North Atlantic 8810A User manual

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

Operations Manual for Model 8810A

ANGLE POSITION INDICATOR

TWO SYNCHRO/RESOLVER MEASUREMENT CHANNELS AND

ONE (OPTIONAL) REFERENCE SUPPLY

North Atlantic Industries, Inc.

631.567.1100 / 631.567.1823 (fax)

2/22/2019

8810A Operations Manual Rev P

110 Wilbur Place, Bohemia, NY 11716

www.naii.com

Cage Code: 0VGU1

Page 1 of 34

GENERAL

This Operations Manual contains general description, installation, operating instructions, maintenance and calibration

verification information for the Model 8810A Angle Position Indicator (API). This Operation Manual is supplemented by

“8810A Programmer’s Reference” which can be found at www.naii.com.

FEATURES

•High-Resolution Touch Screen

•Programmable display options

•Self-Calibrating

•0.0001° Resolution

•Accuracy: Up to ±0.0015°

•Two isolated Input Channels

•Single or Two-Speed Measurements:

Programmable Ratio from 2 to 255

•Three display modes: 0-360°, ±180° or

degrees, minutes & seconds

•Auto-ranging Signal and Reference

•47Hz to 20KHZ Frequency Range

•Auto Phase Correction

•Measures and displays Reference

Voltage, frequency, and VL-L

•Ethernet, USB, IEEE-488 & parallel ports

•Optional 6 VA internal Reference

•CE compliant

DESCRIPTION

The 8810A is a rack mount or bench top API featuring front panel controls (including touch screen display) and input terminals.

This self-calibrating unit is furnished with factory installed rubber feet and foldaway tilt stand and can also be installed in a

3.5” half rack slot. Using optional rack mounting brackets, the 8810A may be installed as a single unit in a full rack slot or as a

tandem mount of two units in a full rack slot.

This second-generation API truly represents a major step forward in Synchro-to-digital conversion technology. The use of an

intelligent DSP design eliminates push buttons and allows all programming to be done either via an integrated touch-screen, front

panel USB optical mouse interface or with the multi-purpose increment/setup knob. In addition, IEEE-488, Ethernet, and USB 2.0

interfaces have been added to extend remote operation capabilities. The display can be set for one of three display modes; 0-360º,

±180°, or Degrees, Minutes, Seconds. A wide frequency range (47 Hz to 20 KHz) is standard.

Improved flexibility is provided by two fully independent inputs that can be used to simultaneously read two separate input signals

or can be combined to measure multi-speed Synchro’s or Resolvers. The gear ratio, for the two-speed mode, is programmable from

2:1 to 255:1. Built-in phase correction eliminates errors caused by quadrature and harmonics when reference and signal are out of

phase by as much as 60°.

The 8810A automatically accepts and displays input voltages from 1.0VL-L to 90VL-L and reference voltages from 2Vrms to 15Vrms

over a broad frequency range of 47 Hz to 20 KHz. Therefore, one Instrument can handle most known Synchro and Resolver

measurement requirements.

The 8810A is a replacement for all variations of the previously supplied standard and special versions of the Model 8810. Contact

factory to determine compatibility.

Optional Reference: This design can also incorporate a 6 VA programmable reference generator that is used for standalone

applications (See P/N).

North Atlantic Industries, Inc.

631.567.1100 / 631.567.1823 (fax)

2/22/2019

8810A Operations Manual Rev P

110 Wilbur Place, Bohemia, NY 11716

www.naii.com

Cage Code: 0VGU1

Page 2 of 34

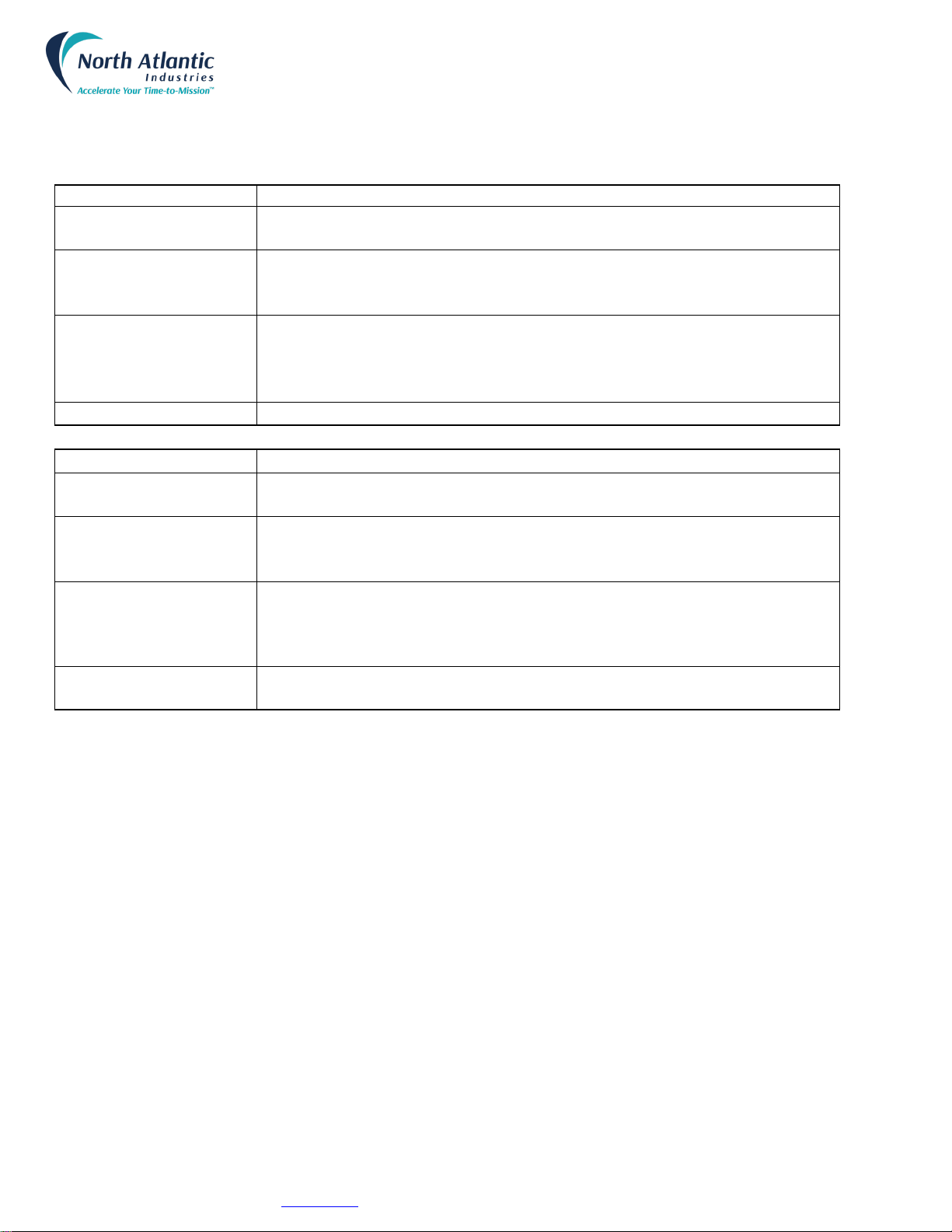

SPECIFICATIONS

Resolution: 0.0001°

Input Channels: 2 separate isolated Inputs

Signal Inputs: Ch.1: Synchro/Resolver programmable; 1 - 90VL-L auto-ranging

Ch.2: Synchro/Resolver programmable; 1 - 90VL-L auto-ranging

Each channel measures the Input VL-L, Reference voltage and frequency. Data is

displayed on the front panel and also available via various digital outputs.

