low temperatures...........................................................................13

1.6.4 Hazards due to lubricants and other substances................................................................13

1.6.5 Hazards due to noise..........................................................................................................13

1.6.6 Hazards due to pressurised coolants .................................................................................13

2Description of gear units..........................................................................................................................14

2.1 Gear unit types and type designations.............................................................................................14

2.2 Name plate.......................................................................................................................................16

3Transport, storage, assembly ..................................................................................................................17

3.1 Transporting the gear unit................................................................................................................17

3.2 Storage and downtimes ...................................................................................................................17

3.2.1 General measures..............................................................................................................17

3.2.2 Storage and downtimes in excess of 3 months ..................................................................18

3.2.3 Storage and downtimes in excess of 9 months ..................................................................18

3.3 Preparing for installation ..................................................................................................................19

3.3.1 Check for damages ............................................................................................................19

3.3.2 Remove corrosion protection agents..................................................................................19

3.3.3 Check rotational direction...................................................................................................19

3.3.4 Check ambient conditions ..................................................................................................19

3.3.5 Drives with nsd tupH surface treatment..............................................................................20

3.3.6 Installing the oil expansion chamber (Option: OA)..............................................................20

3.3.7 Installing the oil reservoir tank (Option: OT) .......................................................................21

3.4 Installing the gear unit......................................................................................................................21

3.5 Installation of a hub on solid shaft (option: V, L) ..............................................................................22

3.6 Fitting push-on gear units with fastening element (option: B)...........................................................24

3.7 Fitting a hollow shaft with shrink disc (Option: S).............................................................................26

3.8 Fitting a hollow shaft with GRIPMAXX™ (Option: M).......................................................................29

3.9 Fitting the covers (option: H, H66) ...................................................................................................31

3.10 Fitting the covers..............................................................................................................................32

3.11 Fitting a standard motor (Option: IEC, NEMA, AI, AN).....................................................................32

3.12 Mounting of the cooling coil onto the cooling system.......................................................................36

3.13 Installation of the external oil/air cooler............................................................................................37

3.13.1 Connecting hoses...............................................................................................................37

3.13.2 Electrical connection...........................................................................................................37

3.14 Installation of an oil expansion chamber (Option: OA).....................................................................38

3.14.1 Installation of the sizes I, II and III ......................................................................................38

3.14.2 Installation of sizes 0A and 0B............................................................................................38

3.15 Subsequent painting ........................................................................................................................39

3.16 Electrical connection of the mounted motor.....................................................................................39

4Commissioning .........................................................................................................................................40

4.1 Checking the oil level.......................................................................................................................40

4.2 Activating the vent............................................................................................................................40

4.3 Activating the automatic lubricant dispenser....................................................................................41

4.4 Cooling coil (Option: CC) .................................................................................................................42

4.5 Running-in time for the worm gear unit............................................................................................43

4.6 Checklist ..........................................................................................................................................43

Gear units – Manual with installation instructions

8 B 1000 en-3921

5Service and maintenance .........................................................................................................................44

5.1 Inspection and maintenance intervals..............................................................................................44

5.2 Service and maintenance work........................................................................................................45

5.2.1 Visual inspection for leaks..................................................................................................45

5.2.2 Check for running noises....................................................................................................45

5.2.3 Checking the oil level..........................................................................................................46

5.2.4 Visual inspection of the rubber buffers (Option: G, VG)......................................................47

5.2.5 Visual inspection of the hoses (Option: OT, CS2-X)...........................................................48

5.2.6 Re-greasing (Option: VL2, VL3, W, AI, AN)........................................................................48

5.2.7 Replacing the automatic lubricant dispenser......................................................................48

5.2.8 Change the oil ....................................................................................................................49

5.2.9 Clean and check vent screw...............................................................................................50

5.2.10 Replacing the shaft sealing ring..........................................................................................50

5.2.11 Re-lubrication of bearings in the gear unit..........................................................................50

