North Atlantic 2250 User manual

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

Industries

170 Wilbur Place

Bohemia,

NY

11716-2416

Phone: (631)567-1100

Fax: (631)567-1823

Email:

sa

les@naii.com

Web site: www.naii.com

Operation

Manual

For

Model 2250

Digital Analyzing

Voltmeter

Model

2250/2251

INFORMATION

FOR

UNITS SOLD

WITillN

THE EUROPEANUNION

GENERAL

Information

contained

within

the

following

paragraphs

supplements

and

in

some

cases supersedes

information

contained

throughout

this

Manual.

Where

there is a conflict

between

information

contained

in

these paragraphs

and

information

contained

elsewhere

in

the

manual,

these

paragraphs take

precedence

for

units

sold

within

the

European Union.

SPECIFICATIONS

Add

to

the

list

of

specifications

the

following

information:

Environmental

Fuses

LINE

CORD

Temperature,

operating

Temperature,

non-operating

Relative

Humidity

Altitude

Overvoltage/Installation

Category

Pollution

Degree

0°

to

70° C, standard

-55°

to

75°

C

95%,

non

condensing

3050

Meters

operating,

12,000 Meters

non-operating

Category

TI

Degree 1

115V

operation -

2.0

amp.

SLO-BLO

230V

operation -

1.0

amp.

SLO-BLO

The

model

2250/2251

is

normally shipped with a UL approved detachable line cord. This line cord

does

not

meet

safety

requirements

of

the

European

Community

and

should

be discarded

and

replaced

with

a properly

approved

type

for

applications within the

European

Community.

INSTALLATION

AND

MAINS

INPUT

The

model

2250/2251

is

designed for bench top or permanent rack-mount installation.

An

IEC-320 appliance coupler

is

provided

for

mains

power

input.

Sheet 1

of2

Model

2250/2251

LINE

VOLTAGE

SELECTION

Selection

of

power

line

voltage

is

accomplished

using

the

rear

panel

line

entry

module.

See

Operator's

Manual

section

2-5

for

additional

information.

SAFETY

GROUNDING

For

safety

from

electrical

shock

and

fire

in

bench-top

applications,

the

unit

must

be

connected

to

Safety

(Earth)

ground

through

the

power

cord.

IMPROPER

USAGE

If

the

equipment

is

installed or

used

in a

manner

not

specified

safety

may

be

impaired.

MAINTENANCE

The

OPERA

TOR

only

has

access

to

the

exterior

of

the

unit.

All

maintenance,

including

any

procedures that

require

removal

of

covers,

must

be

referred

to

qualified

maintenance

personnel

TECHNICAL

ASSISTANCE

Contact

your

local

Sales

Representative

for

any

technical

assistance.

Alternately,

contact

the

Factory

at:

North

Atlantic Industries

170

Wilbur

Place

Bohemia,

NY

11716

USA

Telephone:

Fax:

Email:

Web

site:

(631)

567-1100

(631)

