TEDA XQ140 User manual

PARTS AND OPERATION MANUAL

YANCHENG TEDA DRILLING AND PRODUCTION EQUIPMENT CO. ,LTD

MODEL XQ140/20

HYDRAULIC POWER TONG

https://www.us.invisarig.com/

COPYRIGHT AND DECLARATION

COPYRIGHT

Copyright by Yancheng Teda Drilling & Production Equipment Co.,ltd.all

rights reserved.no part of this manual may be transmitted or copied in any

form whatever without the prior written permission.

DECLARATION

Though we have collated carefully, there might be some bugs in this

manual. You are welcome to give us any comments and suggestions. We will

improve this manual in time.

is our company’s registered trade mark.

Safety Instruction and Legend Description

Safety Instruction

●Operators must read and know this manual well.

●Operators must wear work uniform, safety shoes, safety helmet, safety gloves, etc.

●Tie the back guy according to the instruction. Don’t tie it in the wrong direction.

●Operation at the side of tong body opening.

●Don’t touch the running parts with hands when the tong is running.

●Don’t touch the running parts with hands when the tong is running.

●Keep sundries out of the working area.

●The pump should be off or the hydraulic tong power shut down as maintaining or

hanging the jaw plates, die seats or tong dies.

●Over-pressure and over-torque are forbidden.

●Don’t add or dismount any parts to the tong.

●Original parts made by should be used.

Legend Description

Serious Warning

Warning

Recommendation or Suggestion

Safety first, standard operation

CONTENTS

1.Summary

2.Technical parameters

3.Structure characteristics and working principle

4.Installing, testing and relative requirement

5.Detailed Operation Methods

6.Maintenance

7.Common Troubles and Troubles Shooting Guide

8.Portage, Storage and After Sales Service

9.Accessory and quick-wearing accessory

10.Figs and detail lists of parts

MODEL XQ140/20 HYDRAULIC POWER TONG OPERATION MANUAL

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

1.Summary

Model XQ140/20 hydraulic power tong is a mouth opening power tong which can

quickly make-up or break-out pipe strings in well service. It is used in making-up or

breaking-out tubing, small drilling pipe and small casing with diameters from 2 3/8"

—5 1/2"(60mm to 140mm). Compared with the same type of tongs by other tong

makers, it features simple structure, convenient operation, reliable performance, long

life, broad application range and large torque. It is widely used in onshore or offshore

oilfields. It can reduce workload, improve work efficiency and the well service quality.

2.Technical parameters

Model XQ140/20 Hydraulic Power Tong Technical parameters

1

Application pipe diameter

mm

Ф60—140

in

2 3/8″—5 1/2″

2

Low gear max torque

kN·m

20

ft·lbs

14750

3

Second low gear max torque

kN·m

10.2

ft·lbs

7530

4

Second high gear max torque

kN·m

4.5

ft·lbs

3320

5

High gear max torque

kN·m

2.4

ft·lbs

1770

6

Low gear max rotation speed

RPM

8.7

7

Second low max rotation

speed

RPM

18

8

Second high gear max

rotation speed

RPM

37

9

High gear max rotation speed

RPM

76

10

Max oil supply pressure

MPa

12

PSI

1740

bar

122

11

Max oil supply

LPM

120

GPM

32

12

Combination tong weight

(include backup tong)

kg

700

lbs

1540

13

Overall dimension (include

backup tong) (L×W×H)

mm

1150×630×875

in

45.3×24.8×34.5

MODEL XQ140/20 HYDRAULIC POWER TONG OPERATION MANUAL

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

3. Structure characteristics and working principle

Hydraulic power tong consists of two main parts----master tong and backup tong.

The backup tong clips coupling or joints, (It can also clip the pipe body by lengthening

the front and back guide poles as required.) and the master tong clips pipe string,

turns clockwise or counter-clockwise, in this way, it completes making-up or

breaking-out operations.

