Northern Design Cube400V User manual

Cube400V

Installation Guide

Revision 4

1 Safety

This instruction sheet gives details of safe installation and operation of the Cube400V electricity meter. Labels on each

meter give details of equipment ratings for safe operation. Take time to examine all labels before commencing installation.

Safety symbols on the meter have specific meanings as:

Caution Risk of Danger

Refer to Instructions

Danger

Risk of Electric Shock

Safety may be impaired if the instructions are not followed or the meter is used in a manner not

specified by the manufacturer.

Contains no user serviceable parts. Field wiring and commissioning should only be carried out

by qualified personnel, in compliance with applicable national regulations.

e.g. National Electrical Code (NEC) for US; Canadian Electrical Code for Canada

For further Information contact the manufacturer:

Address: Northern Design (Electronics) Ltd: 228 Bolton Road, Bradford, West Yorkshire, BD3 0QW. (UK)

Web: http://www.ndmeter.co.uk

Email: sales@ndmeter.co.uk

2 Maintenance

The equipment should be maintained in good working order. Damaged equipment must be sent to the manufacturer (or

his authorised agent) for repair. The meter may be cleaned by wiping lightly with a soft cloth. No solvents or cleaning

agents should be used. All inputs and supplies must be isolated before cleaning any part of the equipment.

3 Intended Use

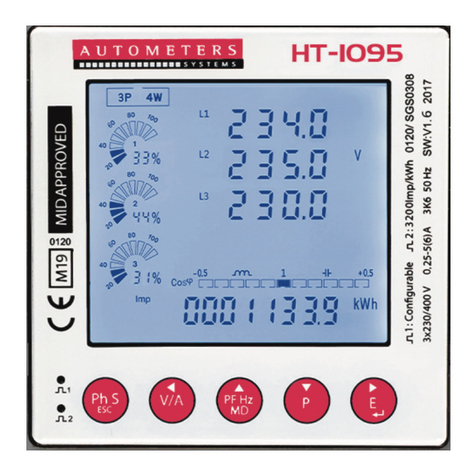

The Cube400V is a precision multi function electricity monitor which measures system power parameters, including kW,

Volts and Amps and displays them on an LCD. Measured parameters may be sent to remote systems for storage or

display using an optional communications interface (e.g. Modbus

RTU RS485 or Ethernet).

The Cube400V is intended for mounting in the faceplate (panel) of an electrical enclosure with only the front

keypad/display panel remaining accessible to an operator after installation. Panels should be 1mm to 4mm (0.04” to

0.16”) thick with a square cut-out of 92mm, +0.8/-0.0mm (3.62” +0.03” -0”). Insert the meter from the front of the panel,

slide the panel clips from the rear of the case and push firmly against the panel ensuring even pressure on each clip.

The safety of any system containing the meter as a component remains the responsibility of

the system manufacturer. After installation in a system, the ratings of the overall system, which

reflect the ratings of the meter, must be visible to the user.

A suitably located and easily reached switch or circuit breaker must be included as part of the

installation. This could, for example, be a safety-interlocking device on the door/front panel of

the electrical enclosure. This switch/circuit breaker must be marked as the disconnecting

device for the equipment and must comply with the relevant requirements of IEC 60947-1 and

IEC 60947-3.

Disconnect / Isolate all supplies before commencing installation.

4 Standard Connections

4.1 Current Transducers

Only current transducers which meet the manufacturer’s specifications should be used.

Current Transducer (CT) connections are not galvanically isolated from the voltage inputs and

must therefore not be accessible to the operator after installation. Installed CT cables and any

extensions to these, must not be accessible to the operator.