Accuracy: See detailed Accuracy Specifications below.

Frequency Range: 47 Hz – 20 kHz. See detailed Accuracy Specifications below.

Angular Range: 0.0000°-359.9999° or ±179.9999° programmable, or output angle can be viewed in

degrees, minutes and seconds

Two-speed mode: Both inputs can be combined with a ratio from 2 to 255

Reference Voltage: 2V to 115 V auto-ranging

Reference Frequency: 47 Hz – 20 kHz

Input Impedance: Input Signal (V L-L) Input Impedance (kΩ)

1 to 3 V 47

3 to 6 V 55

6 to 11.8 V 58

11.8 to 26 V 60

26 to 90 V 200

Tracking Speed: ±10,000°/sec. (±27.7rps)

Settling Time: 1.5 s max. for 180° step change (Based on Bandwidth selected)

3.0 s max. at 47-66 Hz (Based on Bandwidth selected)

Phase Correction: Automatically corrects for up to a 60° phase shift between stator and rotor

Velocity or DC angle ±1000 °/sec = ±10 VDC

for Ch.1 & Ch.2: ±100 °/sec = ±10 VDC

0 to 359.99°= 0 -10 VDC

±179.99° = ±10 VDC

Bandwidth: Automatically set based on frequency of input, up to a max of 100 Hz BW. User can

change this parameter as desired, over a range of 6 to 1200 Hz BW. (See details under

Setup Menus).

Data averaging: Selectable from 10ms to 10 Seconds

Converter Busy: TTL compatible pulses, 1µs wide nom. Pulses present when tracking.

Digital Output: 6-Decade BCD (1-2-4-8) 10 TTL loads

Serial Interfaces: Ethernet, USB, and IEEE-488, and legacy 50 pin connector

Temperature Range: 0-50°C operating; 0-70°C storage

Input Power: 85Vrms to 265Vrms, 47Hz to 440 Hz, < 20 Watts

Weight: 4 lbs.

Dimensions: 13.0” L (33.02 cm) x 9.5” W (24.13 cm) x 3.5” H (8.89 cm)

North Atlantic Industries, Inc.

631.567.1100 / 631.567.1823 (fax)

2/22/2019

8810A Operations Manual Rev P

110 Wilbur Place, Bohemia, NY 11716

www.naii.com

Cage Code: 0VGU1

Page 3 of 34

REFERENCE GENERATOR SPECIFICATIONS (Optional, see part number)

Voltage Output: 2 Vrms to 115 Vrms, Programmable with a resolution of 0.1 V

•2.0 to 10.0 Vrms / 47 Hz to 20 KHz frequency range

•10.1 to 28.0 Vrms / 47 Hz to 10 KHz frequency range

•28.1 to 115.0 Vrms / 47 Hz to 2.5 KHz frequency range

Accuracy (No Load): ±5% of setting < 15 KHz

±10% of setting ≥15 KHz

Regulation ±5% (No Load to Full Load)

Output Drive: 6 VA maximum (See detailed description of Output Drive)

Output Protection: Over-current (10x automatic retry; @ 1.3 sec int.; afterwards, shutdown w/ manual reset)

Frequency: 47 Hz to 20 KHz Programmable with 0.1 Hz steps

Frequency accuracy: The greater of ±0.1% of frequency programmed or ±1 Hz.

THD: ±3% (maximum)

Reference Output Drive: Isolated, single output

(See detailed characterization)

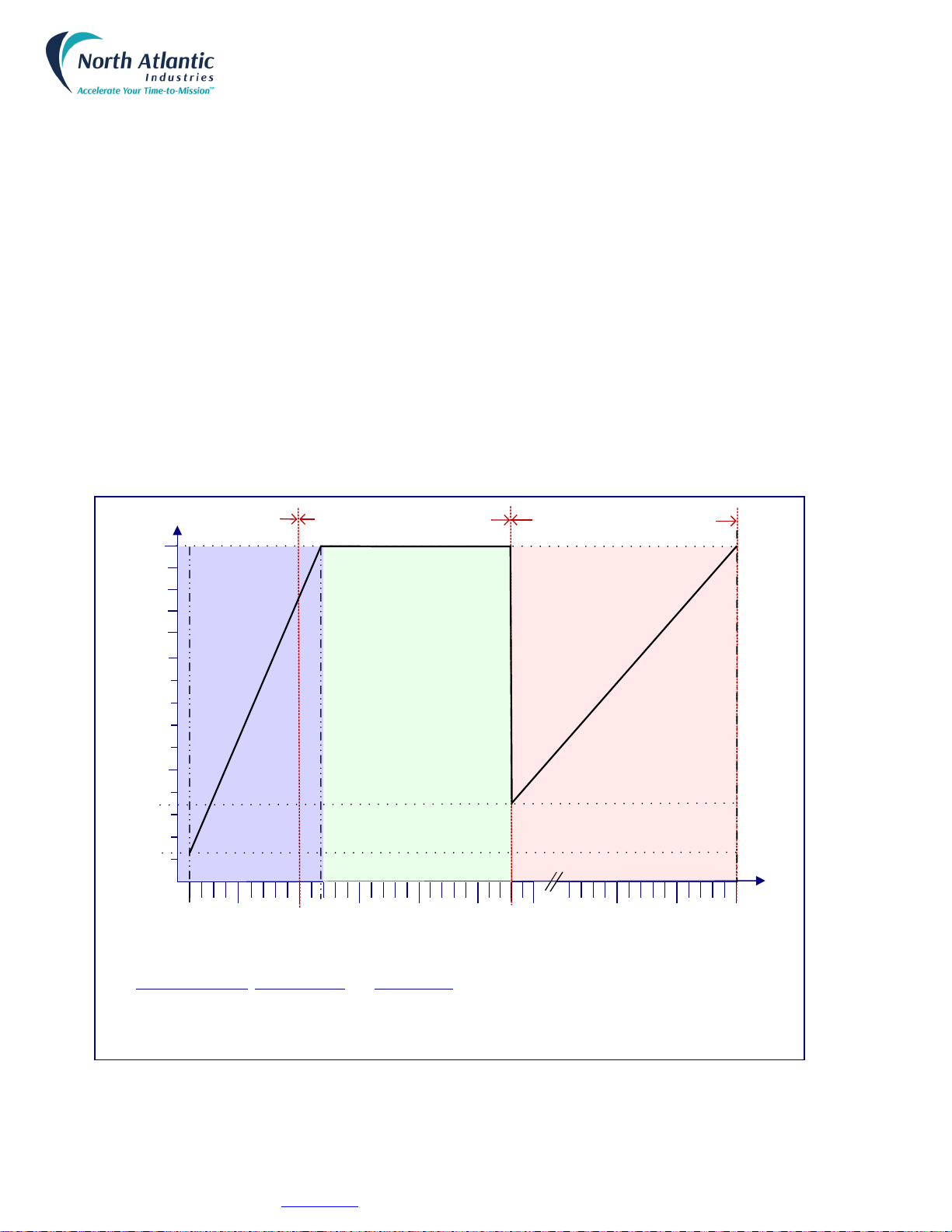

Above figure: Reference output drive detailed characterization

Voltage(V)Output (Programmed)

Power Output (VA)

2.0

4.0

6.0

30

115

25

20

15

10

xx

Max Current ~ 508 mA Max Current ~ 52 mA

Power Derating Curves:

Voltage Range (Vrms)Max Current (mA)Power Derating

2 -11.9 508 6 VA @ 11.8 Vrms (Power derates linearly to 0.5 VA @ 2.0 Vrms)

12 -27.9 508 to 231 6 VA @ 26.0 Vrms (Power constant to 12.0 Vrms)

28 - 115 52 6 VA @ 115 Vrms (Power derates linearly to 1.4 VA @ 28.0 Vrms)

xx

5

2 - 10 V Frequency Range: 47 – 20000 Hz 10.1 – 28 V Frequency Range: 47 – 10000 Hz 28.1 – 115 V Frequency Range: 47 – 2500 Hz

6VA Power Constant

Max Current ~ 508mA to 231 mA

(w/ voltage inversely proportional)

0.5

1.4

North Atlantic Industries, Inc.