567-1823

www.naii.com

Sheet

2

of2

MODEL

2250 (OM-I-5026B) ERRATA SHEET

ER-1-5026B-E

10

JULY 14, 1998

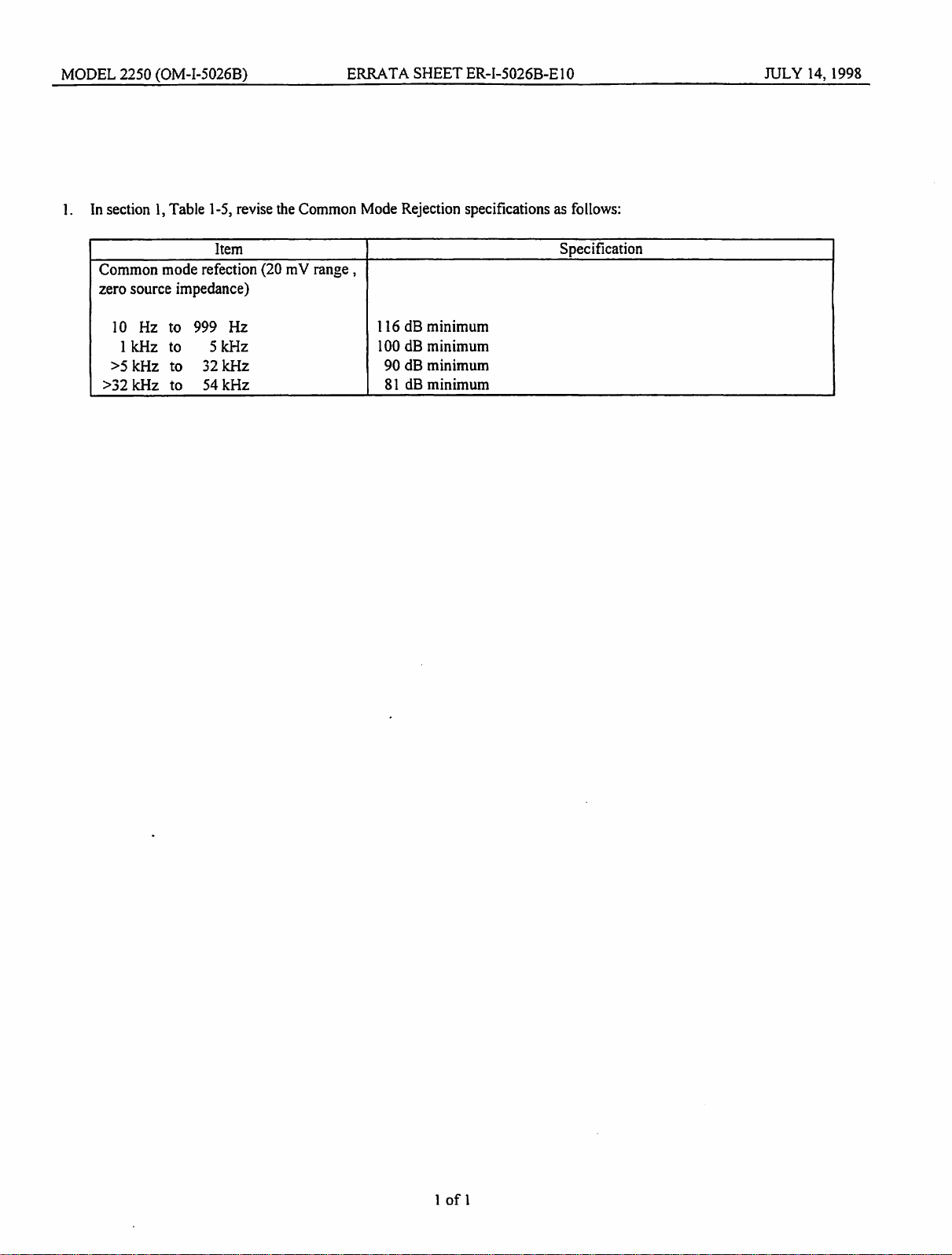

1.

In

section

1,

Table

1-5,

revise

the

Common

Mode

Rejection specifications

as

follows:

Item

Specification

Common mode refection

(20

mV range ,

zero source impedance)

10

Hz

to 999 Hz

116

dB

minimum

I kHz

to

5 kHz 100 dB minimum

>5

kHz to

32kHz

90 dB minimum

>32 kHz to

54kHz

81

dB minimum

1

of

1

MODEL

2250

(OM-1-5026B)

ERRATA

SHEET

ER-I-5026B-E9

I.

In

section

2,

paragraph

2-4

(INSTALLATION),

add

the

following

infonnation after

the

CAUTION

message:

NOTE

If

the

DAV

has

not

been

used

for

an

extended

period

of

time,

the

nickel-

cadmium

memory

backup

battery

may

become

discharged. Power

up

the

DAV

and

allow

it

to

run

for

a

minimum

of

8

hours,

then press the front

panel

CLEAR

VAR

key.

JUNE

5,

1998

2.

In

section

2,

paragraph

2-9

(OPERATIONAL

CHECKOUT

PROCEDURE),

add the following

note

after

the

paragraph

heading:

NOTE

Before

beginning

the checkout procedure,

press

the

front panel

CLEAR

VAR

key.

1

of

1

MODEL 2250

(OM-1-5026B)

PRODUCT REVISION

SHEET#

9-96 SEPTEf\.fBER 12, 1996

1.0

ASSE~LIES

AND REVISIONLEVELS AFFECTED:

Top

Assembly

NAI PIN 402250 Revision

K.

These changes

may

also

be

applicable to assemblies retrofitted with

new

finnware.

2.0

CHANGES:

In section 1change the following:

a.

In

table 1-1

add

the following:

NAI

Manual Number

lvfM-1-5027

A

MM-I-5026B

ITOTAL/AVG

Conforuration)

b. In table 1-2 add the following:

NAI

Manual Number

:MM:-I-5027

A

:MM:-1-5026B

ITOT

AL/

A

VG

Confirruration)

Model

Version

5.15

6.11

Model

Version

1.17

2.13

Check Sum Number

n5.15

n6.11

Check Sum Number

cl.17

c2.13

MODEL

2250 (OM-I-5026B)

ERRATA

SHEET

ER-I-5026B-E7

JUNE

13.

1991

In

Section

2

paragraph

2-7

add

the

following

after

the

last

sentence:

(Optional

rear

input

adapter

cable.

NAI

PIN

548792,·

is

available

£or

use

with

the

Model 225

Emulation

feature/option

F3.)

1

of

1

Publication No. OM-I-50268

OM-I-5026B

STATUS

OF

PUBLICATION

This manual applies

to

units with single Feature/Option numbers

(FX)

only.

Original -April

1989

Change

1 - October 1989

Change

2 - January 1990

Change

3 -

July

1990

Change

4-

May 3, 1991

Change

5 - February 20, 1992

Change

6 - June 12,

1996

SOFTWARE CONTAINED IN PROM(S)

HAS

BEEN

COPYRIGHTED

BY

NORTH ATLANTIC INDUSTRIES, INC.

1991

A

Sec./Para.

SECTION

1

1-1

1-1.1

1-1.2

1-1.3

1-1.4

1-1.5

1-1.6

1-1.

7

1-2

1-3

1-4

1-5

SECTION

2

2-1

2-2

2-3

2-4

2-5

2-5.1

2-5.2

2-6

2-7

2-7.1

2-7.2

2-8

2-8.1

2-8.2

2-8.3

2-8.4

2-8.4.1

2-8.4.2

2-8.5

2-8.5.1

2-8.5.

1.

1

2-8.5

.1.2

2-8.6

2-9

2-9.1

2-9.2

2-9.2.1

2-9.2.2

2-9.2.3

2-9.3

2-9.4

Change 3

OM-I-5026B

TABLE

OF

CONTENTS

GENERAL

INFORMATION.

1-1

Introduction

• • • • • • • • • 1-1

Section

1 -

General

Information.