5.2.12 General overhaul................................................................................................................50

6Disposal .....................................................................................................................................................51

7Appendix....................................................................................................................................................52

7.1 Versions and mounting position.......................................................................................................52

7.1.1 Explanation of symbols.......................................................................................................52

7.1.2 UNIVERSAL/MINIBLOC worm gear units ..........................................................................53

7.1.3 Parallel shaft gear units with oil level tank..........................................................................54

7.1.4 Overview of mounting positions..........................................................................................55

7.2 Lubricants ........................................................................................................................................68

7.2.1 Roller bearing greases .......................................................................................................68

7.2.2 Gear oils.............................................................................................................................69

7.3 Screw tightening torques..................................................................................................................71

7.4 Troubleshooting ...............................................................................................................................72

7.5 Leakage and leak-tightness .............................................................................................................73

7.6 Repair information............................................................................................................................74

7.6.1 Repairs...............................................................................................................................74

7.6.2 Internet information.............................................................................................................74

7.7 Warranty ..........................................................................................................................................74

7.8 Abbreviations ...................................................................................................................................75

List of illustrations

B 1000 en-3921 9

List of illustrations

Figure 1: Name plate............................................................................................................................................. 16

Figure 2: Example of a simple pulling device ........................................................................................................ 22

Figure 3: Permissible application of force to drive and driven shafts..................................................................... 23

Figure 4: Applying lubricant to the shaft and the hub............................................................................................. 24

Figure 5: Removing the factory-fitted closing cap.................................................................................................. 25

Figure 6: Gear unit mounted on shaft with a shoulder using the fastening element .............................................. 25

Figure 7: Gear unit mounted on shaft without a shoulder using the fastening element ......................................... 25

Figure 8: Removal using dismantling device ......................................................................................................... 25

Figure 9: Mounting the rubber buffer (Option G and/or VG) on parallel shaft gear units ....................................... 26

Figure 10: Attaching the torque support on bevel gear and worm gear units ........................................................ 26

Figure 11: Hollow shaft with shrink disc................................................................................................................. 27

Figure 12: GRIPMAXX™, exploded diagram ........................................................................................................ 29

Figure 13: Fitting the covers, Option SH, Option H, and Option H66..................................................................... 31

Figure 14: Disassembly and assembly of the cover cap........................................................................................ 32

Figure 15: Fitting the coupling onto the motor shaft - various types of coupling.................................................... 34

Figure 16: Cooling cover ....................................................................................................................................... 36

Figure 17: Connection of the oil/air cooler............................................................................................................. 37

Figure 18: Position of the oil expansion chamber.................................................................................................. 38

Figure 19: Position of the oil expansion chamber.................................................................................................. 39

Figure 20: Activating the vent screw...................................................................................................................... 40

Figure 21: Activating the pressure vent screw....................................................................................................... 40

Figure 22: Removing the vent plug and fitting the special pressure vent............................................................... 41

Figure 23: Fitting the grease collection container.................................................................................................. 41

Figure 24: Activating the automatic lubricant sensor with standard motor mounting ............................................. 42

Figure 25: Adhesive label...................................................................................................................................... 42

Figure 26: Checking the oil level with a dipstick .................................................................................................... 46

Figure 27: Re-grease IEC/NEMA adapters AI and AN with option BRG1 ............................................................. 48

Figure 28: Switching the automatic lubricant sensor with standard motor mounting ............................................. 48

Figure 29: Parallel shaft gear units with oil level tank............................................................................................ 54

Gear units – Manual with installation instructions

10 B 1000 en-3921

List of tables

Table 1: Version list B 1000..................................................................................................................................... 4

Table 2: Gear unit types and type designations..................................................................................................... 14

Table 3: Versions and options............................................................................................................................... 15

Table 4: Permissible machine shaft tolerances ..................................................................................................... 30

Table 5: IEC and NEMA motor weights................................................................................................................. 32

Table6: Motor parallel keys ................................................................................................................................... 35

