Nordmann Engineering MultiPipe User manual

INSTALLATION AND OPERATING INSTRUCTIONS

NORDMANN

ENGINEERING

NORDMANN

ENGINEERING

Dampfluftbefeuchter econoVap

MultiPipe

2557005 EN 1406

Steam distribution system

3

Contents

1 Notes on steam distribution system MultiPipe 4

1.1 MultiPipe – Steam distribution system for very short humidication distance 4

1.2 Positioning of the steam distribution system 4

1.3 Determination of steam absorption distance 5

1.4 Notes on installation 5

2 Notes for the planning engineer 6

2.1 Layout 6

2.2 Dimension diagrams 6

2.3 Power selection diagram MultiPipe Systems 1...4 7

2.4 Type key 7

2.5 Determination of the humidication distance “BN” 8

2.6 Planning data MultiPipe steam distribution system (for faxing!) 8

3 Mounting 9

3.1 Safety 9

3.2 Delivery 9

3.3 Mounting positions 9

3.4 Mounting the premounted MultiPipe system 10

3.5 Mounting the different parts of the MultiPipe system 11

3.6 MultiPipe Support (accessory) 12

4 Putting into operation and operation 13

4.1 Putting into operation 13

4.2 Operation 13

5 Spare parts list 14

4

1.1 MultiPipe – Steam distribution system for very short humidication distance

The MultiPipe is made from stainless steel and high-grade plastic compo-

nents. It is designed for con nection to the Nordmann steam humidi ers.

The MultiPipe steam distribution system is installed directly in the air duct

or in an air-handling unit. It comprises horizontal collector pipes and several

vertical pipes provided with steam nozzles. The MultiPipe separates the

condensate from the inlet steam and feeds this uniformly and drip-free to

the air ow. In particular the steam ab sorption distance is considerably less

compared with conventional steam distribution pipes.

Note: To ensure a safe support of the collector pipes we recommend the

use of the specially designed support for the steam distribution system

MultiPipe. The entire support is made from stainless steel and available in

four different mounting sets for duct heights ranging from 450 to 3200 mm

(see table in chapter 3.6). The mounting sets comprise all necessary parts

for the correct support of a MultiPipe system.

1.2 Positioning of the steam distribution system

The positioning of the steam distribution system should be determined when

laying out the air-con-ditioning system. The following points should be ob-

served to en-sure correct humidication of the air. The conditions must be

main tained exactly to ensure that the MultiPipe system satises the high

demands made of it. A layout based on incorrect data, an unfavourable

installation position or wrong installation can result in excessive humidity

with separation of condensate and therefore to damage from water. The air

duct must therefore be sealed in the area of the absorption distance and

provided with a water drainage tray with outlet. The system is preferably t-

ted immediately following the air heater (and before the cooling coils). Other

installation situations require additional care. A viewing port immediately

following the system is highly recommended for installation and inspection

of operation of the installation. Installation of the system is always made

laterally to the air ow. With vertical air ow the nozzle tubes are tted at an

angle of 20° to 30° to enable the condensate to ow away easily.

With exception of determination of the steam absorption distance, the

same basic rules apply to the MultiPipe steam distribution system as to the

standard steam distributor pipes (see installation and operating instructions

of the humidier).

1 Notes on steam distribution system MultiPipe

5

1.3 Determination of steam absorption distance

Determination of the absorption distance “BN” depends on various factors.

For simple determination of the absorption distance “BN” the table can be

used. The nominal values obtained from the table refer to an air inlet tem-

perature of 10 °C to 30 °C. The result must be compared with the actual

steam absorption distance or with the minimum spacings to be observed.

1.4 Notes on installation

Before installation check that the correct MultiPipe system is used and

that the system is in accordance with the type and steam output on the

specication label.

The MultiPipe is suitable for installation in air ducts or air-conditioning units.

For this purpose the templates supplied are attached to the ventilation duct

spaced according to the collectors. The duct plate is cut out round. The con-

nection side of the pre-tted system is inserted from inside through these

holes. The connector pieces are then t ted on the pipes from outside and

screwed to the duct wall. The collector pipes should be aligned horizontally

and secured at the end on the duct wall.