• • • • • • 1-1

Section

2 -

Installation

and

Preparation

for

Use • • • 1-1

Section

3 -

Operation

• • • • • • • • • • • • • • 1-1

Section

4

-IEEE-488

Standard

Digital

Interface

Programming • • • • • • • • • • • • • • • 1-1

Section

5 -IEEE

MATE

Control

Interface

Intermediate

Language

Option.

Section

6 -

Theory

of

Operation.

Section

7 -

Update

Information

•••

Features

and

Options

••••••

Functional

Description

Physical

Description

Specifications

••••

INSTALLATION

AND

PREPARATION

FOR

USE

Introduction

••

Unpacking

••••••••

Inspection

•••••

Installation

••••

Power

Requirements

••••

Line

Voltage

Selection

Circuit

Card

••

Grounding.

• • • • • • •

••

Mounting

Procedures

••••••••••••

Initial

DAV

Setup

•••••••••••

Initial

Factory

Switch

Settings

•••

Emulation

of

NAI

Model 225

Selecting

Custom

DAV

Setups

••••••••

Top Cover Removal • • • •

·•

• • • •

Selection

of

Remote Programming (IEEE-488)

Interface

Language

•••••

Model 225

Device

Clear

(DCL)

Options.

Channel

Selection

for

Phase

Lock

Model 2250

Operation

•••••••••

Model 225

Emulation

·•

• • • • • • • •

Selection

of

SUM

or

AVG

TOTAL

Mode

•••••••••

Types

of

TOTAL

modes

••••••

TOTAL

(SUM)

Mode

••••••

TOTAL

(AVG)

Mode

••••••••

Recorder

Output

Voltage

Selection

(I/0

Circuit

Card Assembly)

.•••••.•

Operational

Checkout

Procedure

••

Test

Equipment

Required

•••••

Continuity

and

Isolation

Checks

••••••

Continuity.Tests.

•

•••

Isolation

Checks

••••

Hipot

Tests

••••••

Function

Verification

•••

Amplitude

Accuracy

and

Phase

Check, 400

Hz

••

i

1-1

1-1

1-1

1-3

1-3

1-3

1-6

2-1

2-1

2-1

2-1

2-1

2-1

2-3

2-4

2-4

2-4

2-4

2-10

2-10

2-10

2-10

2-11

2-11

2-11

2-12

2-12

2-12

2-12

2-12

2-13

2-14

2-14

2-14

2-14

2-15

2-15

2-15

2-21

Sec./Para.

2-9.5

2-9.6

SECTION

3

3-1

3-1.1

3-1.2

3..;1.3

3-2

3-3

3-4

3-4.1

3-4.

1.

1

3-4.1.2

3-4.1.3

3-4.2

3-4.2.1

3-4.2.2

3-4.3

3-4.3.1

3-4.3.2

3-4.4

3-4.4.1

3-4.4.2

3-4.5

3-4.5.1

3-4.5.2

3-4.6

3-4.6.1

3-4.6.2

3-4.7

3-4.7.1

3-4.7.2

3-4.7.3

3-5

3-5.1

3-5.2

3-6

3-0.1

3-6.2

3-6.3

3-7

3-7.1

3-7.2

3-7.3

3-7.4

3-8

3-8.1

3-8.2

3-8.3

3-8.4

OM-I-5026B

TABLE

OF

CONTENTS

(Continued)

Amplitude Accuracy and

Phase

Check, Wideband

IEEE-488

Interface

Test

••••••••••

. .. .. . .

... ..

OPERATION.

. . ... . . . . . . . . . . . . . . .. . ..

Introduction

•••••••••••••••••••••

Model 225

Compatible

Operation.

• • • • • • • • • • • •

Custom

DAV

Setups

•••••••••••••••••••••

Remote Programmed

Operation

•••••••••••••

Front

Panel

Controls

and

Indicators

••••••••••••

Rear

Panel

Controls

and

Indicators

•••••••••••••

Modes

of

Operation

•••••••••••••••••

TOTA!.,

Mode. • • • • • • • • • • • • • • • • • • • •

TOTAL

Mode

Measuring

Techniques

••••••••••••••

Measurement

Modifiers.

• • • • • • • •

Display

Ma

th

Modi£

iers.

• • • • • • • • • • •

FUNDamental Mode. • • • • • • • • • • • • • • • • •

Measurement

Modifiers

• • • • • • • • • • • • • •

Display

Math

Modifiers.

• • • • • • •

IN

PHASE

Mode

• • • • • • • • • • • • • • • •

Measurement

Modifiers

••••••

. . . ......

Display

Ma

th

Modifiers.

• • • • • • • • •

QUADrature

Mode

• • • • • • • • • •

Measurement

Modifiers

• • • • • • • ...... . ..

Display

Math

Modifiers.

• •

••

. . .. ..

PHASE

ANGLE

Mode.

• • • • • • • • • • • •

Measurement

Modifiers

• • • • • •

Display

Math

Modifiers

••••••••

THD

Mode.

• • • • • • • • • • • .... . ...

Measurement

Modifiers

••••••

Display

Math

Modifiers

••

. . .. . . ... . .. .

. .... . .. . ..

RATIO

R Modes

•••••

. .. . . .. . .. . . .

RATIO

R Submodes. • • • • • • • •

Measurement

Modifiers

. .. ..

. . . . . . . . .

Display

Math

Modifiers.

.. . . . .

Ranges

of

Operation

•••

.. . . . ... . . .

. .. . . . .. . .

. .... . . . . . . ..

Voltage

Ranges.

.•

• • • • • • •

Ratio

Ranges. • • • • •

Measurement Channels

••••••

...... . . ..