Minimum Current Transducer Specification:

Input Current Range: 0 to 1.2 In (In = nominal rated current in amps)

Output Voltage: 0.33Vac at In

Insulation: 600Vac (Core to secondary conductors)

Cable: Operating Temperature, 105°C (221°F)

Insulated 600Vac

The following list of UL & CE recognised current transducers has been approved for use with the Cube/Rail series of meters:

Part Number Primary Current (XXX) Secondary Window Size

XFR/S0142/XXX 5, 10, 30, 50, 75, 100, 150, 200Amps 0.333Vac 19.1 x 19.1mm(0.75” x 0.75”)

XFR/S0152/XXX 75, 100, 150, 200, 300, 400, 600Amps 0.333Vac 31.8 x 31.8mm (1.25” x 1.25”)

XFR/S0162/XXX 100, 200, 300, 600, 800, 1000, 1500Amps 0.333Vac 50.8 x 50.8mm (2.0” x 2.0”)

XFR/S1142/XXX 5, 10, 30, 50, 70, 100, 150, 200Amps 0.333Vac 19.1 x 19.1mm(0.75” x 0.75”)

XFR/S1152/XXX 50, 70, 100, 150, 200, 250, 300, 400, 600Amps 0.333Vac 31.8 x 31.8mm (1.25” x 1.25”)

XFR/S1162/XXX 100, 200, 300, 400, 600, 800, 1000, 1200, 1500Amps 0.333Vac 50.8 x 50.8mm (2.0” x 2.0”)

XFR/S1172/XXX

1

400, 600, 800, 1000, 2000, 3000Amps 0.333Vac 127.0 x 76.2mm (5.0” x 3.0”)

NOTE 1: Model XFR/S1172/XXX is only approved for use up to an ambient temperature of 30ºC (86°F). All other models

are approved for use up to 55ºC (131°F).

If the current transducer secondary cables require extending, care must be taken to avoid pickup of electrical interference.

With suitable low capacitance screened cables, the cable can be extended to 100m (328ft) or more.

Extensions to the supplied current transducer cables must ensure all connections remain

inaccessible to the operator after installation.

All cables and connections must meet the minimum specifications provided.

4.2 Voltage Connections

To maintain proper insulation from the mains supply, the neutral wire should only be used in

power networks where the system neutral is protectively earthed

4.2.1 Voltage Cables

Voltage cables must be rated for safe use in the electrical enclosure which houses the meter

(e.g. UL1015) and must meet the following minimum specification: Temperature: 105°C

(221°F); Insulation 600Vac.

4.2.2 Auxiliary Mains Supply

The meter is powered from an auxiliary mains supply which is required to energise the metering circuit and display. This

can be connected in parallel with one of the measurement phase voltages if it is rated correctly.

Ensure the auxiliary mains supply L-N is powered from a correctly rated and fused AC source

as specified on the meter label.

4.2.3 Voltage Terminals

Voltage: 277Vac (3-4)

480Vac (4-5, 5-6)

Cable: 30-14 AWG, Stripped 5.5 to 6.5mm (0.2” to 0.25”)

Torque: 0.5Nm (4.4in lb)

4.2.4 Voltage Fuses

Fuses (US/Canada)

Rated Voltage Type Rupture In (A) Standards

≥500Vac Fast 1.0A UL248 (US)

C22.2 No. 248 (CAN)

Fuses (Other Countries)

Rated Voltage Type Rupture In (A) Standards

≥500Vac Fast 1.0A IEC 60269 - 2

4.2.5 Auxiliary Mains Fuses

Fuses (US/Canada)

Rated Voltage Type Rupture In (A) Standards

≥250Vac Fast 0.1A UL248 (US)

C22.2 No. 248 (CAN)

Fuses (Other Countries)