For large systems or in special cases, where this type of installation is not

possible, the collector pipes can be tted individually from out side. The noz-

zle tubes are then inserted in the collectors in the air duct and secured with

the pipe clamps and O-rings. Suitable pliers are required for the installation.

All parts are supplied loose for this case if required.

Then install the steam and condensate hoses according to the instructions

in the installation and operating instructions of the humidier. It is advisable

to drain the con densate separately and not return it to the humidier owing

to the increased volume.

6

2 Notes for the planning engineer

2.1 Layout

The choice of the MultiPipe steam distribution system can be made from

the layout tables. The system is determined by the number of steam con-

nections of the steam humidier. This also determines the maximum steam

output. The maximum possible collector lengths and collector spacing is

selected depending on the duct width and height.

2.2 Dimension diagrams

90 A L

D1

Ø 30

Ø 60.3

D2

H H

Ø 35.0

D1 D1 D1 D1 60

B

90 A L

D1

Ø 30

Ø 60.3

D2D2 120

H

Ø 35.0

D1 D1 D1 D1 60

B

MultiPipe System 1&2

System 4

MultiPipe System 4

Systems 1 and 2

7

2.3 Power selection diagram MultiPipe Systems 1...4

L mm 350 500 650 800 1000 1200 1500 1800 2000 2300 2500

B min. mm 450 600 750 900 1100 1300 1600 1900 2200 2500 2700

System 1 **

mD max. kg/h 23 32

D2 mm 350 500 650 800 1000 1200 1500

H min. mm 450 600 800 950 1150 1350 1650

System 2 **

mD max. kg/h 45 65

D2 mm 350 500 650 800 1000 1200 1500 1800 2000

H min. mm 450 600 800 950 1150 1350 1650 1950 2200

System 4 ***

mD max. kg/h 90 130

D2 mm 300 375 475 575 725 875 1050 1200 1350 1500

H min. mm 800 950 1150 1350 1650 1950 2300 2600 2900 3200

** Systems 1 and 2 for single units only

*** System 4 for double units only

2.4 Type key

X / XXX / XXX / XXX

No. MultiPipe system

Collector length “L” in [mm]

Collector distance “D2” in [mm]

Steam capacity “mD” in [kg/h]

H

B

8

2.5 Determination of the humidication distance “BN”

Entering humidity

φ 1 in % r.H.

Leaving humidity

φ 2 in % r.H.

40 50 60 70 80 90

50.22 m 0.28 m 0.36 m 0.48 m 0.66 m 1.08 m

10 0.20 m 0.26 m 0.34 m 0.45 m 0.64 m 1.04 m

20 0.16 m 0.22 m 0.30 m 0.41 m 0.58 m 0.96 m

30 0.10 m 0.17 m 0.25 m 0.36 m 0.52 m 0.88 m

40 0.11 m 0.20 m 0.30 m 0.45 m 0.79 m

50 0.13 m 0.24 m 0.38 m 0.69 m

60 0.16 m 0.30 m 0.58 m

70 0.20 m 0.45 m

The length of the absorption distance BNin m

is for ducts with <600 mm about 50% longer

2.6 Planning data MultiPipe steam distribution system (for faxing!)

Layout data required Installation 1 Installation 2 Installation 3 Installation 4

1. Clear height of air duct “B”

(without insulation) mm

2. Clear width of air duct “H”

(without insulation) mm

3. Wall thickness of air duct “A”

(without insulation) mm

4. Air volume per hour or m3/h

5. Air speed m/s

6. Air duct static pressure Pa

7. Temperature after humidication °C

8. Abs. humidity before humidication g/kg

9. Humidity increase (∆x) or g/kg

10. Rel. humidity after humidication %

11. Humidier capacity kg/h

12. Steam humidier selected type

13. Number of steam connections pcs.

14. Following air-cond. components type

15. Existing humidication distance m

MultiPipe System selected type

– Collector length (L) mm

– Collector spacing (D2) mm

– Steam output at 500 Pa (mD) kg/h

Order No.