Table 7: Position of the half-coupling on the NEMA motor shaft............................................................................ 35

Table 8: Checklist for commissioning.................................................................................................................... 43

Table 9: Inspection and maintenance intervals...................................................................................................... 44

Table 10: Materials................................................................................................................................................ 51

Table 11: Roller bearing greases........................................................................................................................... 68

Table 12: Gear oils................................................................................................................................................ 70

Table 13: Screw tightening torques ....................................................................................................................... 71

Table 14: Overview of malfunctions....................................................................................................................... 72

Table 15: Definition of leaks according to DIN 3761.............................................................................................. 73

1 Safety information

B 1000 en-3921 11

1 Safety information

1.1 Intended use

These gear units are used to transmit rotary movements. They convert velocity and torque. They are

intended for use as part of a drive system in commercially used plant and machinery. The gear units

must not be operated until it has been established that the plant or machinery can be safely operated

with the gear unit. Suitable protective measures must be provided if failure of a gear unit or a geared

motor could result in a risk to persons. The machine or system must comply with local legislation and

directives. All applicable health and safety requirements must be met. In particular, the Machinery

Directive 2006/42/EC, TR CU 010/2011 and the TR CU 020/2011 must be especially observed in the

relevant areas of application.

The gear units and geared motors to which this manual with installation instructions refers to are

usually components for installation in machines according to the current EC Machinery Directive

2006/42/EG.

In certain individual cases in which the gear unit or the geared motor is considered as a ready-to-

install drive system for specific applications, this drive system is classified as a incomplete machine

according to the current EC Machinery Directive 2006/42/EG. A corresponding declaration of

incorporation is enclosed with the product.

The gear units may not be used in environments in which an explosive atmosphere can occur.

The gear units may only be used according to the information in the technical documentation from

Getriebebau NORD GmbH & Co. KG. Damage to the gear unit may result if the gear unit is not used

as intended and according to the information in the operating and assembly manual. This may also

result in personal injury.

The base or the gear unit mount must be appropriately designed for the weight and torque. All of the

fastenings provided must be used.

Some gear units are equipped with a cooling coil. These gear units may only be operated if the cooling

circuit is connected and in operation.

1.2 Do not make any modifications.

Do not make any structural modifications to the gear unit. Do not remove any protective guards.

1.3 Performing inspection and maintenance work

Due to lack of maintenance and damage, malfunctions may occur which can result in personal injury.

• Carry out all servicing and maintenance work at the specified intervals.

• Also note that servicing is necessary after long storage periods prior to commissioning.

• Do not operate damaged gear units. The gear unit must not have any leaks.

1.4 Personnel qualification

All transport, storage, installation, commissioning and maintenance work must be carried out by

qualified specialist personnel.

Qualified specialist personnel are persons who have the training and experience to recognise and

avoid any possible risks.

Gear units – Manual with installation instructions

12 B 1000 en-3921

1.5 Safety for particular activities

1.5.1 Check for transport damage

Transport damage may cause malfunctions of the gear unit, which may cause personal injury. Oil

which escapes due to leaks may cause a slipping hazard.

• Check the packaging and the gear unit for transport damage.

• Do not operate damaged gear units.

1.5.2 Safety information for installation and maintenance

Before starting work on the gear unit disconnect the drive from the power supply and secure it against

accidental switch-on. Allow the gear unit to cool down. Depressurise the cooling circuit lines.

Damaged or defective components, attachment adapters, flanges and covers may have sharp edges.

Wear work gloves and work clothing.

1.6 Hazards

1.6.1 Hazards when lifting

Persons may be injured by falling or swinging gear units. Therefore also observe the following

information:

• Cordon off a wide area around the hazard area. Take care that there is adequate space to avoid

swinging loads.

• Never stand under suspended loads.

• Use adequately dimensioned means of transport which are suitable for the purpose. The weight of

the gear unit can be obtained from the type plate.

• Only lift the gear units by the eye bolts which are provided. The eye bolts must be fully screwed in.

Only pull on the eye bolts vertically, never cross-wise or at an angle. Only use the eye bolts to lift

the gear unit without other components. The eye bolts are not designed for lifting the gear unit with

attachments. Use the eye bolts on both the gear unit and the motor to lift a geared motor.

1.6.2 Hazards due to rotating parts

Rotating parts cause a risk of entanglement. This may lead to severe injuries such as crushing or

strangling.

• Provide contact protection. In addition to shafts, this also applies to fans as well as drives and

driven elements such as belt drives, chain drives, shrink discs and couplings. Take possible run-on

of the machine into consideration for the design of protective devices.

• Do not operate the drive without covers or hoods.

• Secure the drive to prevent activation during installation and maintenance work.

• For test operation do not switch on the drive without an installed driven element or secure the

motor shaft key.

• Also observe the safety information in the operating and installation instructions provided by

manufacturers of components supplied.

1 Safety information

B 1000 en-3921 13

1.6.3 Hazards due to high or low temperatures

The gear unit may heat up to 90 °C during operation. Touching hot surfaces or contact with hot oil may

result in burns. At very low ambient temperatures freezing may occur on contact.

• Only touch the gear unit when wearing gloves after operation or at very low ambient temperatures.

• Before starting maintenance work, allow the gear unit to cool down sufficiently after operation.

• Provide a contact guard if there is a risk that persons may touch the gear unit when it is in

operation.

• Bursts of hot oil mist may be emitted from the pressure vent screw during operation. Provide a

suitable guard so that persons cannot be injured by this.

• Do not place any flammable materials on the gear unit.

1.6.4 Hazards due to lubricants and other substances

Chemical substances which are used with the gear unit may be toxic. Eye injuries may result if these

substances enter the eyes. Lubricants and adhesives may cause skin irritation.

Oil mist may escape when vent screws are opened.

Due to lubricants and conservation materials, gear units may be slippery and slip out of the hands.

There is a slipping hazard from spilled lubricants.

• When working with chemical substances wear chemical-resistant gloves and work clothing. Wash

your hands after working.

• Wear protective goggles if there is a possibility of splashed chemicals, for example when filling oil

or during cleaning work.

• If chemicals enter the eyes, rinse with large amounts of cold water immediately. Consult a

physician in case of symptoms.

• Observe the safety data sheets for the chemicals. Keep the safety data sheets in the vicinity of the

gear unit.

• Collect spilled lubricants immediately with a binding agent.

1.6.5 Hazards due to noise

Some gear units or attached components may cause hazardous noise levels during operation. Wear

hearing protection if work has to be carried out close to such gear units.

1.6.6 Hazards due to pressurised coolants

The cooling system is under high pressure. Damage or opening a cooling line which is under pressure

may result in injury. Depressurise the cooling circuit before working on the gear unit.

Gear units – Manual with installation instructions

14 B 1000 en-3921

2 Description of gear units

2.1 Gear unit types and type designations

Gear unit types/ Type designations

UNICASE helical gear units

2-stage: SK 02, SK 12, SK 22 SK 32, SK 42, SK 52, SK 62N, SK 62, SK 72, SK 82, SK 92, SK 102

3-stage: SK 03, SK 13, SK 23, SK 33N, SK 43, SK 53, SK 63, SK 73, SK 83, SK 93, SK 103

NORDBLOC.1® helical gear unit

1-stage: SK 071.1, SK 171.1, SK 371.1, SK 571.1, SK 771.1, SK 871.1, SK 971.1, SK 1071.1

2-stage: SK 072.1, SK 172.1, SK 372.1, SK 572.1, SK 672.1, SK 772.1, SK 872.1, SK 972.1

3-stage: SK 373.1, SK 573.1, SK 673.1, SK 773.1, SK 873.1, SK 973.1

STANDARD helical gear units

2-stage: SK 0, SK 01, SK 20, SK 25, SK 30, SK 33

3-stage: SK 010, SK 200, SK 250, SK 300, SK 330

UNICASE parallel gear units

2-stage: SK 0182NB, SK 0182.1, SK 0282NB, SK 0282.1, SK 1282, SK 1282.1, SK 2282, SK 3282, SK 4282,

SK 5282, SK 6282, SK 7282, SK 8282, SK 9282

3-stage: SK 2382, SK 3382, SK 4382, SK 5382, SK 6382, SK 7382, SK 8382, SK 9382, SK 10382,

SK 10382.1, SK 11382

UNICASE bevel gear units

3-stage: SK 9012.1, SK 9016.1, SK 9022.1, SK 9032.1, SK 9042.1, SK 9052.1, SK 9062.1, SK 9072.1,

SK 9082.1, SK 9086.1, SK 9092.1, SK 9096.1

4-stage: SK 9013.1, SK 9017.1, SK 9023.1, SK 9033.1, SK 9043.1, SK 9053.1

NORDBLOC.1® bevel gear unit

2-stage: SK 920072.1, SK 92072.1, SK 92172.1, SK 92372.1, SK 92672.1, SK 92772.1, SK 930072.1,

SK 93072.1, SK 93172.1, SK 93372.1, SK 93672.1, SK 93772.1

UNICASE worm gear units

2-stage: SK 02040, SK 02040.1, SK 02050, SK 12063, SK 12080, SK 32100, SK 42125

3-stage: SK 13050, SK 13063, SK 13080, SK 33100, SK 43125

UNIVERSAL SI worm gear units

1-stage: SK 1SI31, SK 1SID31, SK 1SI40, SK 1SID40, SK 1SI50, SK 1SID50, SK 1SI63, SK 1SID63, SK 1SI75

2-stage (Helical worm gear unit): SK 2SID40, SK 2SID50, SK 2SID63

UNIVERSAL SMI worm gear units

1-stage: SK 1SMI31, SK 1SMID31, SK 1SMI40, SK 1SMID40, SK 1SMI50, SK 1SMID50, SK 1SMI63,

SK 1SMID63, SK 1SMI75

2-stage (Helical worm gear unit): SK 2SMID40, SK 2SMID50, SK 2SMID63

Table 2: Gear unit types and type designations

Double gear units consist of two single gear units. The type designation of the SK 73/22 double gear

unit, for example, means that the double gear unit consists of the single gear units SK 73 and SK 22.

2 Description of gear units

B 1000 en-3921 15

Abbreviation

Description

(without)

Foot mounting with solid shaft

/31

Worm gear first stage

/40

Worm gear first stage

5

Reinforced output shaft

A

Hollow shaft

AI

Standard IEC motor attachment

AI…BRG1

Standard IEC motor attachment with manual re-lubrication

AI…RLS

Standard IEC motor attachment with integrated back stop

AL

Reinforced axial bearing

AN

Standard NEMA motor attachment

AN…BRG1

Standard NEMA motor attachment with manual re-lubrication

AN…RLS

Standard NEMA motor attachment with integrated back stop

B

Fastening element

CC

Cooling coil

D

Torque arm

DR

Pressure vent

EA

Splined hollow shaft

F

B5 flange

G

Rubber buffer for torque arm

H

Cover cap

/H10

Modular helical pre-stage for universal worm gear units

H66

IP66 cover

IEC

Standard IEC motor attachment

K

Torque bracket

L

Solid shaft both sides

M

GRIPMAXX™

MK

Motor bracket

NEMA

Standard NEMA motor attachment

OA

Oil expansion chamber

OT

Oil level tank

R

Back stop

S

Shrink disc

SCP

Screw conveyor flange

SO1

Synthetic oil ISO VG 220

V

Solid shaft (for standard helical gear units: reinforced drive)

VG

Reinforced rubber buffer

VI

Viton radial shaft seals

VL

Reinforced output bearings

VL2

Agitator version

- Reinforced bearings

VL3

Agitator version

- Reinforced bearings

- Drywell

VS

Reinforced shrink disc

W

Free drive shaft

X

Housing foot mounting

Z

B14 flange

Table 3: Versions and options

Gear units – Manual with installation instructions

16 B 1000 en-3921

2.2 Name plate

The name plate must be firmly attached to the gear unit and must not be subjected to permanent

soiling. Please contact the NORD service department if the name plate is illegible or damaged.

Figure 1: Name plate

Explanation

1

DataMatrix code

8

Weight

2

NORD gear unit type

9

Overall gear unit ratio

3

Modes of operation

10

Installation position

4

Year of manufacture

11

Rated speed of gear unit output shaft

5

Serial number

12

Lubricant type, viscosity and quantity

6 Rated torque of gear unit output shaft 13 Customer part number

7

Drive power

14

Operating factor

3 Transport, storage, assembly

B 1000 en-3921 17

3 Transport, storage, assembly

3.1 Transporting the gear unit

WARNING

Hazard due to falling loads

• The thread of the eyebolt must be fully screwed in.

• As shown in the illustration to the right, only lift on

the eyebolts vertically to the female thread and not

more oblique than 45° to the vertical.

• Note the centre of gravity of the gear unit.

Only use the eyebolts attached to the gear unit for transport. If geared motors have an additional

eyebolt attached to the motor, this must also be used.

Transport the gear unit with care. Impacts to the free ends of shafts may cause internal damage to the

gear unit.

No additional loads must be attached to the gear unit.

Use suitable aids such as cross-beams or similar to facilitate transportation of the gear unit. Gear units

may only be transported with shackles and lifting strapschains at an angle of 90° to 70° to the

horizontal.

3.2 Storage and downtimes

3.2.1 General measures

• Store the gear unit in a dry space, relative humidity less than 60%.

• Store the gear unit at a temperature in the range of – 5 °C to + 50 °C without severe temperature

fluctuations.

• Do not expose the gear unit to direct sunlight or UV light.

• There must be no aggressive or corrosive substances (contaminated air, ozone, gases, solvents,

acids, alkalis, salts, radioactivity etc.) in the immediate vicinity.

• The gear unit must not be exposed to vibration or oscillation.

• Store the gear unit in the mounting position (see chapter 7.1 "Versions and mounting position").

Secure it against falling.

Gear units – Manual with installation instructions

18 B 1000 en-3921

3.2.2 Storage and downtimes in excess of 3 months

Note the following measures in addition to Section 3.2.1 "General measures".

• Repair damages to the coating. Check if a corrosion protection agent has been applied to the

flange bearing surfaces, the shaft ends and the unpainted surfaces. If required, apply a suitable

corrosion protection agent to the surfaces.

• Seal all openings on the gear unit.

• The output shaft must be rotated by at least one revolution every 3 months so that the contact

position of the gear teeth and the roller bearings are changed.

3.2.3 Storage and downtimes in excess of 9 months

Under certain conditions, storage of 2 to 3 years is possible. The specified storage duration is for

guidance only. The actual storage duration depends on the local conditions. Note the following

measures in addition to Sections 3.2.1 "General measures"and 3.2.2 "Storage and downtimes in

excess of 3 months".

Gear units can be supplied prepared for long-term storage. The gear units are completely filled with

lubricant, have VCI corrosion protection agent mixed with the gear oil or are filled with small quantities

of VCI concentrate. The adhesive label on the housing shows the respective information.

Conditions of the gear unit and storage area for long-term storage prior to commissioning:

• Store the gear unit at a temperature in the range of -5 °C to +40 °C without severe temperature

fluctuations.

• Check if the sealing cord in the vent screw is in place. It must not be removed during storage.

• Store the gear unit in a dry space. With a relative humidity less than 60%, the gear unit can be

stored for up to two years; with a relative humidity less than 50%, storage of up to three years is

possible.

• For gear units, which are filled with VCI concentrate for long-term storage, the VCI concentrate

must be renewed after 2 years and distributed in the oil by rotating the shaft.

• In tropical regions, protect the gear unit against damage by insects.

• Gear unit components such as brakes, couplings, belt drive, and cooling units must be protected

for a long-term storage in accordance to their operation instructions.

In addition to the preparations listed in 4 "Commissioning", the following measures are necessary

before commissioning:

• Check the gear unit for external damage.

• After storage of more than 2 years, or with storage temperatures outside of the permissible range

from -5 °C to +40 °C, replace the lubricant in the gear unit before commissioning.

• If the gear unit is completely filled, the oil level must be reduced according to the mounting position.

For the lubricant quantity and lubricant type, refer to the information on the name plate.

• For gear units without oil filling, the oil level must be refilled and checked according to chapter 5.2.3

"Checking the oil level" before commissioning. The VCI concentrate may remain in the gear unit.

The VCI concentrate is not mixable with polyglycol-based lubricants (PG oils). If PG oils are used,

the VCI concentrate must be removed from the gear unit. When using VCI additive, only use the oil

types which are specified on the name plate and are approved by Getriebebau NORD (see chapter

7.2.2 "Gear oils").

• For the option with manual re-lubrication, switch the bearing grease after a storage of more than 2

years. The service life of the grease is reduced after a storage time or gearbox shutdown of more

than 9 months (see chapter 5.2.6 "Re-greasing (Option: VL2, VL3, W, AI, AN)").

• Gear units filled with VCI concentrate for long-term storage are fully closed. Take care that the vent

is fitted and released as necessary prior to commissioning.

3 Transport, storage, assembly

B 1000 en-3921 19

3.3 Preparing for installation

3.3.1 Check for damages

Please examine the delivery for transport and packaging damage immediately on receipt. Pay

particular attention to radial shaft seals and sealing caps. Report any damage to the carrier

immediately.

Do not put the drive into operation if damage such as leaks are visible.

3.3.2 Remove corrosion protection agents

All bare metal surfaces and shafts of the drive are protected with corrosion protection agents before

shipping.

Thoroughly remove corrosion protection agents and any dirt (e.g. colour residues) from all shafts,

flange surfaces and gear unit attachment surfaces before assembly.

3.3.3 Check rotational direction

If an incorrect rotational direction may result in damage or potential risk, check for the correct

rotational direction of the output shaft during a test run before attaching it to the machine. Ensure the

correct rotational direction during operation.

For gear units with an integrated back stop, switching the drive motor to the blocked direction of

rotation, may result in damage to the gear unit. Gears with integrated back stops are marked with

arrows on the drive/driven sides. The arrows point in the rotation direction of the gear unit. When

connecting the motor and during motor control, ensure, e.g. by testing the field of rotation, that the

gear unit can only operate in the direction of rotation.

For further explanations refer to Catalogue G1000 and document WN 0-000 40.

3.3.4 Check ambient conditions

Make sure that no aggressive or corrosive substances which attack metal, lubricants or elastomers

are present at the installation site or are subsequently expected during operation. If such substances

are to be expected, contact Getriebebau NORD.

The gear unit, especially its radial shaft seals should be protected from exposure to direct sunlight.

The standard permissible ambient temperature range for synthetic gear unit oils (CLP PG … and

CLP HC…) is –20 °C to +40 °C. This temperature range can be extended according to the lubricant

table (see chapter 7.2.2 "Gear oils"), if all mounted materials of the gear unit and the application-

related speed, torques and modes of operation allow this. Note the project planning documents of the

order for this. In case of doubt, ask Getriebebau NORD.

For mineral oil (CLP), the permissible ambient temperature range in accordance to the above stated

lubricant table is restricted. The lubricant type is indicated on the name plate (see chapter 2.2 "Name

plate ").

For installation altitudes above 1000 m above sea level, the permissible speed and torques may be

reduced. Note the project planning documents of the order for this. In case of doubt, ask Getriebebau

NORD.