REFerence

Channel.

• • •

••••••

SIGnal

Channel.

• • • • • • • •

•••

Phase Lock

Synchronization

Reference

••••

Measurement

Modifiers.

•

•••

Harmonic Measurement. • • • • • • • • • • •

Frequency

Preset.

• •

•••••••••

Display

Averaging

•••••••••••••

Track/Hold.

• • • • • • • • • • • •

Display

Math

Modifiers.

•

••••••

Phase

Offset.

• •

•••••••••

Variable

Scale.

•

•••

Offset.

• • • • • • • • •

•••••

+180°

Phase

• •

•••••

ii

. . .

. .. . . . ..

... . ..

. . . . . ...

. . . . . . . .

.. . . . . . .

. . . . .

. . . .. .

2-23

2-23

3-1

3-1

3-1

3-1

3-1

3-1

3-10

3-12

3-12

3-12

3-12

3-12

3-13

3-13

3-13

3-13

3-14

3-14

3-14

3-14

3-15

3-15

3-15

3-15

3-16

3-16

3-16

3-16

3-16

3-17

3-18

3-18

3-18

3-18

3-18

3-19

3-19

3-19

3-19

3-19

3-20

3-20

3-20

3-20

3-20

3-21

3-21

3-21

Sec./Para.

3-8.5

3-8.6

3-9

3-9.1

3-9.2

3-9.3

3-10

3-10.1

3-10.2

3-10.3

3-11

3-11.1

3-11.2

3-12

3-12.1

3-12.2

3-12.3

3-12.4

3-12.4.1

3-12.4.2

3-12.5

3-12.6

3-12.7

3-12.7.1

3-12.7.2

3-12.7.3

3-12.7.4

3-12.

8

3-12.9

3-12.10

3-12.11

3-12.12

3-12.13

3-12.14

SECTION

4

4-1

4-1.1

4-1.2

4-1.3

4-1.4

4-1.5

4-1.6

4-2

4-2.1

4-2.2

4-2.3

4-3

4-3.1

4-3.

1.

1

4-3.1.

2

OM-I-5026B

TABLE

OF

CONTENTS

(Continued)

Percent

Deviation

••

. .

dB. • • • • • • •

Keypad

Operation

•••••••••••••••••••••

Enter

Data.

• • • • • • • • •

•••••••

Read/Modify

Data.

• • • • • •

••••••••••

Clear

Data

•••••••••••••••••••••••••

Self-Calibration

• • • • • • • • • • • • •

••

Ten

Frequency

Self-Calibration

Storage.

• • • • •

•••

TOTAL

(AVG)

Calibration

• • • • • • • • • • • • •

AUTOCAL

Operation

• • • • • • • • • • • • • •

Recorder

Output

• • • • • • • • • • • • • • • • • • • •

Output

Options.

• • • • • • •

••••••••••

Recorder

Outputs

in

Various

Operating

Modes • • • • • •

Typical

Applications

• • • • • • • • • • • •

AC

Voltage

Measurement. • • • • • • • • • • • • • • • • • •

Phase

Sensitive

AC

Voltage

Measurement

•••••••••••

Phase

Angle Measurement

••••••••••••••••••

Frequency

Response

Measurements

in

dB

•••••••••••

Setup

Frequencies.

• • • • • • • • • • •

•••••••

Measure

Response

•••••••••

THD

Measurements. • • • • • • • •

Percent

Deviation

Measurements

••

. . . . . . ..

Harmonics Measurements

••••••

Harmonic

Fundamental

Amplitude

••••

. .. .

Harmonic

lnphase

Component

Amplitude

••••••••••••

Harmonic

Quadrature

Component

Amplitude

••••••••••

Harmonic

Phase

Angle Measurement

••••••••••

Transfomation

Ratio

Measurement

••••

Synchro/Resolver

Bridge

Null

Indicator

•••

Synchro

Electrical

Zero

(Null)

Tests

••••••

Impedance Angle and Power

Factor

Measurements

••

. . .

. ..

Impedanee

Magnitude

• • • • • • • • • • • • • • • • • • • •

AC

Resistance

and

Reactance

Measurements

•••

Condition

Transducer

Output

for

Convenient

Display.

IEEE-488

STANDARD

DIGITAL

INTERFACE

PROGRAMMING.

. . . . .

Introduction

. . . . . . . . . . . .

Interface

Functions

Supported

••••

Remote Program Language

Selection

••

DAV

Address • • • • • • • • • • • • • • • •

IEEE-488

Interface

Connections

•••••••

Power-Up

•••••••••••

DAV

Front

Panel

Annunciators

••

.. . . .

. . ..

. .. . . . ..

Bus

C0Dm1ands

• • • • • • • • • • • • • • • • • • • •

Bus

Command

Descriptions.

• • • • • • • • • • • • • •

Default

Settings.

• • • • • • • • • • • • • •

••

Serial

Poll

• • • • • • • • • • • • • • • • • • • • • • • •

Model 22~0

NATIVE

Language

Device

Dependent Messages

•••

Mode

Pro~::.

amming. • • • • • • • • • • . . ..

Mode

Programming

Examples.

• • • •

••

Ratio

R

Mode

Programming Examples

•••••

. . ..

iii

3-21

3-21

3-22

3-22

3-22

3-22

3-23

3-23

3-23

3-23

3-23

3-24

3-24

3-24

3-25

3-26

3-27

3-28

3-28

3-28

3-29

3-29

3-30

3-30

3-30

3-31

3-31

3-32

3-33

3-34

3-35

3-36

3-37

3-38

4-1

4-1

4-1

4-1

4-2

4-2

4-2

4-5

4-5

4-5

4-6

4-6

4-6

4-6

4-6

4-7

Sec.