9

3 Mounting

3.1 Safety

The MultiPipe steam distribution system must only be installed by adequately

qualied personnel.

Observe and comply with all safety instructions in the installation and

operating instructions of the steam humidier.

3.2 Delivery

The MultiPipe steam distribution system will be delivered either premounted or

as single components. Observe the corresponding mounting instructions.

3.3 Mounting positions

The MultiPipe steam distribution system can be installed in horizontal or

vertical ducts. When mounting in a vertical duct the nozzle pipes must

have a minimum declination of 20° and the end pieces of the collector pipes

must be turned, so that the vertical condensate connection directs straight

downwards (see gure below).

Note: Before mounting the MultiPipe system check the type designation

and steam capacity on the data plate to ensure that the correct MultiPipe

system is installed in the right place.

In addition to this installation and operating instructions please observe and

comply with the instructions regarding the steam installation (positioning,

max. length of steam pipe, etc.) in the installation and operating instructions

of the steam humidier.

20°

1x

+70°

–70°

10

3.4 Mounting the premounted MultiPipe system

1. Remove the protection covers.

2. Measure the distance of the collector pipes and afx the installation

template on the duct wall at the designed place with this distance (per-

missible variation ±3 mm) and cut out the openings.

3. From inside of duct, insert the collector pipes through the prepared open-

ings.

4. Slip from the outside ange, O-ring and steam hose connections onto the

tube and x them by the four screws. Pay attention that the condensate

drains are below the steam hose connection.

5. Starting with the lowest collector pipe x the steam hose connections

with the 4 screws at the duct wall.

6. Align the collector pipes with a down-slope of 2° against the steam con-

nector. Then, fasten the pipe ends on the duct using M8 threaded rod

or the specially designed support available as accessory (see mounting

drawing in chapter 3.6).

7. Connect the steam hose and the condensate hose to each collector pipe

according to the instructions in the installation and operating instructions

of the humidier.

Note: with the system 1 connect the steam hose ø35/46 mm to the lower

steam connector DV71 and close the upper steam connector with the

sealing cap supplied.

1

56M8

M8

7

42 3

ø64 mm

ø3.6 mm

2°

2°

11

3.5 Mounting the different parts of the MultiPipe system

1. Remove the protection covers.

2. Afx the installation templates on the duct wall at the designed place with

the correct distance of the collector pipes (permissible variation ±3 mm).

Cut out the openings.

3. Slip the ange, O-ring and steam hose connections onto the tube and x

them by the four screws. From outside of the duct, insert the premounted

collector pipes through the prepared openings.

4. Put one half tube clip with O-ring onto both ends of the nozzle pipes.

Slide the nozzle pipes into the holes of the collectors to the limit stop and

so that the nozzles are situated one against the others. With a suitable

clamp press both halves of the clips together until they will be xed by

a “click”.

5. Starting with the lowest collector pipe x the steam hose connections

with the 4 screws at the duct wall.

6. Align the collector pipes with a down-slope of 2° against the steam con-

nector. Then, fasten the pipe ends on the duct using M8 threaded rod

or the specially designed support available as accessory (see mounting

drawing in chapter 3.6).

7. Connect the steam hose and the condensate hose to each collector pipe

according to the instructions in the installation and operating instructions

of the humidier.

Note: with the system 1 connect the steam hose ø35/46 mm to the lower

steam connector DV71 and close the upper steam connector with the

sealing cap supplied.