Rated Voltage Type Rupture In (A) Standards

≥250Vac Fast 0.1A IEC 60269 - 2

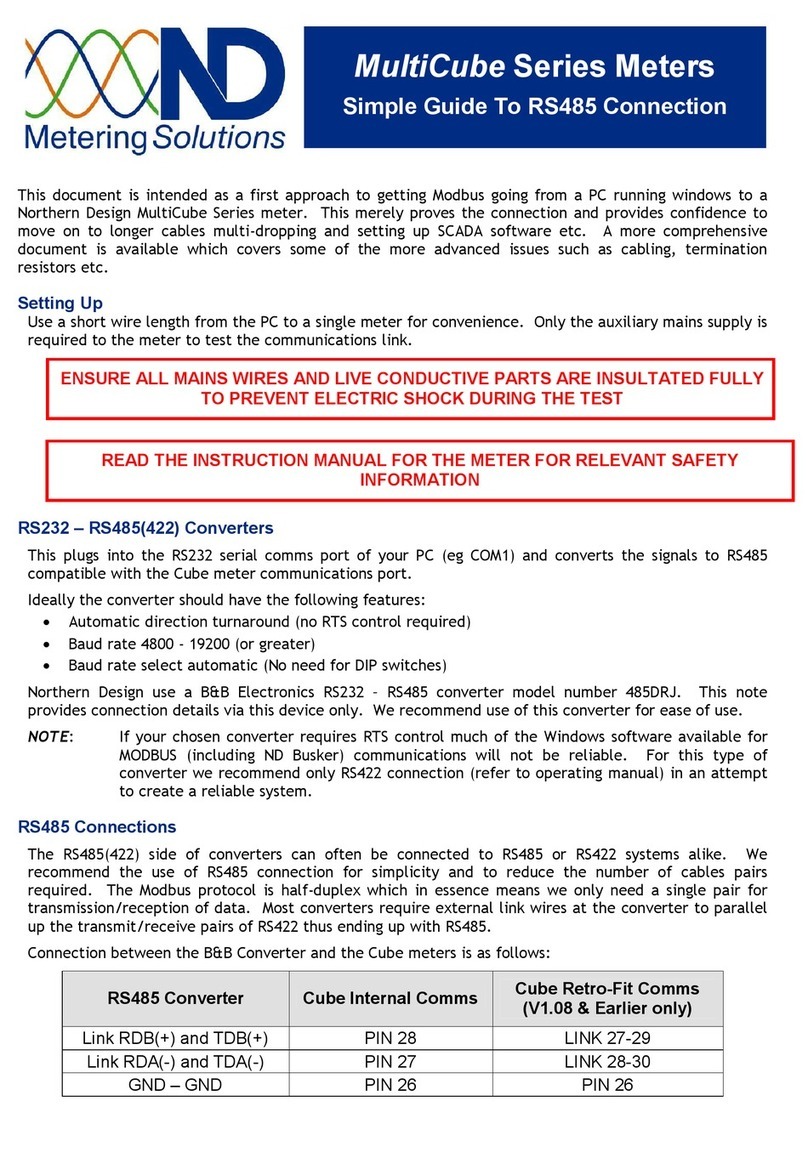

4.3 Communications Options

Communications outputs are safety isolated from the measurement voltages at a minimum of 3.5kV.

Communications cables running within an electrical enclosure may come close to high voltages

and therefore must be insulated to the following minimum specification:

Safety Compliant: e.g UL1015; Operating Temperature: 105°C (221°F); Insulation 600Vac

4.3.1 RS485 Output Terminals (Optional)

Voltage: 30Vdc

Cable: 30-14 AWG, Stripped 5.5 to 6.5mm (0.2” to 0.25”)

Torque: 0.5Nm (4.4in lb)

4.3.2 Ethernet Output (Optional)

Connection: RJ45

Cable: Cat5e FTP (Foil screened)

4.4 Pulse Output Connections

The pulse outputs take the form of isolated volt free normally

open contact pairs. Pulse 1 is associated with active energy

(kWh) and Pulse 2 with reactive energy (kvarh).

The contacts are isolated from all other circuits (3.5kV).

Pulses can be used as input to remote counters, pulse loggers,

building energy management system etc.

Light emitting diodes and remain ON

during each associated output pulse.

Pulse output cables running within an electrical enclosure may come close to high voltages

and therefore must be insulated to the following minimum specification:

Safety Compliant: e.g UL1015; Operating Temperature: 105°C (221°F); Insulation 600Vac

4.4.1 Pulse Output Terminals

Voltage: 70Vdc/33Vac (13-14, 13a-14a)

Cable: 30-14 AWG, Stripped 6.0 to 7.0mm (0.24” to 0.28”)

Torque: 0.5Nm (4.4in lb)

4.5 Typical Connections

3-Phase 3 or 4-Wire (*Optional Neutral)

Single Phase

NOTE: For single phase systems it is advisable to link out unused current inputs (9-10 and 11-12) with a short insulated

wire link. This prevents unwanted noise affecting meter readings.