/Para.

4-3.2

4-3.2.1

4-3.2.2

4-3.3

4-3.4

4-3.4.1

4-3.4.2

4-3.4.3

4-3.4.4

4-3.5

4-3.5.1

4-3.5.2

4-3.5.3

4-3.5.4

4-3.5.5

4-3.5.6

4-3.6

4-3.

7

4-4

4~4.1

4-4.2

4-4.3

4-4.4

4-5

4-6

4-6.1

4-6.2

4-6.3

4-6.4

4-7

4-8

4-8.1

4-8.

1.1

4-8.

1.2

4-8.2

4-8.2.1

4-8.2.2

4-8.2.3

4-8.2.4

4-8.2.5

4-8.2.6

4~8.2.7

4-8.3

4-8.4

4-9

4-9.1

4-9.

1.1

4-9.

1.2

4-10

4-11

4-11.1

OM-I-5026B

TABLE

OF

CONTENTS

(Continued)

Range Programming • • • . • • • • • • • • • • • • •

Voltage

Range

Programming.

•

•••••

Ratio

Range

Programming.

•

•••

Measurement Channel Programming

••••

Measurement

Modifier

Programming

••••••••••••••

Harmonic Measurement Programming

••

Frequency

Preset

••••••••••••

Data

Averaging.

• • • • • • • • •

•••

Track/Hold

Programming

•••••••••

Data

Math

Modifier

Programming

••

Phase

Offset

Programming

••

Variable

Scale

Programming

••

Offset

Programming

••••.•••••••••

+180°

Phase

Programming

•••

Percent

Deviation

Programming

•••

dB

Programming• • • • • • • • • • • • •

Self-Calibration

Programming. •

•••••••

AUTO

CAL

Function

Programming

Model 2250

NATIVE

Language

Talk

Messages

••

TALK

Message Format Programming

•••••••

Main

Display

Transmission

Format

•••••••

Frequency

Display

Transmission

Format.

Status

Transmission

Format

••••••••••

Model 2250

NATIVE

Language

Serial

Poll

Model 2250

NATIVE

Language

Service

Request

Programming

Assert

SRQ

With

Stable

Data

or

Measurement Timeout

•••••

Assert

SRQ

Continuously

Programming

•••••

Assert

SRQ

On

External

Trigger

Programming

••

Cancel

SRQ

Function

Programming

•••••••••

Model 2250

NATIVE

Language Group

Execute

Trigger

Programming

••••••••••••••••••

Model 225

Emulation

Listen

Message Programming

Listen

Message

Data

Format.

• • • • •

Long Format

Listen

Syntax

••••••••••••

Short

Format

Listen

Syntax.

• • • • • • • • • • • •

••

Model 225

Emulation

Listen

Instructions

and

Arguments.

Listen

Instructions

Mode

Arguments.

• • • • •

Range

Arguments.

• •

••

Frequency

Arguments

•••••••••

Reference

(Phase)

Offset

Arguments.

Variable

Scale

Arguments

••••

Data

Output

Format

Programming.

Modifier

Value

Storage

••••••

Self-Calibration

Programming

•••

Model 225

Emulation

Talk

Messages •

Talk

Message

Data

Format.

•

••

Long

Talk

Message Format

••••••••

. ... . .

Short

Talk

Message

Format.

• • •

•••

Model 225

Emulation

Serial

Poll.

Model 225

Emulation

Service

Request

•

..

. . . . .

. . .

. . .

Assert

SRQ

With

Stable

Data

or

Measurement

Timeout.

. . . .

iv

4-8

4-8

4-8

4-8

4-9

4-9

4-9

4-10

4-10

4-10

4-10

4-10

4-11

4-11

4-12

4-12

4-12

4-13

4-13

4-13

4-14

4-14

4-14

4-15

4-15

4-16

4-16

4-16

4-17

4-17

4-20

4-20

4-20

4-20

4-21

4-21

4-21

4-21

4-22

4-22

4-22

4-23

4-23

4-23

4-24

4-24

4-24

4-24

4-25

4-25

4-25

Sec.

/Para.

4-11..2

ij-fl.3

~

12.

JI--•

3

SECTION

5

5-1

5-1.1

5-1.2

5-1.3

5-2

5-2.1

5-2.2

5-2.3

5-2.4

5-2.5

5-2.6

5-2.6.1

5-2.6.2

5-2.6.3

5-3

5-3.1

5-3.2

5-3.3

5-3.4

5-3.5

5-3.6

5-3.7

5-3.8

5-3.9

5-3.10

5-3

.11

5-3

.12

5-3

.13

5-3.14

5-4

5-5

5-6

5-7

5-8

5-9

5-10

5-11

5-12

5-12.1

5-12.2

5-12.3

5-12.4

5-13

Change 3

f

OM-I-5026B

TABLE

OF

CONTENTS

(Continued)

Assert

SRQ

On

Second Reading Programming.

Assert

SRQ

Continuously

Programming.

Model 225

Emulation

Group

Execute

Trigger

Request

Programming

Model 225

Emulation

Device

Clear

Options

IEEE-488

MATE

CONTROL

INTERFACE

INTERMEDIATE

LANGUAGE

OPTION

Introduction

Input/Output

String

Notation.

•

Selection

of

IEEE-488

MATE

Operation.