631.567.1100 / 631.567.1823 (fax)

2/22/2019

8810A Operations Manual Rev P

110 Wilbur Place, Bohemia, NY 11716

www.naii.com

Cage Code: 0VGU1

Page 4 of 34

DETAILED ACCURACY SPECIFICATIONS

NOTE: SPECIFICATIONS APPLY AFTER A 15 MINUTE WARMUP AND CALIBRATION

Accuracy: 8810A

Resolver mode: 2.0 to 28 VL-L

±0.004° from 47 Hz to 5 KHz

Resolver mode: 28 to 90 VL-L

±0.004° from 47 Hz to 1 KHz

Resolver mode: 2.0 to 12 VL-L

±0.004° to ±0.008° from 5 KHz to 10 KHz derated linearly

Resolver mode: 2.0 to 12 V

L-L

±0.008° to ±0.015° from 10 KHz to 15 KHz derated linearly

Resolver mode: 2.0 to 12 V

L-L

±0.015° to ±0.02° from 15 KHz to 20 KHz derated linearly

Resolver mode: 1.0 to 2.0 VL-L

±0.006° from 47 Hz to 5 KHz

Resolver mode: 1.0 to 2.0 VL-L

±0.006° to ±0.015° from 5 KHz to 10 KHz derated linearly

Resolver mode: 1.0 to 2.0 VL-L

±0.015° to ±0.025° from 10 KHz to 15 KHz derated linearly

Resolver mode: 1.0 to 2.0 VL-L

±0.025° to ±0.035° from 15 KHz to 20 KHz derated linearly

Synchro mode: 2.0 to 90 V

L-L

±0.004° from 47 Hz to 1 KHz

Accuracy: 8810AH

Resolver mode: 2.0 to 28 V

L-L

±0.0015° from 47 Hz to 5 KHz

Resolver mode: 28 to 90 VL-L

±0.002° from 47 Hz to 1 KHz

Resolver mode: 2.0 to 12 V

L-L

±0.0015° to ±0.005° from 5 KHz to 10 KHz derated linearly

Resolver mode: 2.0 to 12 V

L-L

±0.005° to ±0.01° from 10 KHz to 15 KHz derated linearly

Resolver mode: 2.0 to 12 VL-L

±0.010° to ±0.015° from 15 KHz to 20 KHz derated linearly

Resolver mode: 1.0 to 2.0 VL-L

±0.0025° from 47Hz to 5 KHz

Resolver mode: 1.0 to 2.0 VL-L

±0.0025° to ±0.01° from 5KHz to 10 KHz derated linearly

Resolver mode: 1.0 to 2.0 VL-L

±0.010° to ±0.02° from 10 KHz to 15 KHz derated linearly

Resolver mode: 1.0 to 2.0 VL-L

±0.02° to ±0.03° from 15 KHz to 20 KHz derated linearly

Synchro mode: 2.0 to 28 V

L-L

±0.0015° from 47 Hz to 1 KHz

Synchro mode: 28 to 90 VL-L

±0.0025° from 47 Hz to 1 KHz

North Atlantic Industries, Inc.

631.567.1100 / 631.567.1823 (fax)

2/22/2019

8810A Operations Manual Rev P

110 Wilbur Place, Bohemia, NY 11716

www.naii.com

Cage Code: 0VGU1

Page 5 of 34

TABLE OF CONTENTS

FEATURES ................................................................................................................................................................ 1

DESCRIPTION........................................................................................................................................................... 1

SPECIFICATIONS ..................................................................................................................................................... 2

REFERENCE GENERATOR SPECIFICATIONS (OPTIONAL,SEE PART NUMBER).................................................. 3

DETAILED ACCURACY SPECIFICATIONS ......................................................................................................... 4

TABLE OF CONTENTS ............................................................................................................................................ 5

SAFETY SUMMARY .................................................................................................................................................. 7

GENERAL SAFETY NOTICES .............................................................................................................................. 7

REPAIR ..............................................................................................................................................................................7

HIGH VOLTAGE .................................................................................................................................................................7

INPUT POWER ALWAYS ON ............................................................................................................................................7

INTERFACES............................................................................................................................................................. 8

J1 CONNECTOR, API PARALLEL PIN DESIGNATIONS ..................................................................................................8

J2 CONNECTOR, IEEE - 488 PIN DESIGNATIONS..........................................................................................................8

J3 CONNECTOR: ...............................................................................................................................................................8

•

USB-B (USB 2.0) Rear Connector, for communications only....................................................................................8

CONTROLS & INDICATORS GENERAL DESCRIPTION ....................................................................................... 9

CHANNEL SELECTION ............................................................................................................................................. 10

INTERNAL REFERENCE SETUP ................................................................................................................................ 11

SYNCHRO /RESOLVER MODE SELECT..................................................................................................................... 11

RATIO SELECT ....................................................................................................................................................... 12

ANGLE DIFFERENCE ............................................................................................................................................... 12

PROGRAMMING ..................................................................................................................................................... 13

REMOTE PROGRAMMING /LEGACY 8810 SUPPORT (REFER TO 8810A PROGRAMMER’S REFERENCE GUIDE) .............. 13

IEEE-488 ..........................................................................................................................................................................13

USB ..................................................................................................................................................................................13

Ethernet ............................................................................................................................................................................13

GENERAL PROGRAMMING /OPTIONS SELECTING ..................................................................................................... 13

USB Port Selection ...........................................................................................................................................................13

Ethernet Port Selection .....................................................................................................................................................14

SETUP MENUS ....................................................................................................................................................... 15

ORDERING INFORMATION .................................................................................................................................... 21

PART NUMBER: .......................................................................................... ERROR! BOOKMARK NOT DEFINED.

ACCESSORIES:.......................................................................................................ERROR!BOOKMARK NOT DEFINED.

OPTIONAL MOUNTING ACCESSORIES ......................................................................ERROR!BOOKMARK NOT DEFINED.

INSTALLATION AND MAINTENANCE .................................................................................................................. 22

UNPACKING AND INSPECTION ........................................................................................................................ 22

SHIPPING............................................................................................................................................................ 22

INSTALLATION ................................................................................................................................................... 22

Rack Mounting Instructions:..............................................................................................................................................22

Bench Installation:.............................................................................................................................................................22

MAINTENANCE................................................................................................................................................... 22

Input AC Power Fuse(s):...................................................................................................................................................22

Rear Panel Cooling Fan Filter:..........................................................................................................................................23

CALIBRATION ..................................................................................................................................................... 23

Calibration Verification......................................................................................................................................................23

North Atlantic Industries, Inc.