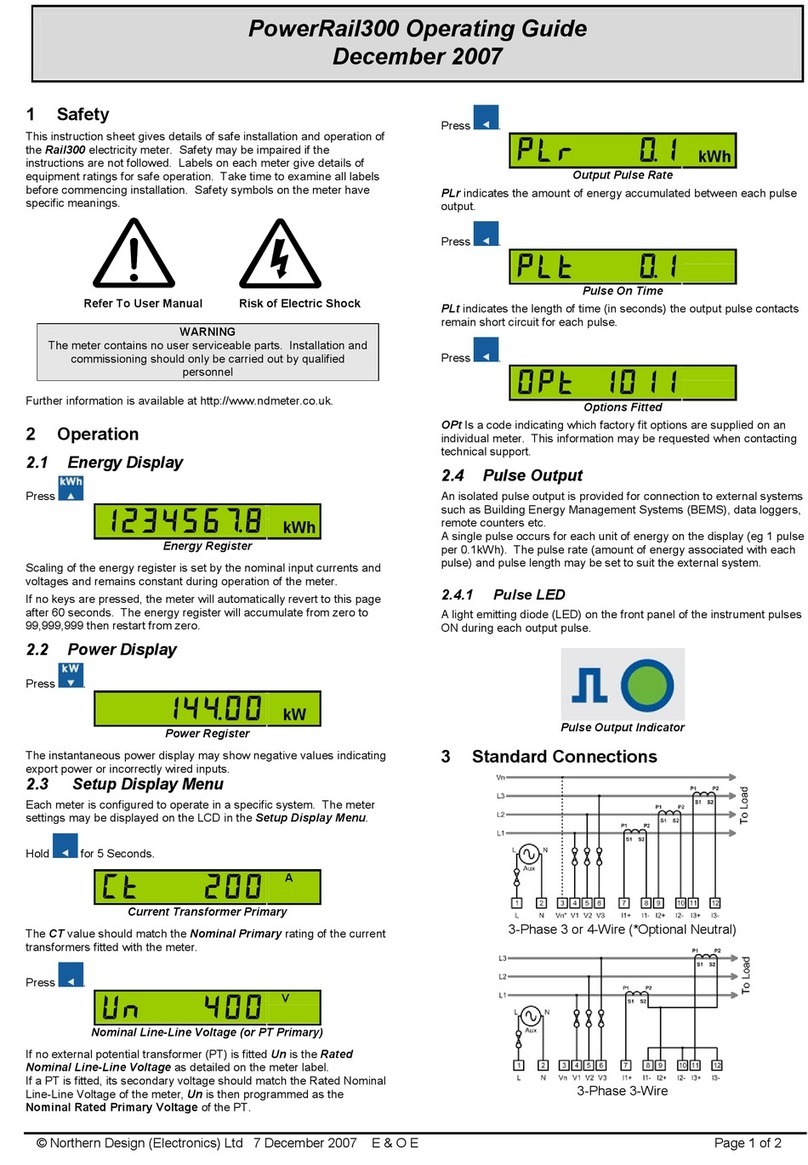

5 Display Menus

+

Enter/Exit Quality Menu

5

A

150.0

150.0

150.0

230.0

230.0

V

230.0

-

kVAr

3-Phase

239.0

276.0

kVA

138.0

kW

kWh

1234567.8

RMS Phase Amps RMS Phase Volts System Power

1

Real Energy (kWh)

3 4

Amps Quality Menu

/

Next/Prev

Pk hold

A

150.0

150.0

150.0

L-L

400.0

400.0

V

400.0

46.00

46.00

46.00

kW

kVArh

1234567.8

THD

15.0

15.0

A%

15.0

Peak Hold Amps

3

RMS Line-Line Volts Per-Phase Real Power Reactive Energy (kvarh)

3 4

Total Amps % Distortion

A

T-Avg

150.0

150.0

150.0

Pk hold

230.0

230.0

V

230.0

bal

A

3-Phase

10.0

50.0

Hz

1.000

Cos∅

∅∅

∅

KVA h

1234567.8

10.0

10.0

A%

02 10.0

Harmonic

Time-Averaged Amps Peak Hold Volts

3

System Page 2

1

Apparent Energy (kVAh)