Initial

Setup.

Inputs

Format

of

Inputs.

Format

of

FNC

•

Noun.

MCHAR.

Channel Number.

Modifier

Fields

Set

Codes •

Modifier.

Nonstandard

Form.

Programming

Applications

(FNC)

TOTAL

Mode.

FUNDamental Mode.

IN

PHASE

Mode.

QUADrature

Mode.

PHASE

ANGLE

Mode.

Total

Harmonic

Distortion

(THD)

Harmonic

Phase.

Harmonic

Voltage.

Frequency.

Averaging.

Voltage

Ranging.

Track/Hold

Mode.

Reference

Channel

Measurements.

Calibration.

Format

of

INX.

Format

of

FTH.

Format

of

CLS.

Format

of

OPN.

Format

of

RST •

Format

of

STA.

Format

of

IST.

Format

of

CNF.

Outputs

•

Errors.

Response

to

INX.

Response

to

FTH.

Response

to

STA.

Atlas

Constructions.

V

. .

.

..

..

, .

4-26

4-26

4-26

4-26

5-1

5-1

5-1

5-1

5-2

5-2

5-2

5-3

5-3

5-3

5-3

5-3

5-3

5-3

5-4

5-4

5-4

5-4

5-4

5-5

5-5

5-5

5-5

5-5

5-5

5-6

5-6

5-6

5-7

5-7

5-7

5-8

5-8

5-8

5-9

5-9

5-9

5-9

5-10

5-10

5-11

5-12

5-12

5-14

Sec./Para.

5-13.1

5-13.2

5-13.3

5-13

.4

5-13.5

5-13.6

5-13.7

5-13.8

5-13.9

5-13.10

5-14

5-14.1

5-14.2

5-14.3

5-14.4

5-14.5

5-14.6

5-14.7

5-14.8

5-14.9

5-14.10

5-14.11

SECTION

6

6-1

6-2

6-2.1

6-2

.1.1

6-2.1.2

6-2.2

6-2.3

6-2.4

6-2.5

6-2.6

6-2.7

6-2.8

6-2.9

6-2

.10

6-2.11

6-2

.12

6-3

6-3.1

6-3.2

SECTION

7

7-1

OM-I-5026B

TABLE

OF

CONTENTS

(Continued)

Calibration

••••••••••••••••••••••••

Standard

(Non-Referenced)

AC

Voltage

Measurement

(True

Rms

Voltage)

•••••••••••••••••••

Referenced

AC

Voltage

Measurements (True

Rms

Voltage)

•••

Referenced

AC

Voltage

Measurements -FUNDamental

Component. • • • • • • • • • •

·•

• • • • • • • • •

Referenced

AC

Voltage

Measurements -

IN

PHASE

Component

••

Referenced

AC

Voltage

Measurements -QUADrature

~

Component. • • • • • • • • • • • • • • • • • • • • • • •

Referenced

AC

Voltage

Measurements -Harmonic Component

••

PHASE

ANGLE

Measurements -FUNDamental Component

••••••

PHASE

ANGLE

Measurement -Harmonic Component.

Total

Harmonic

Distortion

Measurement

••••••••

CIIL

Railroad

Diagrams

••••••••••••••••••

Standard

(Non-Referenced)

AC

Voltage

Measurement

True

RMS

• • • • • • • • • • • • • • • • • • • •

Standard

(Referenced)

AC

Voltage

Measurement

True

RMS

•••

Referenced

AC

Voltage

Measurement FUNDamental Component

••

Referenced

AC

Voltage

Measurement

IN

PHASE

Component

••••

Calibration

•••••••••••••••••••••

~

Referenced

AC

Voltage

Measurement QUADrature Component

•••

Referenced

AC

Voltage

Measurement Harmonic Component

••••

PHASE

ANGLE

Measurement FUNDamental Component •

PHASE

ANGLE

Measurement Harmonic Component

•••••••••

Total

Harmonic

Distortion.

• • • • • • •

••

Summary

of

MATE

Programming

Syntax.

• • • •

••

THEORY

OF

OPERATION.

Introduction

• • • •

••••••••••

Overall

Block

Diagram

Discussion

••••

Front-End

Section.

• • • • • • • • •

••••••

Input

Signal

Path

••••••••••••••••

Reference

Signal

Path.

• • • •

•••••••••••

Analog

to

Digital

Converters.

• • • • • • • • • • •

Filter

CCA.

• • • • • • • • • • •

.•

• • • • •

The

Accumulator

(2)

• • •

•••••••

Timing and

Control

CCA.

• • • •

••

. ....

Phase-Locked Loop (PLL)

CCA

••••••••

. . . .

Autocalibration

CCA

••••••••••••••••••

Microprocessor

CCA

•••

,.:ROM

and

RAM

(Memory

CCA)

•

.

Input/Output

CCA.

• • • •

The

Display

Driver

CCA

••••

Keyboard and

Display

CCA.

Power

Supplies

•••••

System

Level

Power Supply •

Isolated

Power

Supplies

•

UPDATE

INFORMATION

. . . . .

. .. . . . .. . . . .

. . . . . . . . . . ...

. . . . . .

. . .. .

. . . . . .

Introduction

. . . . . . . . . . . . . . . . . . . . . . .