Gear units – Manual with installation instructions

20 B 1000 en-3921

3.3.5 Drives with nsd tupH surface treatment

Drives with nsd tupH surface treatment must be electrically decoupled from other components by the

use of non-conductive intermediate layers in order to prevent galvanic corrosion.

3.3.6 Installing the oil expansion chamber (Option: OA)

Mount the oil expansion chamber (Option OA) according to document WN 0-530 04. For gear units

with a M10x1 vent screw or pressure relief vent, document WN 0-521 35 must also be observed

during installation.

Other manuals for B 1000

2

Table of contents

Other Nord Drivesystems Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

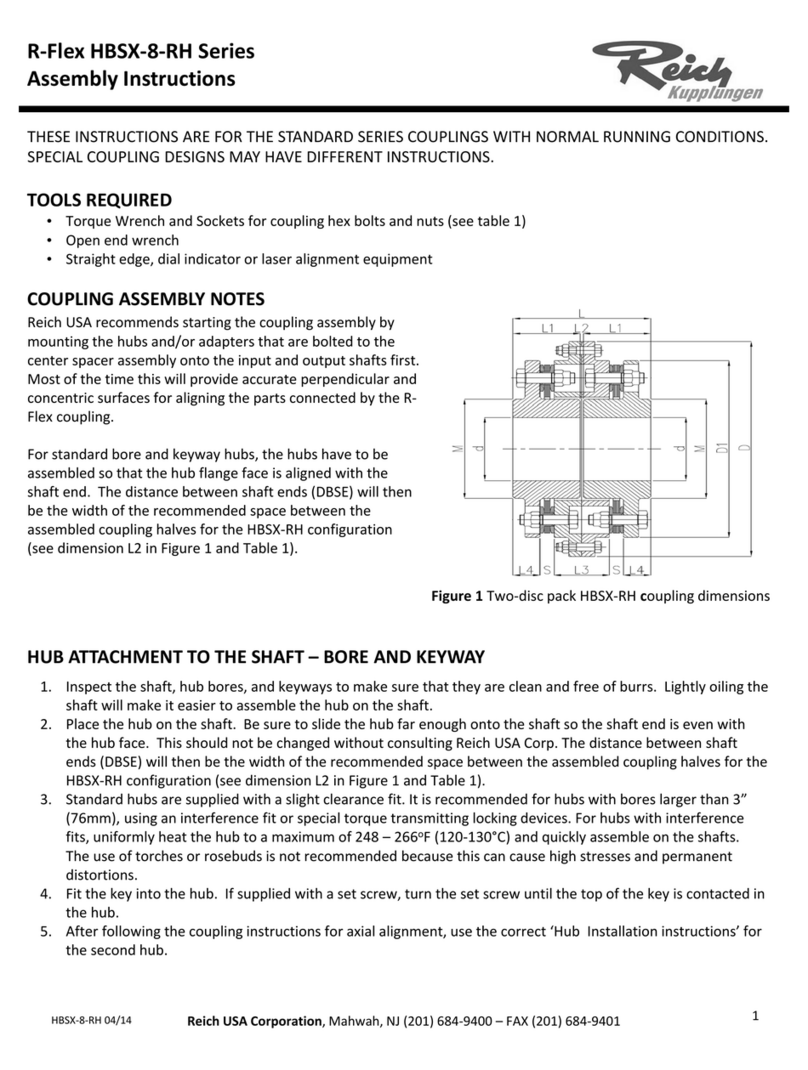

Reich Kupplungen

Reich Kupplungen R-Flex HBSX-8-RH Series Assembly instructions

Grundfos

Grundfos Oxiperm OCD-164 Installation and operating instructions

Doosan

Doosan F30i Series Maintenance manual

AIRSLED

AIRSLED AM1200 owner's manual

KAKA Industrial

KAKA Industrial TB-12 Operation manual

HSD

HSD ES327 Assembly instructions