3.1 Transmission System

Hydraulic power tong has four shifts to reduce speed, as shown in figure 1.

Low Gear Engagement: Z2, Z1, Z3, Z5, Z6, Z7, Z11, Z12, Z13

Second Low Gear Engagement: Z2, Z1, Z3, Z5, Z10, Z11, Z12, Z13

Second High Gear Engagement: Z2, Z4, Z6, Z7, Z11, Z12, Z13

High Gear Engagement: Z2, Z4, Z8, Z9, Z10, Z11, Z12, Z13

Fig 3-1 Transmission Diagram

Hydraulic motor

Hand control valve

MODEL XQ140/20 HYDRAULIC POWER TONG OPERATION MANUAL

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

3.2 Tong Head Assembly (Fig.3-2, Fig.3-3, Fig.3-4)

Fig 3-2 Main View of Tong Head Assembly

1. upper roller support frame;2. centralizing roller;3. jaw plate frame;4. braking plate;

5.tong head cover;6. upper centralizing roller assembly(2);7. reversing shaft;8.connection

plate;9.shaft cover;10.bake band;11.stop ring;12. hexagon socket head cap screw;13.open

gear cover;14.open cover;15.lowerroller support plate;16. centralizing roller shaft;17.

centralizing roller;

3.2.1 Clamping Mechanism (Fig.3-2, Fig.3-3)

The clamping mechanism adopts inner curved bilateral clamping mechanism. It

consists of ramp plate, roller, roller axle, jaw plate, die seats, tong dies and jaw plate

frame assembly. The jaw plate frame assembly is fixed in the inner side of the open

gear. The spline on the board matches the spline on the connection plate of braking

mechanism. When the transmission system starts to drive the open gear to turn, the

jaw plate frame assembly doesn’t turn first at all under the braking force from the

braking mechanism, the curved ramp plate turns together with the open gear, the

roller on the jaw plate climbs along the curved surface of the ramp, moving jaw plate

assembly towards the center, thus the preliminary clamping is achieved.

As the torque increases and exceeds the braking moment, the open gear drives

the spline connection plate, braking disc, jaw plate frame assembly and the jaw plate

in the braking mechanism to turn together with the pipe string. The backup tong

clamping mechanism is the same as that of the master tong. The hydraulic oil drives

rack plunger to make reciprocating movement and also drives the duplex gear and the

jaw plate frame to turn inside the main body of the backup tong, which drives the

roller to climb, finally clips or loses the pipe string.

3.2.2 Braking Mechanism (Fig.3-2)

Jaw plate frame assembly must be braked to drive roller and ramp to move in

opposite directions (i.e. climbing and resetting). The braking mechanism consists of

braking plate, braking steel disc, spline connection board, upper and lower friction

disc, adjusting screw, spring and lock nut. It can change braking moment by adjusting

the compress force from the spring.

MODEL XQ140/20 HYDRAULIC POWER TONG OPERATION MANUAL

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

3.2.3 Reset Mechanism (Fig.3-2)

The initial working position of hydraulic power tong refers to the jaw plate frame

and the open gear face the opening of the shell body of the master tong, the jaw plate

frame of the back-up tong faces the opening of backup tong main body. The openings

of master and backup tongs should be in alignment. After one making-up and

breaking-out operation ends, operate the hand control valve in the opposite direction

to return the hydraulic power tong to its initial working position, allowing the pipe

string in or out through the tong opening smoothly. During making-up and

breaking-out, reset knobs on the master and backup tongs should be in the same

direction.

1.jaw plate frame 2.die seat 3.dies 4.ramp

plate 5.jaw plate 6.roller axle 7.roller 8.cone

point fastening screw 9.cylindrical pin

10.screw stopper11.hexagon socket head screw

12.positioning screw

Fig.3-3 A-A Cutaway View of Tong Head

Assembly

3.2. Centralizing Mechanism (Fig.2 and Fig.4)

The centralizing mechanism centralizes from up and down, inside and outside. It

consists of roller support frame, centralizing roller, centralizing roller axle and roller,

which are respectively installed on the shell body and the cover of the tong head.