3 4

Amps Harmonics 2-15

Pk hold

A

T-Avg

150.0

150.0

150.0

T-Avg

230.0

230.0

V

230.0

KVA

46.00

460.0

46.00

HRs

Run

1234567.8

V

olts Quality Menu

/

Next/Prev

Peak Time-Averaged Amps

3

Time-Averaged Volts Per-Phase Apparent Power Hours Run

2

Pk hold

T-Avg

230.0

230.0

V

230.0

-

KVAr

-

46.00

460.0

-46.00

Export

kWh

1234567.8

THD

15.0

15.0

V%

15.0

Peak Time-Averaged Volts

3

Per-Phase Reactivet Power

1

Export Real Energy

3 4

Total Volts % Distortion

1.000

1.000

1.000

Cos∅

∅∅

∅

Export

kVArh

1234567.8

10.0

10.0

V%

02 10.0

Harmonic

Per-Phase Power Factor

1

Export Reactive Energy

3 4

Volts Harmonics 2-15

MD

kVAr

3-Phase

239.0

276.0

kVA

138.0

kW

Power Maximum-Demand

1

Pk hold MD

kVAr

3-Phase

239.0

276.0

kVA

138.0

kW

Peak-Hold Mean-Demand

1

Note 1: A display of after a value indicates a capacitive load.

Note 2: The Hours Run register accumulates the total time during which the real power (kW) exceeds a preset level.

This is always displayed with a resolution of 0.1hour.

The percentage level of kW at which the Hours Run register accumulates is user programmable from 1% to 100% of full

scale current. Hours run reset cannot be disabled.

Note 3: Press and together and hold for 2 seconds to reset the displayed value. This feature may be disabled

before mounting in a panel. Refer to Cube400 option links guide to disable

Note 4: Scaling of the energy registers is set by the nominal input currents and voltages and remains constant during

operation of the meter. Energy registers will each accumulate from zero to 99,999,999 then restart from zero.

Note 5: Power quality menus are optional on some meters.

6 Programming

A

Ct

Pri

L 200

Current Transformer Primary

V

Pt

Pri

L-L

L 480

and to enter programming.

or selects from the standard list of settings while L

LL

Lis displayed. (List Mode)

or increases or decreases the value while F

FF

Fis displayed. (Fine adjust)

and together to toggle between L

LL

Land F

FF

F. Accepts the set value.

Voltage Transformer Primary 6

MD

PER

ÄÅin

30

Set the integration period in minutes used for the sliding time window MD calculation for kW and

kvar.

or increments or decrements the value. Accepts the set value.

Power MD Integration Time

T-Avg

PER

SEC

10

Set the integration period in seconds used for the sliding time window calculation for voltage and

current.

or increments or decrements the value. Accepts the set value.

Current/Voltage Average Time

HRS

Run

SEt 250

kW

Set the instantaneous system kW level above which the Hours Run timer will accumulate. Below

this level Hours Run will remain unchanged.

or increments or decrements the value. Accepts the value.

Hours Run Trigger Point

kWh

PULS

RAtE

0.1

Set the amount of energy (kWh Pls1 kvarh pls2) required to trigger each Pulse Output.

or selects the next/previous Pulse Rate. Accepts the value.

Pulse Rate (kWh per Pulse)

PULS

LE

0.1

Set the contact closure time for both pulse outputs.

or selects the next/previous Pulse Length from a standard list. Accepts the value.

Pulse On Period (Seconds)

PULS

TEST

Hld 999

Tests both pulse outputs and associated circuits without the need of a test load.

or starts/stops a test pulse stream. The display shows Hld (Hold) or RU . The

counter shows the total number of pulses during the test.

and reset the test counter to zero. exits pulse test mode. Pulse Test Mode

Note 6: If external VT is not used, DO NOT ALTER the voltage transformer primary setting for any other system voltage

i.e. for 110V, 208V, 230V system. LEAVE Un (Voltage Transformer Primary Setting) TO 480V ONLY.

If external VT is used, alter the voltage transformer primary setting as stated in the following examples.