631.567.1100 / 631.567.1823 (fax)

2/22/2019

8810A Operations Manual Rev P

110 Wilbur Place, Bohemia, NY 11716

www.naii.com

Cage Code: 0VGU1

Page 6 of 34

APPENDIX A - MECHANICAL OUTLINE, MODEL 8810A .................................................................................... 24

APPENDIX B – SUPPLEMENTAL INFORMATION FOR UNITS SOLD WITHIN THE EUROPEAN UNION ....... 25

GENERAL............................................................................................................................................................ 25

SPECIFICATIONS ............................................................................................................................................... 25

Environmental...................................................................................................................................................................25

Fuses ................................................................................................................................................................................25

LINE CORD ......................................................................................................................................................... 25

INSTALLATION AND MAINS INPUT ................................................................................................................... 25

LINE VOLTAGE ................................................................................................................................................... 25

SAFETY GROUNDING........................................................................................................................................ 26

IMPROPER USAGE ............................................................................................................................................ 26

TECHNICAL ASSISTANCE................................................................................................................................. 26

APPENDIX C – 8810A SERIES DECLARATION OF CONFORMITY.................................................................... 27

APPENDIX D – INTERNAL CALIBRATION OPERATION ADDENDUM .............................................................. 28

APPENDIX E – 8810A NEW FEATURES OPERATION ADDENDUM .................................................................. 30

REVISION HISTORY................................................................................................................................................ 34

TABLE OF FIGURES

Figure 1 – Front Panel Controls & Connections ...........................................................................................................................9

Figure 2 – Indicators on the front panel main display of the 8810A............................................................................................10

Figure 3 – Channel Selection .....................................................................................................................................................10

Figure 4 – Internal Reference Setup ..........................................................................................................................................11

Figure 5 – Synchro / Resolver Mode Select ...............................................................................................................................11

Figure 6 – Ratio Select...............................................................................................................................................................12

Figure 7 – Angle Difference Select.............................................................................................................................................12

Figure 8 – Remote Operation .....................................................................................................................................................13

Figure 9 – USB Port Selection....................................................................................................................................................13

Figure 10 – Ethernet Port Selection ...........................................................................................................................................14

Figure 11 – IEEE-488 Port Selection..........................................................................................................................................14

Figure 12 – Setup Menus ...........................................................................................................................................................15

Figure 13 – Options Menu..........................................................................................................................................................15

Figure 14 – Factory Setting ........................................................................................................................................................16

Figure 15 – Custom Settings......................................................................................................................................................16

Figure 16 – Brightness Control ....................................................................................................................................................16

Figure 17 – Calibration Menu .....................................................................................................................................................17

Figure 18 – Help Menus .............................................................................................................................................................17

Figure 19 – Default Values.........................................................................................................................................................18

Figure 20 – D/A Setup................................................................................................................................................................18

Figure 21 – Bandwidth ...............................................................................................................................................................18

Figure 22 – Strip Chart Feature..................................................................................................................................................19

Figure 23 – Strip Chart Configuration Menu ...............................................................................................................................19

Figure 24 – Angle Averaging......................................................................................................................................................20

Figure 25 – Angle Limits & Thresholds.......................................................................................................................................20

North Atlantic Industries, Inc.

631.567.1100 / 631.567.1823 (fax)

2/22/2019

8810A Operations Manual Rev P

110 Wilbur Place, Bohemia, NY 11716

www.naii.com

Cage Code: 0VGU1

Page 7 of 34

SAFETY SUMMARY

This symbol is intended to alert the presence of un-insulated dangerous voltage and shock hazard if

misuse or improper handling.

This symbol is intended to alert the presence of important information in the literature accompanying

this device. All information should be read carefully to avoid misuse and potential harm to the user

and/or device.

GENERAL SAFETY NOTICES

The following general safety notices supplement the specific warnings and cautions appearing elsewhere in the manual.

They are recommended precautions that must be understood and applied during operation and maintenance of the

instrument covered herein.

REPAIR

DO NOT ATTEMPT REPAIR. Under no circumstances should repair of energized instrument be attempted. All repairs

to this instrument must be accomplished at the Factory.

HIGH VOLTAGE

HIGH VOLTAGE is used in the operation of this equipment.

DEATH ON CONTACT may result if personnel fail to observe safety precautions. Learn the areas containing high

voltage on this equipment. Be careful not to contact high-voltage connections when installing, operating or maintaining

this instrument.

INPUT POWER ALWAYS ON

The design of the model 8810A is such that AC input power is continuously supplied to the power supply independent of

the front panel ON/OFF Switch. The primary means of disconnect is pulling the line cord from the instrument

WARNINGS

North Atlantic Industries, Inc.

631.567.1100 / 631.567.1823 (fax)

2/22/2019

8810A Operations Manual Rev P

110 Wilbur Place, Bohemia, NY 11716

www.naii.com

Cage Code: 0VGU1

Page 8 of 34

INTERFACES

The 8810A is available with several different interfaces for ATE applications. Interfaces include Ethernet, USB, IEEE-

488, and a legacy 50 pin connector for API parallel BCD outputs. Below is information, for each interface. Detail

programming commands / information are included in “8810A Programmer’s Reference Guide”.The Ethernet

connector and the USB connector, J3, are industry standard connections.

J1 CONNECTOR, API PARALLEL PIN DESIGNATIONS

DD50P, Mate DD50S or equivalent

Pin

Designation

Pin

Designation

1

Do Not Use(1)

26

R2 CH.2 REF LO Input

2

Do Not Use(1)

27

Not Data Freeze

3

Chassis ground

28

0.02º (BCD Output)

4

Digital ground

29

0.08º (BCD Output)

5

S1 CH.1 Resolver (Sin LO); Synchro (X)

30

0.1º (BCD Output)

6

S2 CH.1 Resolver (Cos HI); Synchro (Z)

31

0.4º (BCD Output)

7

S3 CH.1 Resolver (Sin HI); Synchro (Y)

32

2º (BCD Output)

8

S4 CH.1 Resolver (Cos LO)

33

8º (BCD Output)

9

R1 CH.1 REF HI Input

34

Not Used

10

R2 CH.1 REF LO Input

35

Not Used

11

Converter busy

36

Reference Output HI(3)

12

0.04º (BCD Output)

37

Reference Output LO(3)

13

0.01º (BCD Output)

38

0.008º (BCD Output)

14

0.8º (BCD Output)

39

0.002º (BCD Output)

15

0.2º (BCD Output)

40

0.001º or 0.005º for 179.99º

16

4º (BCD Output)

41

DC out Ch.1(2)

17

1º (BCD Output)

42

Data Freeze

18

Not Used

43

Remote Ch. select

19

DC out Ch.2(2)

44

0.004º or 0.005º for

20

Local/Rem select

45

20 deg. (BCD Output)

21

S1 CH.2 Resolver (Sin LO); Synchro (X)

46

40 deg. (BCD Output)

22

S2 CH.2 Resolver (Cos HI); Synchro (Z)

47

80 deg. (BCD Output)

23

S3 CH.2 Resolver (Sin HI); Synchro (Y)

48

10 deg. (BCD Output)

24

S4 CH.2 Resolver (Cos LO)

49

100 deg. (BCD Output)

25

R1 CH.2 REF Hi Input

50

200º or + bit for 179.9º

Notes:

1- Previous models allowed power input at pins 1 & 2. To meet new safety requirements, power input is ONLY via the Power

Entry module.

2- DC outputs on pins 19 & 41 are referenced to pin 4, digital ground.

3- Only Available with selected Internal Reference Generator option.

