How To Use This Manual

This manual provides detailed instructions on installation,

annual maintenance and parts identification. Use the

following Table of Contents to locate required information.

Table of Contents

Introduction .....................Page1

Balanced Couplings .................Page1

General Assembly Information ............Page1

Installation ..................Pages 2 thru 3

Annual Maintenance .................Page3

Installation & Alignment Data .............Page4

Parts Identification ..................Page5

Order Information ..................Page5

CAREFULLY FOLLOW THE INSTRUCTIONS IN THIS

MANUAL FOR OPTIMUM PERFORMANCE AND TROUBLE

FREE SERVICE.

INTRODUCTION

This manual applies to standard free end float Falk Freedom

Disc Couplings which are normally used as the fourth bearing

in a three bearing system. These couplings will compensate for

only angular misalignment. When these couplings are used in

conjunction with a floating shaft, refer to Manuals 478-510 or

478-520 for proper instructions. For vertical or restricted

limited end float applications, refer to the Factory.

Balanced Couplings

The fasteners provided are matched sets and must not be

mixed or substituted. Assembly balanced couplings are match

marked and must be assembled

with mating match marks

aligned. Components parts of

assembly balanced couplings

must not be replaced without

re-balancing the complete

assembly. Some balanced

couplings may have the runout

etched at 90° intervals around

the flange O.D. Recheck runouts

after coupling is mounted. Any

wide variation in these readings must be corrected. Some

possible causes of variation are burrs on mating components

or bent shafts.

GENERAL ASSEMBLY INFORMATION

Standard mechanics tools, torque wrenches, a straight edge

and feeler gauges are required to install Falk Freedom Disc

Couplings. For best results use a dial indicator to check final

alignment and make certain bolts are tightened to the

required elongation or torque listed in Table 1 or 2. Outside

micrometer sizes required to measure drive bolt elongation

are listed in Table 1 or 2.

INTERFERENCE FIT HUBS — Unless otherwise specified,

Falk Freedom Disc Couplings are furnished for an

interference fit without set screw. Heat hubs to a maximum

275°F (135°C) using an oven, torch, induction heater or an

oil bath. DO NOT heat hubs beyond a maximum

temperature of 400°F (205°C).

When an oxy-acetylene or blow torch is used, use an excess

acetylene mixture. Mark hubs near the center of their length in

several places on hub body with a temperature sensitive

crayon, 275°F(135°C) melt temperature 400°F (205°C)

maximum to prevent over heating. Direct flame towards hub

bore using constant motion to avoid overheating an area.

WARNING: If on oil bath is used, the oil must have a flash

point of 350°F(177°C) or higher. Do not rest hubs on the

bottom of the container. Do not use an open flame in a

combustible atmosphere or near combustible materials.

Heat hubs as instructed above. Mount hubs as quickly as possible

with hub flange face flush with shaft end. Allow hubs to cool

before proceeding. Insert set screws (if required) and tighten.

CLEARANCE FIT HUBS — Clean all parts using a

non-flammable solvent. Check hubs, shafts and keyways for

burrs. Do not heat clearance fit hubs. Install keys, mount hubs

with flange face flush with shaft ends and tighten set screws.

Maximize Performance & Life

The performance and life of couplings depend largely upon

how you install and maintain them. Before installing

couplings, make certain that foundations of equipment to be

connected meet manufacturers’ requirements. Check for soft

foot. The use of stainless steel shims is recommended.

Measuring misalignment and positioning equipment within

alignment tolerances is simplified with an alignment computer.

These calculations can also be done graphically or

mathematically.

It is recommended that final alignment be checked using

either an alignment computer or graphical analysis. Both

methods allow the incorporation of “cold offsets”, which will

compensate for shaft position changes due to thermal growth.

WARNING: Consult applicable local and national safety

codes for proper guarding of rotating members. Observe all

safety rules when installing or servicing couplings. Lockout

starting switch of prime mover and remove all external loads

from drive before installing or servicing couplings.