They match the open gear and the groove on the cover of the open gear to guarantee

the open gear turns along the original axle central line to avoid deflection and axial

running-out, thus the tong head is centralized.

Fig.3-4 Tong Head Assembly C-Side View

1.pin shaft

2.roller

3.cotter pin

MODEL XQ140/20 HYDRAULIC POWER TONG OPERATION MANUAL

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

3.3 Hydraulic System

Hydraulic system consists of hydraulic source, bucket valve, hydraulic bucket,

hand control valve, hydraulic motor, hydraulic oil cylinder, pressure gauge, quick

coupler, pipe line, etc.

Fig.3-5 Hydraulic System

3.3.1Corresponding relationship between input pressure and output torque from tong

head (Fig.3-6).

Fig.3-6 Corresponding Table between Pressure and Torque

1.hydraulic motor

2.master tong control valve

3.backup tong control valve

4.hydraulic bucket control valve

MODEL XQ140/20 HYDRAULIC POWER TONG OPERATION MANUAL

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

3.3.2 Hydraulic Oil

The hydraulic oil used for power tong must be effectively filtrated to prevent

sand, iron scraps entering to guarantee the efficient oil usage. Oil filtration accuracy

mustn’t be lower than 0.025mm (10mil).

Recommended hydraulic oil is as follows:

(1) YC-N46 low temperature solidification hydraulic oil, the appropriate

environmental temperature is–20 ℃----+40 ℃;

(2) YB-N46 abrasion resistant hydraulic oil, the appropriate environmental

temperature is -10 ℃---- +40 ℃;

(3) YA-N46 hydraulic oil, the appropriate environmental temperature is 0 ℃

----+40 ℃.

4. Installing, testing and relative requirement

Installing procedures are as follows when

hydraulic power tong is used on well site.

4.1 Check before Installation

□Check power tong damaged or not during

transportation. If damaged, it should be

repaired.

□Check the fastening parts loose or not, tighten

any loose parts.

□Check jaw plate, die seatsand dies complete

or not. (Fig.5.1)

4.2 Lifting

Lifting operation at the drilling rig or work-over rig

is shown as Fig.12

□Install a pulley on the mast, which can bear load of 4400bf or more.

□Install a pulley on the mast, which can bear load of 4400bf or more.

□Install a pulley on the mast, which can bear load of 4400bf or more or bigger, put

Fig.4-1

MODEL XQ140/20 HYDRAULIC POWER TONG OPERATION MANUAL

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

this wire through the pulley on the mast, one Install a pulley on the mast, which

can bear load of 4400bf or more.

4.3 Install hydraulic line

see 10.15

4.4 Leveling (Fig.4-2)

□Push hydraulic power tong to the clamping position.

□Check whether tongs head level or not. If it is not

level, keep master tong level by adjusting four

screws on the suspension bar.

□Check whether the backup tong parallel to the

master tong or not, if not, adjust them. (Specific

operation as 5.5)

The support point of the pulley must be installed 15 meters above the well

head.

Central line of the power tong head is located at 0.6m away from the

vertical line of the well head in free suspension state.

Avoid breaking the hose due to twisting in use.

Avoid breaking the hose due to twisting in use.

The suspension height of the hydraulic tong can be adjusted easily with the

hydraulic bucket.

When the backup tong directly faces the pipe string coupling or the drilling

pipe joint, the piston rod of the bucket should be located at half of the

stroke

Power tong leveling is very important, if not level, the tong head

clamping will fail to work.

Four screws should be adjusted in coordination.

Fig.4-2

Adjusting screw

MODEL XQ140/20 HYDRAULIC POWER TONG OPERATION MANUAL

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

4.5 Tie Back Guy (See Fig.4-3)

□Back guy should be tied well after leveling the tong. One end of the back guy should

be tied to the pin axle at the tail of the tong; the other end should be tied to the mast.

□The height of the end of back guy tied to the mast should be same as that of the tong.

The back guy should be vertical with the central line of tong body and also be pulled

tightly.

□Pay attention to the direction of the guy, the back guy should be tied to the right hand

side of the tong in the making-up operation, but it should be on the left in the

breaking-out operation when observed from the front of the tong head. Don’t tie it in

the wrong direction(All above-mentioned are suitable for Right Hand thread, as for

Left Hand thread, on the contrary.)

Back guy, which is usually soft wire rope, must be able to bear load

of over 6600bf.

Right

Left

Breaking-out direction

Making-up direction

Fig 4-3 Illustration of Back Guy

MODEL XQ140/20 HYDRAULIC POWER TONG OPERATION MANUAL

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

4.6Running-in Operation

□Supply hydraulic power tong with oil.

□Control the lifting bucket; adjust the height of power tong.

□Keep free-load running at low gear for 1 to 2 minutes.

□Keep free-load running at high gear for 1 to 2 minutes.

□Test tong head running in clockwise and counter-clockwise directions, watch

whether master tong and backup tong being synchronous or not. Adjust the

direction of reset knob if they are not synchronous. (see Fig.28)

□Open the safety door, deliver tong to the well head, and watch whether the space

between master tongs and backup tong suitable or not. Adjust the space between

them if not suitable. The adjusting procedure is shown at 5.5

□Try to clamp the pipe string at high gear, adjust system oil supply pressure by

adjusting the overflow valve in the hydraulic system according to the table of the

making-up torque value, shifts, torque and pressure parameter (See Fig. 6)

recommended by API.

Note: Being synchronous means both the master tong dies and the backup tong

dies and the backup tong dies stretch out when operating the hand control valve in one

direction. When operating hand control valve in the opposite direction, the jaw plate

frame of the master tong and the opening gear face the opening of master tong, the jaw

plate frame of the backup tong and the main body of backup tong, too. The reason for

being non-synchronous are: 1.the wrong direction of the reset knob; 2.wrong

connection of the hoses of the backup tong is sure to slip, see 5.3.2 for the right

connection method.

Don’t disassemble hydraulic pipe at high pressure, otherwise,

accidents may occur and the equipment may be damaged.

Don’t approach the running part of hydraulic power tong by your

body or clothes.

Only operators are allowed to approach hydraulic tong to avoid

any trouble caused by turning the operating lever.

The hand control valve may be slightly operated to realize gear

shifting at low gear to avoid damaging the gear.

MODEL XQ140/20 HYDRAULIC POWER TONG OPERATION MANUAL

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

4.7 Making-up Or Breaking-out Operation

See 5.6 5.7 for recommended steps.

4.8 Treatment after use

Operate as the following procedures after the work is finished.

□Cut off power source.

□Remove the high-pressure hose.

□Protect oil inlet and outlet to prevent sand or iron scraps getting in.

□Check fastening parts, fasten the loose parts.

□Put down power tong, place it in an even place, otherwise the tong will be

damaged if the place is not even. Clean and maintain power tong as (6).

Proper treatment prolongs the life of power tong after use.

5.Detailed Operation Methods

5.1 Selecting and Dismounting Jaw Plate, Die Seat And Dies

(State any special specification in your order)

5.1.1 Jaw plate selection

5.1.1.1 Jaw plate specification and parts number are shown in table 5-1.

Table 1 Die Seat Specification

The temperature of the hydraulic oil should not be over

65℃. Overheating can make hydraulic system seal fail to work

and slow down the running speed of tong.

Jaw plate

Stopper pin

Roller

Roller axle

Fig.5-1

MODEL XQ140/20 HYDRAULIC POWER TONG OPERATION MANUAL

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

No.

Purchase No.

Drawing

name

Part

name

Notes

1

XQ20-77

XQ20.1.1-7

Jaw plate

Used for master tong, suitable

for all adaptive pipe diameters.

2

XQ20-227

XQ20.2-7

Jaw plate

Used for backup tong, suitable

for all adaptive pipe diameters.

5.1.1.2 Jaw plate assembly and its mounting /Dismounting

□Jaw plate assembly consists of jaw plate, roller, roller axle and stopper pin etc.(see

Fig.5-1).

□When dismounting jaw plate, take out two die seats first, then turn the tong head,

expose the positioning screw on the jaw plate frame from the opening of the tong

head, loose the positioning screw, then the jaw plate can be taken out from the

center of the tong head.

□Mounting operation procedure is just on the contrary (See Fig.5-2)

Backup tong jaw plate

Positioning screw

Jaw plate of master tong

Hexagon socket

Backup tong jaw plate frame

Hex Wrenches

Stop screw

Fig.5-2

MODEL XQ140/20 HYDRAULIC POWER TONG OPERATION MANUAL

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

5.1.2Die seat, die choose and dismounting

5.1.2.1 Specification and parts number of die seats (10 kinds in total, one kind is

especially for backup tong) and dies(three kinds in all, suitable for both master tong and

backup tong).

This power tong clamp pipe string of different outside diameters by changing die

seats and dies of different specifications. The die `seats and dies are equally useful for

master and backup tongs when clamping pipe strings of the same outside diameter. When

selecting die seat and dies, refer to the stamp marks and part numbers on their back.

□Die seats specification and part number are shown in table 5-2.

Dies specification and part numbers are shown in table 5-3.

5.1.2.2 Recommendation table of die

seats and dies (see Table 5-4)

5.1.2.3 Die seats assembly and

mounting/dismounting. Die seats

assembly consists of die seats and screw

stopper (see Fig.5-3)

Dismounting die seat assembly: pull one die seat assembly to the center of tong head,

lift it upward out of tong head directly, take out the other one in the same way. Mounting

operation is the other way round (see Fig.5-4).

5.1.2.4 Dies mounting/dismounting

Take out die seat and loose the screw pin on one end, then take out dies. Mounting

operation is the other way round, tighten the screw pin after mounting(see Fig.5-3)

Screw driver

Screw stopper

Die seat

Fig.5-3

Fig.5-4

Die

MODEL XQ140/20 HYDRAULIC POWER TONG OPERATION MANUAL

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

Die seats and dies must be changed in pairs.

Refer to the steel mark on the die seat and dies for the specification.

Table 5-2 Die seat specification

Table 5-3 Dies specification

Serie

s No.

Purchase No.

Part name

Mark (steel mark)

Note

1

XQ20-71(1)

Die (1)

73-78

2

XQ20-71(2)

Die (2)

89-114

3

XQ20-71(3)

Die (3)

121-156

The hydraulic power source must be cut off when changing jaw plates,

die seats and dies.

Serie

s No.

Purchase No.

Part name

Mark (steel mark)

Note

1

XQ20-72(1)

Die seat(1)

138-143

2

XQ20-72(2)

Die seat(2)

132

3

XQ20-72(3)

Die seat (3)

127

4

XQ20-72(4)

Die seat (4)

114

5

XQ20-72(5)

Die seat (5)

105

6

XQ20-72(6)

Die seat (6)

89

7

XQ20-72(7)

Die seat (7)

73

8

XQ20-72(8)

Die seat (8)

60

User

purchase

9

XQ20-72(9)

Die seat (9)

121

10

XQ20-226

Die seat

156

Assembly of jaw plate

Die plate assembly

Dies

Pipe string

Φ pipe outer diameter mm

Jaw plate

Jaw plate roller

Roller shaft

Fig.5-5 Clamping illustration

MODEL XQ140/20 HYDRAULIC POWER TONG OPERATION MANUAL

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

Table 5-4 Recommendation table of die seats and dies

Pipe string

type

O.D

mm(inch)

Die seat (stamp mark)

Dies (stamp mark on the

backside)

