4

INM9380-RD Rev 2

c) An assembly has limited ingress protection and must be provided with protection

appropriate to the environment in which it is located.The following table provides

guidance on minimum environmental protection for specific locations.

Location Minimum environmental protection

Safe area IP20

Zone 1 or

Zone 2

Ex e or Ex d certified enclosure; ≥IP54 - increase level for more

severe conditions

Note: For installation in Zone 1 or 2, the combination of a 9387-FB-Px-R open frame

assembly and its protective Ex e or Ex d enclosure will require certification as a

complete assembly by a third-party certifying authority.

d) An assembly will provide the best thermal performance when mounted on a

vertical surface. Other orientations are possible but may require some de-rating of

the permitted operating temperature range.

e) Adequate security should be provided against unauthorised interference with the

equipment.

f) If the chosen protective enclosure is liable to encounter significant levels of

condensation, it is advisable to incorporate a drain/breather to minimise moisture

accumulation.

3.2 Preparation

NOTE: The weight of an assembly must be considered when chosing a suitable

mounting location. Use the following figures for guidance.

Assembly/Component Guide weight (kg)

Baseplate, carriers and TTA (no modules) 2.8

Fieldbus barrier module 9377-FB-R 0.95

Alarm module 9379-ALM (including connectors) 0.07

Trunk terminator module (max. 1 per assembly) 0.12

Trunk surge suppressor module (max. 1 per assembly) 0.16

Spur surge suppressor module (max. 1 per spur) 0.04

a) Remove any temporary protection or packing materials.

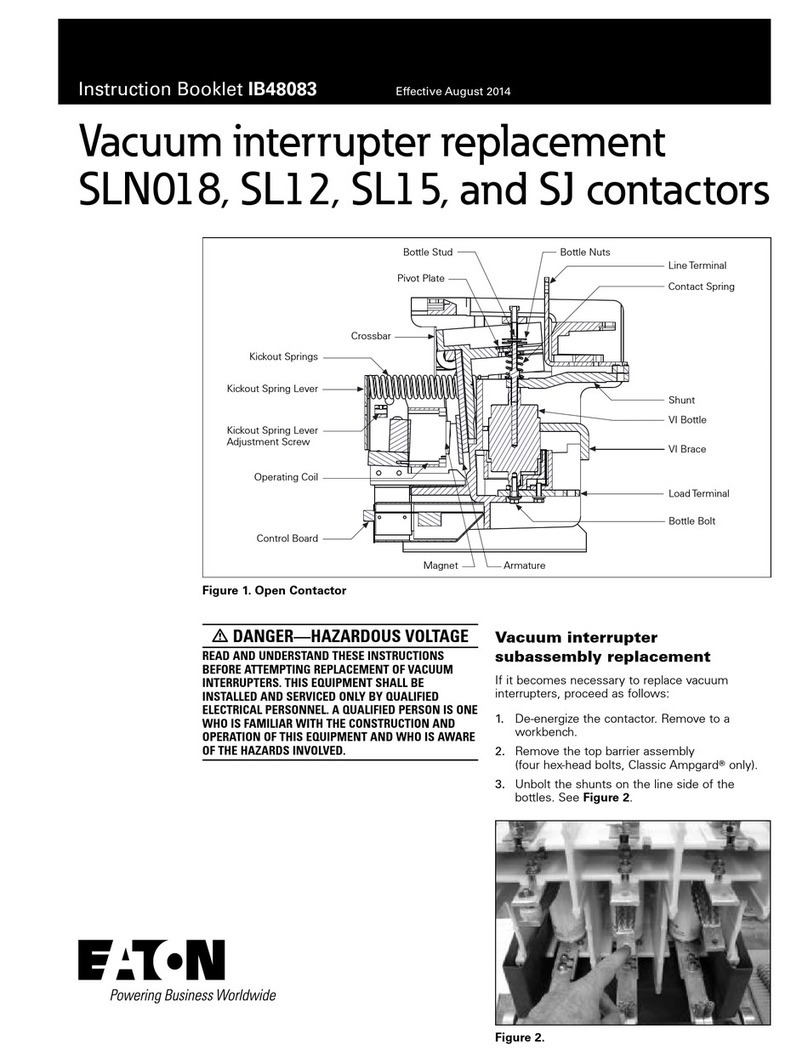

b) The assembly can be mounted on any suitable structure via the mounting holes in

the corners- see Figure 3.1 for details.

c) All fixings must be suitable for the mounting surface and the environmental

conditions that are likely to be encountered.

3.3 Mounting the assembly in a suitable enclosure

WARNING!

To minimise the risk of ignition by electrical apparatus in hazardous

areas, efficient installation, inspection and maintenance of apparatus

and systems is essential, and the work should be carried out by suitably

trained personnel in accordance with the prevailing code of practice.

The certification documents specify “Conditions for safe use” that

must be adhered to and the copy certificate supplied should be

studied and understood. Additionally it is recommend that a working

knowledge of IEC EN 60079 -14 be attained, as this standard provides

guidance in respect to the installation of electrical equipment in

hazardous areas.

3.3.1 Fixing the assembly

Either define hole or stud positions based upon the dimensions given in Figures 3.1,

or use the baseplate as a template. Prepare the fixings being used, then attach the

assembly.