J2 CONNECTOR, IEEE - 488 PIN DESIGNATIONS

Standard IEEE Interface Connector

Pin

Designation

Pin

Designation

Pin

Designation

Pin

Designation

1

DIO1

7

NRFD

13

DIO5

19

Gnd., NRFD

2

DIO2

8

NDAC

14

DIO6

20

Gnd., NDAC

3

DIO3

9

IFC

15

DIO7

21

Gnd., IFC

4

DIO4

10

SRQ

16

DIO8

22

Gnd., SRQ

5

EOI

11

ATN

17

REN

23

Gnd., ATN

6

DAV

12

Shield

18

Gnd., DAV

24

Gnd., Logic

J3 CONNECTOR:

•USB-B (USB 2.0) Rear Connector, for communications only

•Ethernet (10/100/1000 Base-T copper)

North Atlantic Industries, Inc.

631.567.1100 / 631.567.1823 (fax)

2/22/2019

8810A Operations Manual Rev P

110 Wilbur Place, Bohemia, NY 11716

www.naii.com

Cage Code: 0VGU1

Page 9 of 34

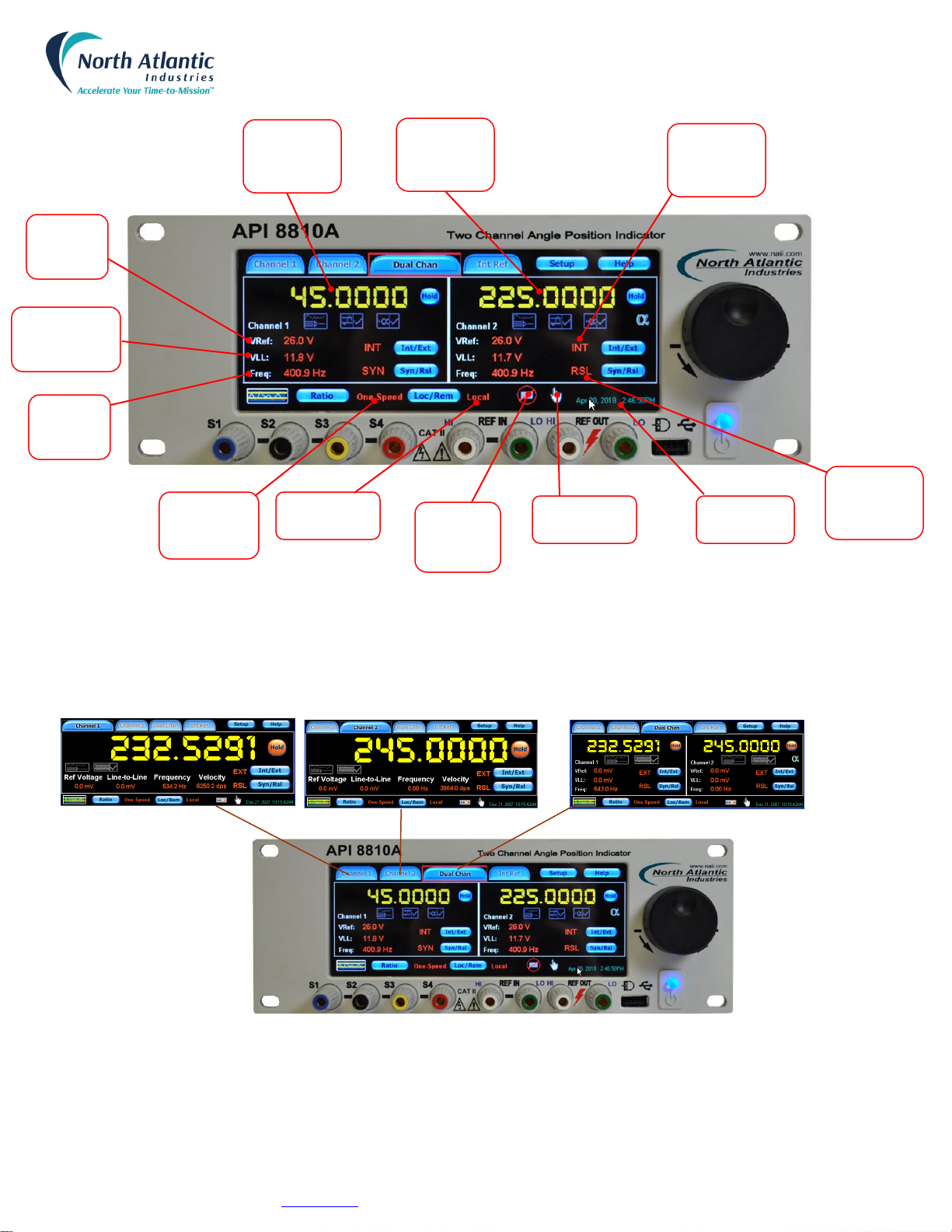

CONTROLS &INDICATORS GENERAL DESCRIPTION

Below is a general description of the Controls and Connections on the front panel main display of the 8810A.

Figure 1 – Front Panel Controls & Connections

Channel Select

Tabs

Internal

Reference

Setup

Setup Menu

Help Menu

Track & Hold

Display

Increment

Select Knob

Internal

External

Reference

Select

Synchro

Resolver

Mode

Select

Main

Power

Button

USB Port for

Optical

Mouse (only)

Internal

Reference

Output

External

Reference

Input

Channel One

Front/Back

Input Select

Touchscreen

Enable

Disable

Select

Synchro Resolver

Inputs

Angle

Averaging

View

Angle

Limits

Views

Strip

Chart

View

Channel Ratio

Configuration

Local / Remote

Select

North Atlantic Industries, Inc.

631.567.1100 / 631.567.1823 (fax)

2/22/2019

8810A Operations Manual Rev P

110 Wilbur Place, Bohemia, NY 11716

www.naii.com

Cage Code: 0VGU1

Page 10 of 34

Figure 2 – Front Panel Indicators

Channel Selection

To select channel 1, channel 2 or dual channel mode, select corresponding tab by using either the touch screen, mouse

or increment/setup knob. Below shows each channel select button along with the corresponding channel display.

Figure 3 – Channel Selection

Reference

Voltage

Display

Multi-Speed

Ratio

Indicator

Signal

Voltage (VLL)

Display

Reference

Frequency

Display

Local / Remote

Indicator

CH.1 Input

from Rear

Connector

Touch Screen

Enable

Time & Date

Display

Synchro

Resolver

Indicator

Reference

Source

Display

CH. 1 Main

Angle

Display

CH. 2 Main

Angle

Display

North Atlantic Industries, Inc.

631.567.1100 / 631.567.1823 (fax)

2/22/2019

8810A Operations Manual Rev P

110 Wilbur Place, Bohemia, NY 11716

www.naii.com

Cage Code: 0VGU1

Page 11 of 34

Internal Reference Setup

If internal reference option is installed in the 8810A; on the main screen, select the Int Ref button and the

setup screen for the internal reference will be displayed as shown below:

Figure 4 – Internal Reference Setup

Set the internal reference generator voltage and frequency parameters, using the setup screens shown above.

When done, press any of the channel buttons or any other function to exit this setup menu.

To enable output of the optional on-board reference source, insure the “Ref Out Signal:” displays “Available”.

Note: To turn on internal reference, ensure that the Int/Ext button located on any of the channel

displays is toggled on. Reference source indicator will display Int.

Synchro / Resolver Mode Select

On any channel screen, toggle the Syn/Rsl button to select either the Synchro or the Resolver mode.

The mode which is selected, will be displayed next to the button as shown below

Figure 5 – Synchro / Resolver Mode Select

North Atlantic Industries, Inc.

631.567.1100 / 631.567.1823 (fax)

2/22/2019

8810A Operations Manual Rev P

110 Wilbur Place, Bohemia, NY 11716

www.naii.com

Cage Code: 0VGU1

Page 12 of 34

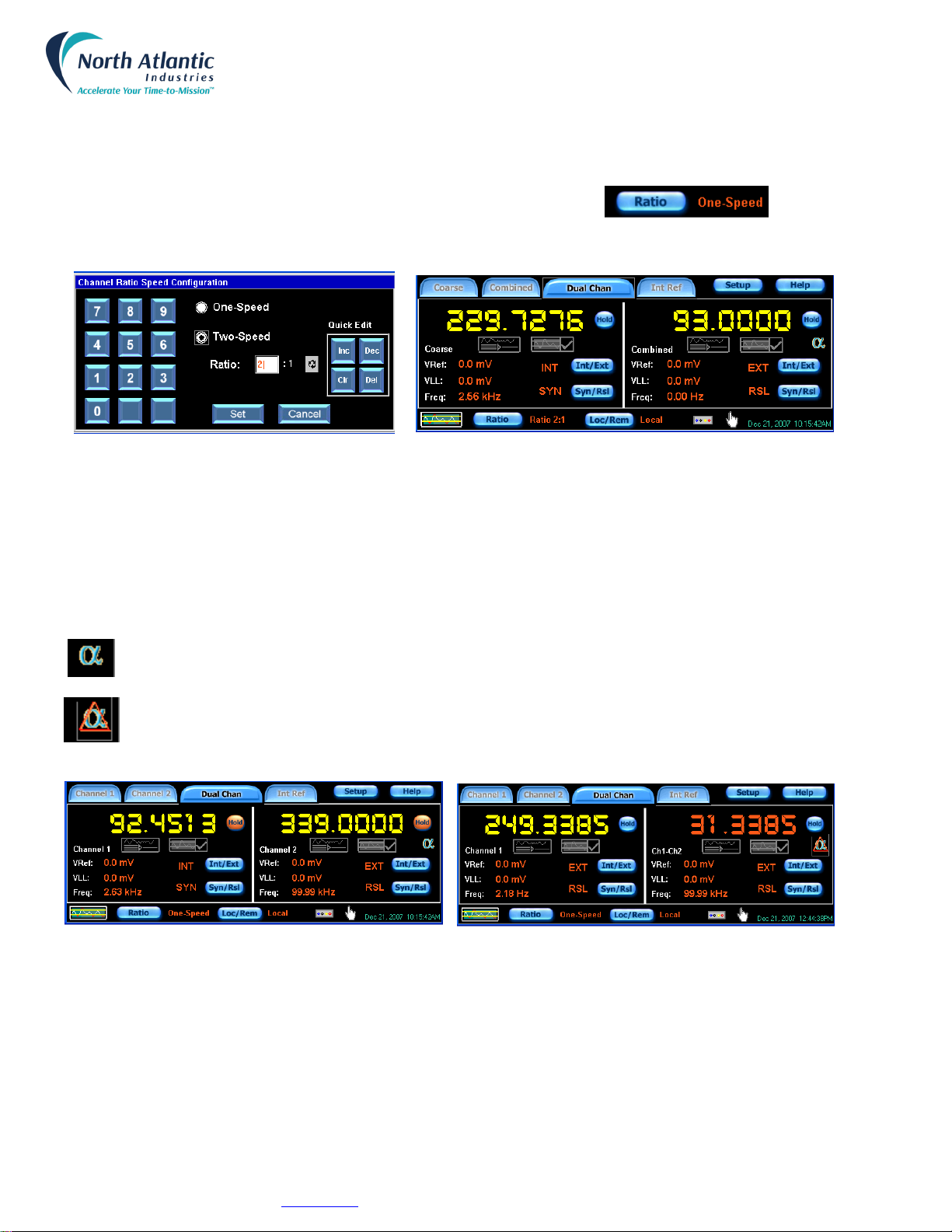

Ratio Select

The two inputs on the 8810A can be combined with a ratio of 2 to 255.

To enter the ratio menu and select the combined ratio, select the Ratio button and the menu

shown below will be displayed

Figure 6 – Ratio Select

Refer to the menu displayed above left. Select Two-Speed and enter the desired ratio from 2 to 255. Value may be

entered via keypad or with the Increment / Decrement buttons. Values may also be cleared or deleted using the quick

edit keypad. Once value is selected, hit Set button and unit will return to the channel display. Refer to the display to the

right and note that the ratio which has been set is now displayed next to the Ratio button. Also note that the channel

select tabs at the top have now changed from Channel 1 to Course and Channel 2 to Combined.

Angle Difference

The Channel 2 input signal is shown on the 8810A when the angle difference mode is disabled. The angle

data value is displayed in yellow.

The difference between two inputs on the 8810A can be displayed when the angle difference mode is

enabled. The angle difference is displayed in red.

Figure 7 – Angle Difference Select

North Atlantic Industries, Inc.

631.567.1100 / 631.567.1823 (fax)

2/22/2019

8810A Operations Manual Rev P

110 Wilbur Place, Bohemia, NY 11716

www.naii.com

Cage Code: 0VGU1

Page 13 of 34

PROGRAMMING

Remote programming / Legacy 8810 support (refer to 8810A Programmer’s Reference Guide)

IEEE-488

Language support is provided for the following legacy 8810 instrument features: (No language support for MATE/CIIL)

API-8810 Native

API-8810 SR103

API-8810 HSR202

API-8810HSR203

API-8810A Native Language provides remote programmability for features available in the 8810A.

USB

API-8810A Native Language provides remote programmability for features available in the 8810A.

Ethernet

API-8810A Native Language provides remote programmability for features available in the 8810A.

Remote Operation Setup

Figure 8 – Remote Operation

General Programming / Options selecting

The 8810A may be remote programmed through a USB port, an Ethernet port, an IEEE-488 port or the J1 connector. The

main setup screen for remote programming is shown above. The sections below show the setup for each mode.

From any of the Channel Displays, select the Loc/Rem button to enter the remote configuration menu

as shown below. Select remote button, then select desired port.

USB Port Selection

Selection of the USB port is accomplished by simply selecting the USB button as shown below. Once entered, hit set

and unit returns to main display.

Figure 9 – USB Port Selection

Note: the USB is now displayed next to the Loc/Rem button

North Atlantic Industries, Inc.

631.567.1100 / 631.567.1823 (fax)

2/22/2019

8810A Operations Manual Rev P

110 Wilbur Place, Bohemia, NY 11716

www.naii.com

Cage Code: 0VGU1

Page 14 of 34

Ethernet Port Selection

Selection of the Ethernet port is accomplished by selecting the Ethernet address button as shown below, entering the

Ethernet configuration for your network. Once entered, hit set and unit returns to main display. Modification of the

Ethernet port is accomplished by selecting the Ethernet address button and entering a valid IP address, the Submask

and Gateway address for your Ethernet network. The Ethernet Port used by the 8810A is always Port 23.

Figure 10 – Ethernet Port Selection

IEEE-488 Port Selection

This section describes the operation and programming of the Model 8810A using the IEEE-STD 488-1978, Standard

Digital Interface for Programmable Instrumentation. Selection of the IEEE port is accomplished by selecting the IEEE

Address button as shown above and entering an address. Once entered hit set and unit goes back to main display

Figure 11 – IEEE-488 Port Selection

Note: ETHERNET is now displayed next to the Loc/Rem button

Note: IEEE Address is now displayed next to the Loc/Rem button

North Atlantic Industries, Inc.

631.567.1100 / 631.567.1823 (fax)

2/22/2019

8810A Operations Manual Rev P

110 Wilbur Place, Bohemia, NY 11716

www.naii.com

Cage Code: 0VGU1

Page 15 of 34

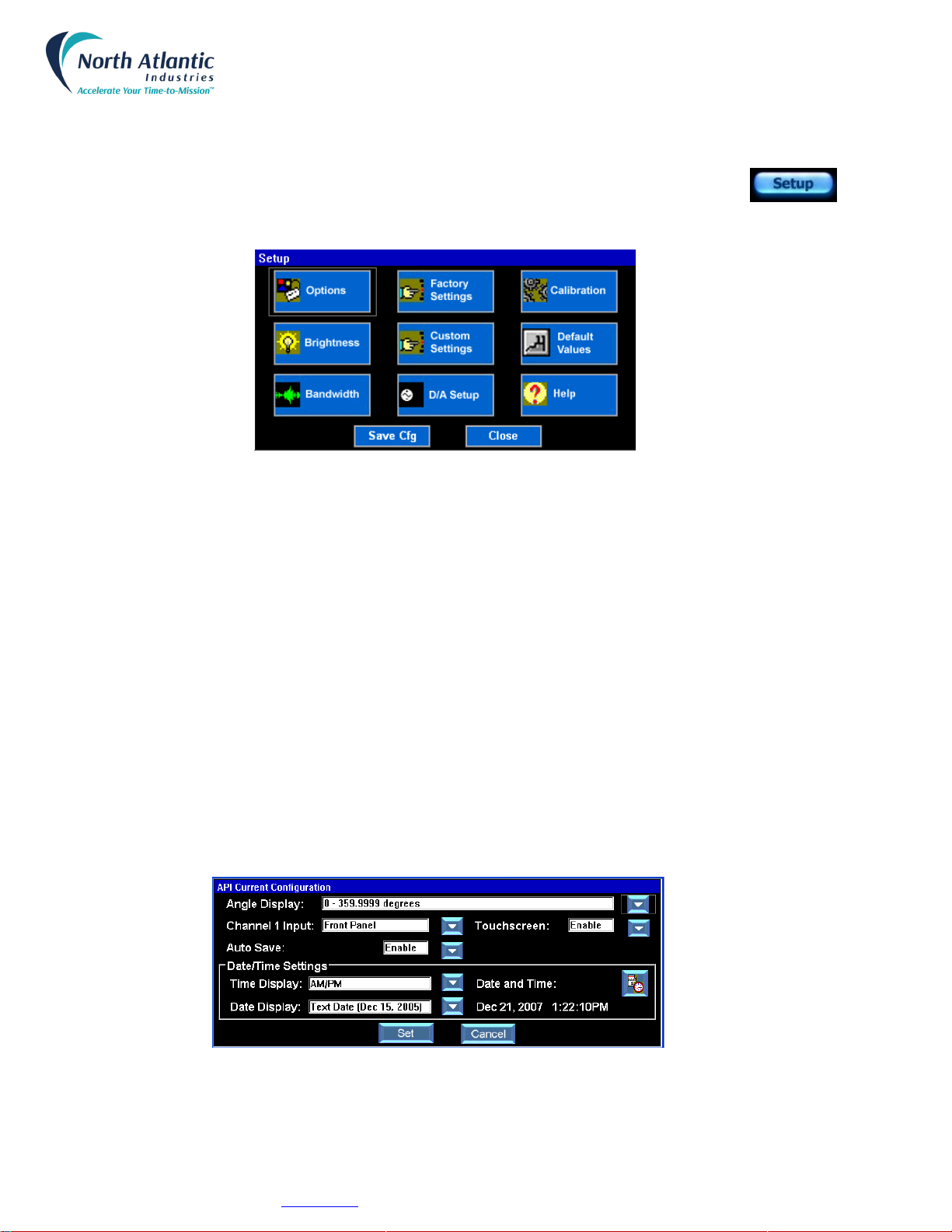

Setup Menus

The 8810A setup menu accesses many of the features of the API and allows the user to easily configure it through the

front panel. The setup menu is accessed by pressing the Setup button at the top of the main

display screen. As shown by the screen below, there are ten choices in the setup menu. The

section below describes each setup menu option.

Figure 12 – Setup Menus

A sample of the Options Menu is shown below. This menu allows configuration of the following:

•Angle Display may be configured for the following parameters

o0 to 359.9999 degrees

o-179.9999 to 179.9999 degrees

oDegrees, Minutes and Seconds

•Channel 1 Input may be configured for the following parameters

oFront Panel Input

oBack Connector Input (J1)

•Touch screen

oEnabled

oDisabled (re-enable using the Increment /Setup knob or mouse to select Options menu)

•Auto Save (feature available on non-revision B units)

oEnabled – 8810A will automatic save the 8810A configuration when the user changes the configuration

from the front panel or remotely.

oDisabled

•Date/Time Settings may be configured for the following parameters

oTime Display Format either AM/PM or Military

oDate Display Format either Text Date or Numeric only Date

oSetting of Time and Date

Figure 13 – Options Menu

North Atlantic Industries, Inc.

631.567.1100 / 631.567.1823 (fax)

2/22/2019

8810A Operations Manual Rev P

110 Wilbur Place, Bohemia, NY 11716

www.naii.com

Cage Code: 0VGU1

Page 16 of 34

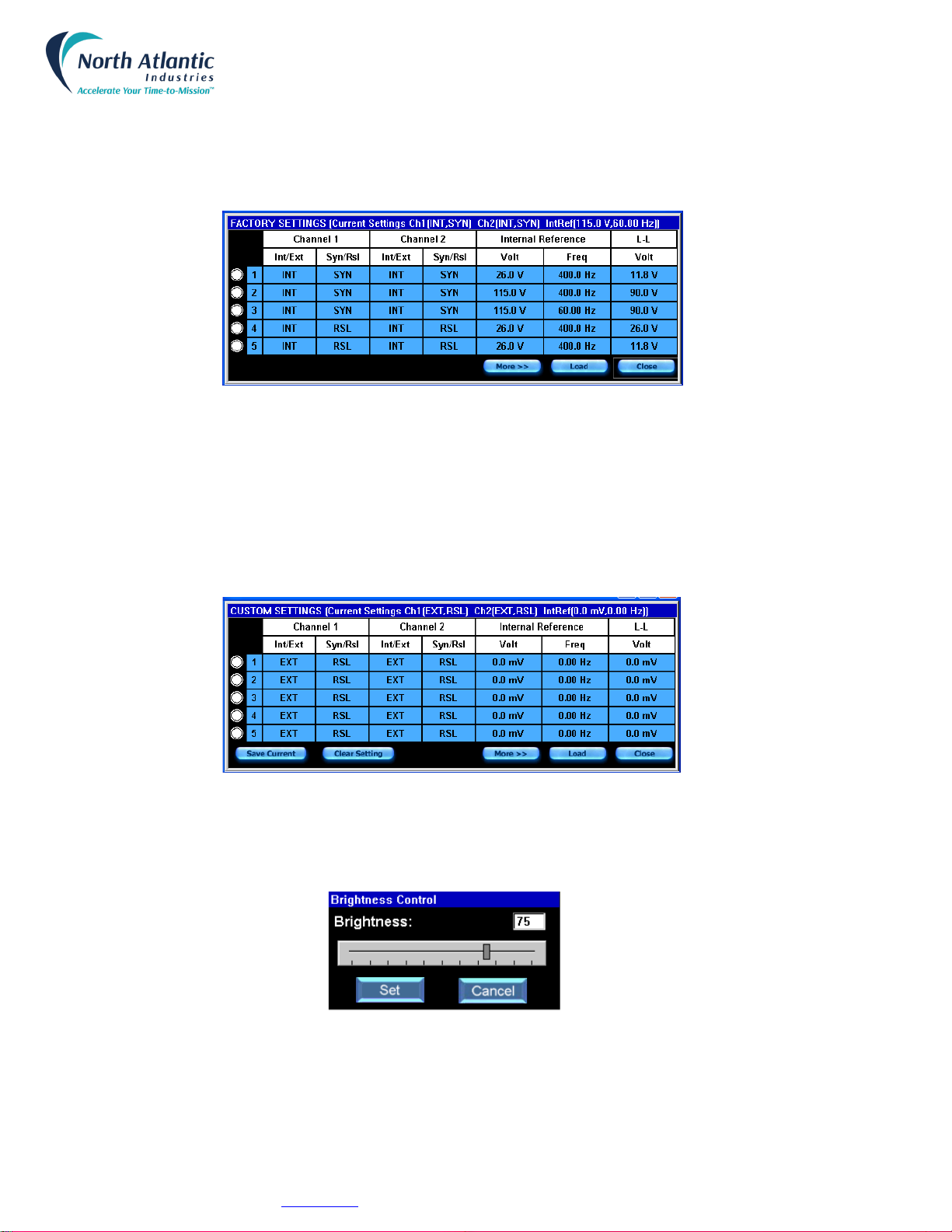

A sample of the Factory Setting screen is shown below. Factory settings contain 10 sets of parameters that are

permanently configured at the factory. These parameters include the settings for reference source, reference voltage,

reference frequency and Synchro / Resolver configuration. The pre-set parameter is chosen by simply selecting the

button on the left, followed by the Load button. Once completed, the API will return to the main display screen and the

values are stored until changed. Settings 1 through 5 are shown below. Select “More>>” to see 6 through 10.

Figure 14 – Factory Setting

A sample of the Custom Settings Screen is shown below. The 8810A also contains the ability for the user to assign up

to 10 custom configurations. These parameters include the settings for reference source, reference voltage, reference

frequency and Synchro / Resolver configuration. Custom parameters are set by saving current parameters which have

been previously set up on the main screens and then saving them to the 10 custom settings. This is accomplished by

selecting the button to the left to choose the number 1 – 10 line and then selecting the Save Current button. The

previously saved parameter is then chosen by selecting the button on the left, followed by the Load button. Settings 1

through 5 are shown above. Select “More>>” to see 6 through 10.

Figure 15 – Custom Settings

A sample of the Brightness Control screen is shown below. Brightness of the display is adjusted from 0 to 100% by

touching the scale bar until the desired brightness percentage is obtained. Note that the brightness value is displayed

above the bar.

Figure 16 – Brightness Control

North Atlantic Industries, Inc.

631.567.1100 / 631.567.1823 (fax)

2/22/2019

8810A Operations Manual Rev P

110 Wilbur Place, Bohemia, NY 11716

www.naii.com

Cage Code: 0VGU1

Page 17 of 34

Shown below is the main Calibration Menu screen which contains a calibration routine for the Touchscreen display and

a calibration routine for the measurement circuitry of the 8810A.

The Touchscreen Calibration will give prompts for the user to touch the screen in two places. The Touchscreen

calibration calibrates the “user’s touch” calibrating the touchscreen input position with the displayed content. When

completed and successful, it will display “Calibration Complete”.

The Unit Calibration will start an internal circuit calibration which requires no user intervention or external equipment.

The unit will commence a full (off-line) calibration of all ranges (as opposed to background calibration which is

continually running and calibrates the unit seamlessly while the unit is on-line at the particular voltage/frequency the unit

is currently operating). Unit Calibration takes approximately 4 minutes to complete and will display “Calibration

Completed” after successful completion.

Figure 17 – Calibration Menu

Shown above are examples of the Help Menu screens. The help menu gives things such as specification summaries,

descriptions of available buttons and descriptions of available functions included with the 8810A. The Help Menu screen

shows the unit’s serial number, date code, MAC address, model information and firmware revision.

Figure 18 – Help Menus

North Atlantic Industries, Inc.

631.567.1100 / 631.567.1823 (fax)

2/22/2019

8810A Operations Manual Rev P

110 Wilbur Place, Bohemia, NY 11716

www.naii.com

Cage Code: 0VGU1

Page 18 of 34

Default Values screen allow for restoring the 8810A to factory settings.

Figure 19 – Default Values

Each channel (0-360° or ±180° display mode only) can be independently set to provide a DC voltage representation of

either angular position (Vdc/degree) or angular velocity (Deg./Sec.). The D/A output range can be set to +/- 10 Vdc

max. See example below in Figure 20.

Figure 20 – D/A Setup

Two options are provided for setting the Bandwidth (BW) characteristics for each channel. As shown below, “Auto-

Bandwidth” or user preferred BW selection is possible as follows:

Auto-Bandwidth – The 8810A measures the reference frequency and then sets the BW to 12.5% of the ref. frequency.

The calculated BW will not exceed 100 Hz or be set below 6 Hz. This setting is the optimum for best compromise

between response / settling time and stability (Jitter of the lower LSB’s.) When this mode is selected the display

indicates the calculated BW setting in the BW Value window.

User Selected – The Auto-Bandwidth box unchecked allows the user to select the BW over the range of 6 to 1200 Hz.

It is recommended that BW not exceed 12.5% of the carrier frequency.

Figure 21 – Bandwidth

North Atlantic Industries, Inc.

631.567.1100 / 631.567.1823 (fax)

2/22/2019

8810A Operations Manual Rev P

110 Wilbur Place, Bohemia, NY 11716

www.naii.com

Cage Code: 0VGU1

Page 19 of 34

The 8810A includes a built-in strip chart feature which displays the angle readings in the form of a strip chart. Below is

a sample of the screen displayed

Figure 22 – Strip Chart Feature

The configure menu is shown in Figure 23. This menu allows the strip chart to be configured for the following

parameters:

•Data plotted as either angle, angle error or velocity

•Display of either channel 1, channel 2 or both channels

•Sampling rate (minimum 100 milliseconds, maximum 30 minutes)

•Upper and lower range

Figure 23 – Strip Chart Configuration Menu

The 8810A has a feature which allows Averaging of the Angle Readings. To access this feature select the angle

averaging button on the main display (shown below left). The averaging period may be set from 10 msec to 10 sec. The

number of angle readings which will be averaged is dependent on the rate of change of the angular data being

monitored. These values may be set by using the keypad or the knob shown above.

Other manuals for 8810A

1

Table of contents

Other North Atlantic Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Precision Digital Corporation

Precision Digital Corporation Helios PD2-6300 instruction manual

BIRD

BIRD SiteHawk SK-6000 Operation manual

Total Control Systems

Total Control Systems 700-20 Engineering manual

Aalborg

Aalborg GFM 17 operating manual

Voltex

Voltex AMP operating manual

Tobi

Tobi PI Wi-Z Quick installation guide