Backup tong

Master tong

Backup

tong

Backup

tong

Oil tube

)"2(60 8

3

60

73

73-78

73-78

Oil tube

)"2(73 8

7

73

89

73-78

89-114

Oil tube

)"3(89 2

1

89

114

89-114

89-114

Oil tube

)"4(114 2

1

114

138-143

89-114

121-156

Oil tube

)"4(114 2

1

114

132

89-114

121-156

Oil tube

)"5(127

127

138-143

121-156

121-156

Oil tube

)"5(140 2

1

138-143

156

121-156

121-156

Drill pipe

"2 8

7

( male)

105

(flat butt joint)

105

105

89-114

89-114

Drill pipe

"3 2

1

( male)

121

(flat butt joint)

121

156

121-156

121-156

Note:

Diameter refers to the outside diameter of tubing and casing, master tong clamps the

pipe body, and backup tong clamps the coupling in making-up and breaking-out operation.

Both master tong and backup tong clamp the drilling pipe joint. The outside diameter

of the drilling pipe refers to the outside diameter of the joint.

Use prolonged guide pole, select die seats and dies according to the actual diameter

of pipe body to be clamped when backup tong clamps the body of the pipe.

It is not suitable for the pipe string with surface hardness degree≥340HB.

Special die seat and dies can be custom-made.

Before operation, select the needed jaw plate, die seats and dies

according to Table 5-2, Table 5-3 .

MODEL XQ140/20 HYDRAULIC POWER TONG OPERATION MANUAL

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

5.2 Making-up operation steps (This manual is suitable for making-up or breaking-out

direction with right hand thread, but the left hand thread is on the contrary.)

□Hydraulic power tong does racing, make it back to preliminary working state.

Select proper gear according to actual requirement (usually high gear).

□Turn the reset knobs of the master tong and backup tong to the making-up

direction; make sure the knobs point in the same direction.

□Close the safety door.

□Push the tong tail to make the tong turn around the rotating center, tighten the

guy.

□Push hand control valve lever gently to begin the making-up operation.

□Pull the lever of the hand control valve to make tong back to the initial working

position.

□Open the safety door, push tong back to the preliminary position. One

making-up operation is over.

Making up under over torque circumstances can damage tubing as

well as the hydraulic power!

In case of insufficient braking spring or spring failure, make up the

number or change the spring.

Please make-up according to recommended API torque valve.

Fig.5-6

Making-up direction

Breaking-out direction

Reset knob

Breaking-out direction

Making-up direction

The indication direction of the knob

MODEL XQ140/20 HYDRAULIC POWER TONG OPERATION MANUAL

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

5.3 Breaking-out operation steps (based on right hand thread, left hand thread is on the

contrary.)

□Hydraulic power tong does racing, make it back to preliminary working state.

Select proper gear according to actual requirement (usually low gear).

□Turn the reset knobs of the master tong and backup tong to breaking-out

direction; make sure the knobs point in the same direction (see Fig.28).

□Open the safety door, push hydraulic power tong towards the pipe string, and

make sure the clamping position of master tong and backup tong is proper.

□Close the safety door.

□Pull the tong tail to make tong turn around the rotating center, tighten the back

guy.

□Pull the hand control valve operating lever gently to start breaking-out operation.

□Continue breaking-out operation till all screws thread out, then release operating

lever.

□Push hand control valve operating lever to make tong back to the preliminary

working state.

□Open the safety door, push tong back to the preliminary position. One

breaking-out operation is finished.

5.8 Installing rack plunger

Remove the upper cover of the backup tong (XQ20-210), duplex gear (XQ20-230

and cylinder cover (XQ20-244), push out the rack plunger, install Yx seals at two ends of

the cylinder liner, then push rack plunger to the center of cylinder liner, finally install

duplex gear and other parts when the jaw plate frame (XQ20-214)faces the opening of

the backup tong. (see Fig. 5-7)

Over torque can damage casing as well as the hydraulic power

tong!

Don’t make-up or break-out before the safety door is closed well !