Rexnord Industries, LLC, Coupling Group 478-150

5555 S. Moorland Rd., New Berlin, WI 53151-7953 USA Telephone: 262-796-4060 February 2001

Falk™ Freedom®Disc Couplings •Installation & Maintenance

Sizes 8 thru 8770 •Types M20 & N20 (Page 1 of 5)

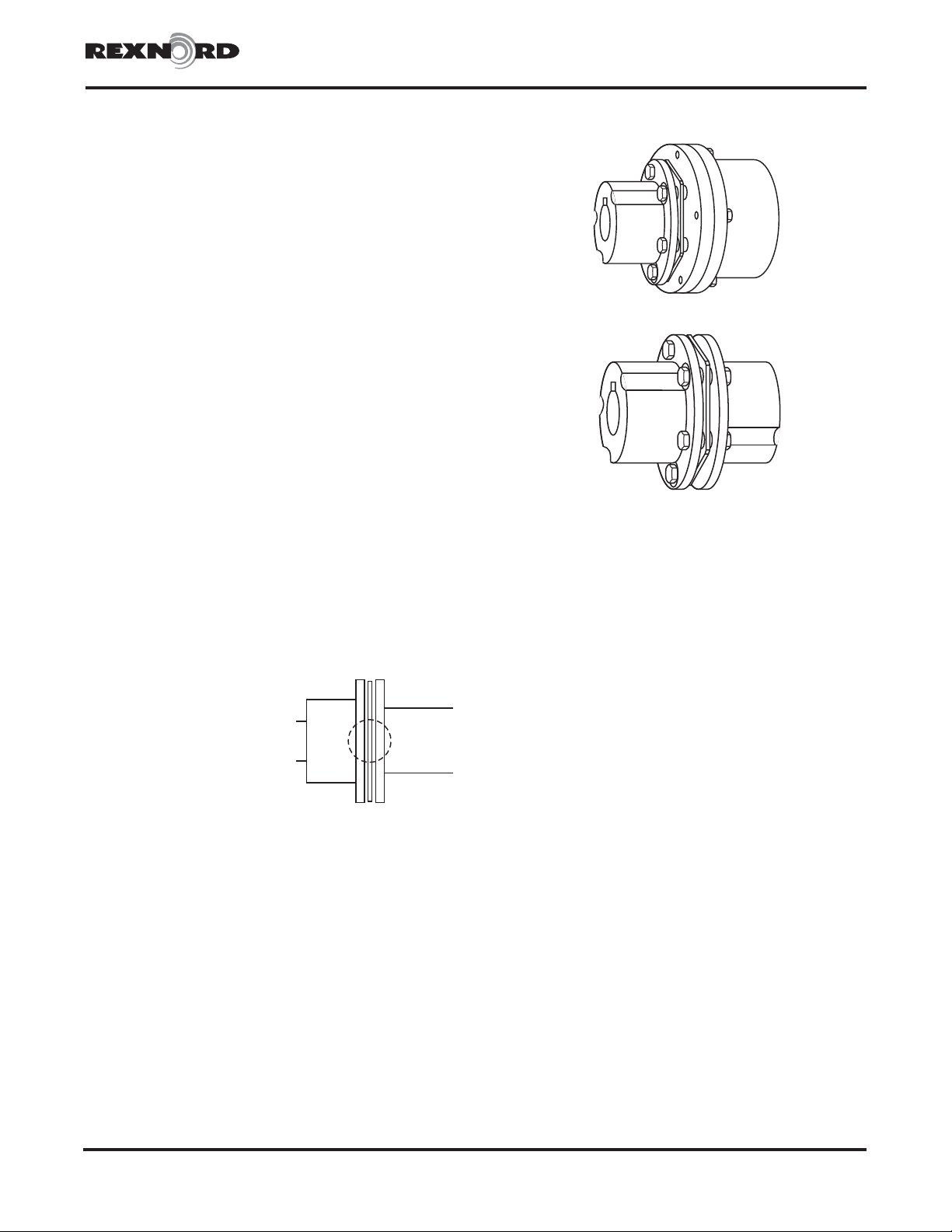

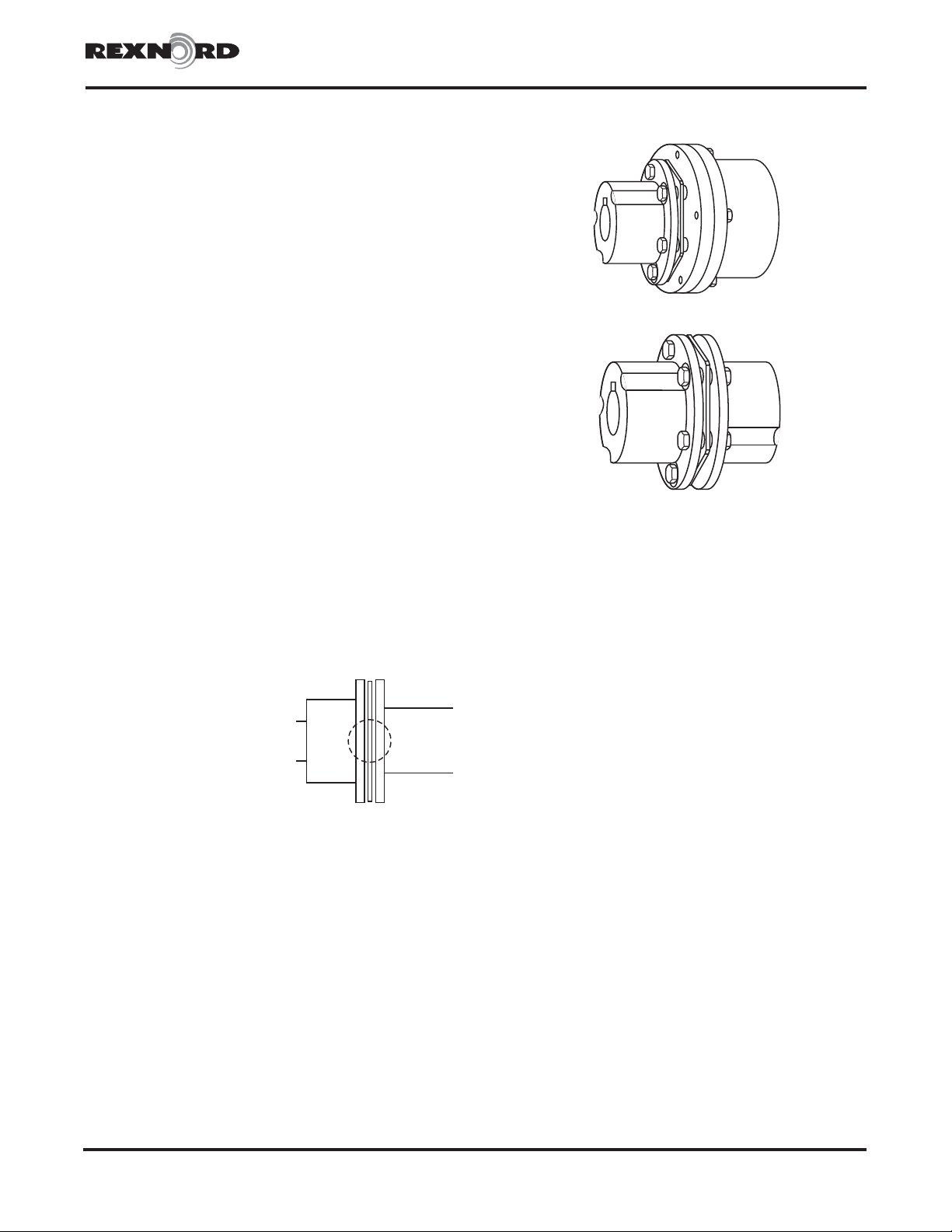

Type M20

Type N20

A1

A1 MATCH

MARKS