5-14

5~14

5-15

5~15

5-16

5-16

5-17

5-18

5-18

5-19

5-20

5-20

5-21

5-22

5-23

5-24

5-25

5-26

5-27

5-28

5-29

5-30

6-1

6-1

6-1

6-1

6-1

6-1

6-3

6-3

6-3

6-3

6-3

6-3

6-3

6-3

6-4

6-4

6-4

6-4

6-4

6-4

7-1

7-1

vi

Change 3

Figure

1-1

2-1

2-2

2-3

2-4

2-5

2-6

3-1

3-2

4-1

4-2

4-3

4-4

4-5

5-1

6-1

Table

1-1

1-2

1-3

1-4

1-5

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

3-1

3-2

3-3

3-4

3-5

4-1

4-2

4-3

4-4

4-5

Change 2

OM-I-5026B

LIST

OF

ILLUSTRATIONS

Model 2250

Digital

Analyzing

Voltmeter

DAV

Outline

and

Dimension

Drawing.

Inserting

Voltage

Selection

Circuit

Top

Cover

Removal

•••.••.••

Optional

Function

Switch

Locations

Function

Verification

••••.••

Amplitude

Accuracy

and

Phase

Check,

Front

Panel

Controls

and

Indicators

Rear

Panel

Controls

and

Connectors

Rear

Panel

DIP

Switches

Card

(400

Hz)

Long

Format

Listener

Format.

•

•••••

Short

Format

Listener

Format

.••••

Long

Format

Talk

Message

•••.•••••

Short

Format

Talk

Message

••

IEEE-488

MATE

Address

Switch

Selection

Model 2250

DAV

Overall

Block

Diagram

LIST

OF

TABLES

Fl/FlX

Model

Identification

Chart.

F2/F2X Model

Identification

Chart

•

Features

and

Options

Model 2250

Major

Assemblies.

Specifications

.•••.•.

Initial

Factory

Switch

Settings

for

Fl

Option.

Initial

Factory

Switch

Settings

for

F2

Option

...••

Initial

Factory

Switch

Settings

for

F3

Option

.••••

Test

Equipment

• • . . • . • •

Function

Verification

Procedure

•••..

Amplitude

Accuracy

and

Phase

Check

•••.••••.•

Amplitude

Accuracy

and

Phase

Check (Wideband) •

IEEE-488

Test

Program

••••.•••

Front

Panel

Controls

and

Indicators.

Rear

Panel

Controls

and

Connectors

Rear

Panel

Mating

Connector

Contacts

Channel

Used

For

Phase

Lock

••

De

Recorder

Outputs

vs.

Mode

•••.•

IEEE-488

Interface

Functions

and

Descriptions

IEEE-488

Interface

Language

Selection

••••

Device

Address

Codes

••••...•..••

IEEE-488

Interface

Connector

Pin

Assignments

Bus

Connnands

• • • • • • . • • • • . . • • •

vii

1-5

2-2

2-3

2-10

2-11

2-20

2-22

3-1

3-10

4-2

4-20

4-20

4-24

4-24

5-2

6-2

1-2

1-2

1-3

1-4

1-6

2-4

2-6

2-8

2-14

2-16

2-21

2-23

2-24

3-2

3-10

3-11

3-19

3-24

4-1

4-1

4-3

4-4

4-5

!ml§.

4-6

4-7

4-8

4-9

4-9A

4-10

4-11

4-12

4-13

4-14

4-15

4-16

4-17

4-18

4-19

4-20

4-21

4-22

4-23

4-24

5-1

5-2

5-3

5-4

OM-1-5026B

LIST

OF

TABLES (Continued)

Mode Programming Mnemonics

..........................................

.

Modifiers

Allowed

In

Each

Mode

..................•.....•....••..........•

Voltage Range Codes • • . . . . . . . . . . . . . . . . . • • . . . . • . . • . . . . . • . • . . . . . . • . . . . . .

Ratio Range Codes . . . . . . . . • . . . . . . . . . . . . . . . . . . • • . . . . . . . • . . . . . . . . . • . . . .

Serial Poll Status Byte . . . . . . . . . . . . . . . . . . . . . . . • • • . • . . . . . • . • • • • . . . . . . . . .

2250 Native Language Reference Guide • . . . . . . • • • • • . . • . • . • . • • . . . . • . . . . . . .

..

Calibration Error Descriptions . . . . . . . . . . . . . • • . . . . . . . . . . . . . . . • . . . . • . . . . . . .

Model

225

Emulation Listen Instructions

....••......•.....•......•..•......

Mode Programming

.•.............................•.....••..•..•..•..

Range Arguments

..............................•....••...•.........•

Frequency Arguments . . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . • • . . . . . . . . . . . .

Reference Offset Arguments . . . . . . • . . . . . . . . . • . . . . . • • • . • . . . . . . . . . • • . • . . . .

Variable Scale Arguments

...•.........................•........•.......

Data

Output

Format Arguments

.............................•....•.•.....

Model

225

Emulation Serial Poll Status Byte

..........•.•.....•..............

Service Request Arguments . . . . . . . . . . . . . . . • . . • • . . . . . . . .

..

• . . . . . . . . • . . . . .

Group Trigger Enable Arguments . . . . . . . . . . . • • . • • • • . . . . . . • . . . • . . • . . . . . . . . .

225

Emulation Device Clear Options . . . . . . . • . • . • . . . . . . . . . . . . • • . . . . . . . . . .

..

Model

225

Emulation Programming Guide

•••........•...................•....

Model

225

Emulation Long Talk Message Summary

..........•....•.......•....

Voltage Range Selection . . . . . . . . . . . . . . . . . . . • . . . . . . . . . . . • . . . . . . . . . . • . . . . .

Error Messages

........................•...•......•..•..............

CIIL Codes

..........................•.............................