During the breaking-out operation, the max length of the backup

tong moving downward should be longer than the length of the

screw extended out, otherwise the front and back guide pole

should be repaired.

Keep the operating area of the power tong clean to prevent

sundries in. Tidy the hydraulic hose, electric wire, and signal line to

avoid twisting or getting cut off.

This manual suits for next models

1

Table of contents

Other TEDA Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Contractor

Contractor CAB-110P instructions

Thompson

Thompson YBX3 Series instruction manual

R.V.R. Elettronica

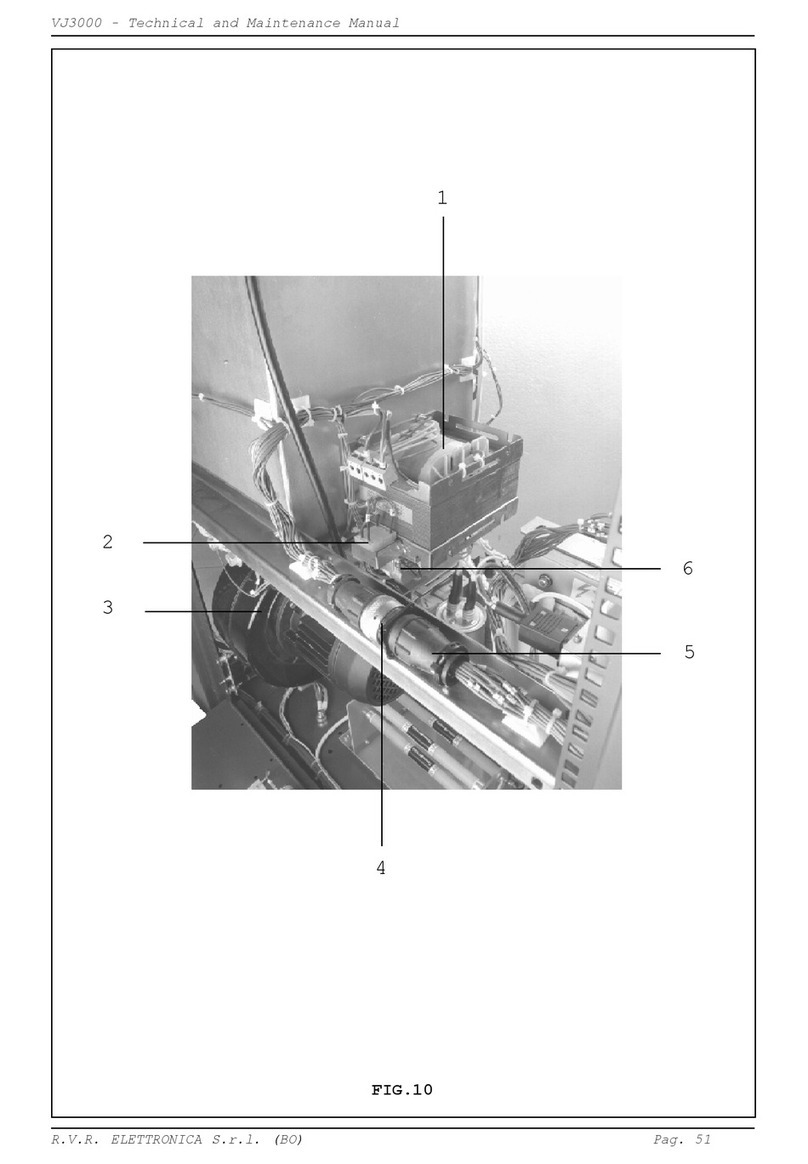

R.V.R. Elettronica VJ3000 Installation, Technical and Maintenance Manual

Roger Technology

Roger Technology T90/F2S Instruction and warnings for the installer

GIGAIPC

GIGAIPC QBiX-Pro-WHLA8265H-A2 quick start guide

Aerotech

Aerotech PRO115SL Series Hardware manual