For 11000/110V VT, alter the setting to 48000 (multiplying factor: 11000 / 110 = 100 i.e. 480X100)

For 6600/110V VT, alter the setting to 28800 (multiplying factor: 6600 / 110 = 60 i.e. 480X60)

7

Specification

INPUTS

System 3 Phase 3 or 4 Wire Unbalanced Load or Single Phase

Voltage Un 480/277V. 3 Phase 3 or 4 Wire

Current Sensors

Output @ Nominal In

Accuracy

Phase Error

0.333Vac

±1% (0.1In – 1.2In)

5A-50A Models <2.5°at 0.5In. Other models <2.0°at 0.5In

Measurement Range Voltage 20% to 120% Un

Current 0.2% to 120%

Frequency Range Fundamental 45 to 65Hz

Harmonics Up to 30th harmonic at 50Hz

Individual to the 15th

Voltage Burden <0.1VA per phase

Overload Voltage x4 for 1 hour

Current

x2 Continuous

DISPLAY

Type Custom, Supertwist, LCD

Data Retention 10 years min. Stores kWh & Meter set-up

Format 2 Rows x 4 Digits, 1 Row x 8 Digits + Legends

Scaling Direct reading. User programmable CT & PT

CT Primary programmable from 5A to 25kA

VT primary programmable from 10V to 440kV

Legends Wh, kWh, MWh etc. depending on user settings

AUXILIARY SUPPLY

Standard 230V 50/60 Hz ±15%

Options 110V 50/60 Hz ±15%

Load 5 Watt Max.

Overload x1.2 continuous

METER ACCURACY All errors ± 1 digit

kWh Better than Class 1 per EN 62053-21 & BS 8431

Kvarh Better than Class 2 per EN 62053-23 & BS 8431

kW & kVA Better than Class 0.25 IEC 60688

kvar Better than Class 0.5 IEC 60688

Amps & Volts Class 0.1 IEC 60688 (0.01In – 1.2In or 0.1Un – 1.2Un)

PF ±0.2° (0.05In – 1.2In and 0.2Un – 1.2Un)

Neutral Current Class 0.5 IEC 60688 (0.05In – 1.2In)

OVERALL METERING ACCURACY

5A-50A Models

Other Models

Better than Class 2 Meter with Class 1 CTs

Better than Class 1 Meter with Class 1 CTs

PULSE OUTPUTS

Function 1 Pulse per unit of energy

Scaling Settable between 1 & 1000 counts of energy register

Pulse Period 0.1 sec. default; Settable between 0.1 and 20 sec

Rise & Fall Time < 2.0ms

Type N/O Volt free contact. Optically isolated BiFET

Contacts 100mA ac/dc max ; 70Vdc/33Vac max ; 5W maximum load

Isolation 3.5kV 50Hz 1 minute

MODBUS® Serial Comms (Option)

Bus Type RS485 2 wire + 0v. ½ Duplex, ¼ unit load

Protocol MODBUS® RTU with 16 bit CRC

Baud Rate 4800, 9600 or 19,200 User settable

Address 1 – 247 User settable

Latency Reply within 250ms max.

Command Rate New command within 5ms of previous one

Isolation 3.5kV

ETHERNET (Option)

Electrical IEEE std 802.3. 2000 Edition

Data Rate 10 Mbits/s

Protocol TCP, UDP, DHCP, FTP, TFTP, HTTP, SNTP, SNMP

Connection 10/100 Base T - RJ45

Isolation 3.5kV

GENERAL

Temperature Operating -10°C to +55°C (14°F to 131°F)

Storage -25°C to +70°C (-13°F to 158°F)

Humidity < 75% non-condensing

Environment IP54 (when correctly mounted, as described, in a panel)

Altitude <2000m (6561ft)

MECHANICAL

Terminals Rising Cage. 4mm

2

(12 AWG) cable max.

Enclosure DIN 43700 96 x 96

Material Mablex® with fire protection to UL94-V-O. Self extinguishing

Dimensions 96 x 96 mm x 83.5 mm (72 mm behind panel)

3.78” x 3.78” x 3.29” (2.83” behind the panel)

Weight ~ 250 gms

SAFETY

Conforms to EN 61010-1 Overvoltage Category III & BS 8431

E. & O. E.

© Northern Design (Electronics) Ltd, October 2016

Table of contents

Other Northern Design Measuring Instrument manuals

Northern Design

Northern Design PowerRail300 User manual

Northern Design

Northern Design multicube User manual

Northern Design

Northern Design MultiCube Series Instruction Manual

Northern Design

Northern Design Rail350V-IP User manual

Northern Design

Northern Design MultiCube950mV User manual

Northern Design

Northern Design Cube 400 User manual