Modifier Limits . . . . . . . . • . . . . . . . • . . • . . . . . . . . • . . . . . . . • . . . . . . . . . . . . . . . . .

f.w.

4-6

4-7

4-8

4-8

4-15

4-17

4-19

4-21

4-21

4-22

4-22

4-22

4-23

4-23

4-25

4-26

4-26

4-27

4-28

4-29

5-6

5-10

5-12

5-13

viii Change 6

WARNING

VARNING

Failure

to

ground

the

chassis

could

bring

operator

and

maintenance

personnel

in

contact

with

high

voltages

capable

of

causing

personal

injury

or

death.

WARNING

If

the

top

cover

of

the

Model 2250

is

removed

while

the

guard

terminals

are

driven

with

a

voltage,

operator

and

maintenance

personnel

could

come

in

contact

with

high

voltages

capable

of

causing

personal

injury

or

death.

WARNING

The

front

SIG

and

REF

binding

posts

are

connected

to

the

corresponding

rear

panel

connectors.

If

a

high

voltage

is

applied

to

the

front

input

binding

posts,

high

voltages

capable

of

causing

personal

injury

or

death

will

appear

at

the

rear

input

connectors.

Similarly,

if

a

high

voltage

is

applied

at

the

rear

input

connectors,

a

high

voltage

capable

of

causing

personal

injury

or

death

will

appear

at

the

front

binding

posts.

1-1

INTRODUCTION

OM-I-5026B

SECTION

1

GENERAL

INFORMATION

This

manual

provides

operational

instructions

for

the

Digital

Analyzing

Voltmeter

Model

2250 shown

in

figure

1-1.

hereinafter

referred

to

as

the

DAV.

The

manual

is

divided

into

six

sections

as

follows:

1-1.1

Section

1 -

General

Information.

This

section

provides

general

physical

and

functional

descriptions

of

the

DAV.

It

includes

a

table

of

specifications.

feature/

option

information

with

version

type

and

corresponding

check

sum

numbers

for

unit

feature

identification.

and

how-to-order

information.

1-1.2

Section

2 -

Installation

and

Preparation

for

Use.

This

section

gives

instruc-

tions

for

unpacking,

general

inspection.

installation

and

mounting

procedures.

power

requirements.

initial

setups.

custom

setups,

and

a

comprehensive

operational

checkout

procedure

for

the

DAV.

1-1.

3

Section

3 -

Operation.

This

section

illustrates

and

explains

specific

operation

of

controls

and

indicators.

general

unit

operation.

and

includes

examples

of

practical

applications.

1-1.

4

Section

4 - IEEE- 488

Standard

Digital

Interface

Programming.

This

section

contains

procedures

and

programming

examples

for

remote

operation

of

the

DAV

using

the

IEEE-488

digital

interface

and

for

NAI

Model 225

Phase

Angle

Voltmeter

emulation.

1-1.

5

Section

5 - IEEE

MATE

Control

Interface

Intermediate

Language

Option.

This

section

describes

the

operation

and

programming

of

the

DAV

using

the

IEEE-488

MATE

CONTROL

INTERFACE

INTERMEDIATE

LANGUAGE

(CIIL)

OPTION.

1-1.

6

Section

6 -

Theory

of

Operation.

This

section

describes

functional

theory

of

operation

for

the

DAV.

It

includes

a

block

diagram

illustrating

major

system

components

and

basic

signal

paths.

1-1.7

Section

7 -

Update

Information.

As

NAI

continues

to

improve

the

performance

of

the

DAV.

corrections

and

modifications

to

the

manual

may

be

received.

This

section

contains

Product

Revision

Sheet

(PRS)

data

which

updates

the

unit

to

the

most

current

configuration

available.

The

manual

reflects

current

and

previous

configurations

of

the

Model

2250.

For

model

identification

purposes.

on

power-

up

the

unit

displays

a

check

sum

or

version

identification

number

for

two

seconds.

Ref

er

to

tables

1-1

and

1-

2

to

determine

versions

and

corresponding

check

sum/version

identification

numbers.

Version

numbers

are

assigned

as

follows:

1.00,

1.01.

1.02

...

1.0X;

2.00, 2.01.

2.02

...

2.0X:

etc.

The X

indicates

all

features

are

applicable

to

that

particular

version.

Change 4

1-1

OM-1-5026B

The Model

2250

has been manufactured in

two

different hardware configurations. These units either have the

TOT

AL/

AVG function

or

they do not. Unitversions can

be

identified

by

theircheck sum

or

version identification

numbers. Tables

1-1

and 1-2identify model versions

and

check sum number/version identification data

as

well

as

the NAI manual

that

should accompany the unit.

The following NATIVE mode

F1

/F1

X models

are

identified by

front

panel displayed check sum numbers

at

power-up:

1.04

and lower

2.05

and lower

5.06

and lower

6.01 and lower

All other NATIVE mode

F1

/F1

X models have a Version Identification number

(a

lower

case

"n"

followed bythe

version number -e.g., n6.02) displayed on the front panel

at

power-up.

1-2 Change 6

This manual suits for next models

1

Table of contents

Other North Atlantic Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Greenlee

Greenlee CM-1360 instruction manual

Smart temp

Smart temp SMT-IAQ3 manual

CARLO GAVAZZI

CARLO GAVAZZI LDI 35 - CONFIGURATION SOFTWARE operating instructions

Michell Instruments

Michell Instruments QMA601 user manual

Endress+Hauser

Endress+Hauser Proline Promag W 400 HART operating instructions

Futech

Futech QUATTRO manual