Nordson Prodigy HDLV User manual

Other Nordson Water Pump manuals

Nordson

Nordson EP2 User manual

Nordson

Nordson Spectrum VT Feed Center User manual

Nordson

Nordson PermaFlo Series Reference guide

Nordson

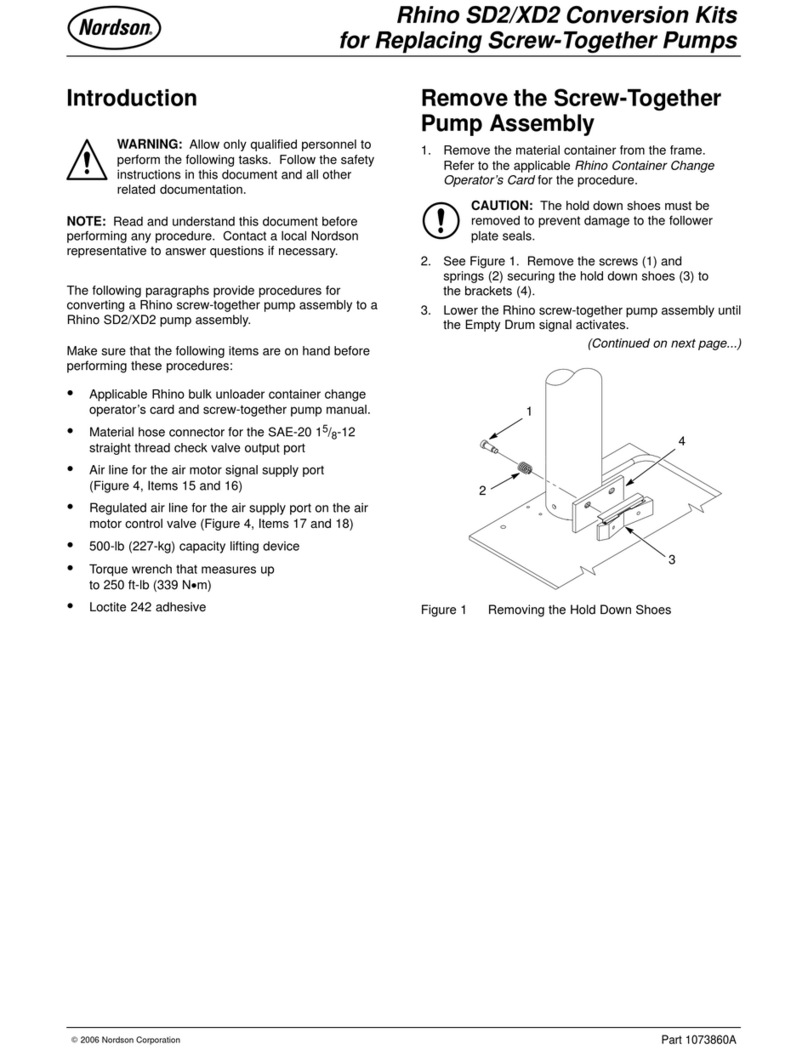

Nordson Rhino SD2 Reference guide

Nordson

Nordson PermaFlo 815 User manual

Nordson

Nordson Rhino XD2 User manual

Nordson

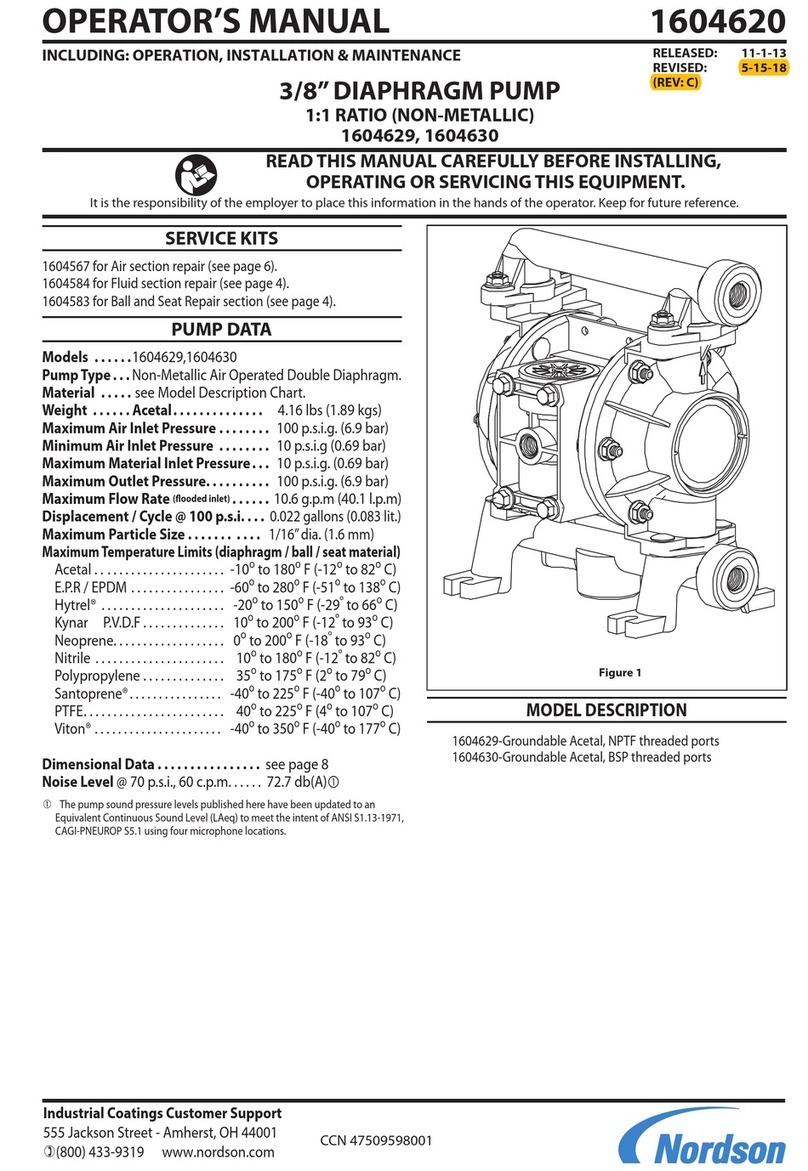

Nordson 1604629 User manual

Nordson

Nordson Rhino XD2 User manual

Nordson

Nordson cp User manual

Nordson

Nordson Rhino SD User manual

Nordson

Nordson 32 User manual

Nordson

Nordson StediFlo 57:1 Reference guide

Nordson

Nordson Rhino SD2 User manual

Nordson

Nordson Rhino SD3 Reference guide

Nordson

Nordson 25B Reference guide

Nordson

Nordson 25B Reference guide

Nordson

Nordson Prodigy Generation II User manual

Nordson

Nordson Tribomatic 635598 User manual

Nordson

Nordson Rhino SD3 Reference guide

Nordson

Nordson BM 200 Parts list manual

Popular Water Pump manuals by other brands

DUROMAX

DUROMAX XP WX Series user manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Xylem

Xylem e-1532 Series instruction manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual