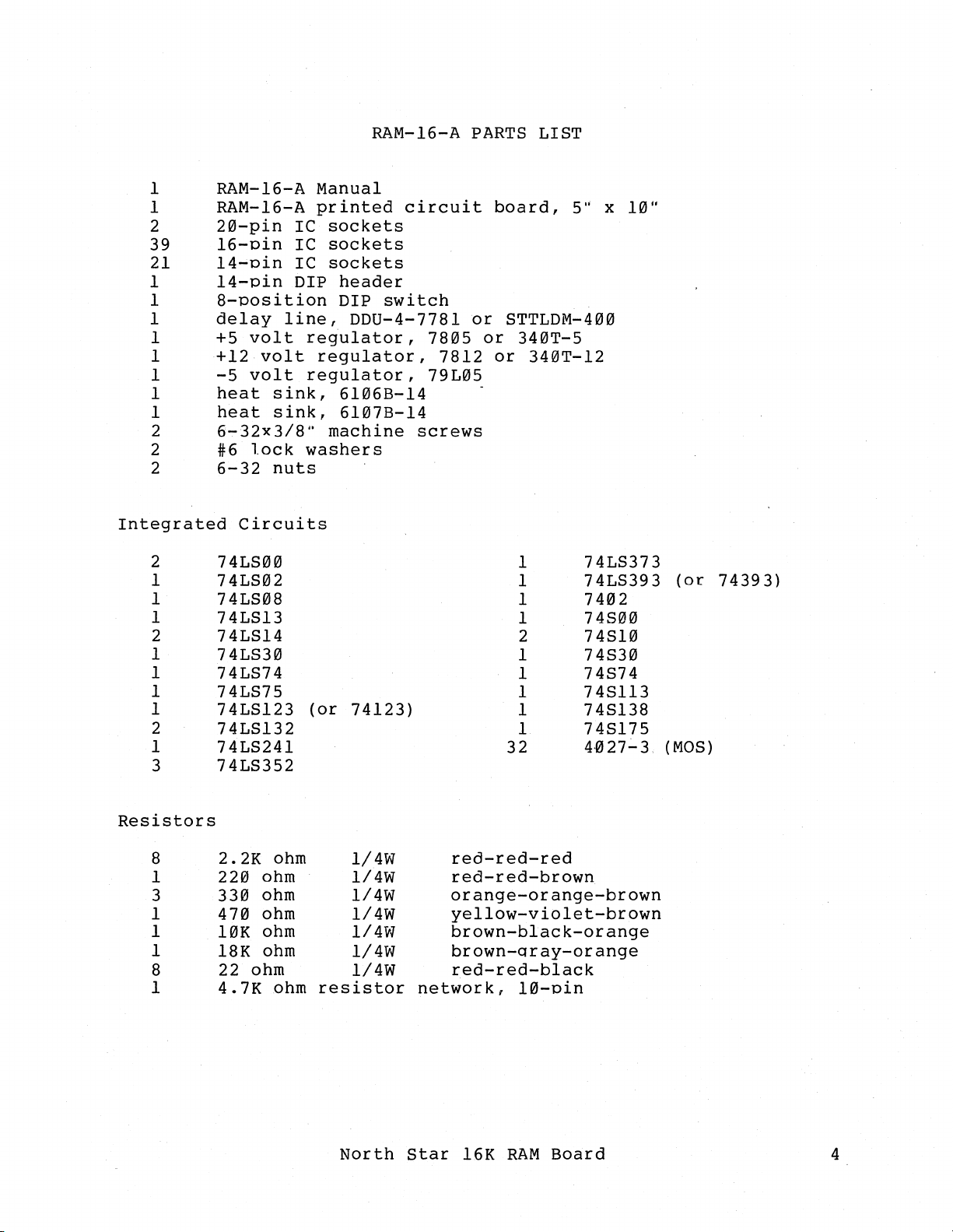

ASSEMBLY INFORMATION

Read completely through each section before beginning the first

instruction step of that section. Perform all operations in the

sequence indicated. Read each step entirely, including any notes

that accompany the step, before beginning to follow the step.

WORK AREA AND TOOLS

Start with a clean, well-lit and well-ventilated area to work.

The area should be large enough to accommodate the kit, tools,

parts and assembly instructions. Suggested tools are:

screwdrivers, needle-nose pliers, diagonal cutters, soldering

iron, solder, ahd masking tape. A number of tests will require

using a VOM (ohmmeter-voltmeter), or VTVM. Also highly

desirable, but not necessary, are an IC inserter, a screw-holding

screwdriver, an oscilloscope or logic probe, and an extender

card. [Note that if you do not have an oscilloscope or logic

probe, waveforms can be detected by one of the procedures

described in Appendix 1.]

SOLDERING TIPS

For best results use a 15 to 25 watt soldering iron or an iron

with a temperature controlled tip (approximately 700 degrees).

The tip should be no wider than the solder pads on the printed

circuit board. Use only a fine gauge rosin core solder (60/40 or

63/37). Do NOT use acid core solder as this can severely damage

a printed circuit board. When soldering, keep the soldering iron

tip on the pad just long enough for the solder to completely

flow. If the solder does not draw up the wire then more solder

is required. Do not use so much solder that it overflows the

pad. If a solidified joint is not shiny, it may be a cold solder

joint and should be remelted. The soldering iron tip should be

cleaned frequently by wiping on a damp sponge

When you have completed assembly of a board, inspect it for

unintended solder connections or "bridges", as well as unsoldered

leads. After soldering, it is recommended that the rosin flux be

removed from the board using flux remover, FREON or paint-thinner

type solvent. This will make looking for soldering problems

easier and give the board a clean, professional appearance

IC SOCKET INSTALLATION

Integrated circuit (IC) sockets can be installed by first

inserting them into the printed circuit board, then placing

another flat board over the IC sockets and finally turning over

this sandwich. Be sure that each IC socket is inserted into the

proper location and is oriented such that pin 1 of the socket

corresponds to the pin 1 indication on the PC board layout

legend. (Refer to figure 1A to identify pin 1 on an IC socket.)

To solder IC sockets, first solder just two opposite corner pins

North Star 16K RAM Board 6