4

5 6 M8

M8

7

2 31

ø64 mm

ø3.6 mm

2°

2°

12

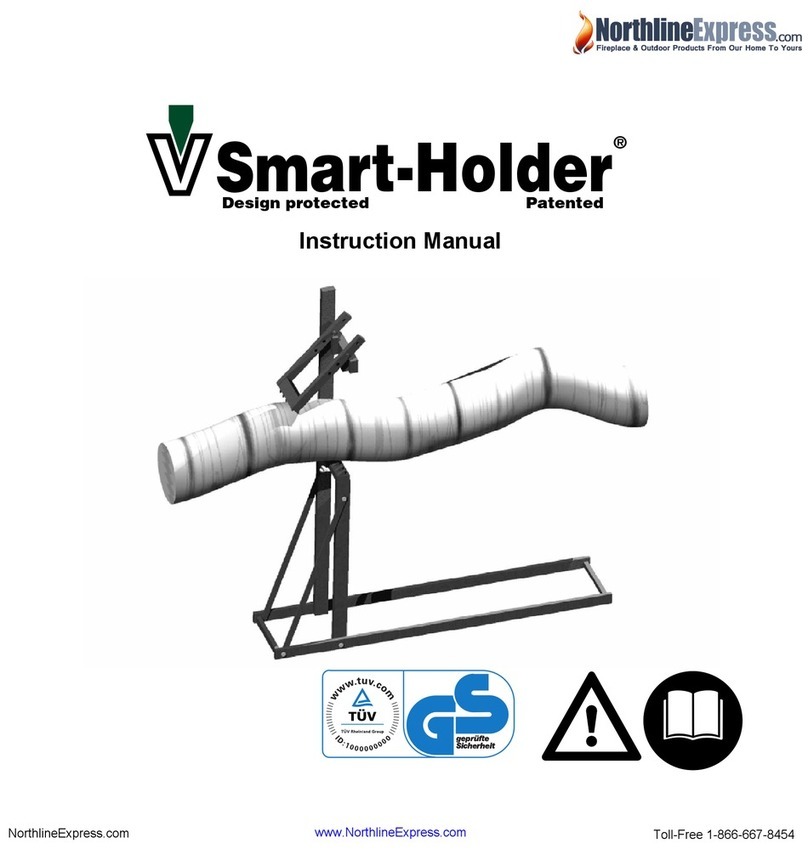

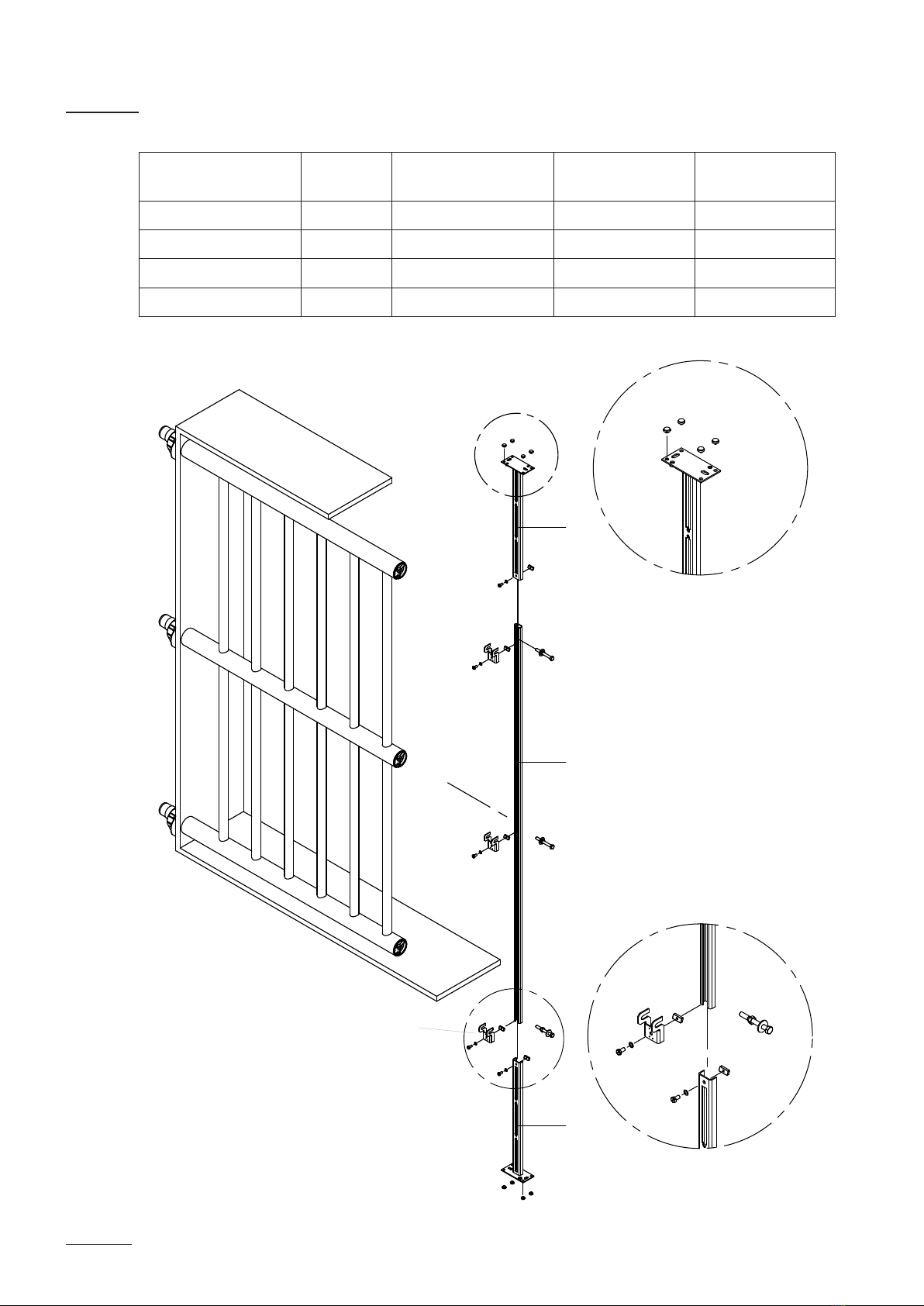

3.6 MultiPipe Support (accessory)

Range duct height

[mm]

Art.-No. Foothold (Pos. 1)

No. x Length [mm]

Rail (Pos. 2)

[mm]

Bracket (Pos. 3)

450...950 1117477 1 x 450 mm 500 4

950...1350 1117478 2 x 450 mm 500 4

1350...2300 1117479 2 x 450 mm 1400 4

2300...3200 1117480 2 x 450 mm 2300 4

1

1

2

3

13

4.1 Putting into operation

When connected to several basic units these should be operated in parallel.

Otherwise condensate runs into the units switched off and lls these until

overow occurs. Problems can then arise when switching on again.

The following should be ensured when putting into operation:

1. that the system pressure don’t increase over 1500 Pa. The system

pressure is componed of the airduct static pressure, the pressure drop

over the MultiPipe system (typical 500 Pa) and the back pressure in the

steam hose (typical 100 Pa/m)

2. that no water splashes from the steam distribution system and the con-

densate runs out of the system satisfactorily. Condensating formation

may be caused by:

• Steam supply pipe not properly drained

• Metallic steam pipe inadequately insulated

• Overstressed steam generator feeds water through steam pipe

• System condensate drain is block ed

• Extreme back-pressure in condensate hose

• Incorrect installation of conden sate hose

4.2 Operation

• Carry out visual checks periodically

• Further details according to the installation and operating instructions of

the humidier

4 Putting into operation and operation

14

Pos. Article Art.-/SAP-No.

1 Flange connection cpl. DV71 2546102

2 O-ring ø59.69 x ø5.34 (3 pcs) 2556745

3Sealing cap with xation 2556746

4 Sealing cap ø10 (3 pcs) 2559240

5 Hose clamp DS35 (2 pcs) 2539583

6 Internal sealing 2556747

7 Pipe clamp with O-ring 2556748

8 O-ring for pipe clamp (5 pcs) 2556749

--- Sealing cap ø41 2567040

5 Spare parts list

1

4

5

2

6

3

7

8

© Nordmann Engineering Ltd., Printed in Switzerland

Technical modifications reserved

NORDMANN

ENGINEERING

NORDMANN

ENGINEERING

Dampfluftbefeuchter econoVap

Reg.No. 40002-2

Manufacturer:

Nordmann Engineering Ltd.

www.nordmann-engineering.com, [email protected]

Table of contents